Patents

Literature

35 results about "Function motor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Is an umbrella term used to describe any activity or movement which is completed due to the use of motor neurons. MOTOR FUNCTION: "Motor function is the basic understanding of movement or activity through the use of motor neurons.".

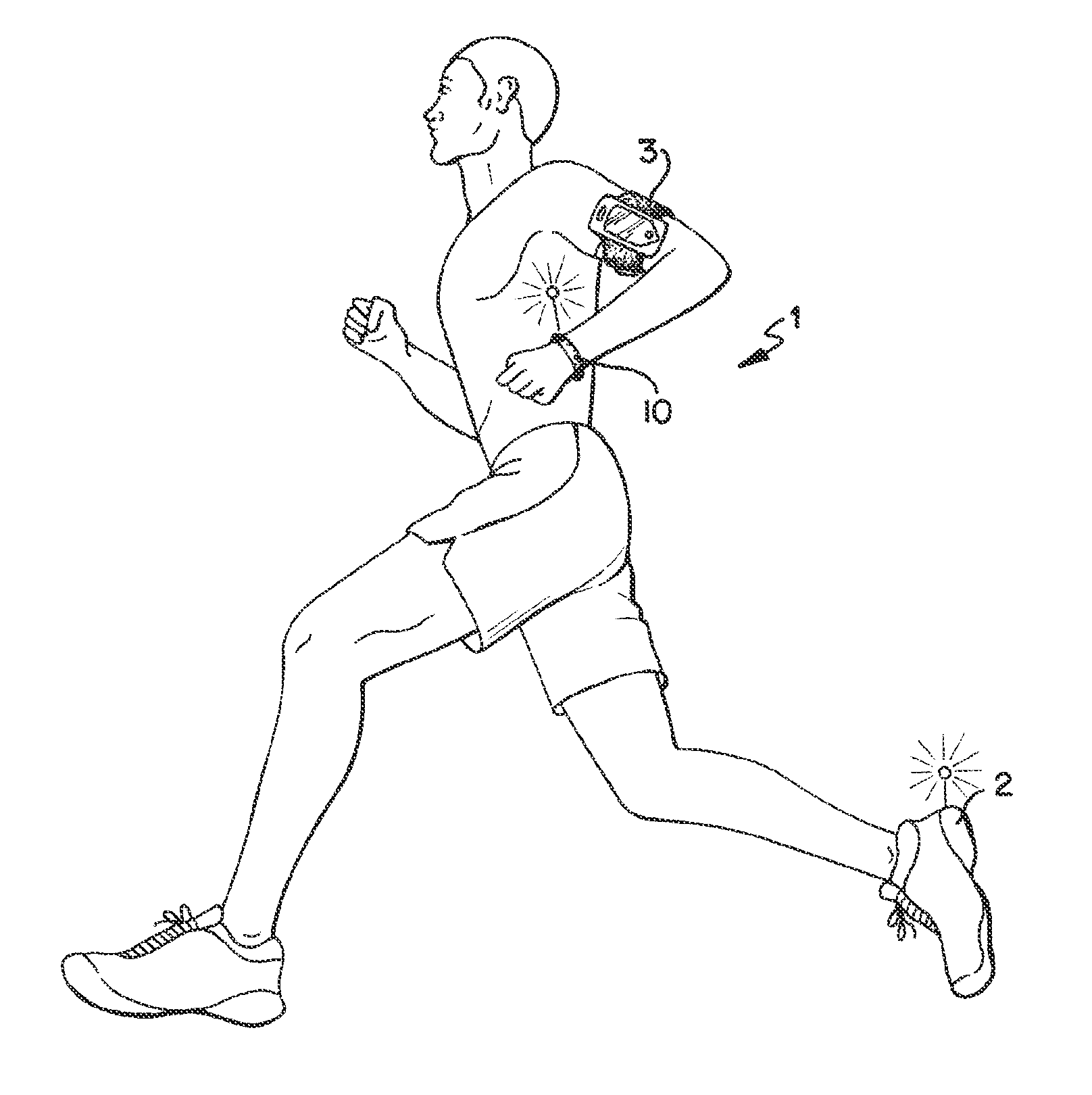

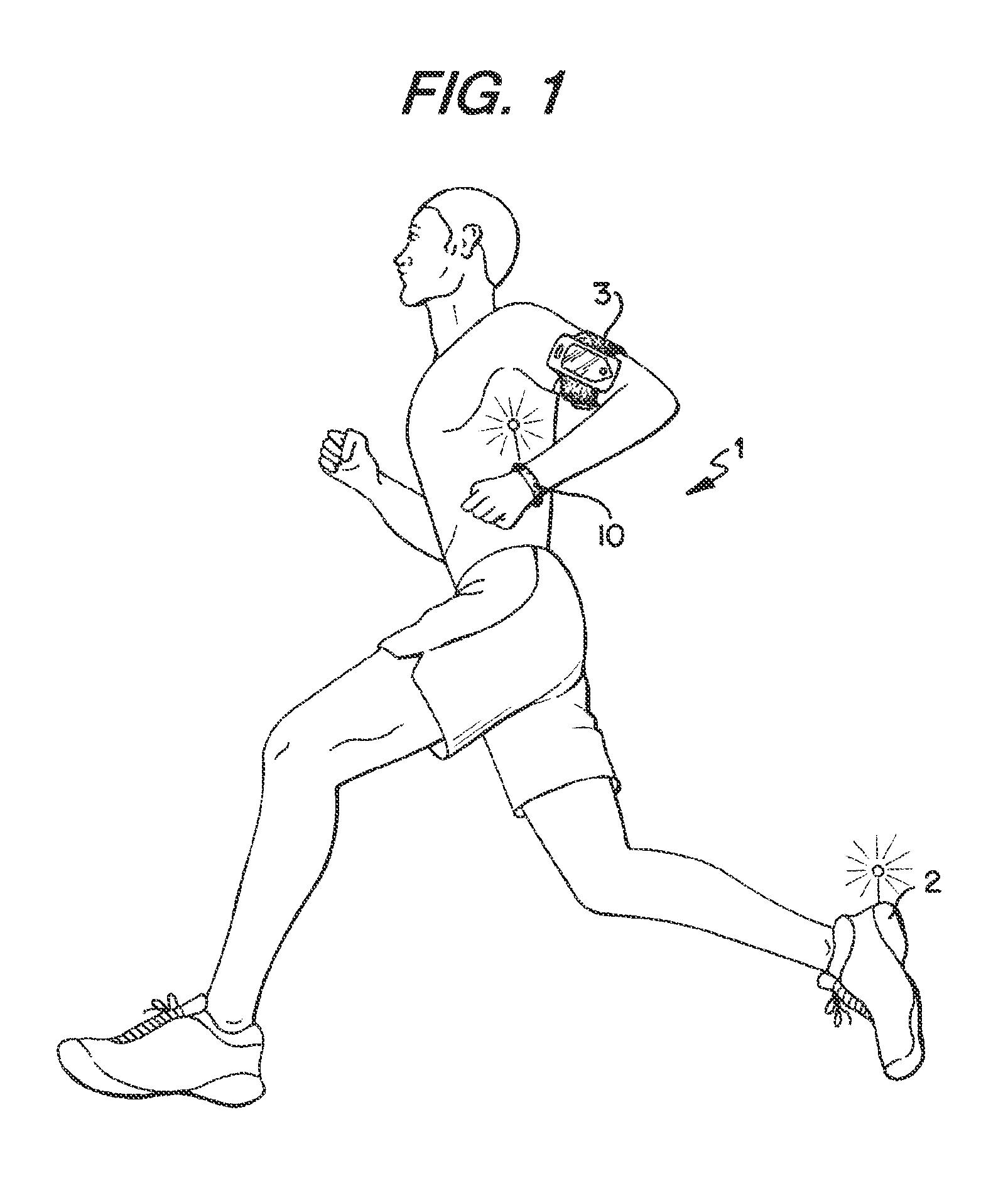

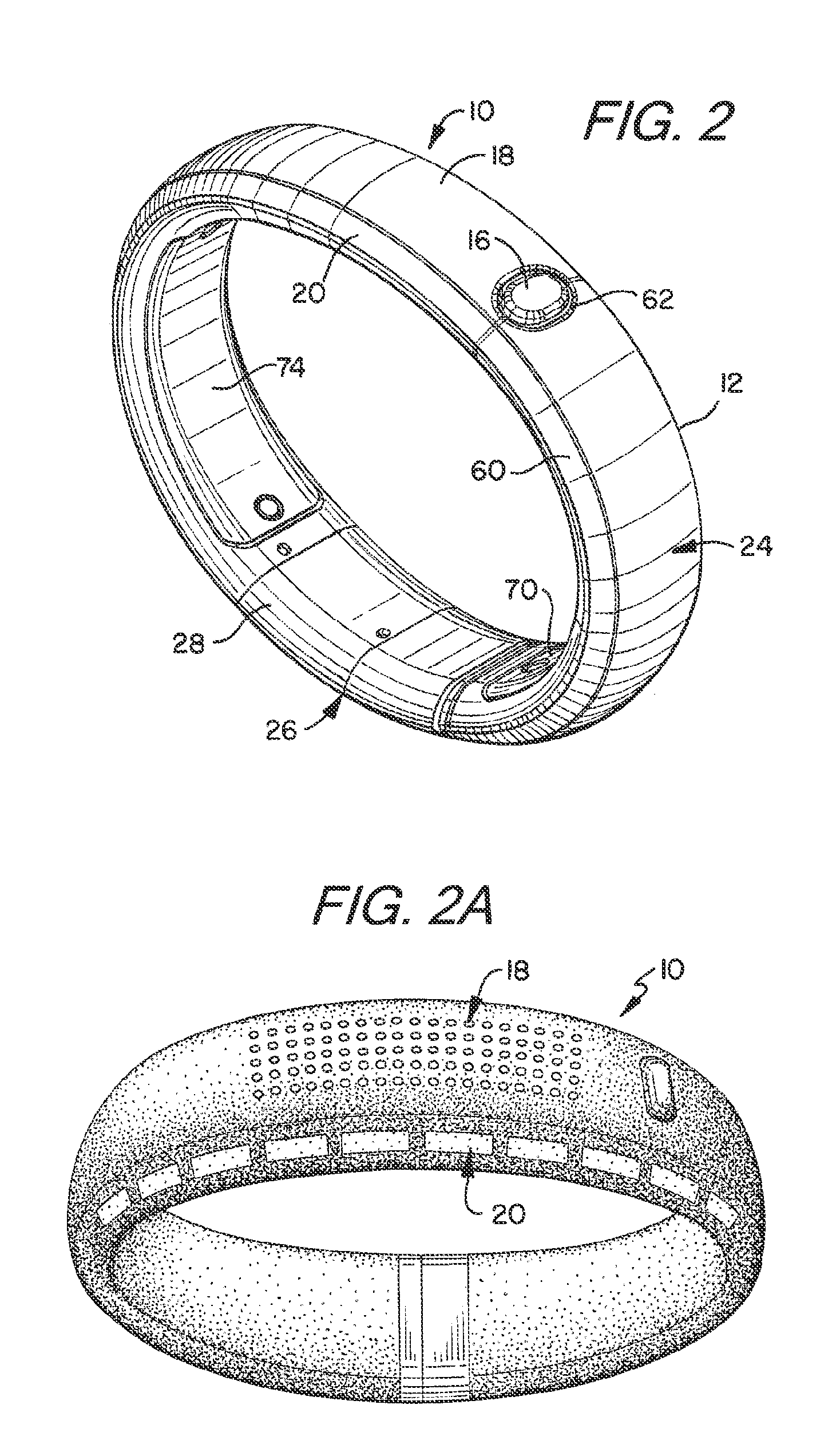

Wearable Device Assembly Having Athletic Functionality

ActiveUS20130106684A1Physical therapies and activitiesElectronic time-piece structural detailsDisplay deviceFunction motor

A wearable device assembly has a housing supporting a controller, display and indicator system thereon. The controller has at least one sensor wherein activity of a user wearing the device is detected. The controller selectively illuminates the indicator system to indicate a level of activity of the user.

