Multifunctional motor support

A motor bracket and multi-functional technology, which is applied in the direction of casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems of high cost and large space, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding and implementation of the present invention, the embodiments of the present invention will now be described with reference to the drawings, and the drawings provided are only examples.

[0019] The embodiment of the present invention relates to a multifunctional motor support.

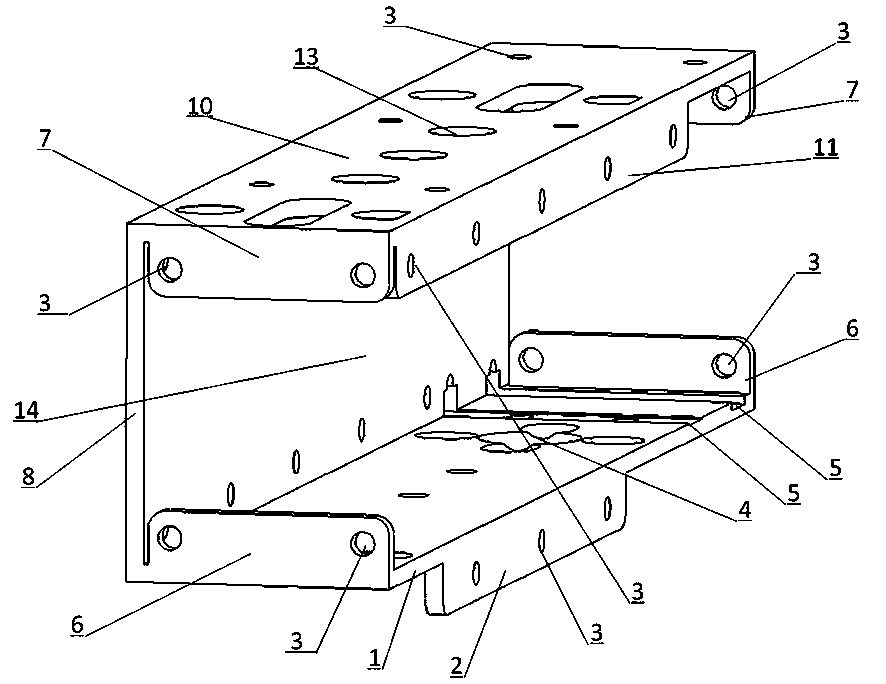

[0020] figure 1 It is a structural schematic diagram of the bracket of the present invention, which includes: 1 bottom shell of the bracket, 2 side flanges of the bottom shell, 3 openings, 4 motor installation positions, 5 slide rail installation positions, 6 bottom shell end face folding, 7 top shell end face Folding, the middle shell of 8 brackets, the top shell of 10 brackets, the side flanges of 11 top shells, 13 process holes, and the inner cavity of 14 brackets.

[0021] As can be seen from the figure, the bracket includes bottom shell 1, bottom shell side fold 2, bottom shell end fold 6, middle shell 8, top shell 10, top shell end fold 7, top shell side f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com