Owner:NIKE INC

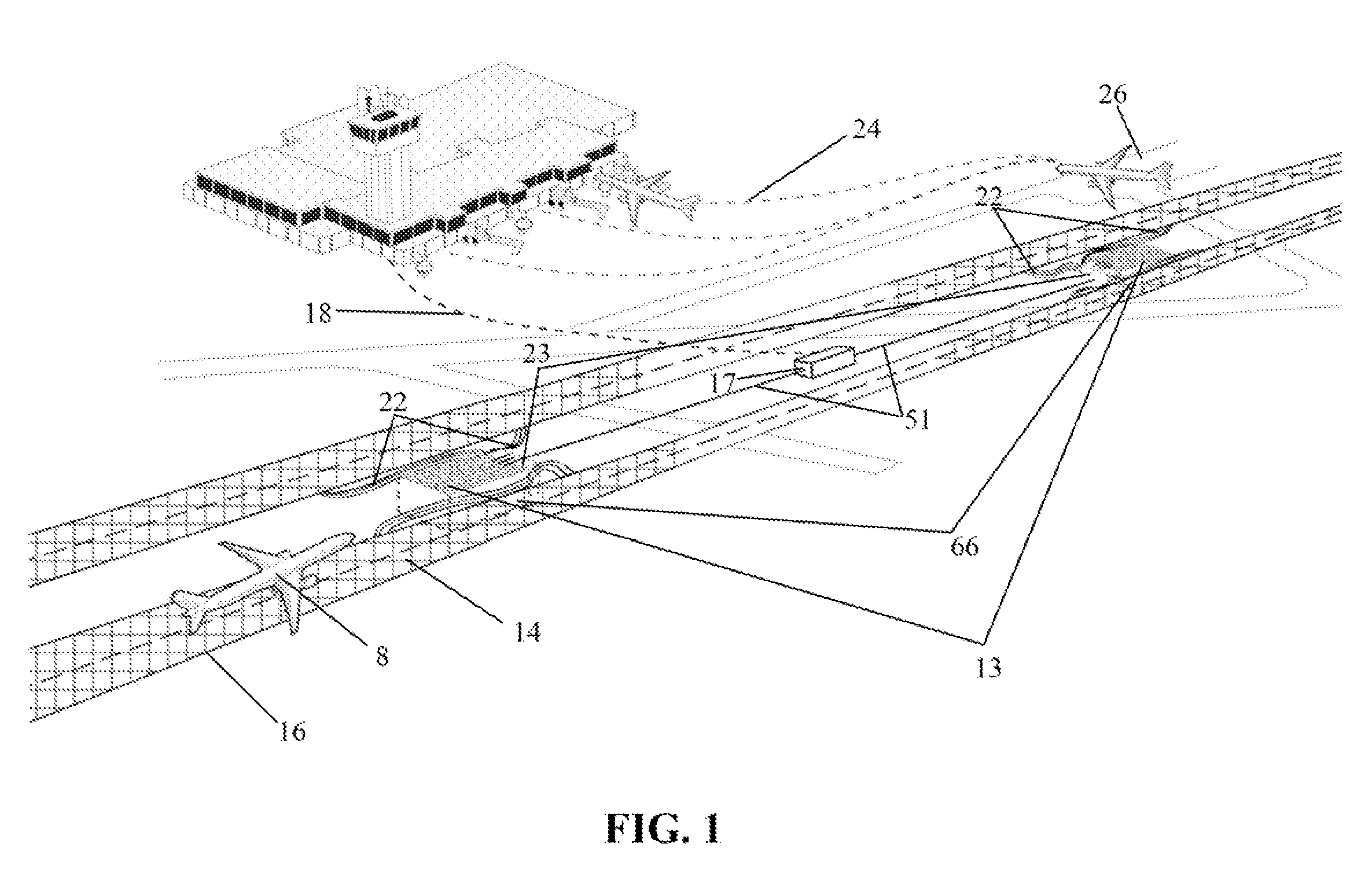

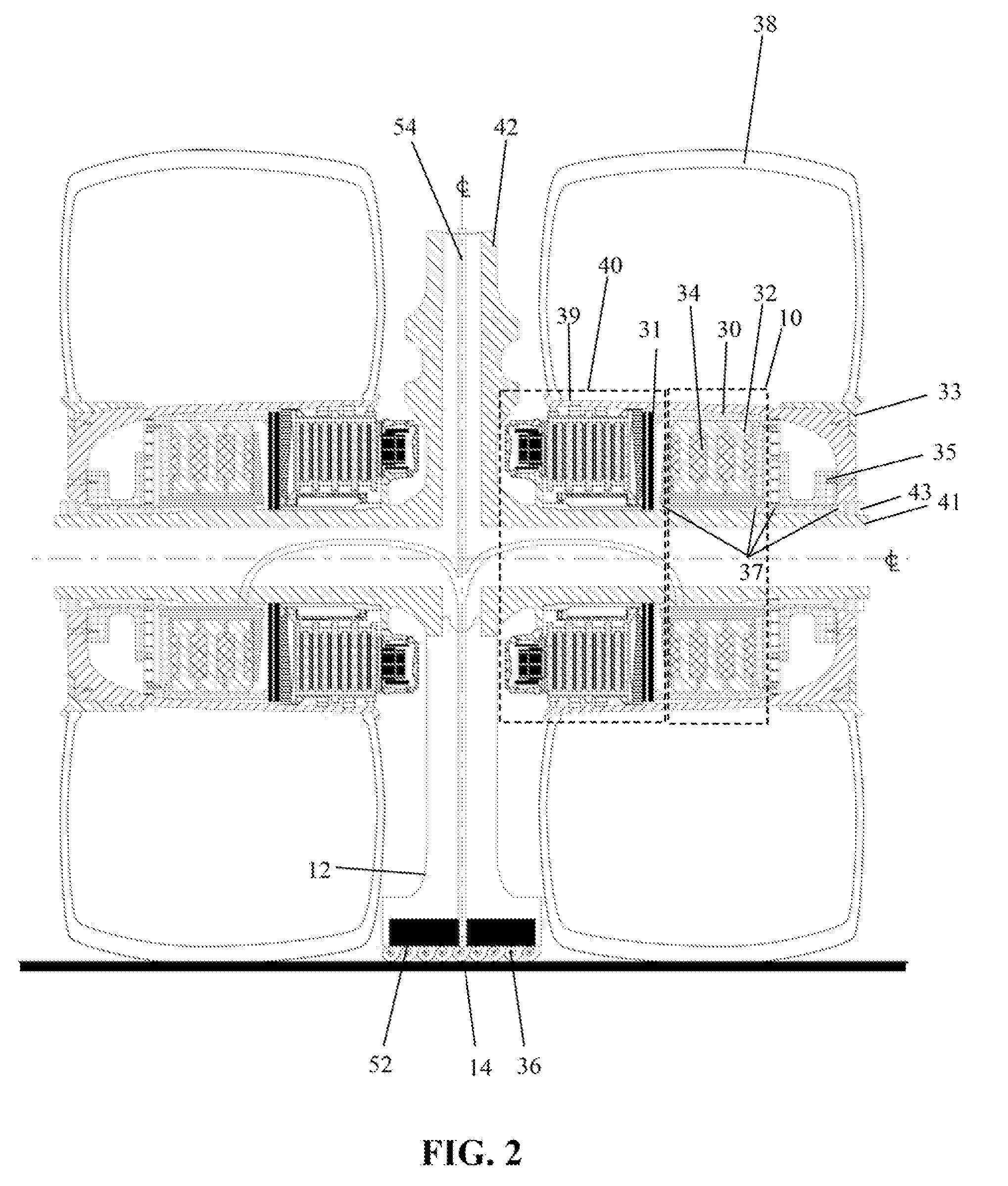

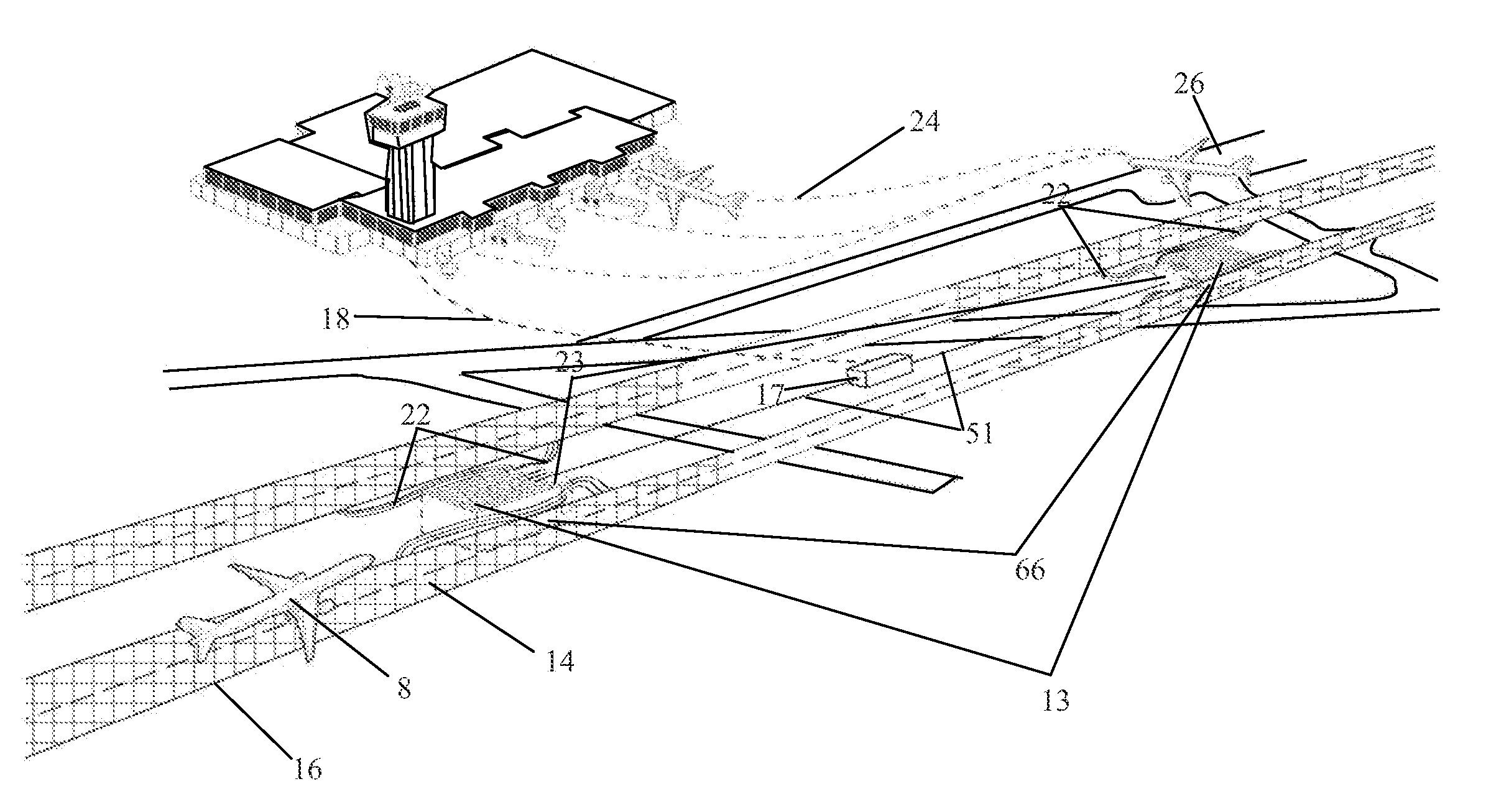

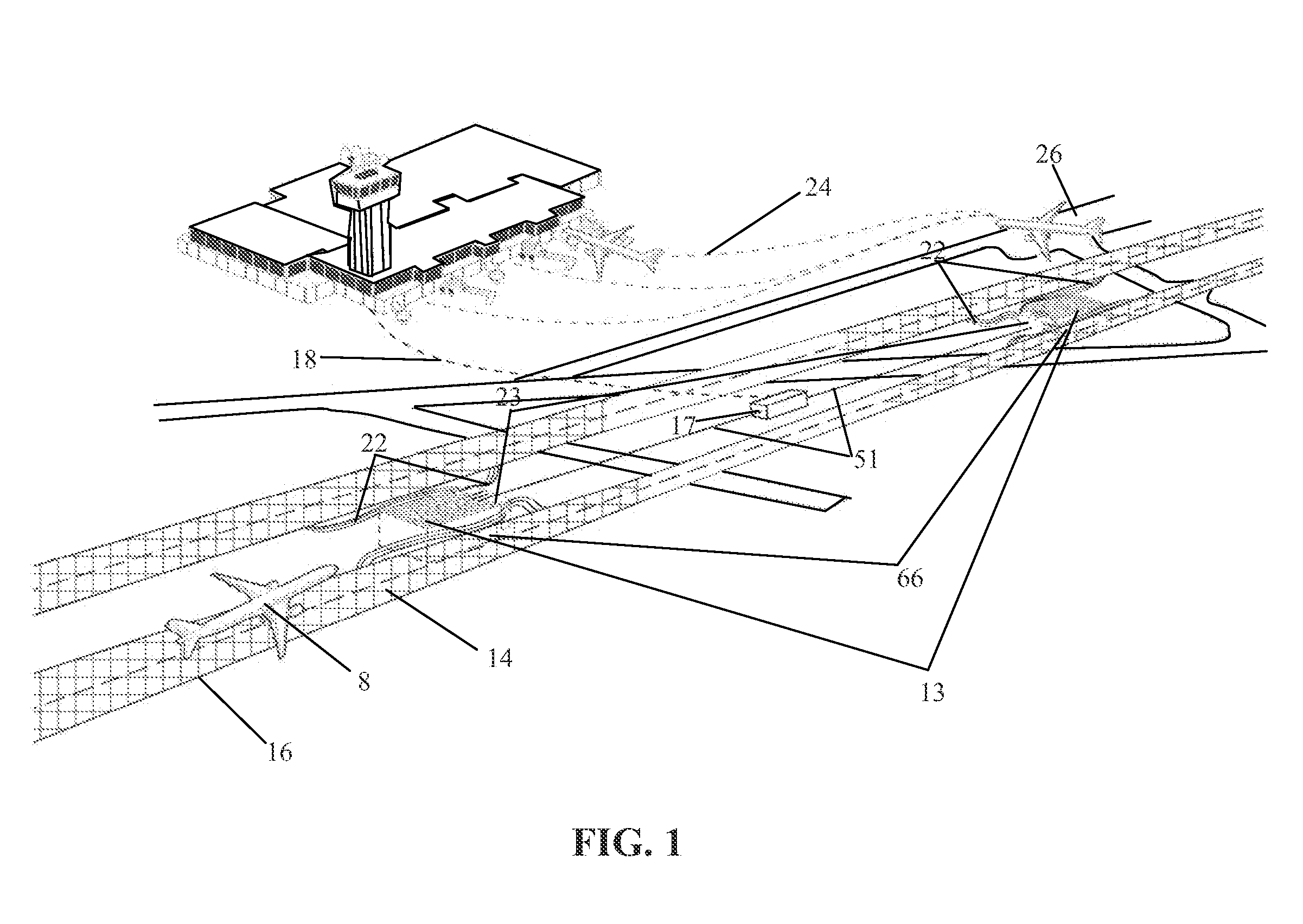

Aircraft kinetic landing energy conversion system

ActiveUS20080258014A1Increase braking powerAvoid heatArresting gearRailway vehiclesElectric potential energyElectric generator

A kinetic energy system which transfers the kinetic landing into recoverable electric energy for an aircraft. The system incorporates at least one wheel supporting the aircraft for landing and takeoff coupled with a dynamic functioning motor / generator mounted to and operated by rotation of the wheel to create electrical energy from kinetic energy. An induction shoe structurally connected to the aircraft and electrically connected to the motor / generator, which shoe draws the converted energy from the generator which supplies the load created by the inductively coupled induction shoe to the an ancillary load provided by the resistive heat sink on by the capacitor storage bank. This provides the generator circuit for conversion of the rotational energy of the wheel to electrical energy and creates braking drag. In exemplary embodiments, the system employs an energy storage system acting as the load to store electrical potential energy created by the generator. Additionally, the generator is employable as a motor, receiving energy from the storage system for traction power to the associated aircraft wheel. An induction grid or a surface mounted conductive layer mounted into or onto a runway is employed for transferring energy to and from the motor / generator.

Owner:THE BOEING CO

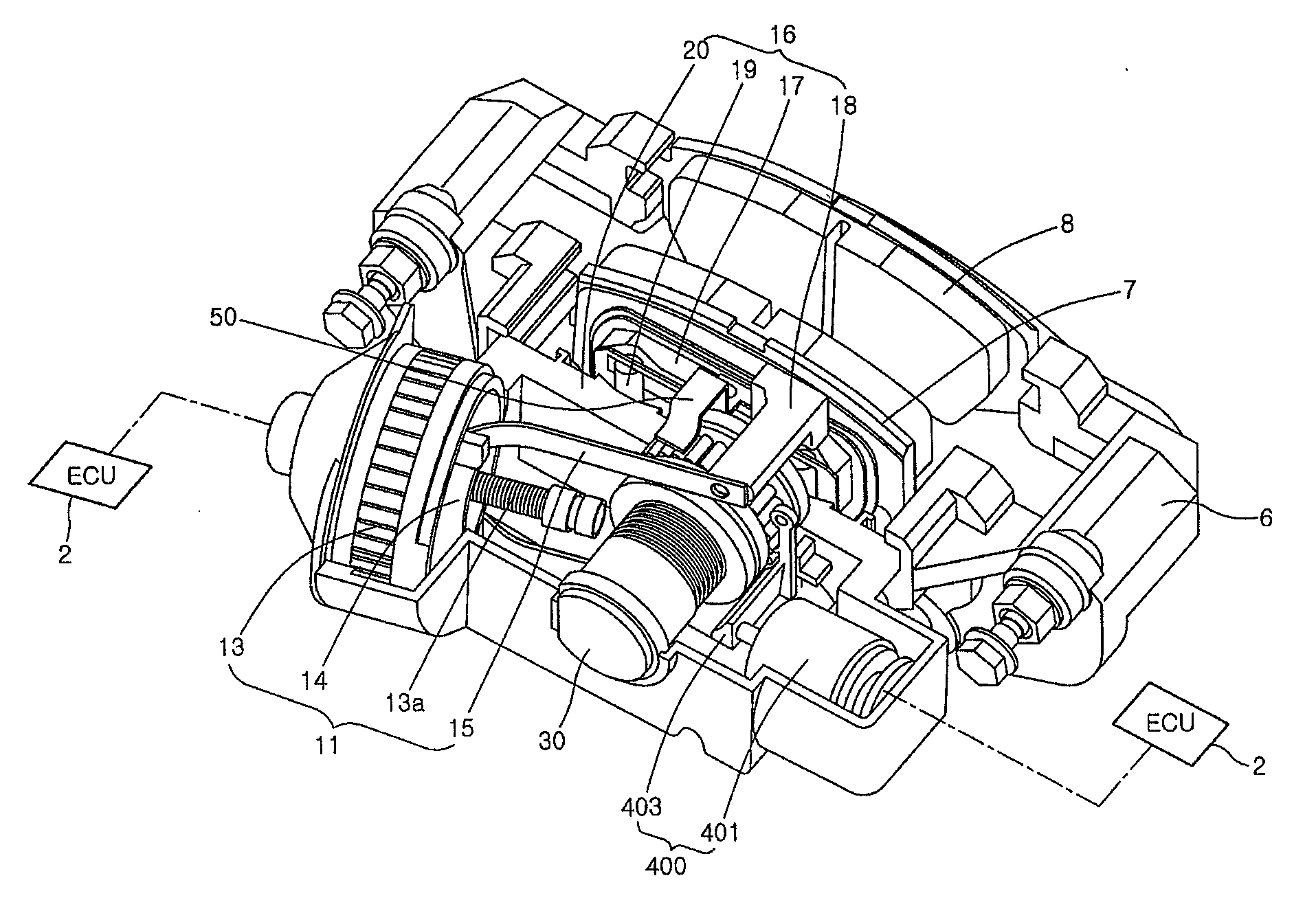

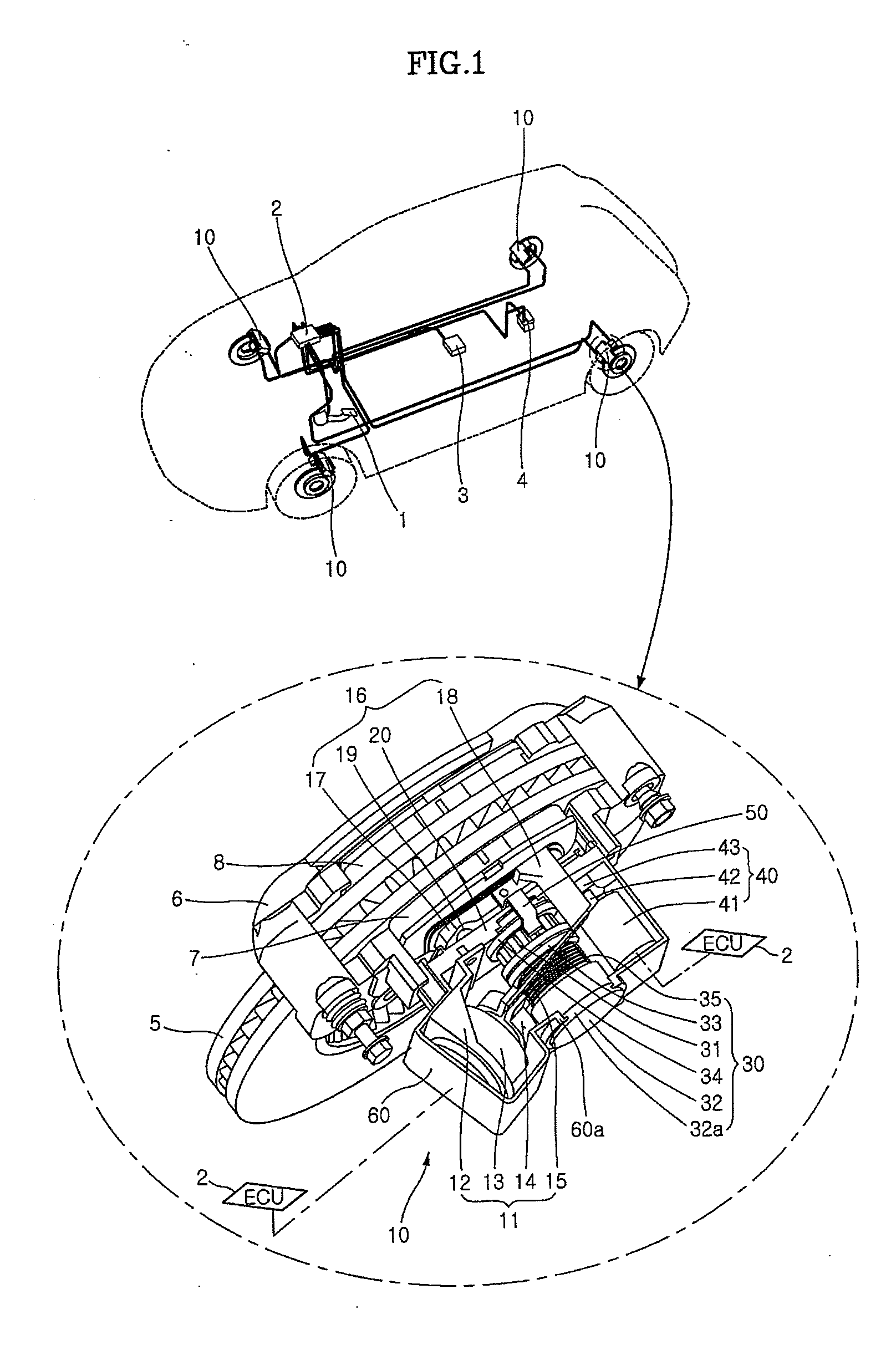

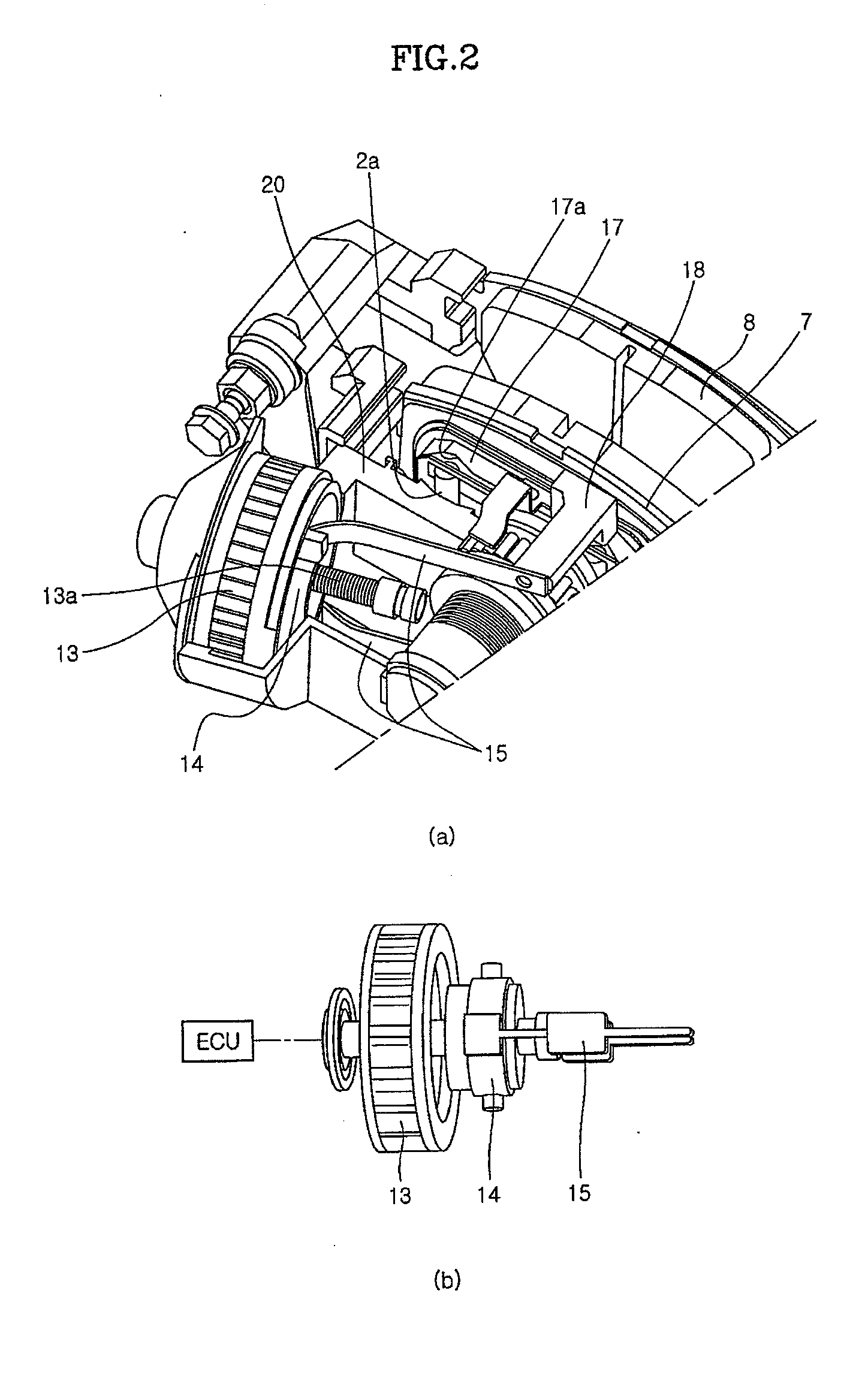

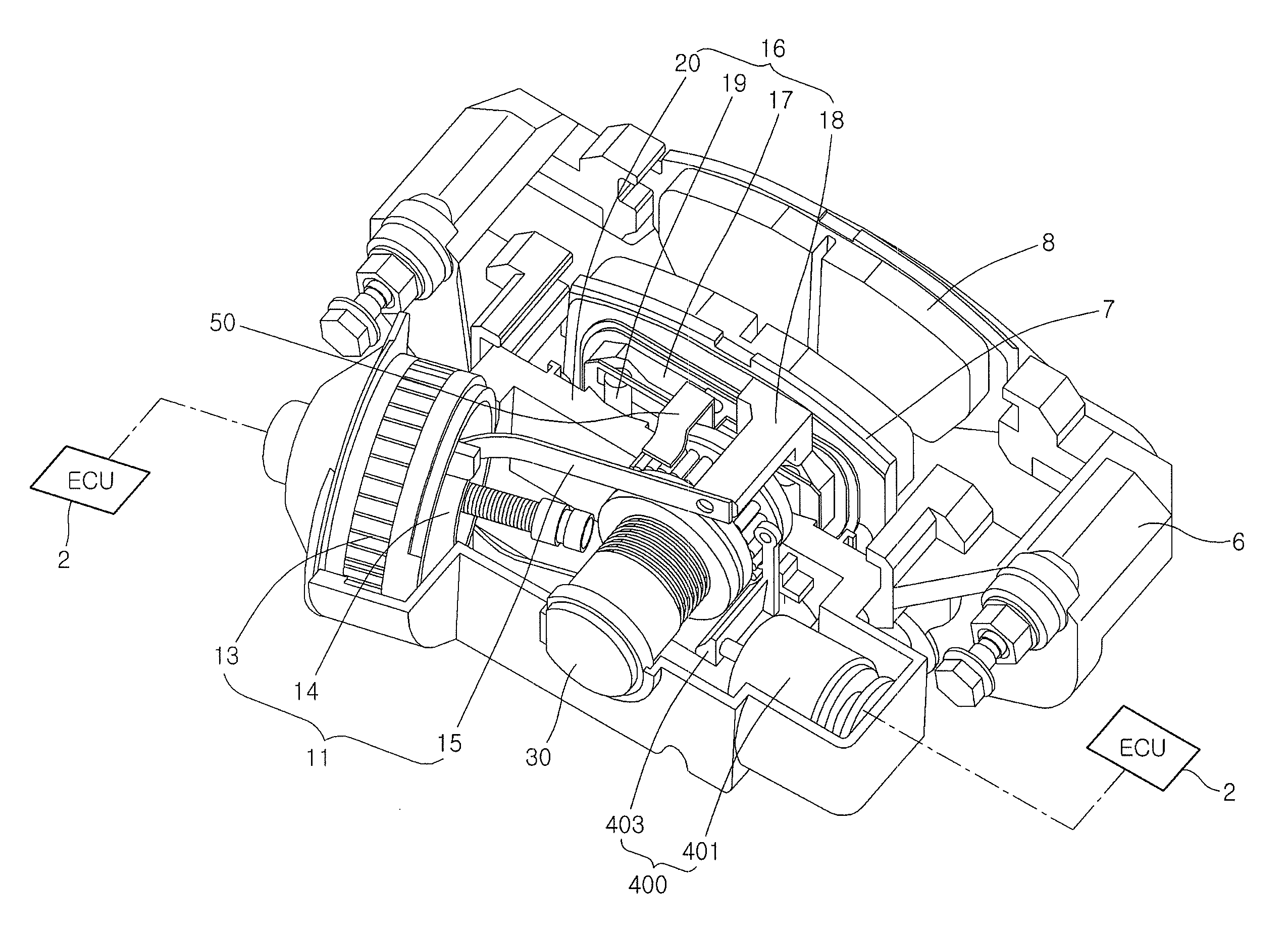

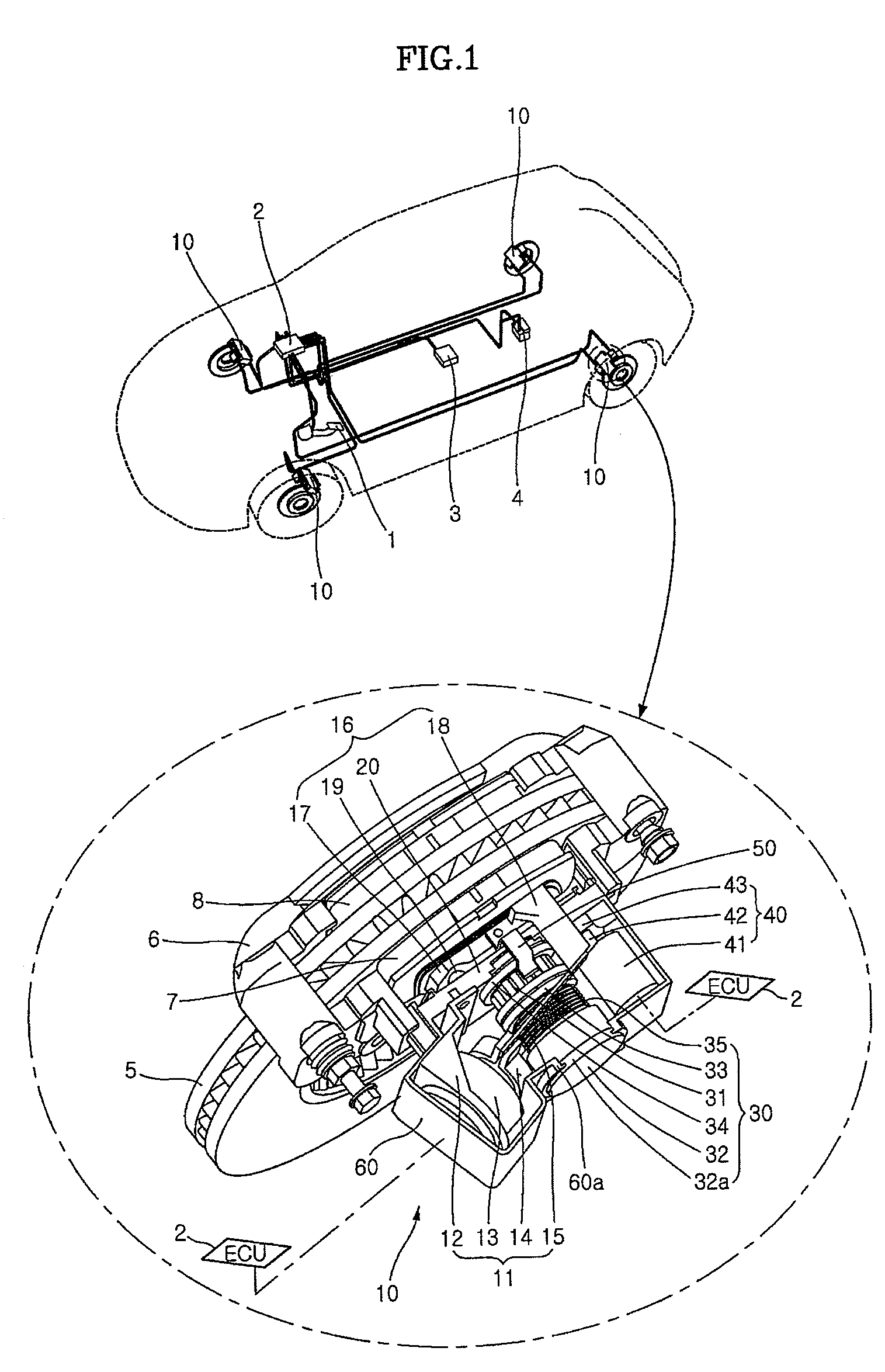

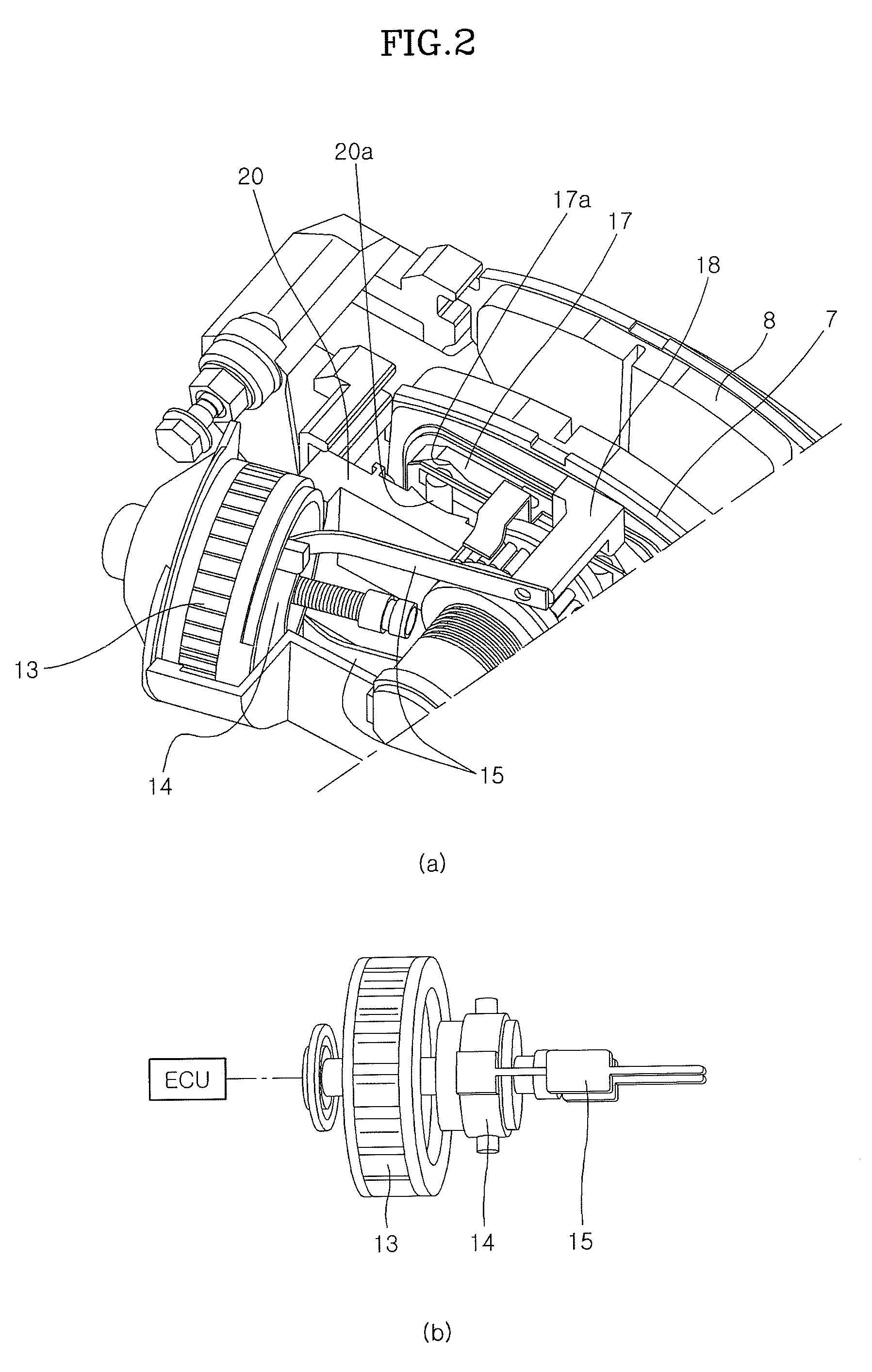

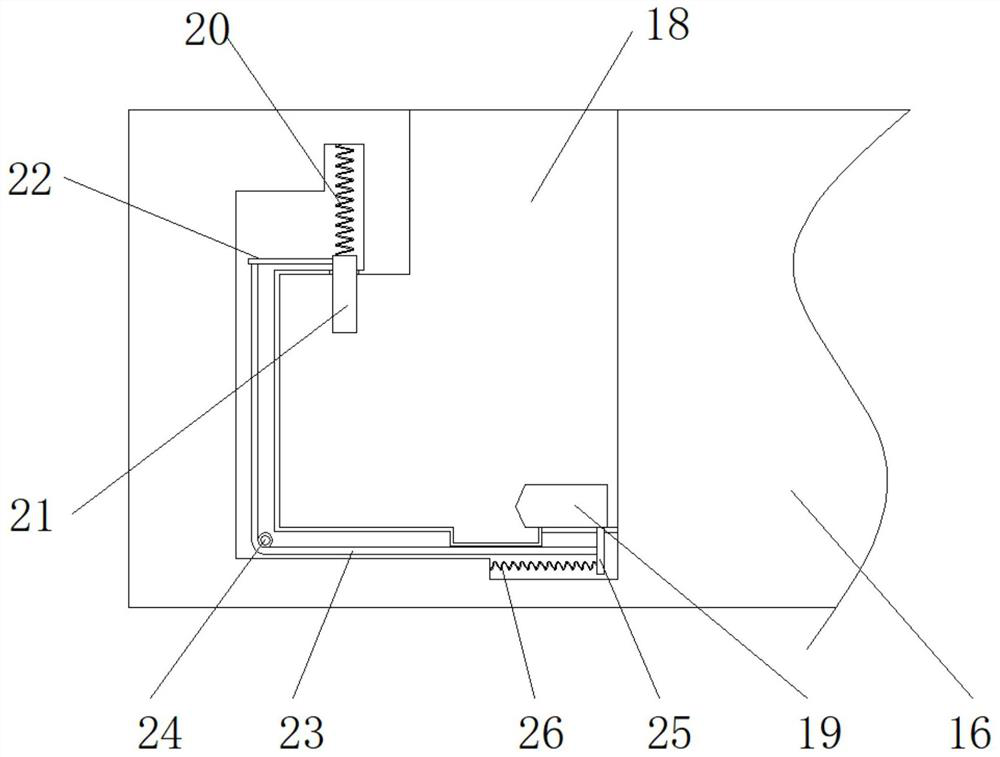

Single motor electro wedge brake system using solenoid mechanism for implementing additional functions

InactiveUS20080314695A1Assembly property can be improvedSmall sizeMechanically actuated brakesBrake actuating mechanismsSolenoid valveElectric machine

The present invention provides an electro wedge brake (EWB) system that implements a main braking function by using power generated by one motor. Further, the electro wedge brake system implements various additional functions such as a function for maintaining a set clearance of a pad, a Fail-Safe function, and an EPB function, by using that the forward movement of a push rod shaft screwed using a NSL (Non-Self Locking) type screw is restrained or released on the basis of ON / OFF control of the solenoid mechanism interlocked with the main braking function motor. Accordingly, since only one motor is used to generate power, it is possible to reduce the number of parts and to simplify the structure.

Owner:HYUNDAI MOBIS CO LTD

Aircraft kinetic landing energy conversion system

ActiveUS8123163B2Increase braking powerAvoid heatCharging stationsEnergy efficient operational measuresElectric potential energyElectric generator

Owner:THE BOEING CO

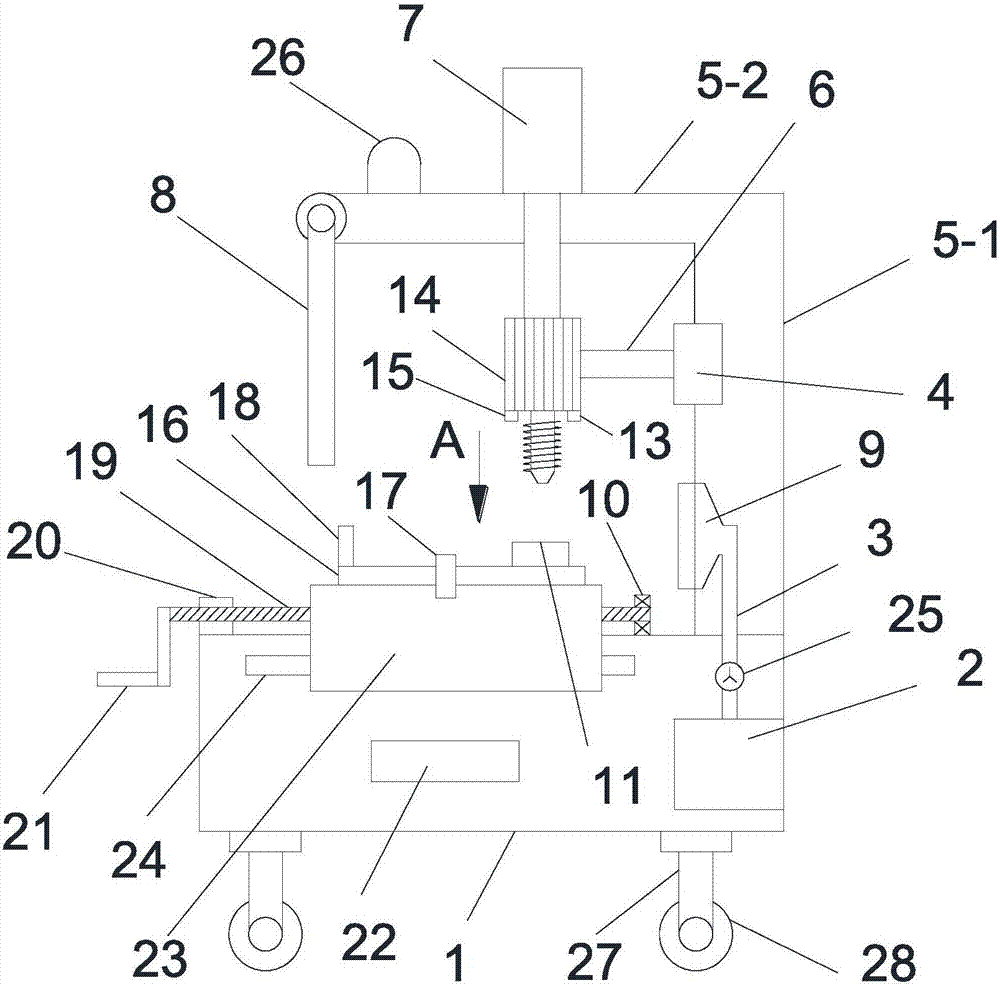

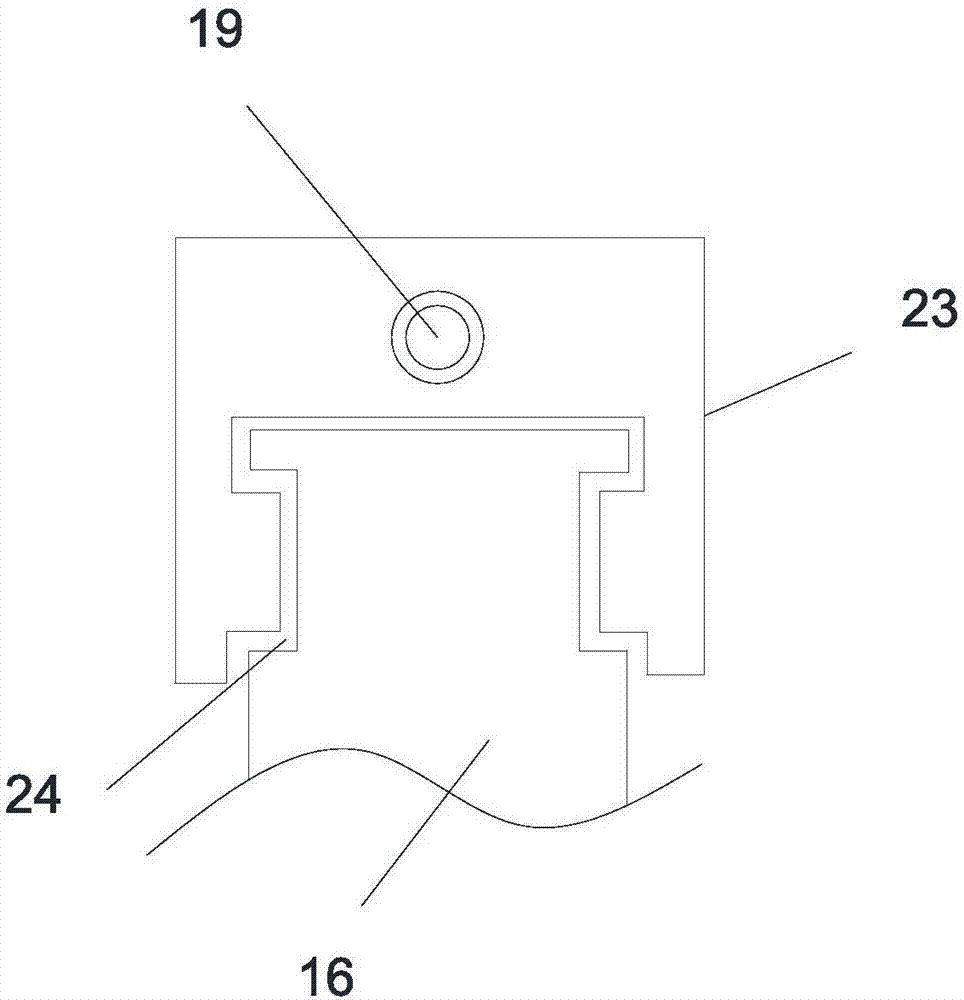

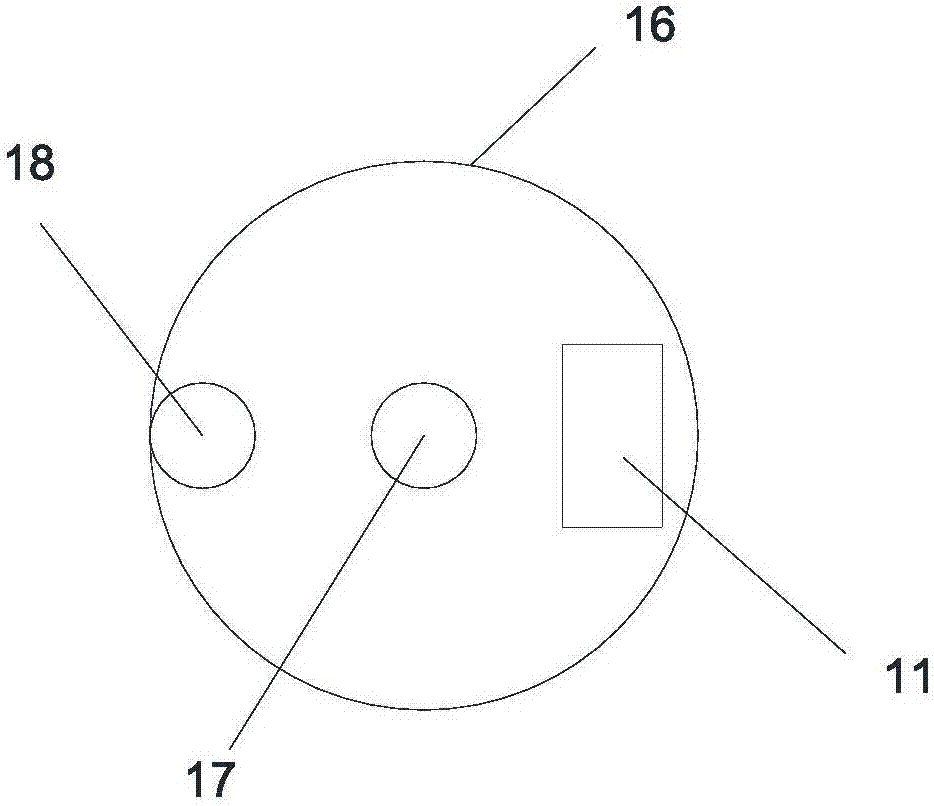

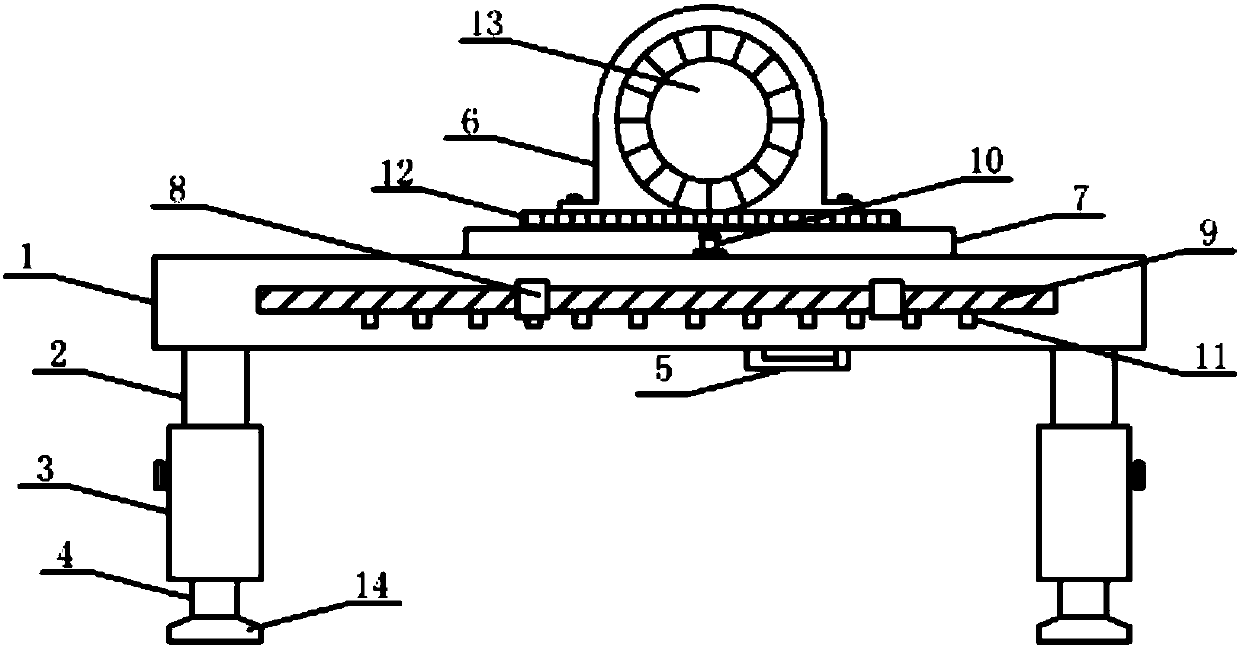

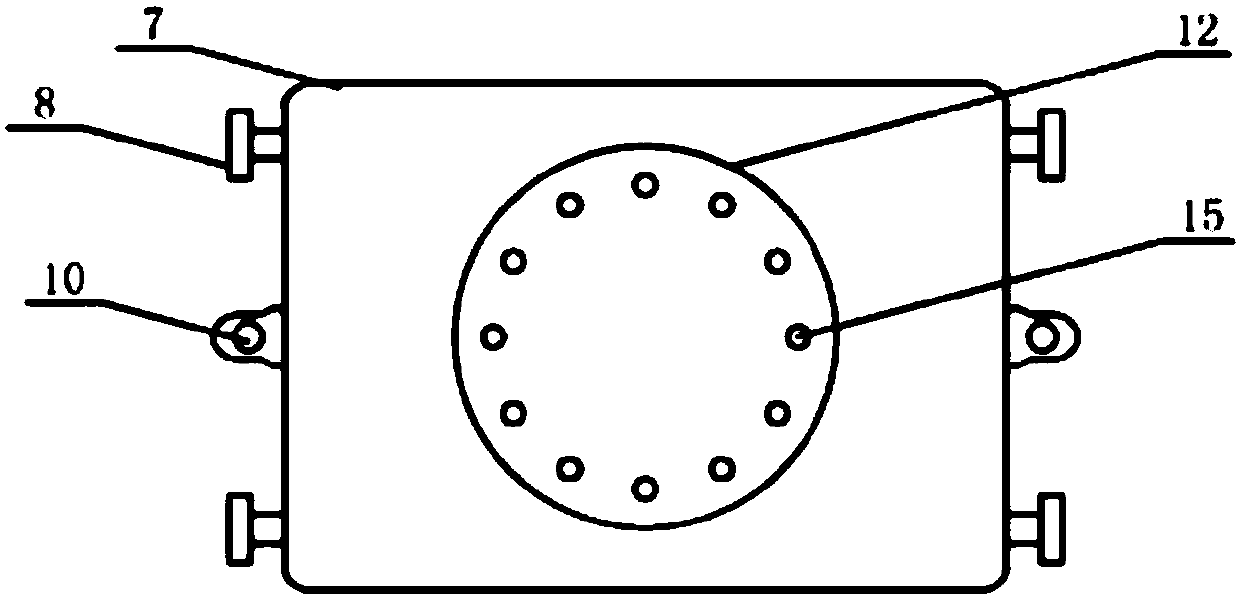

Motor end cover drilling device with cooling function

InactiveCN107186241AAvoid damagePrevent affecting drilling qualityMeasurement/indication equipmentsLarge fixed membersFunction motorSpray nozzle

A motor end cover drilling device with cooling function, comprising a base, a frame is arranged on the base, the frame includes a vertical frame and a horizontal support, an electric hydraulic cylinder is installed upside down on the horizontal support, and the bottom of the electric hydraulic cylinder is fixedly installed There is a drill bit seat, a drill bit is arranged on the drill bit seat, a temperature sensor and a distance sensor are fixedly installed at the lower part of the drill bit seat, a slideway is arranged on the side of the base, a slide seat is installed on the base, and the slide seat is connected with the slideway; the slide seat passes through the turntable The shaft is rotatably installed with a turntable, the edge of the turntable is provided with a handle, a screw rod is passed through the first limit sleeve and the second limit sleeve, and the left end of the screw rod is provided with a rocking handle; the controller and the temperature sensor are electrically connected The vertical frame is provided with an atomizing nozzle, a water pipe is connected between the atomizing nozzle and the water tank, and a water pump is installed on the water pipe; the invention is flexible and convenient to adjust, and the drilling operation is simple and fast; service life and drilling quality.

Owner:FOSHAN ZHENGLUE INFORMATION TECH CO LTD

Fuel oil generator set of hybrid electric vehicle

InactiveCN102182554AReduce consumptionEasy to controlGas pressure propulsion mountingElectric machinesManufacturing cost reductionFuel oil

The invention discloses a fuel oil generator set of a hybrid electric vehicle. The fuel oil generator set comprises a fuel oil engine, a three-phase rectifier, a storage battery set, a permanent magnetic body connected with an external rotor, a stator and a three-phase winding, and is characterized in that: a two-function motor is arranged at one end of the fuel oil engine; the two-function motor is either a starting motor or a generator, and performs control over starting, generation and charging of the fuel oil engine through a function converter and a starting controller; and a hall element for controlling the two-function motor is arranged on a pole pair of a stator of each phase of the two-function motor. The fuel oil generator set has the advantages of relieving of weight, reduction of energy consumption and manufacturing cost, convenience of vehicle control and safety running.

Owner:潘世澄

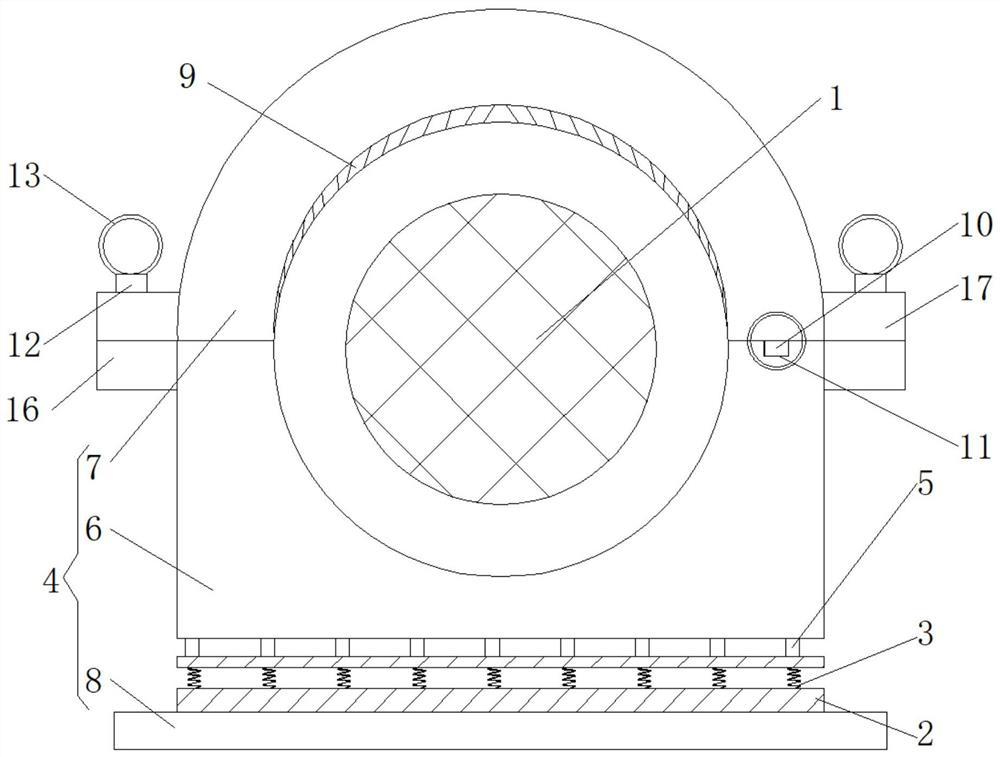

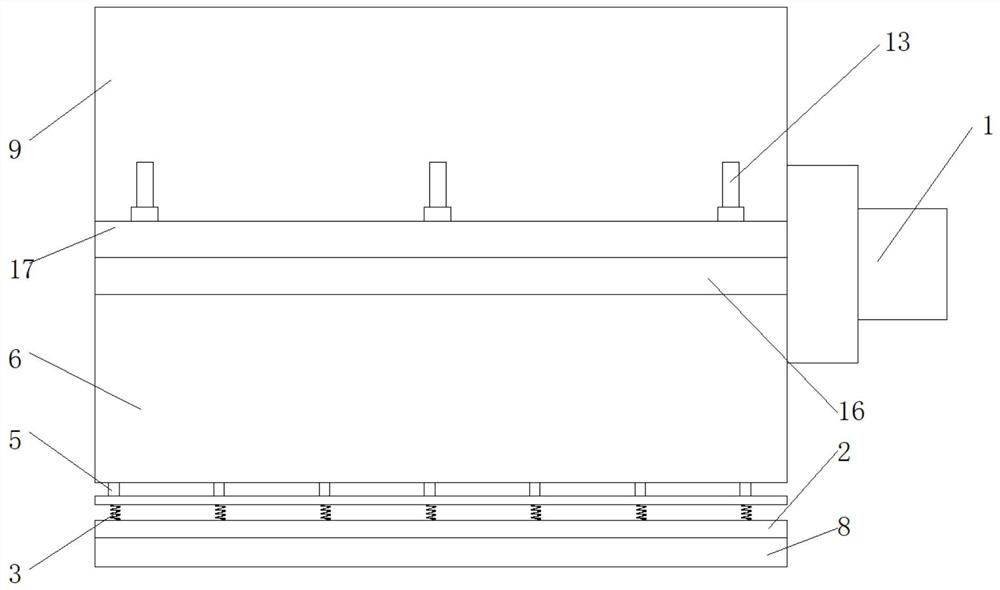

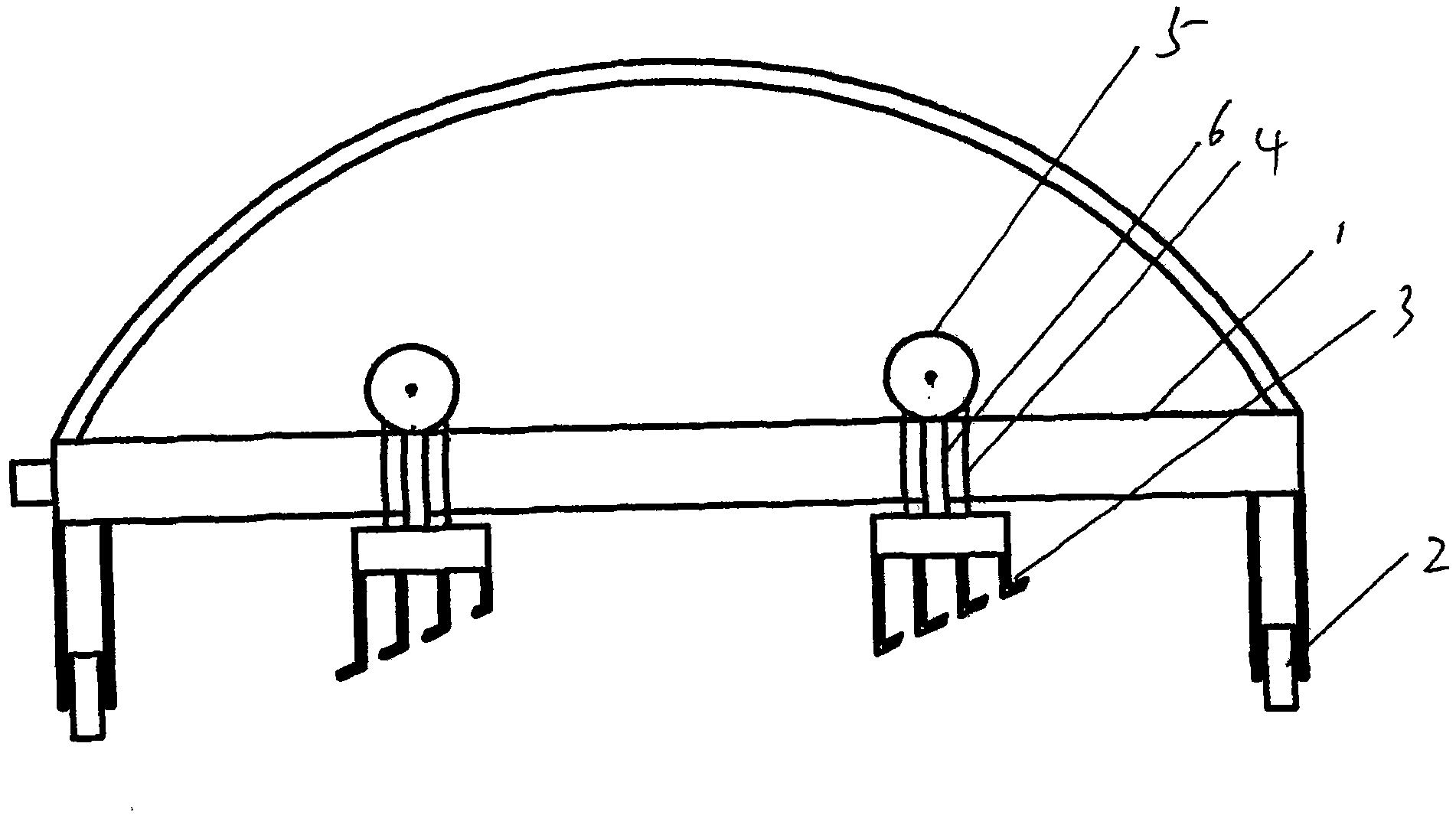

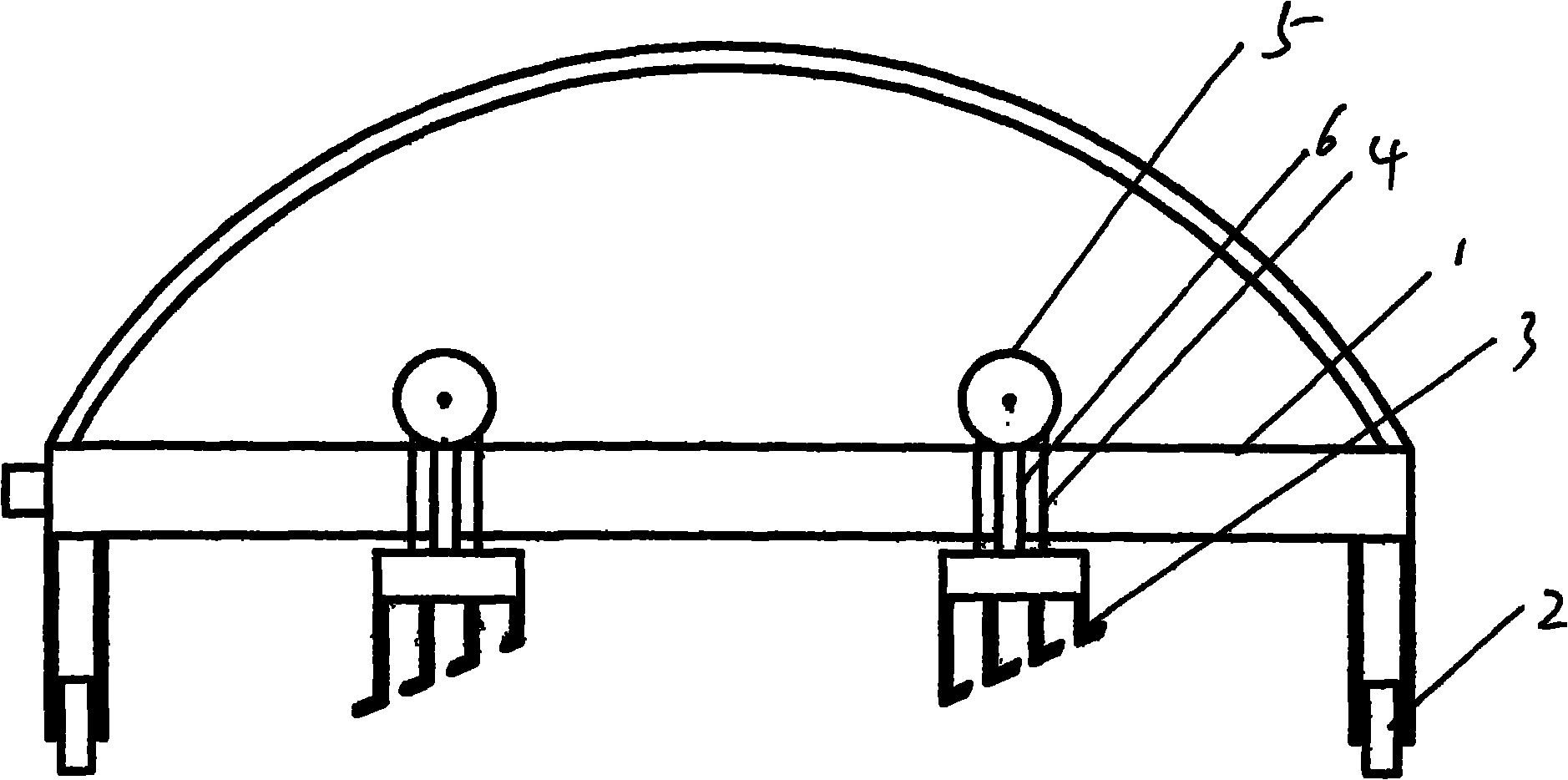

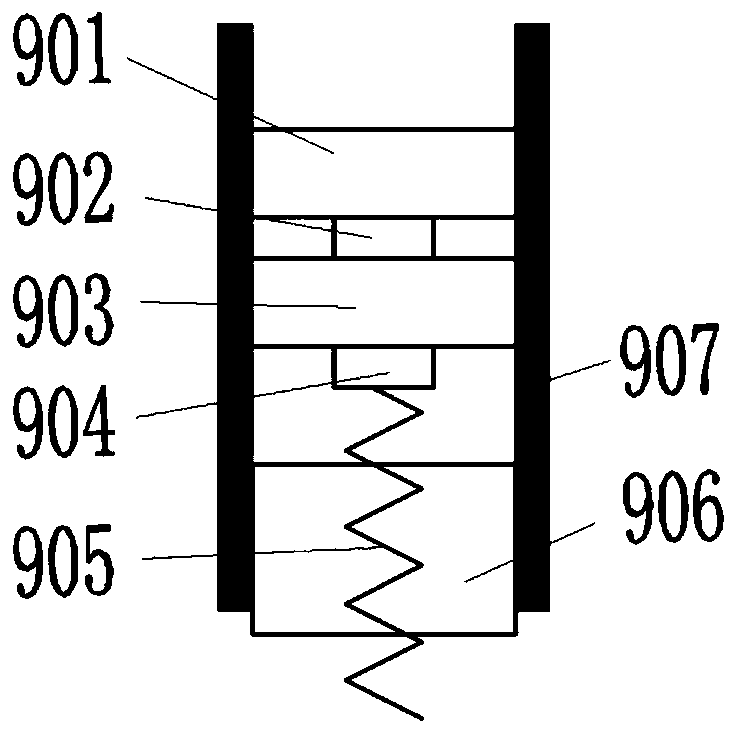

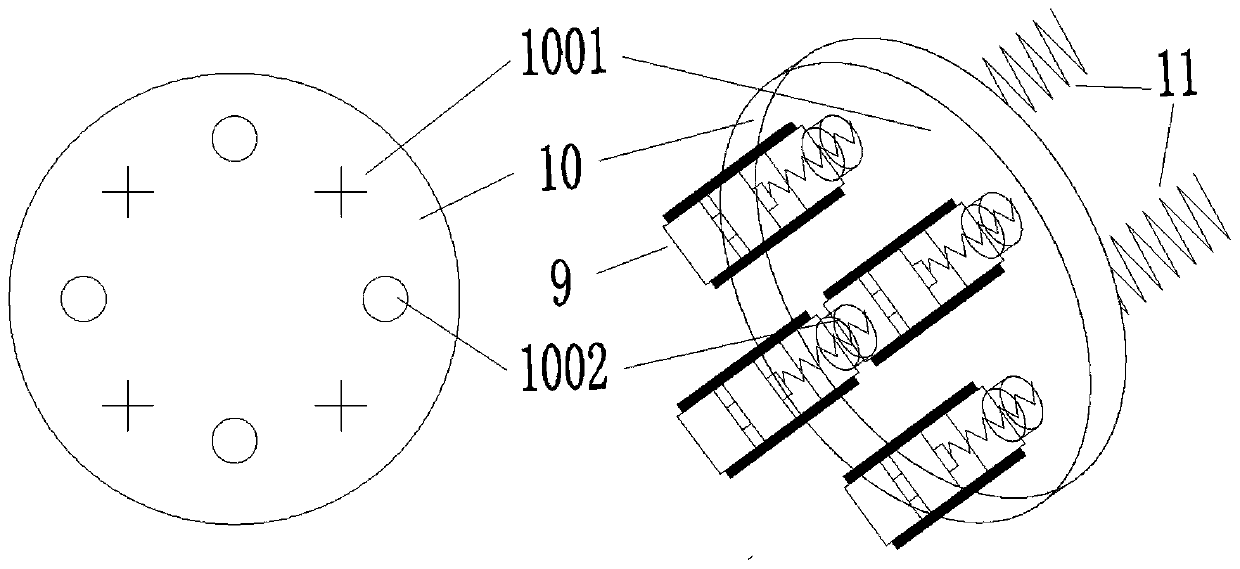

Switched reluctance motor with motor rack having functions of noise reduction and vibration resistance

PendingCN107659041AReduce vibrationReduce noiseAC motor controlSupports/enclosures/casingsArchitectural engineeringNoise reduction

The invention discloses a switched reluctance motor with a motor rack having functions of noise reduction and vibration resistance in the technical field of switched reluctance motors. The switched reluctance motor is characterized in that four corners of the bottom of a supporting frame are provided with telescopic rods, the bottom of each telescopic rod is provided with a fixing rod, the top ofthe supporting frame is provided with a mobile platform, both the top and the bottom of two sides of the mobile platform are provided with supporting sliding strips, the outer walls at two sides of the supporting frame are provided with supporting sliding slots matched with the supporting sliding strips, two sides of the mobile platform are provided with positioning pins respectively, two sides ofthe supporting frame are provided with moving slots mutually matched with the positioning pins in a movable manner at the top, and an inner cavity of the supporting frame is provided with positioningholes matched with the positioning pins. The switched reluctance motor is compact in structure, and can effectively reduce the vibration generated in operation of the motor, reduce the noise broughtabout by the operating vibration of the motor and avoid noise pollution for the surrounding environment. The horizontal displacement and the selection angle of the switched reluctance motor can be conveniently adjusted, and the practicability of the switched reluctance motor is improved.

Owner:扬州知行动力科技有限公司

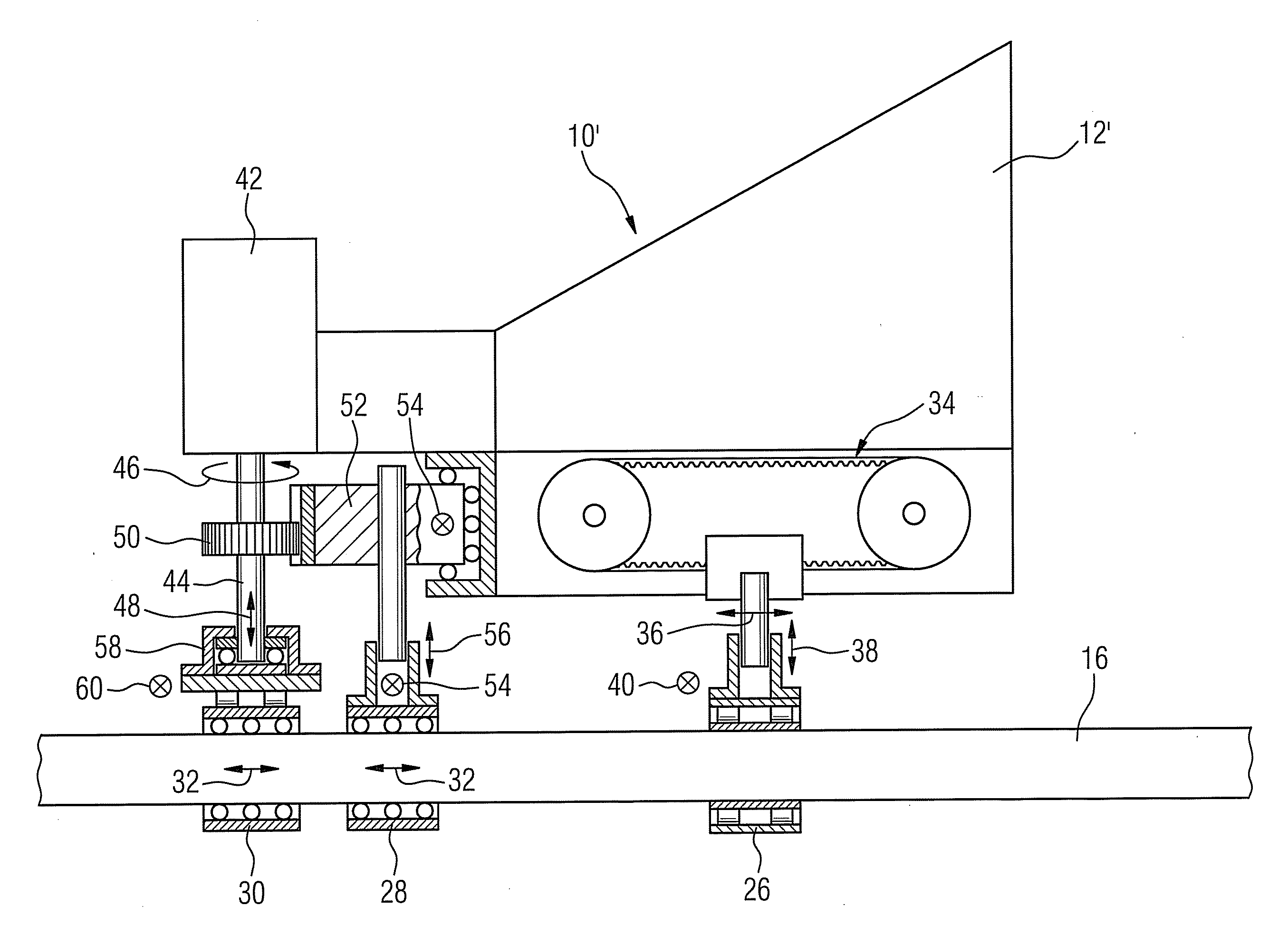

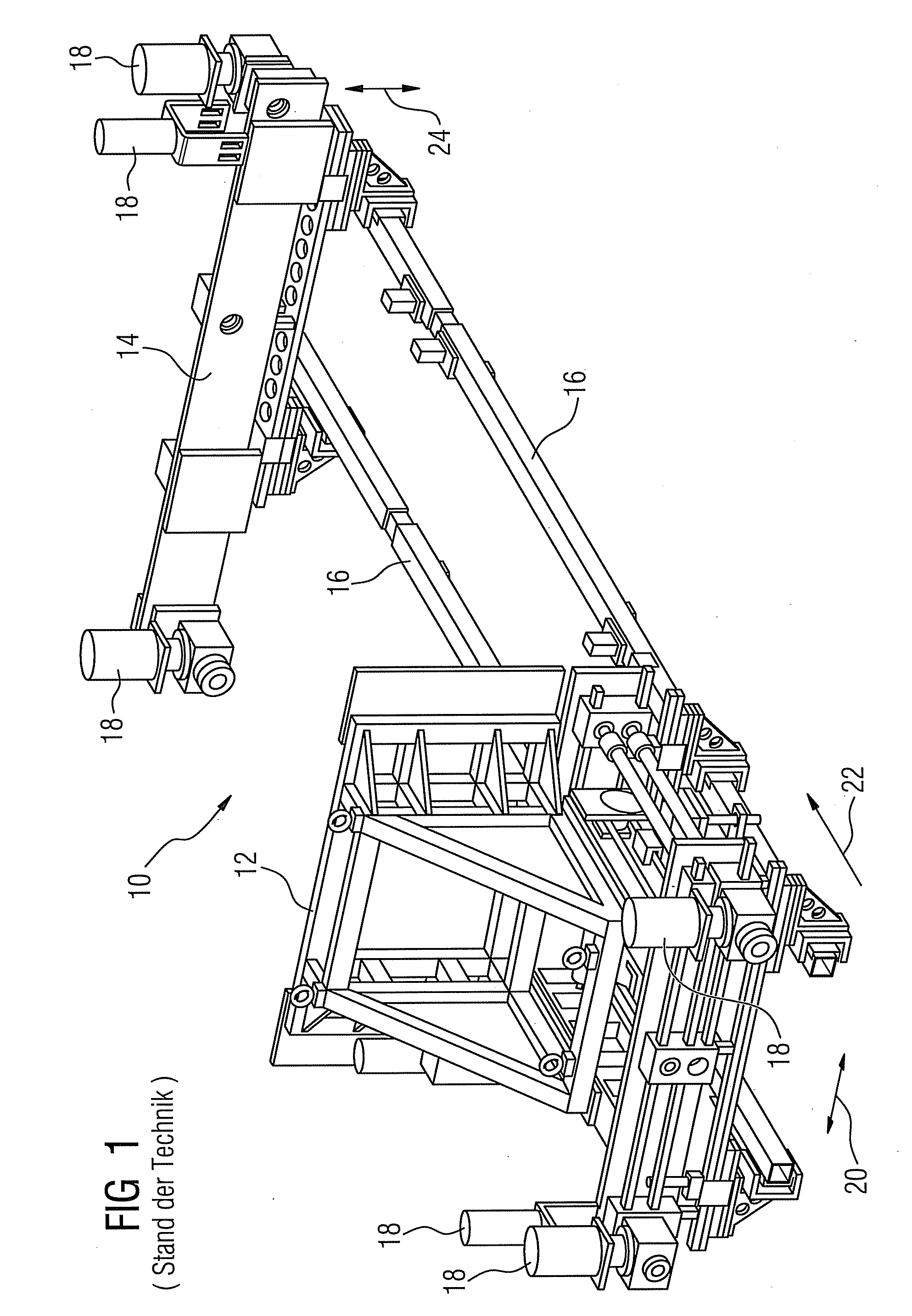

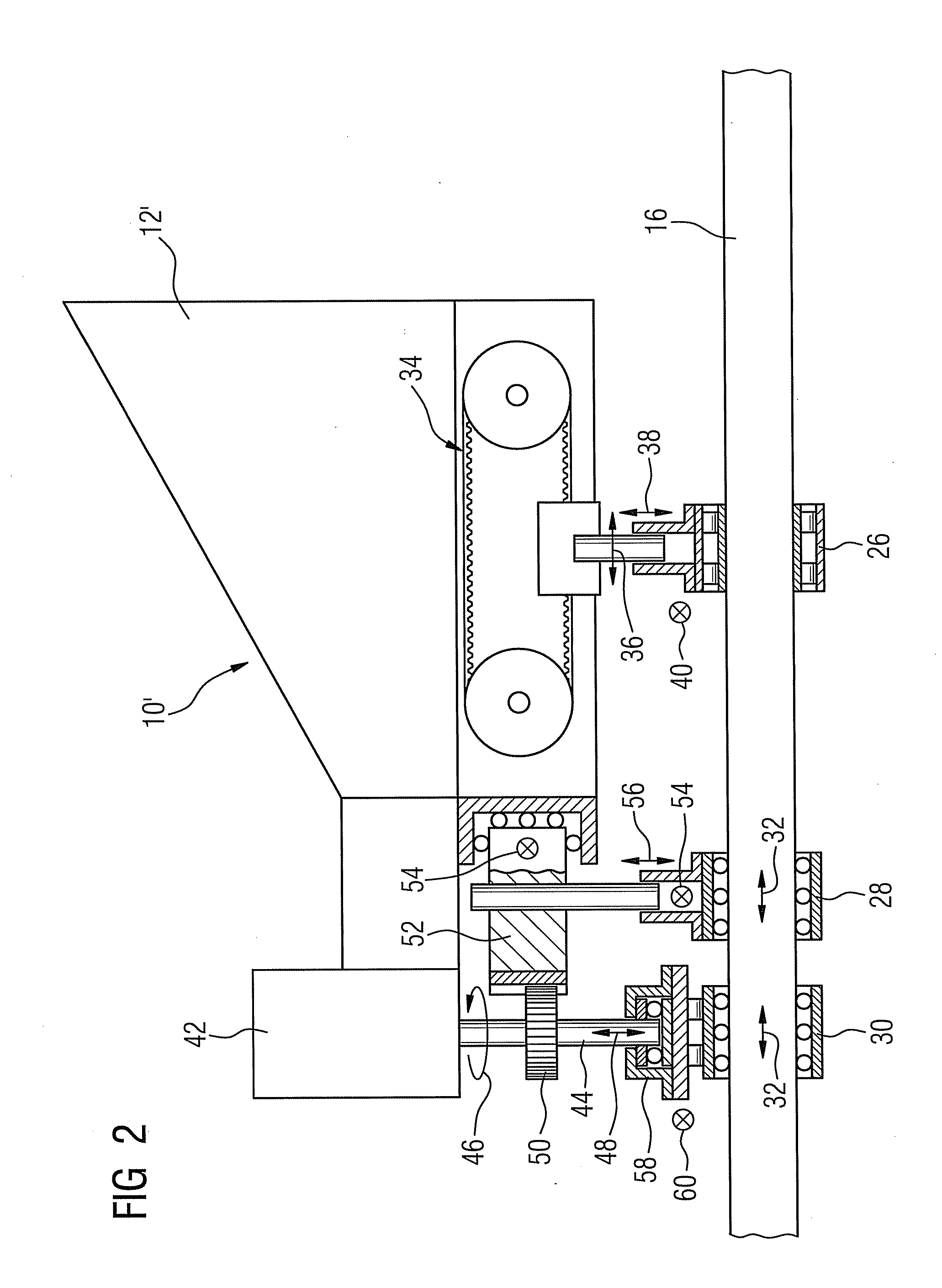

Transfer system

InactiveUS8505710B2Metal-working feeding devicesForging/hammering/pressing machinesTransfer systemFunction motor

Owner:SIEMENS AG

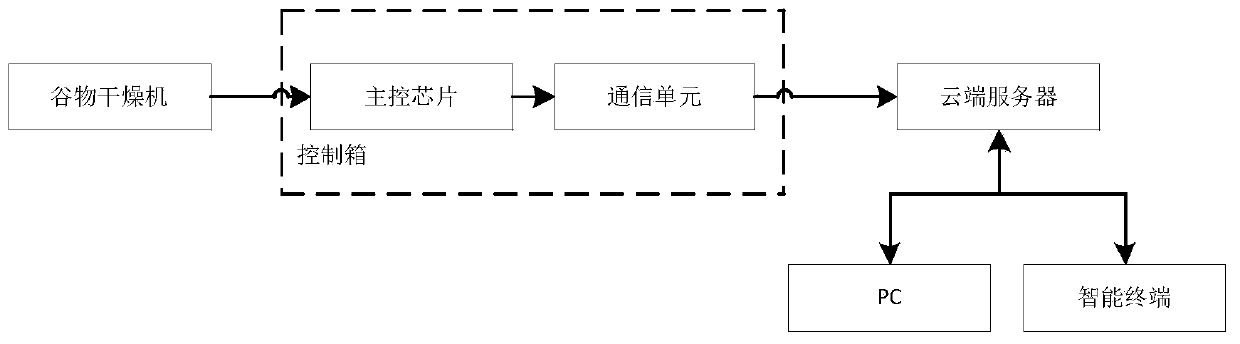

Grain dryer monitoring system

PendingCN109751863AFind faults in timePrevent abnormal drying problemsSeed preservation by dryingDrying solid materialsTerminal serverCommunication unit

The invention discloses a grain dryer monitoring system, which comprises a grain dryer and a control box. The control box internally comprises a main control chip and is further internally provided with a communication unit; and the main control chip is connected with the communication unit, the communication unit is connected with a cloud terminal server, and the cloud terminal server is connected with an intelligent terminal or a PC terminal. The grain dryer monitoring system has the advantages that operation data of the grain dryer are obtained by remote monitoring, and remote monitoring bya user is convenient; through the remote monitoring mode, the relevant data can be conveniently viewed not locally, and thus convenience and high efficiency are achieved; and the monitored data comprise the temperature of hot air entering the dryer, the grain moisture, the grain temperature, the grain weight after drying, the grain drying time, dryer positioning, the dryer grain loading state, the operation states of all function motors of the dryer and the like, and monitoring personnel conveniently process and adjust dryer parameters in time.

Owner:芜湖小禾信息科技有限公司

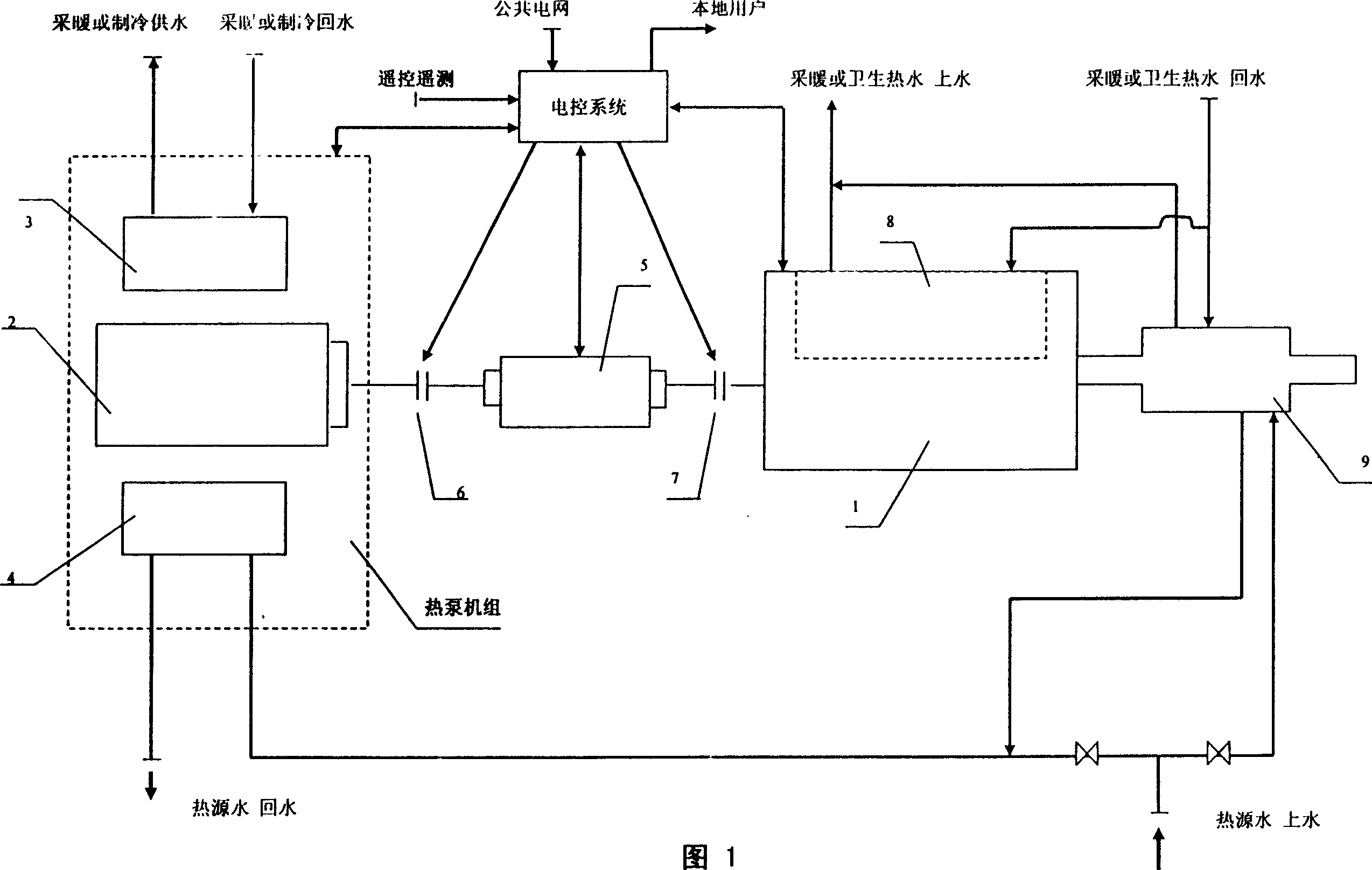

Thermal supplying apparatus with co-shaft of three device connected directly and its use

InactiveCN1680762AAchieve any combinationRealize functions such as energy regulationHeat pumpsInternal combustion piston enginesWater sourceElectric control

This invention is a unit of three motors links in series, which comprises an engine, a double function motor, heat pumps set and electric control system. To the two axis of the motor link the heat pumps set and the engine through controllable clutches in series. The controllable clutches control the open / close of the motor to engine or motor to heat pumps set. Through the electric control system and the controllable clutch, it is possible to control the rotate speed and open / close of the heat pumps set. The electric control system links the motor to electricity net. This unit is fixed with heat recover unit and fuel gas heat recover unit, which link to heat pumps set, heating system, hot water supply system and ground water source. There are four working manners of the invented unit realizing a flexible link of motor to engine and motor to heat pumps set and taking advantage of electricity using dale.

Owner:SHENYANG DONGYU GRP CO LTD

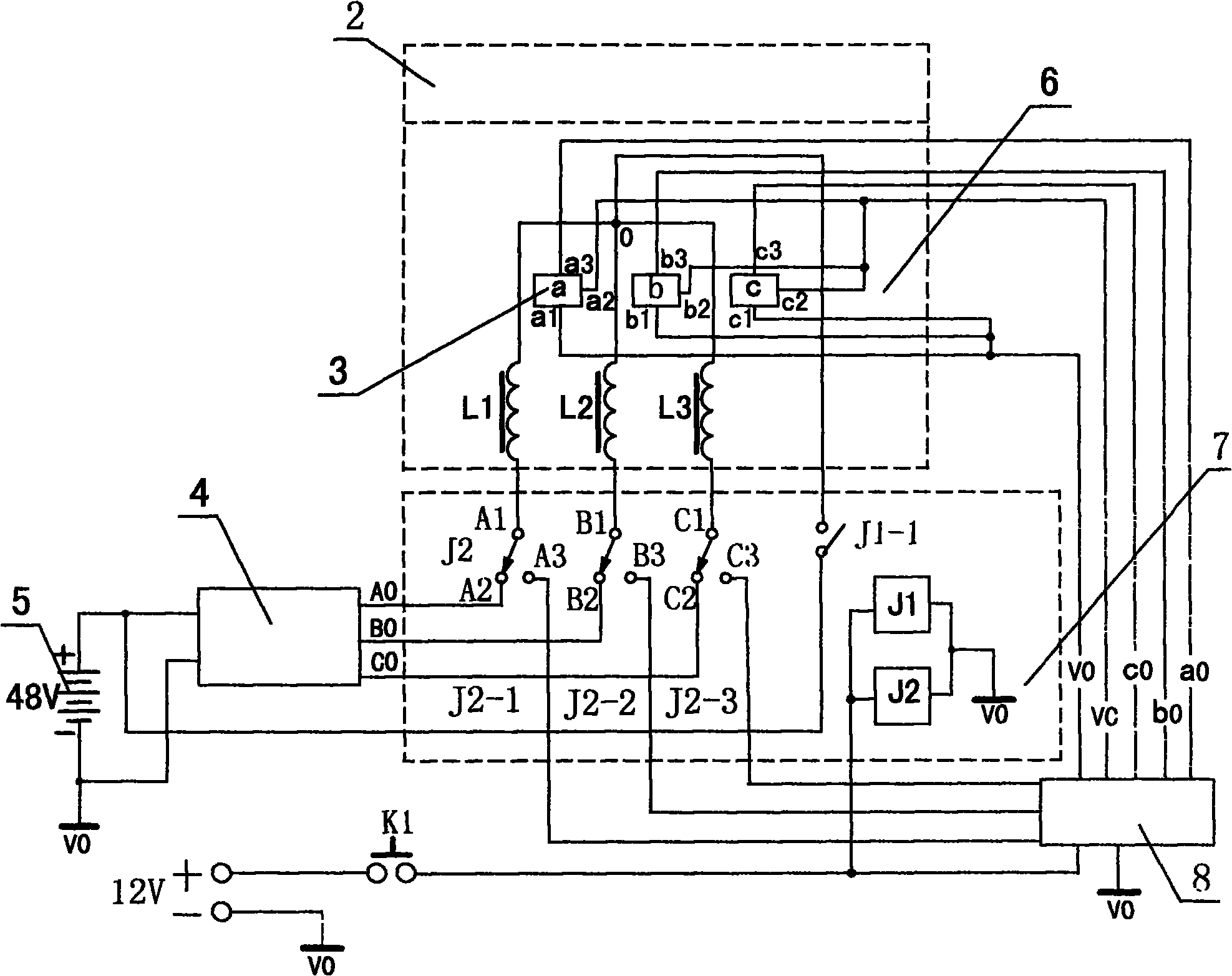

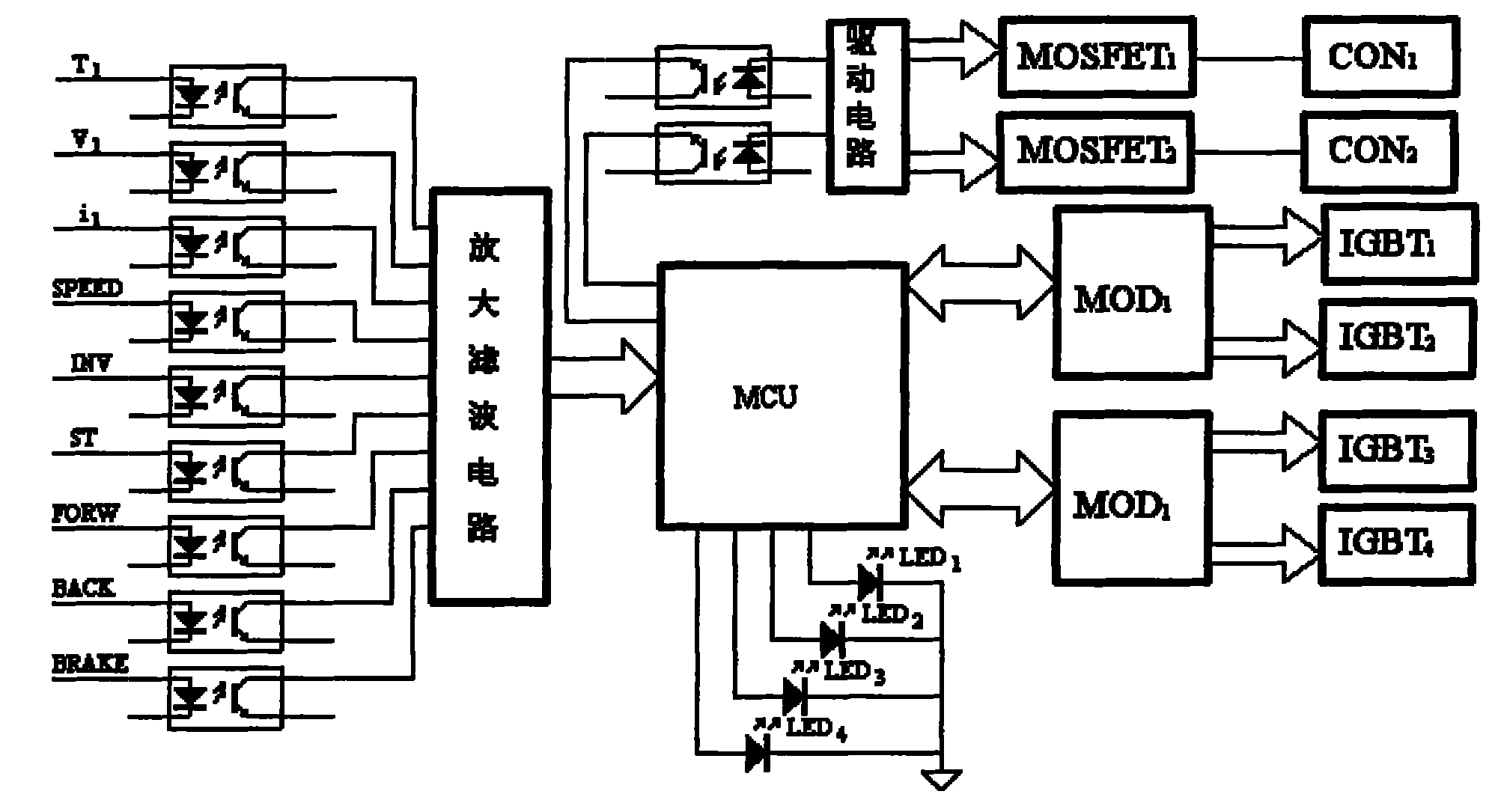

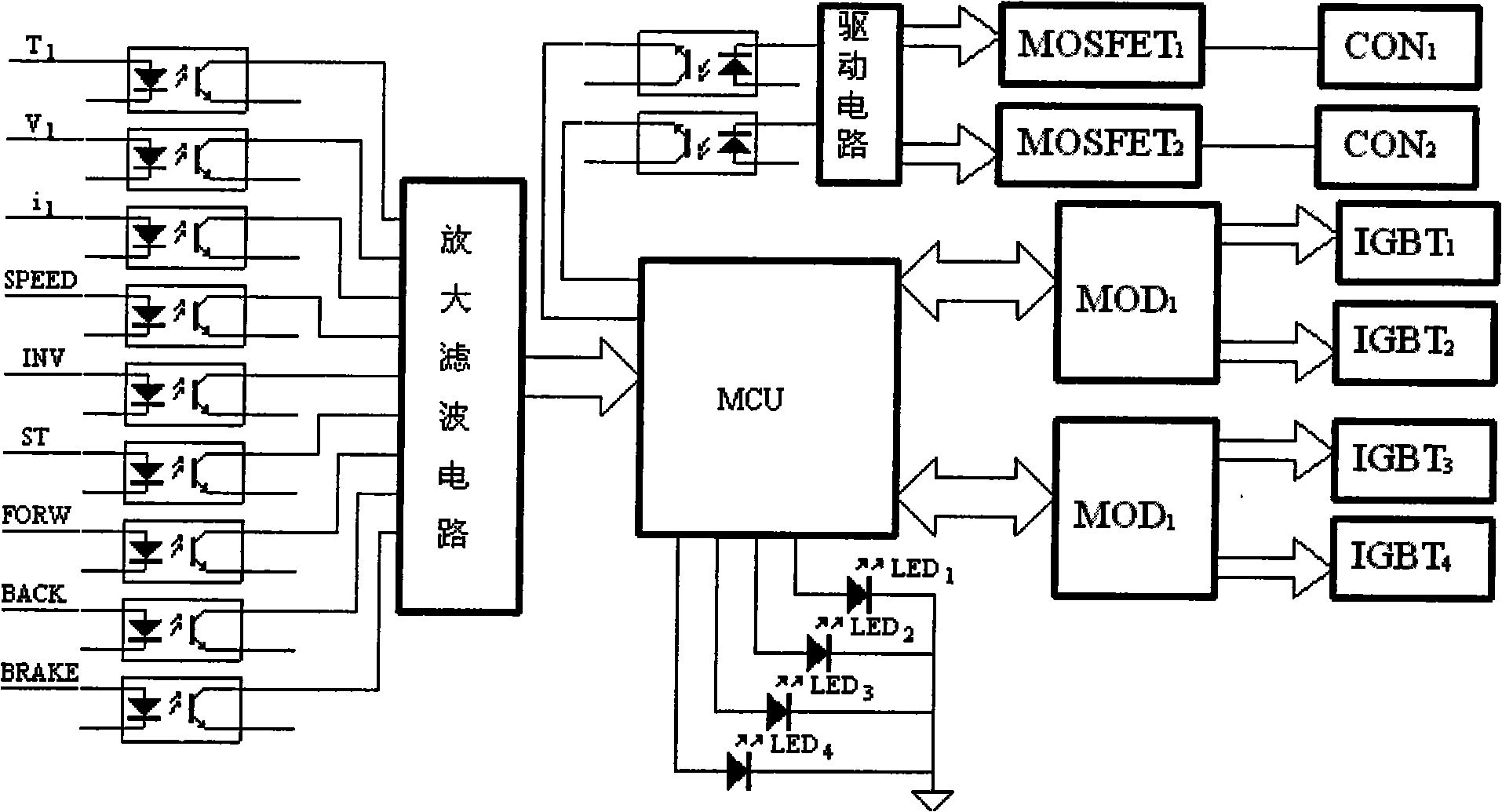

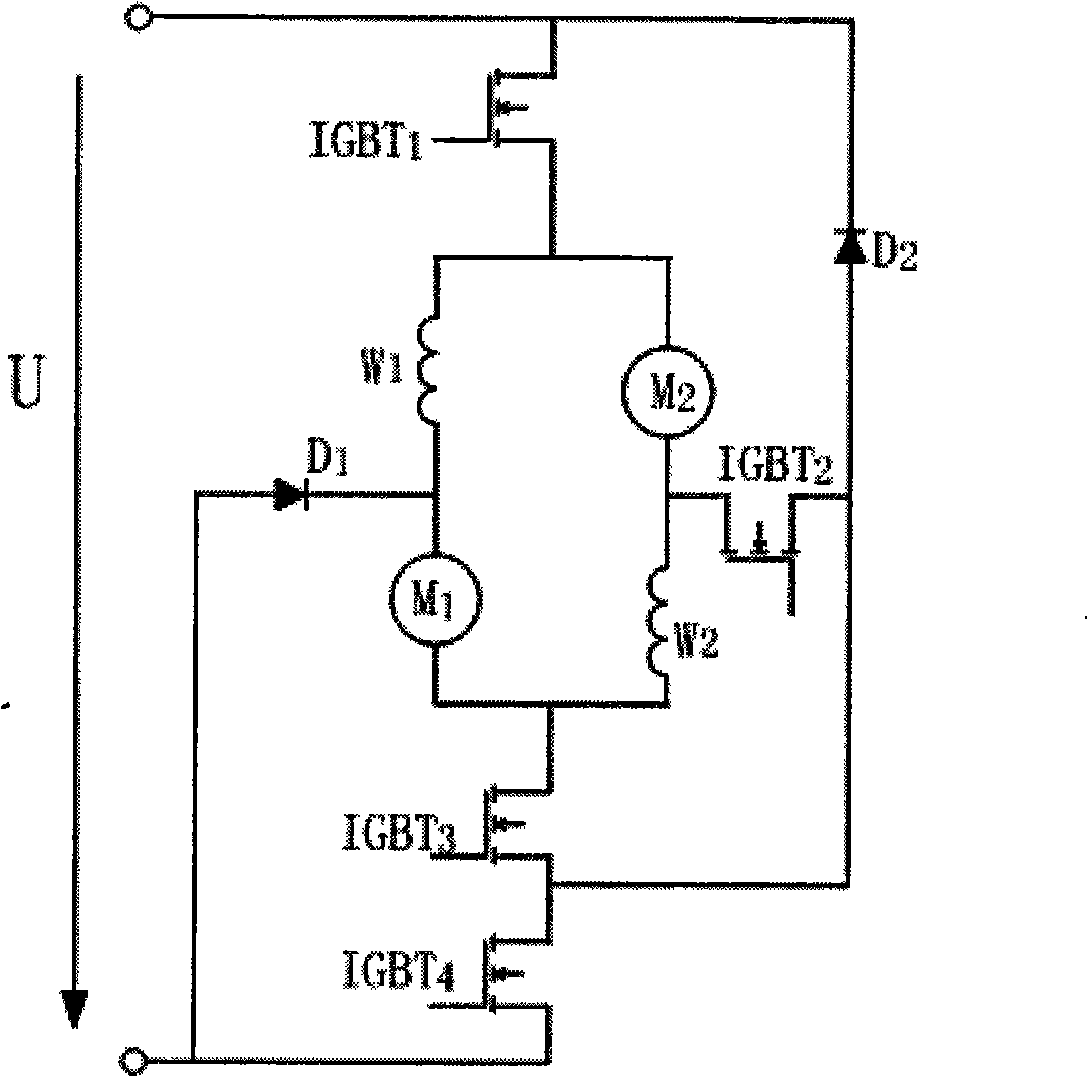

A control system with braking function of series excited direct current cross-connected double motor

InactiveCN101552584BImprove utilization efficiencyAchieve energy consumptionElectric motor speed/torque regulationMicrocontrollerCross connection

The invention discloses a control system with braking function of series excited direct current cross-connected double motor used for electric motor cars, which is characterized by comprising a core cell microcontroller (MCU), a complete signal inputting and conditioning circuit, an output executive circuit, a fault display circuit, an input-output isolating circuit, a power electronic switch, a drive circuit thereof and the like; two series excited direct current motors are crossly connected, namely the single motor self is serially excited and two motors are connected in parallel; the main circuit connection driven by the motors consists of two current fly-wheel diodes, four power switch electronic devices, two contactors, etc. The motor connection mode, main circuit and controller disclosed in the invention can realize the functions of motors of rotating the motors normally and reversely, starting current limit, regulating speed, braking, etc. The motors can realize regenerative braking and has high efficiency, and the whole system has characteristics of perfect control functions, high reliability and the like.

Owner:XI AN JIAOTONG UNIV

Single motor electro wedge brake system using solenoid mechanism for implementing additional functions

InactiveUS7987950B2Improve propertiesReduce in quantityMechanically actuated brakesBrake actuating mechanismsElectric machineFunction motor

The present invention provides an electro wedge brake (EWB) system that implements a main braking function by using power generated by one motor. Further, the electro wedge brake system implements various additional functions such as a function for maintaining a set clearance of a pad, a Fail-Safe function, and an EPB function, by using that the forward movement of a push rod shaft screwed using a NSL (Non-Self Locking) type screw is restrained or released on the basis of ON / OFF control of the solenoid mechanism interlocked with the main braking function motor. Accordingly, since only one motor is used to generate power, it is possible to reduce the number of parts and to simplify the structure.

Owner:HYUNDAI MOBIS CO LTD

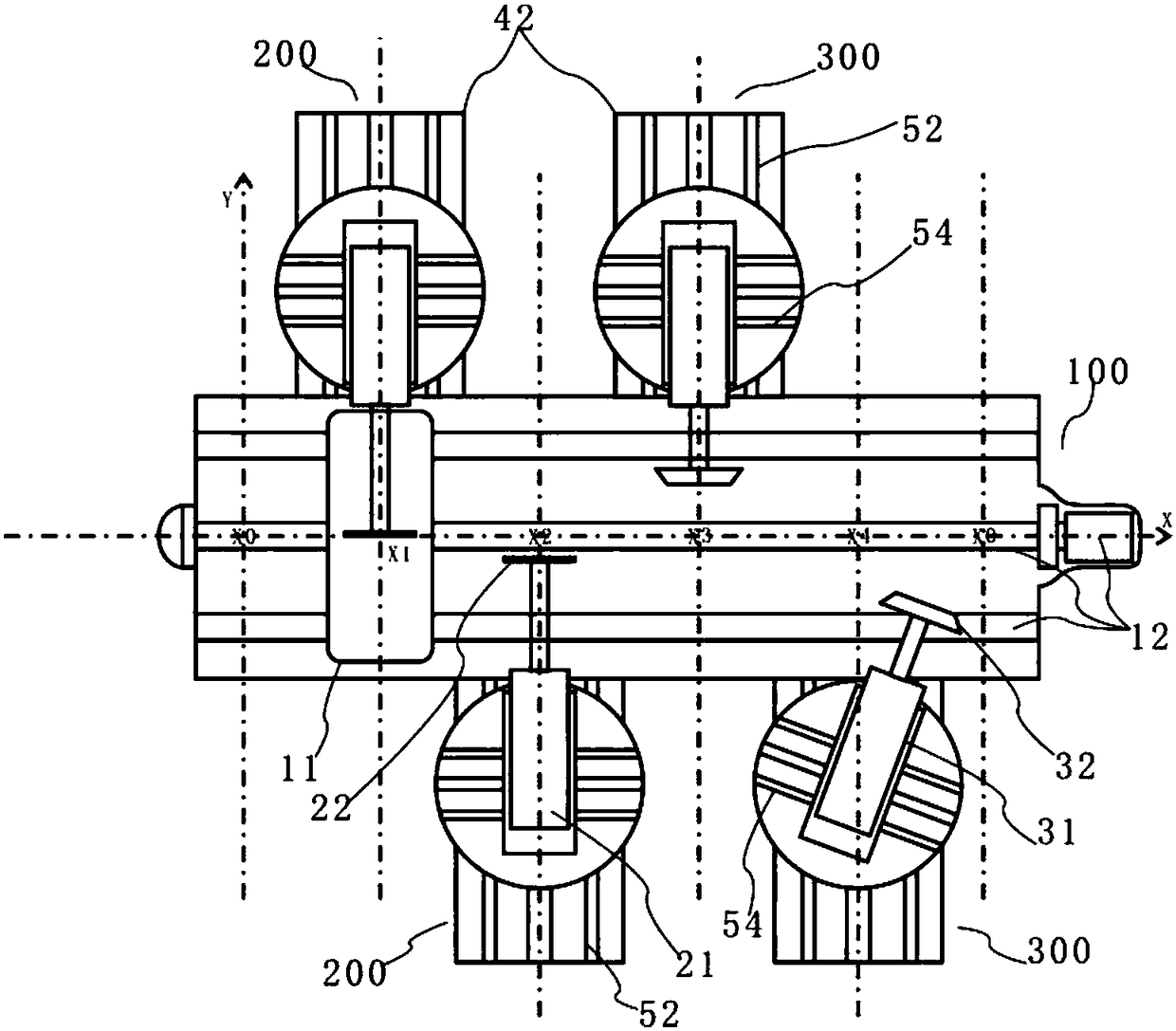

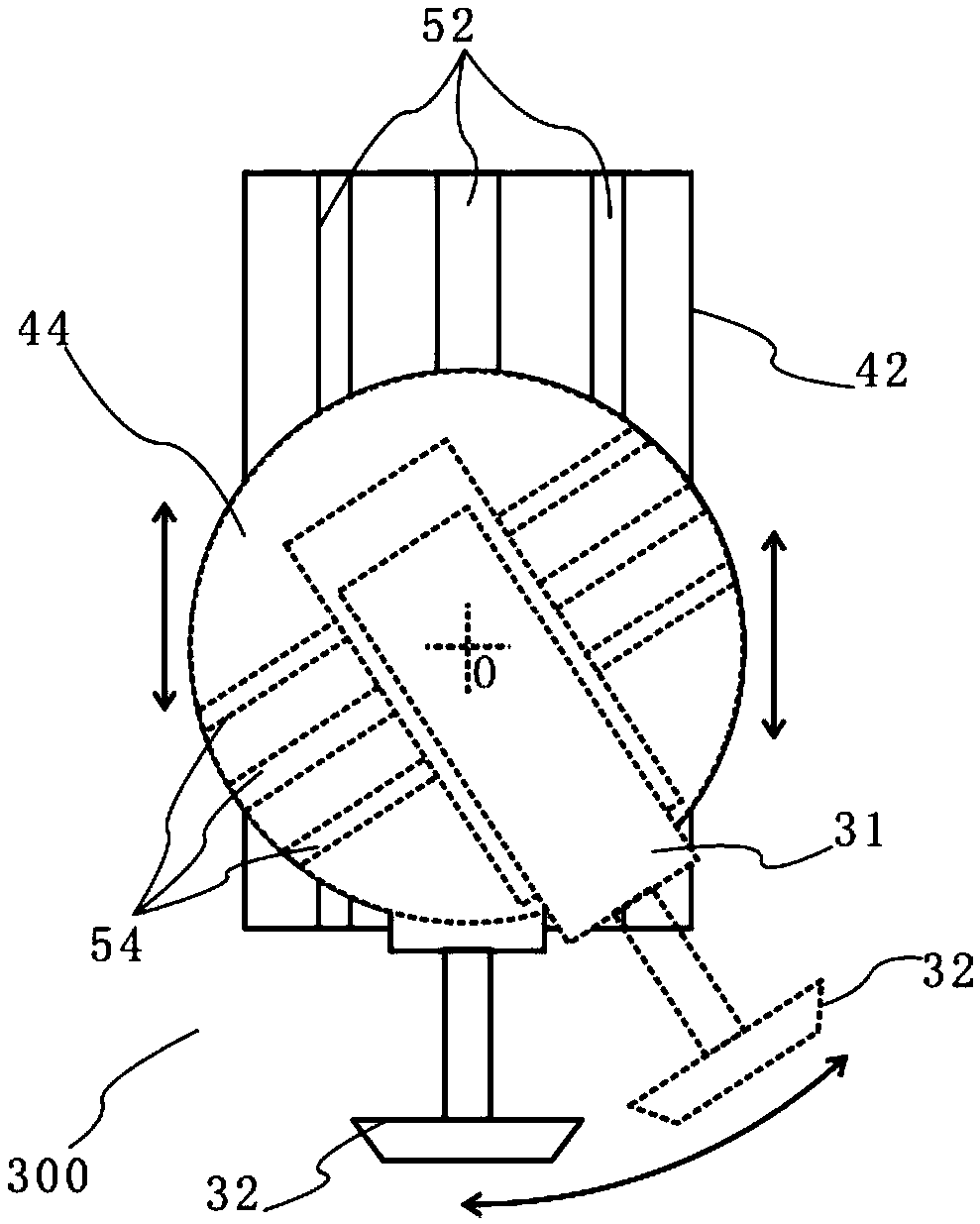

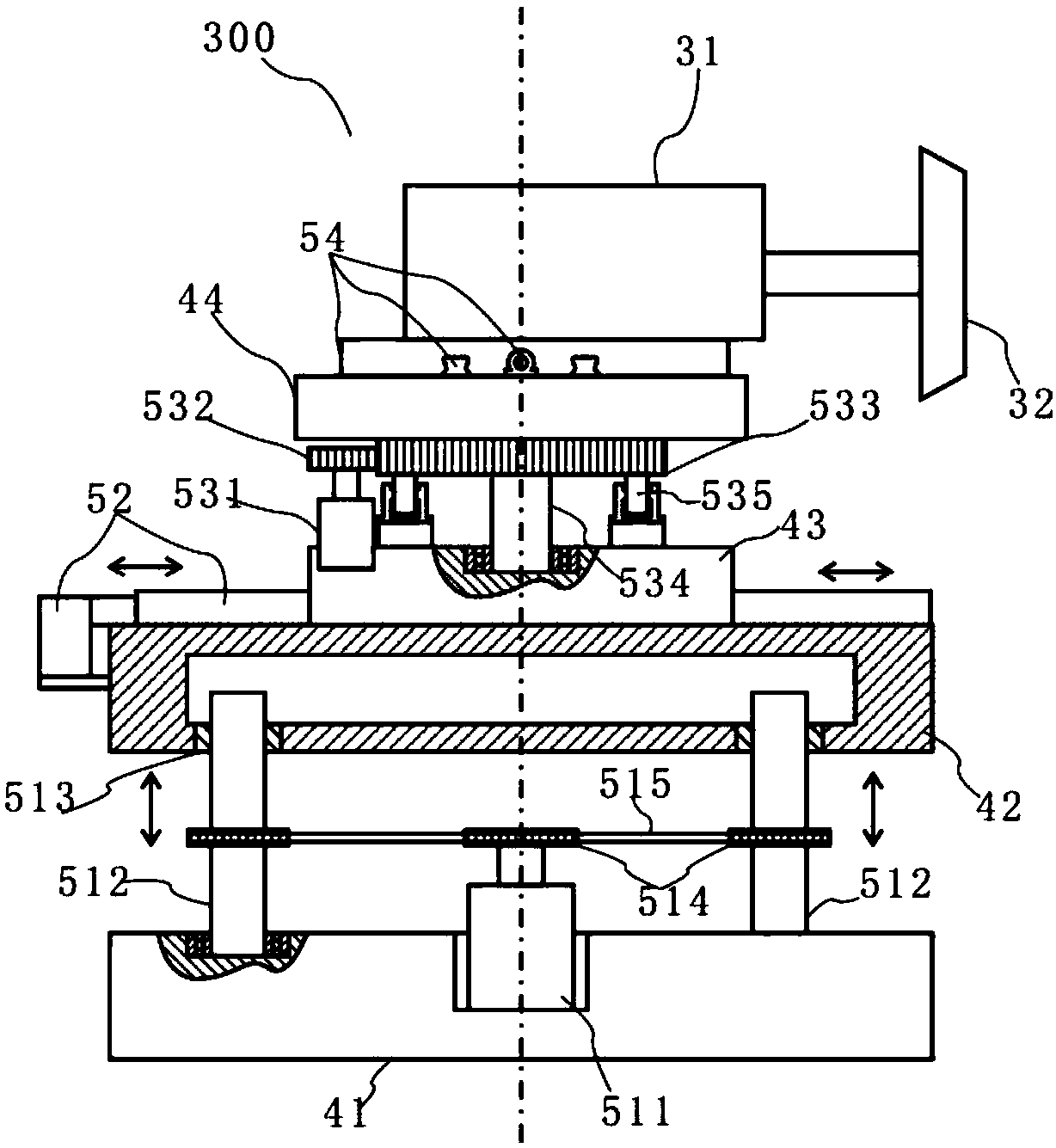

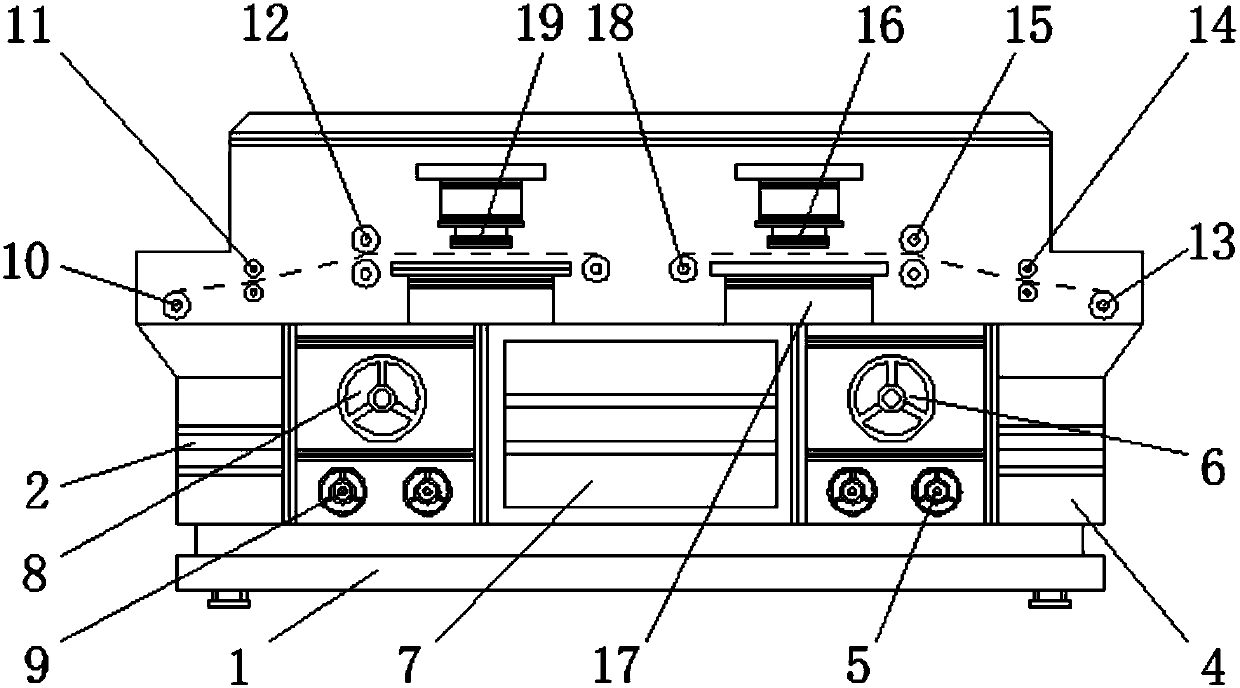

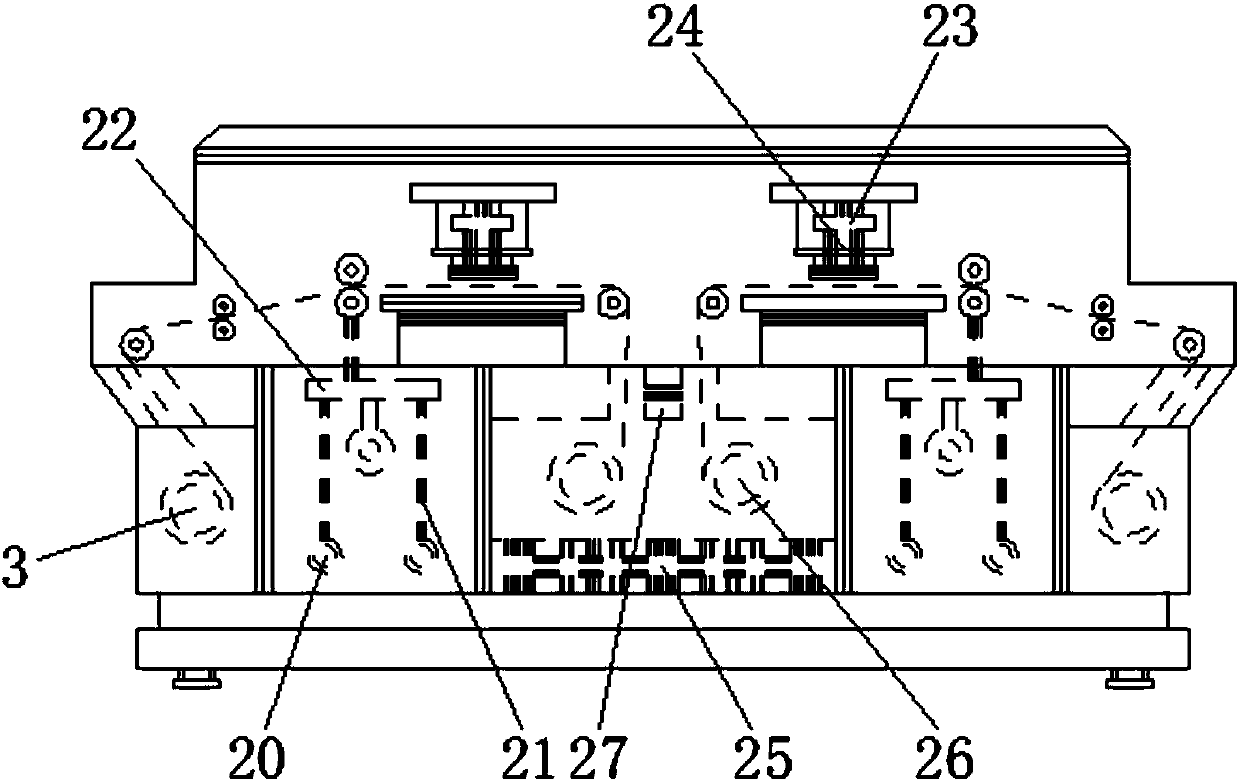

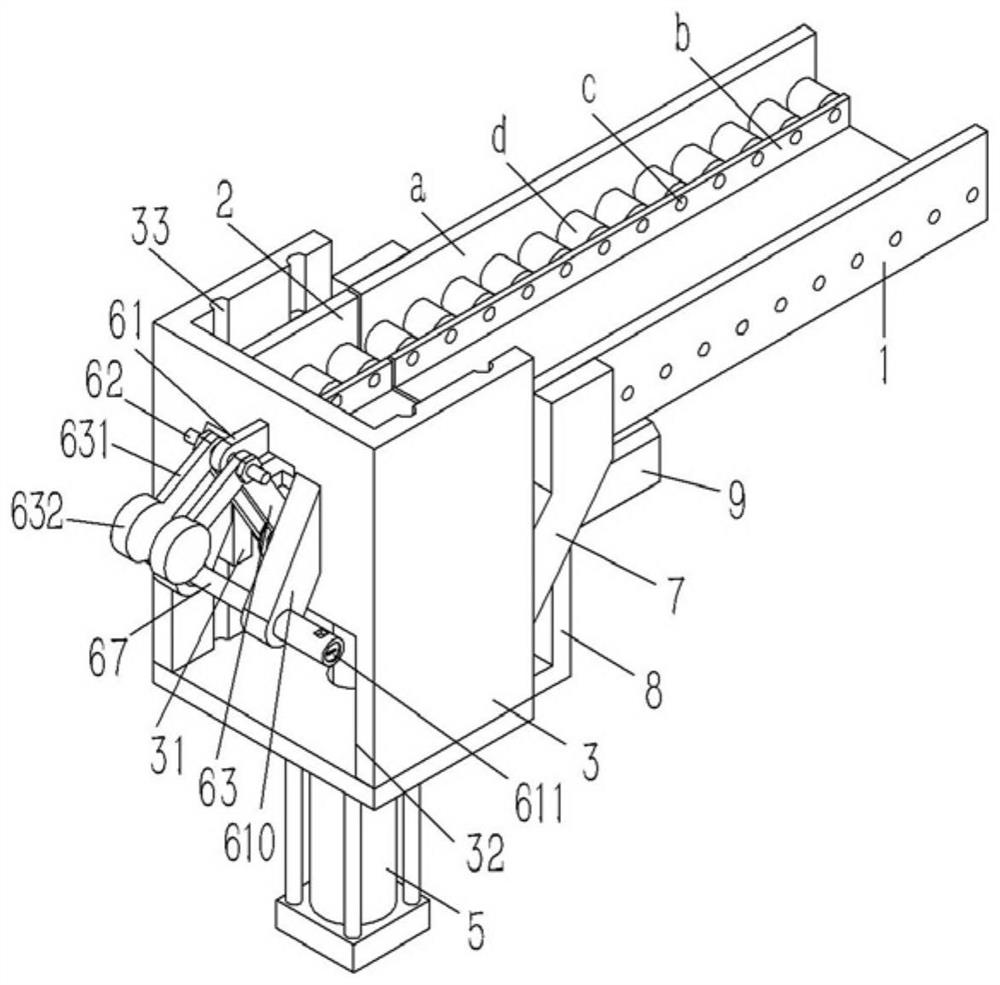

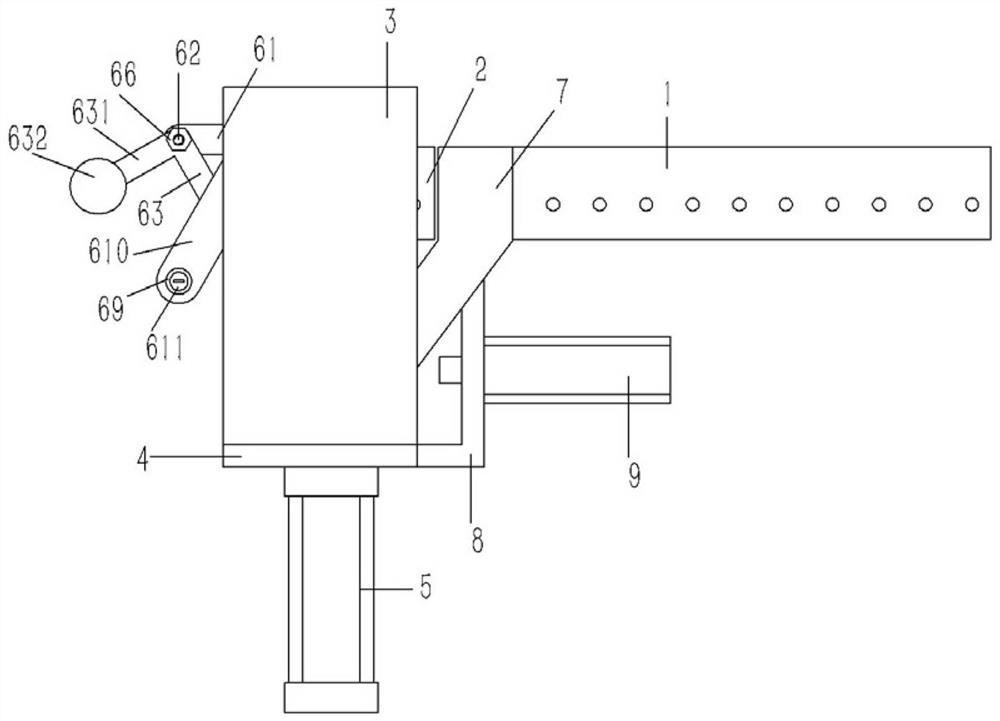

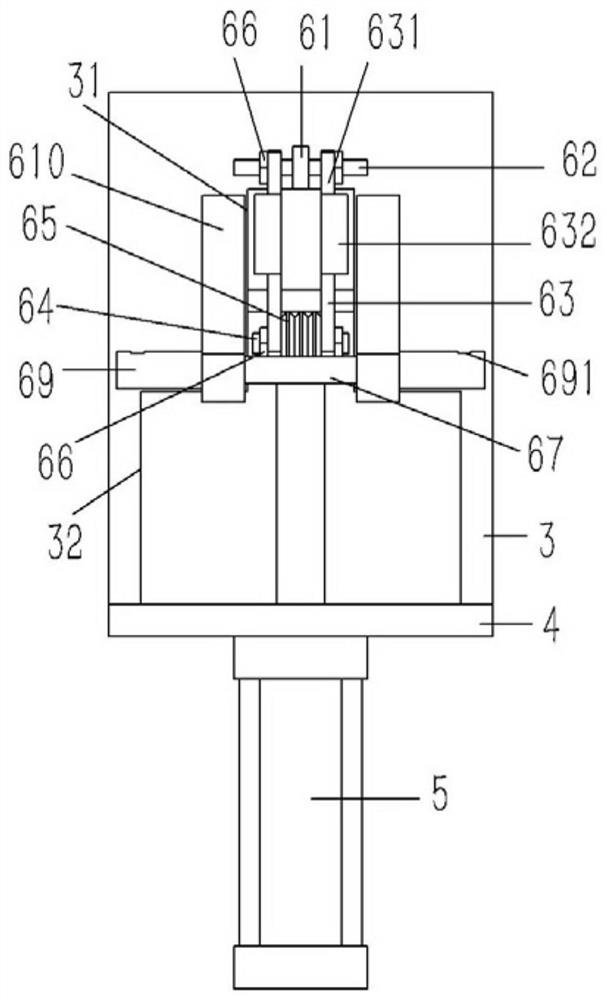

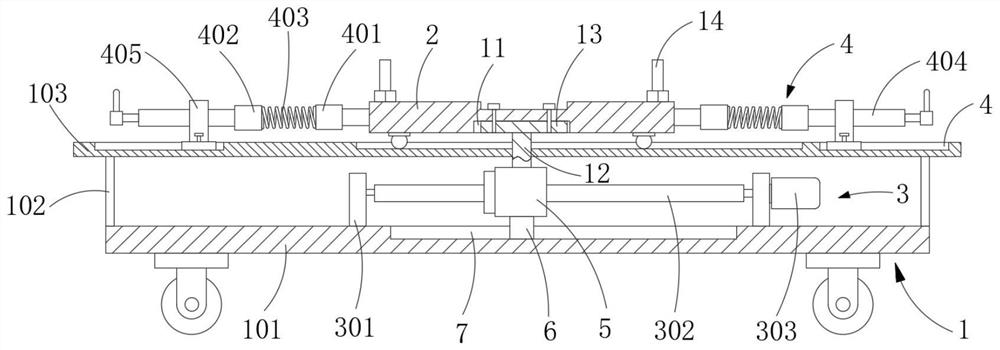

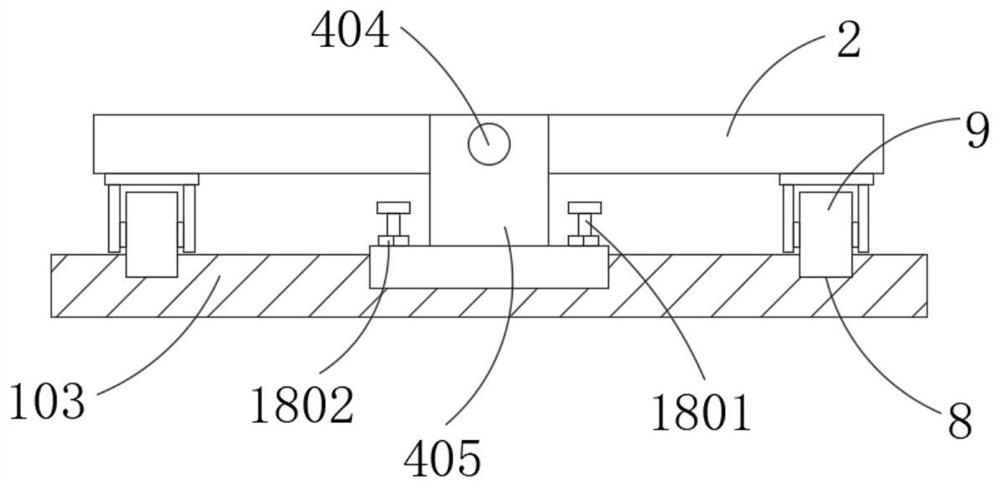

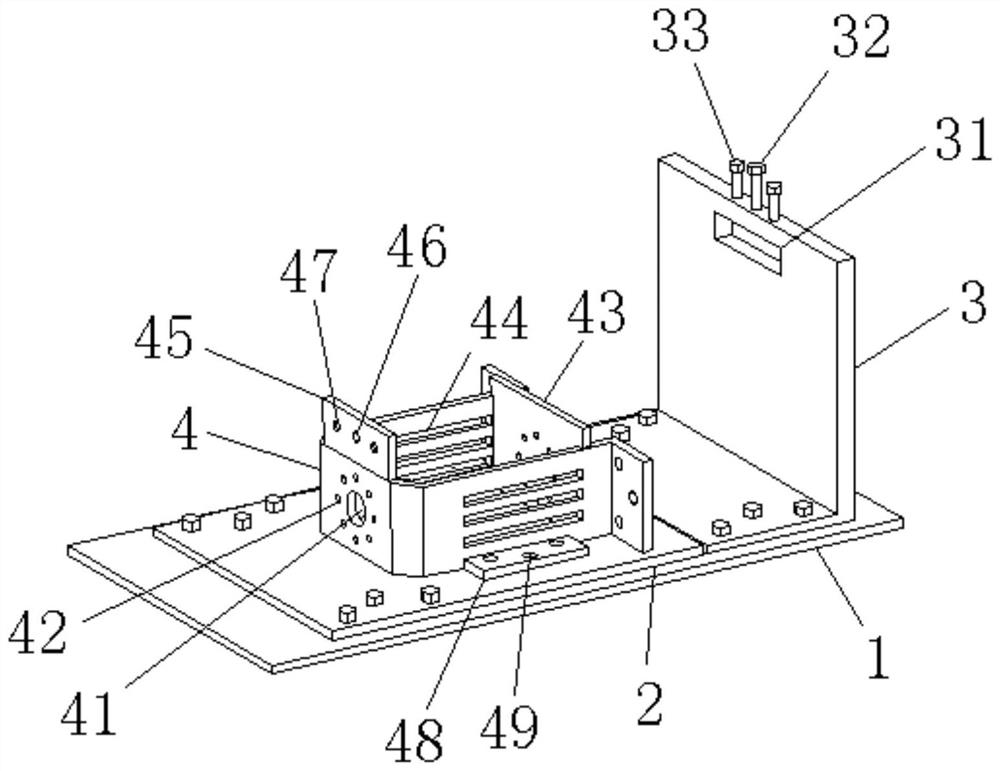

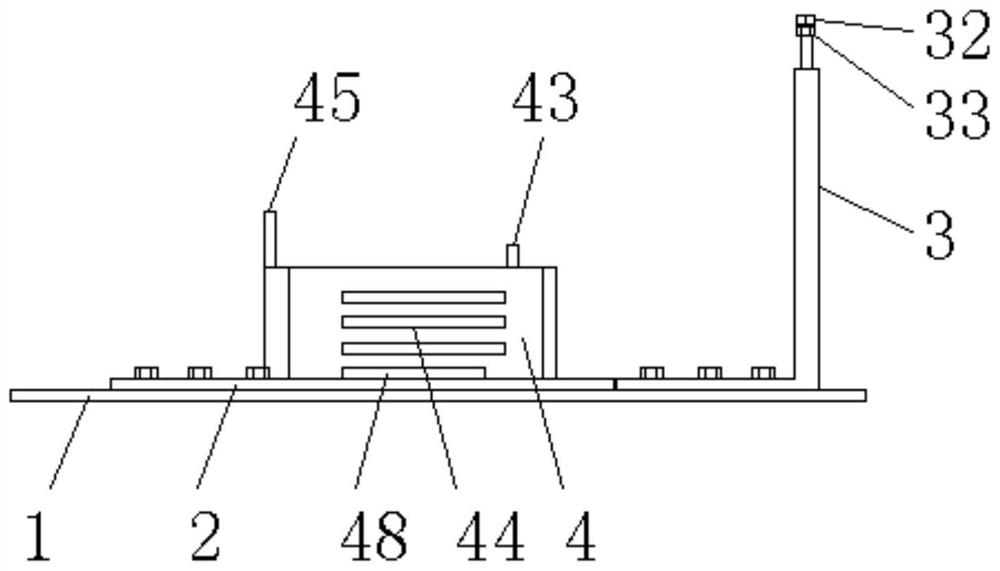

Grooving-chamfering machining process for automobile brake pad, and special grooving-chamfering combined machine

PendingCN109158840AImprove consistencyAvoid processing position deviationOther manufacturing equipments/toolsVehicle componentsElectric machineryFunction motor

The invention relates to a grooving-chamfering machining process for an automobile brake pad, and a special grooving-chamfering combined machine. The grooving-chamfering machining process and the special grooving-chamfering combined machine are capable of meeting the machining requirements of straight grooves, inclined grooves, straight-sided chamfers, inclined-sided chamfers and the like, and high in automation level and machining consistency; and a workpiece is located in one process, and chamfering and grooving machining is completed in an assembly-line manner. Specifically, the grooving-chamfering combined machine comprises a workpiece slide table, a grooving unit and a chamfering unit, wherein each unit comprises a motor seat; each motor seat comprises a support base, a Z-axis base, aY-axis middle seat and a rotary upper seat; each Z-axis base is installed on the corresponding support base in a manner of lifting up and down through a Z-axis lifting mechanism; each Y-axis middle seat is installed on the corresponding Z-axis base in a manner of translating along Y axis through a Y-axis translation mechanism; each rotary upper seat is rotatably installed on the corresponding Y-axis middle seat around a central plane through a rotation mechanism; and a function motor is installed on each rotary upper seat in a manner of translating through a motor translation mechanism, and arotation center corresponds to an output shaft of the function motor when the function motor is located at the origin of a motor translation path.

Owner:晋江市凯燕新材料研究院股份有限公司

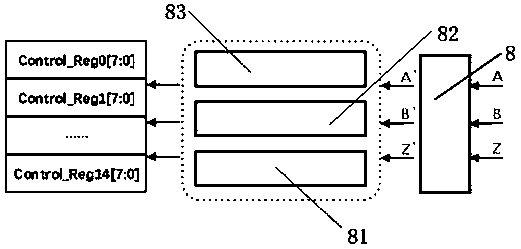

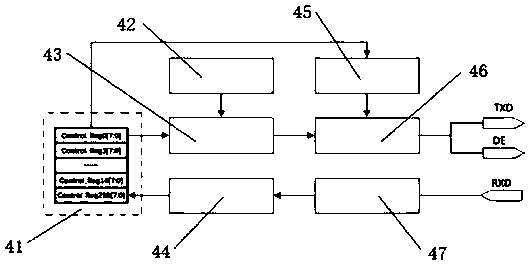

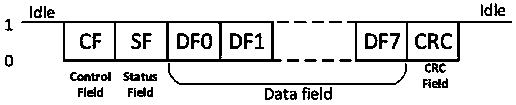

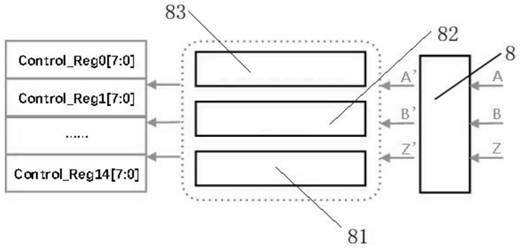

ZYNQ-based multi-axis multifunctional motor position decoding system

ActiveCN110752798AReduce the burden onImprove real-time performanceElectronic commutatorsComputer architectureElectric machinery

The invention discloses a ZYNQ-based multi-axis multifunctional motor position decoding system. The system comprises a processor system unit and a programmable logic unit which are arranged on a ZYNQchip and can carry out data interaction, wherein the processor system unit is provided with an ARM module used for realizing parameter configuration and data processing on the programmable logic unit,and the programmable logic unit is provided with a decoding module, an eight-bit parallel port module, a selector module and a man-machine interaction module; the decoding module is used for decodingvarious encoder signals input by an external motor; the eight-bit parallel port module is used for providing a corresponding interface when an external processor accesses an internal register; the selector module is used for selectively inputting motor encoder signals into the corresponding decoding modules for decoding; and the man-machine interaction module is used for realizing man-machine data interaction. According to the invention, various decoding modules are intensively arranged on the programmable logic unit for parallel decoding, so that the real-time performance and the synchronismof encoder signal decoding are effectively improved, the burden of a CPU (Central Processing Unit) is relieved to a great extent, and favorable conditions are provided for realizing a more complex algorithm.

Owner:HUNAN HYFLEX TECH

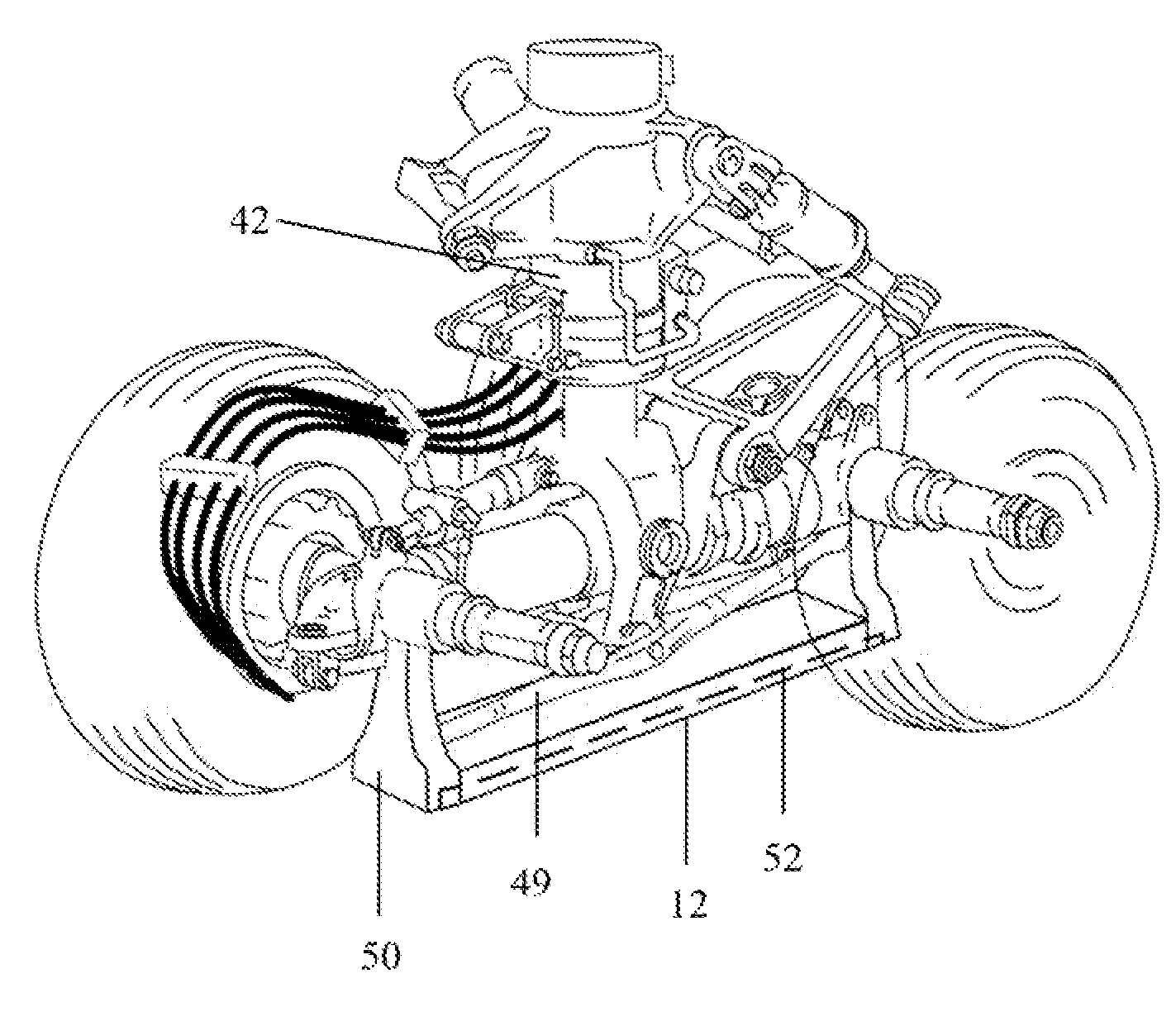

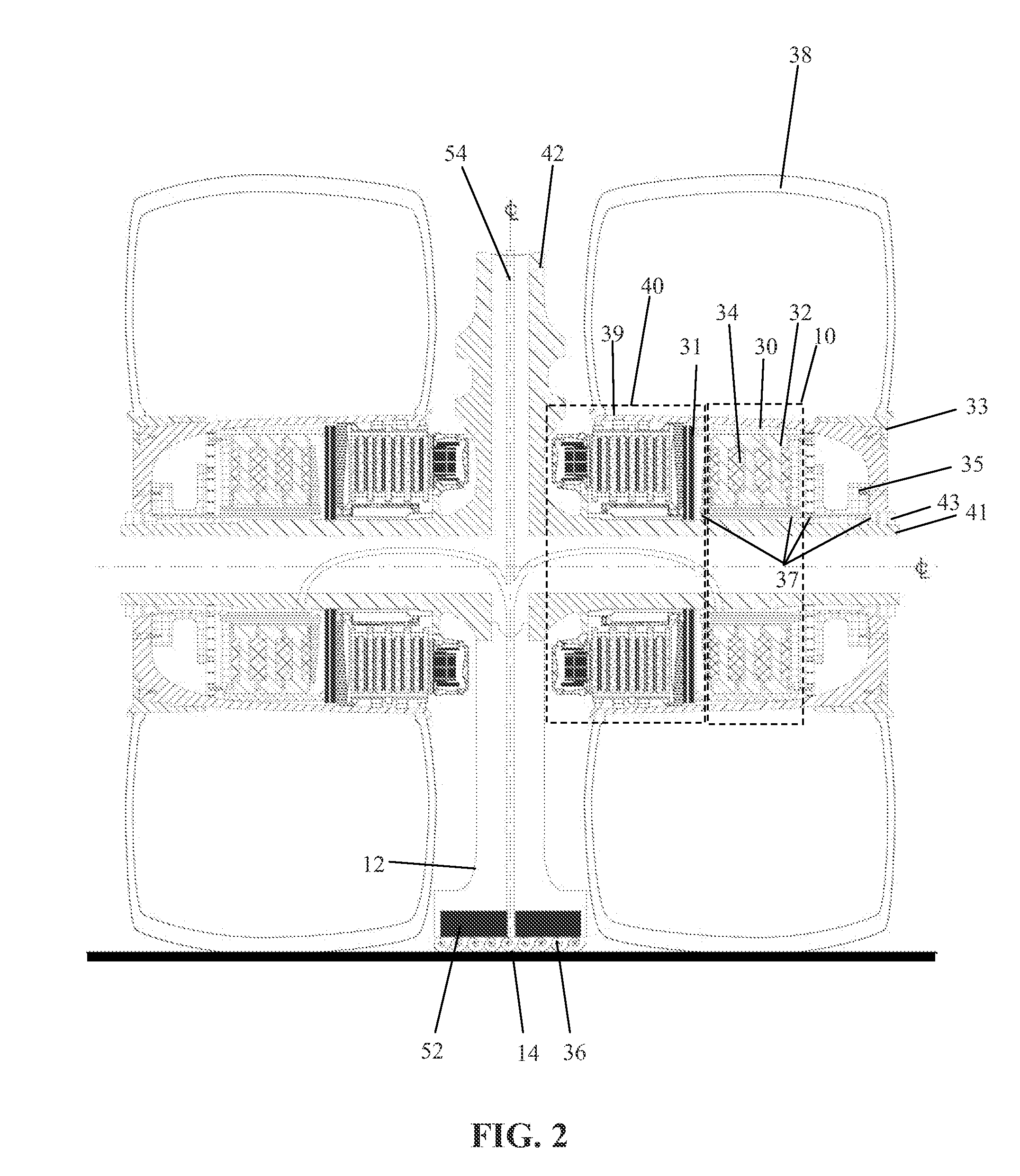

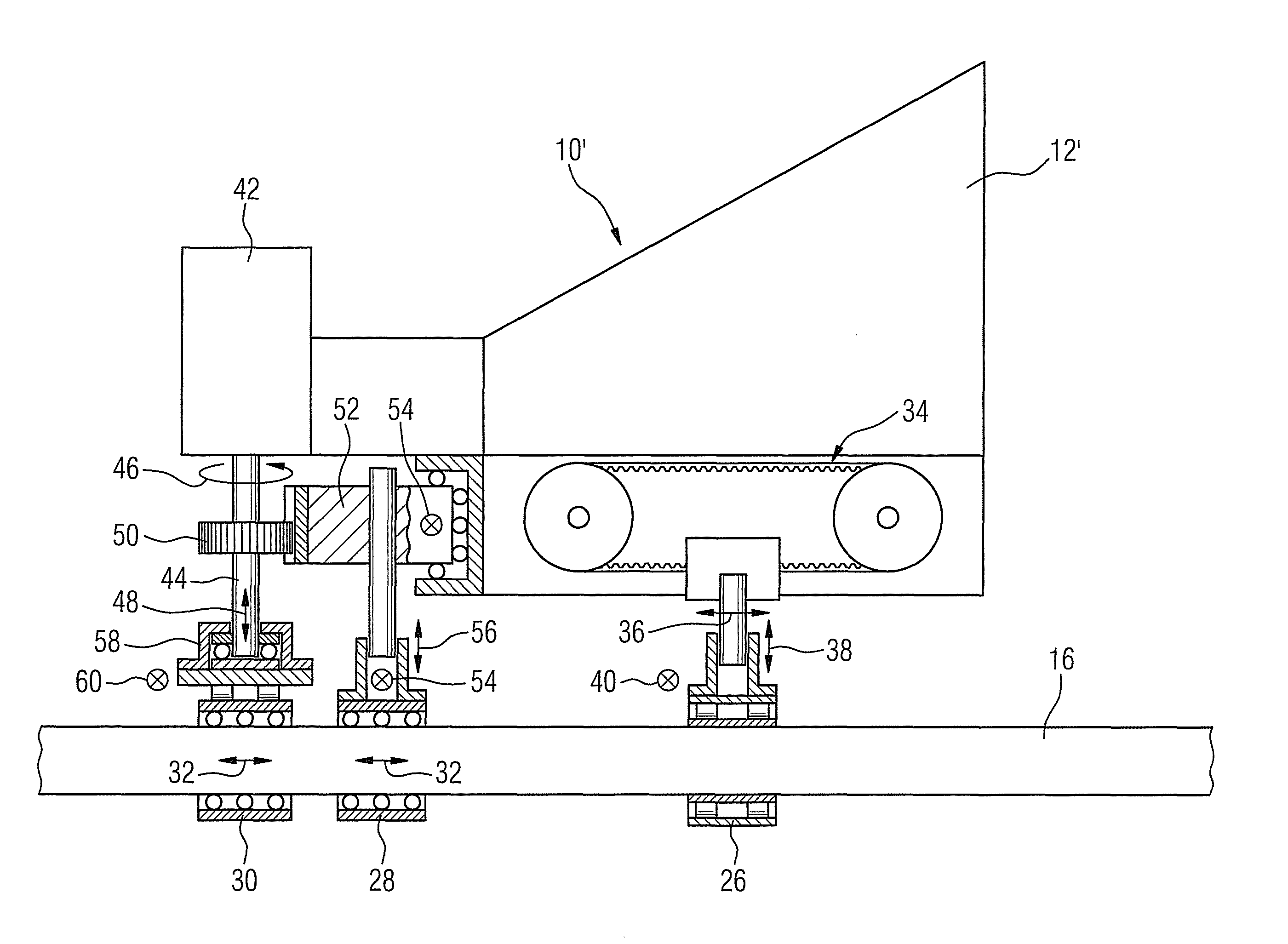

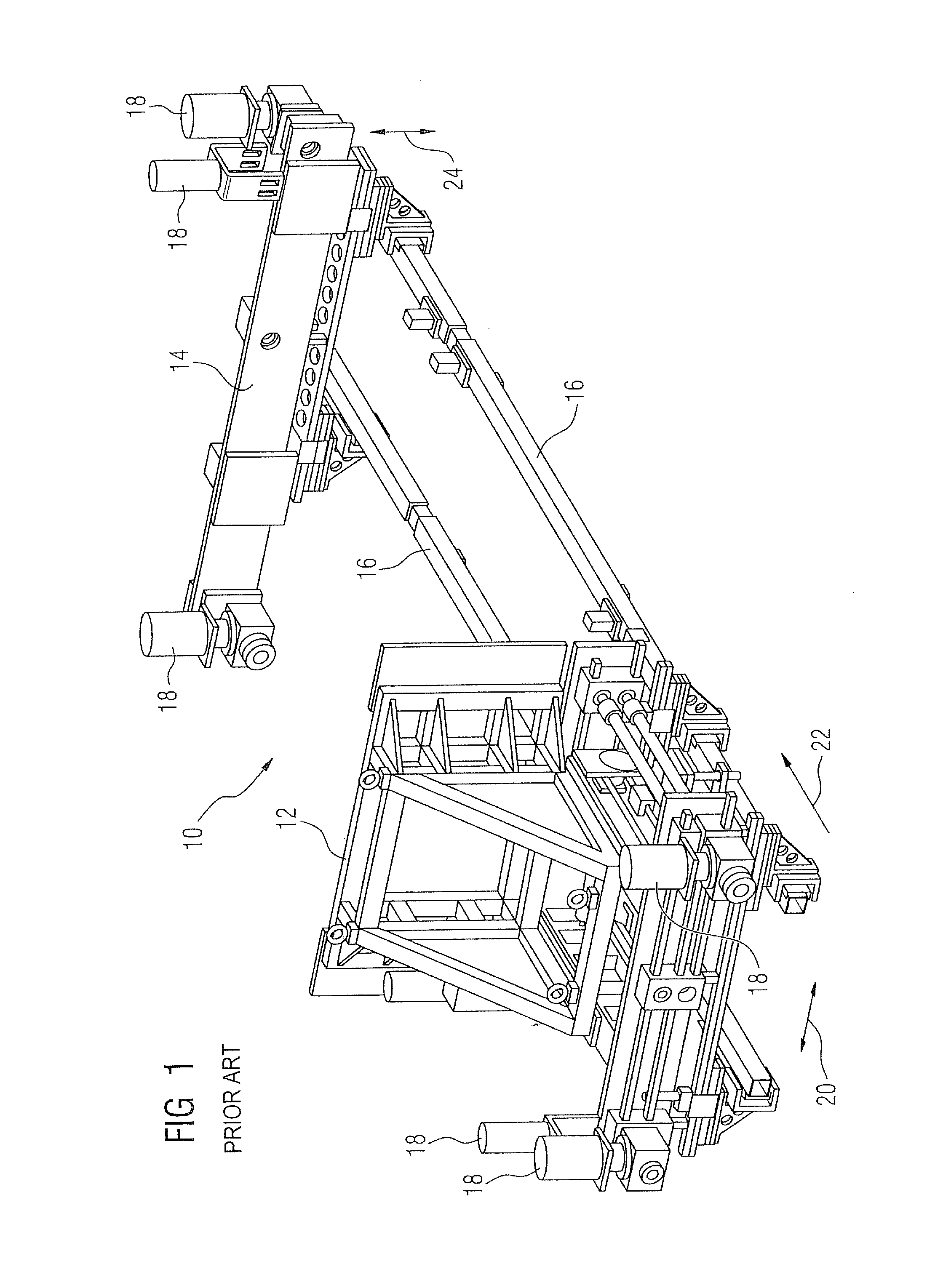

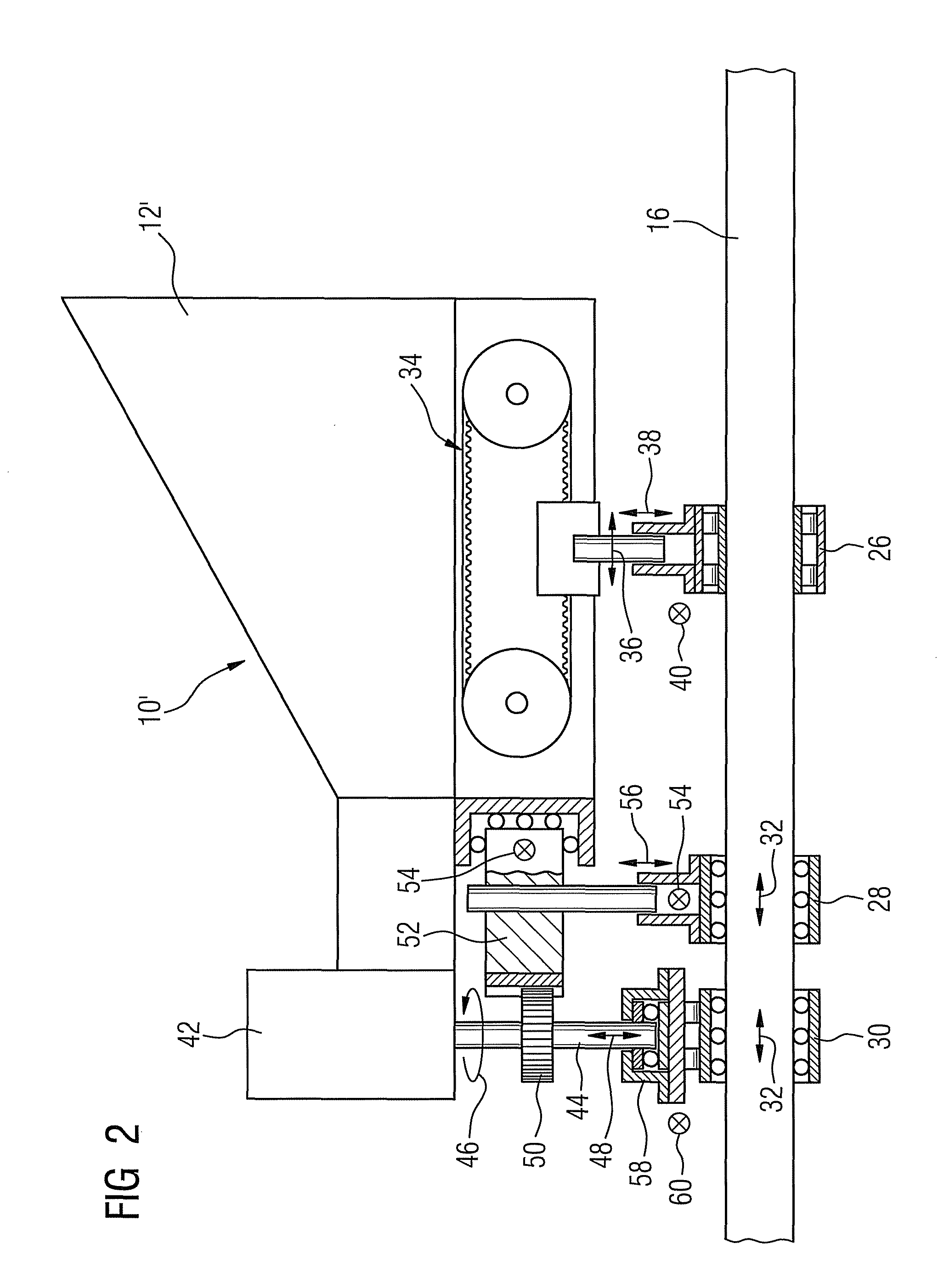

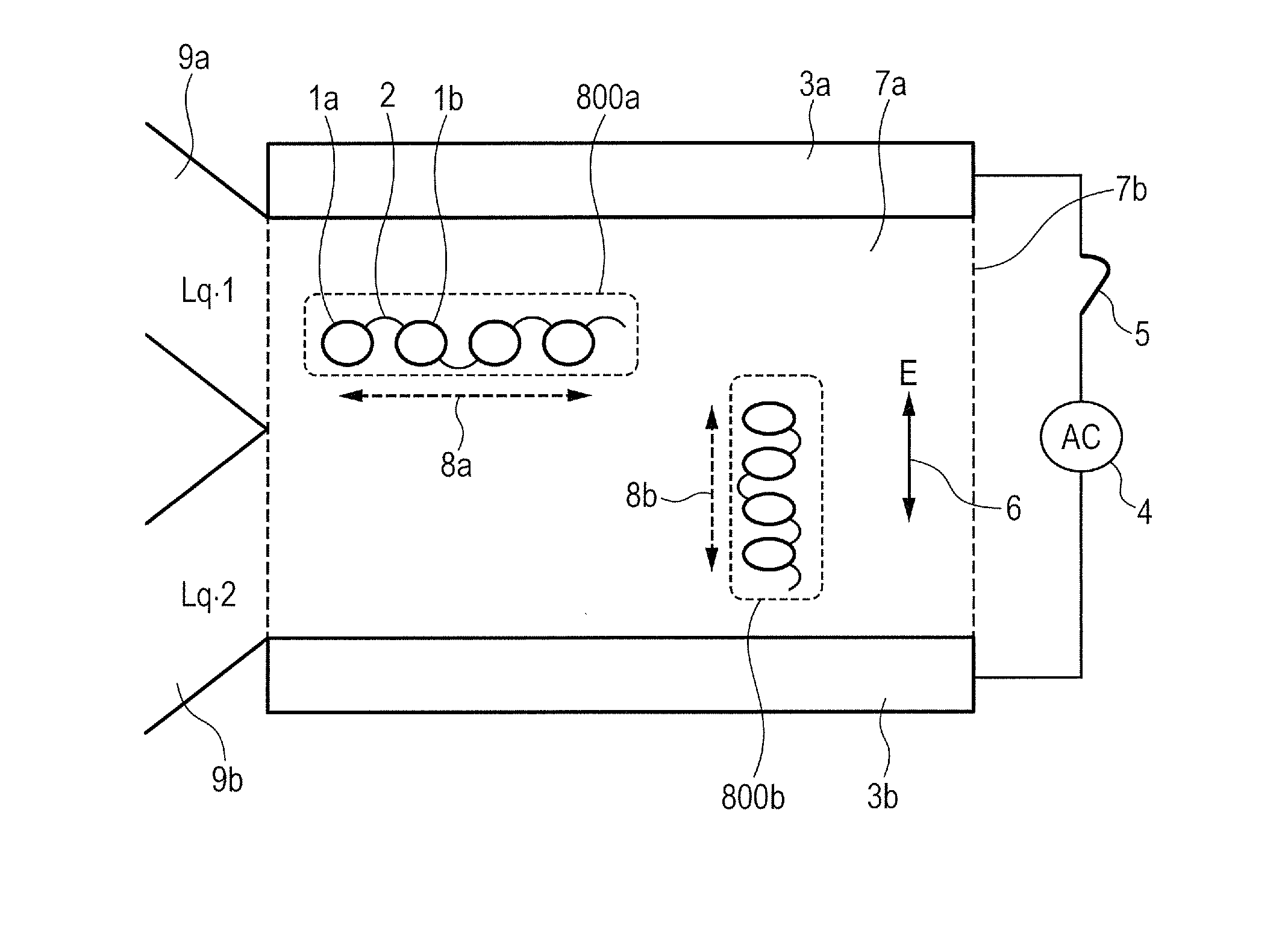

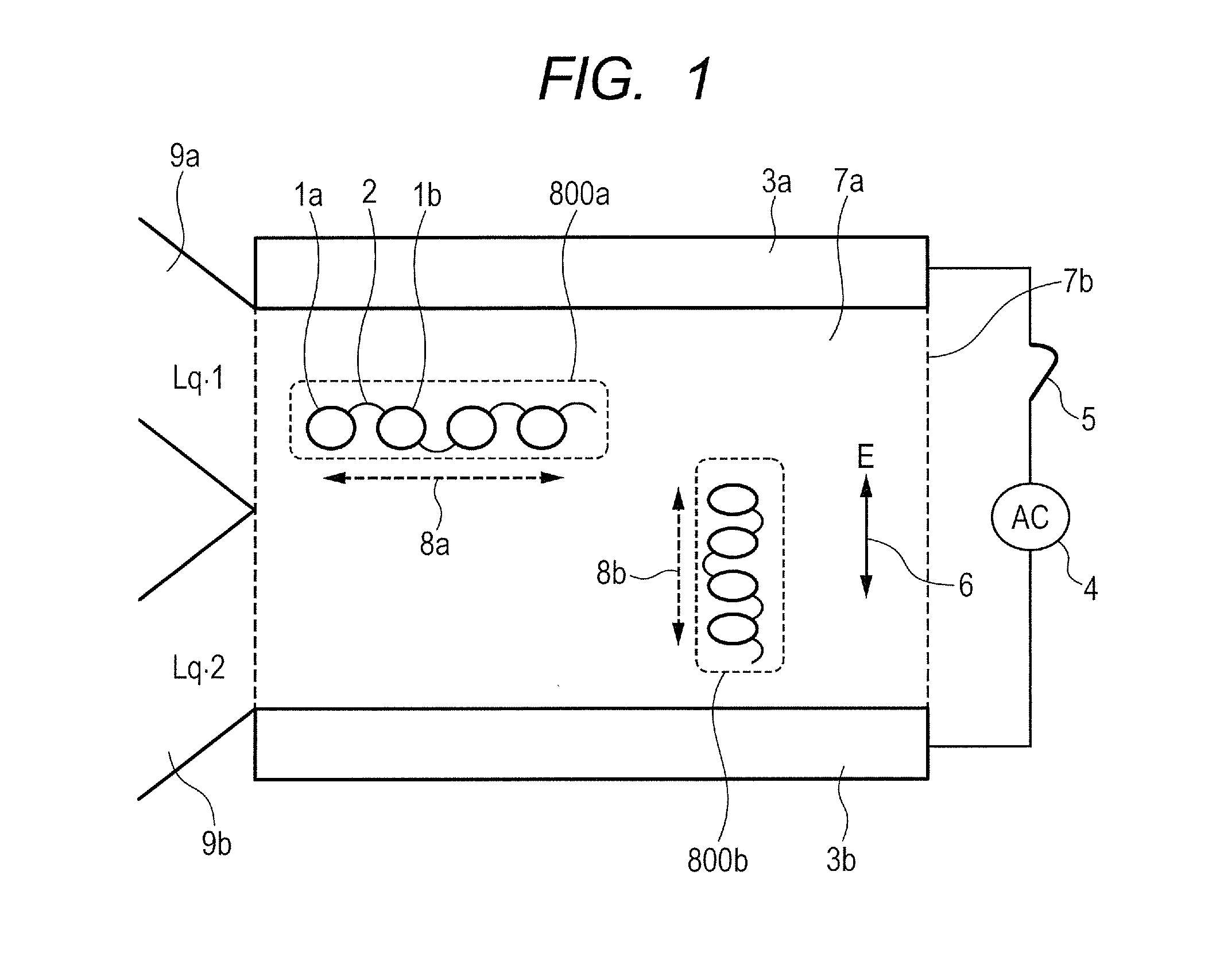

Transfer System

InactiveUS20100202866A1CompactMetal-working feeding devicesForging/hammering/pressing machinesTransfer systemFunction motor

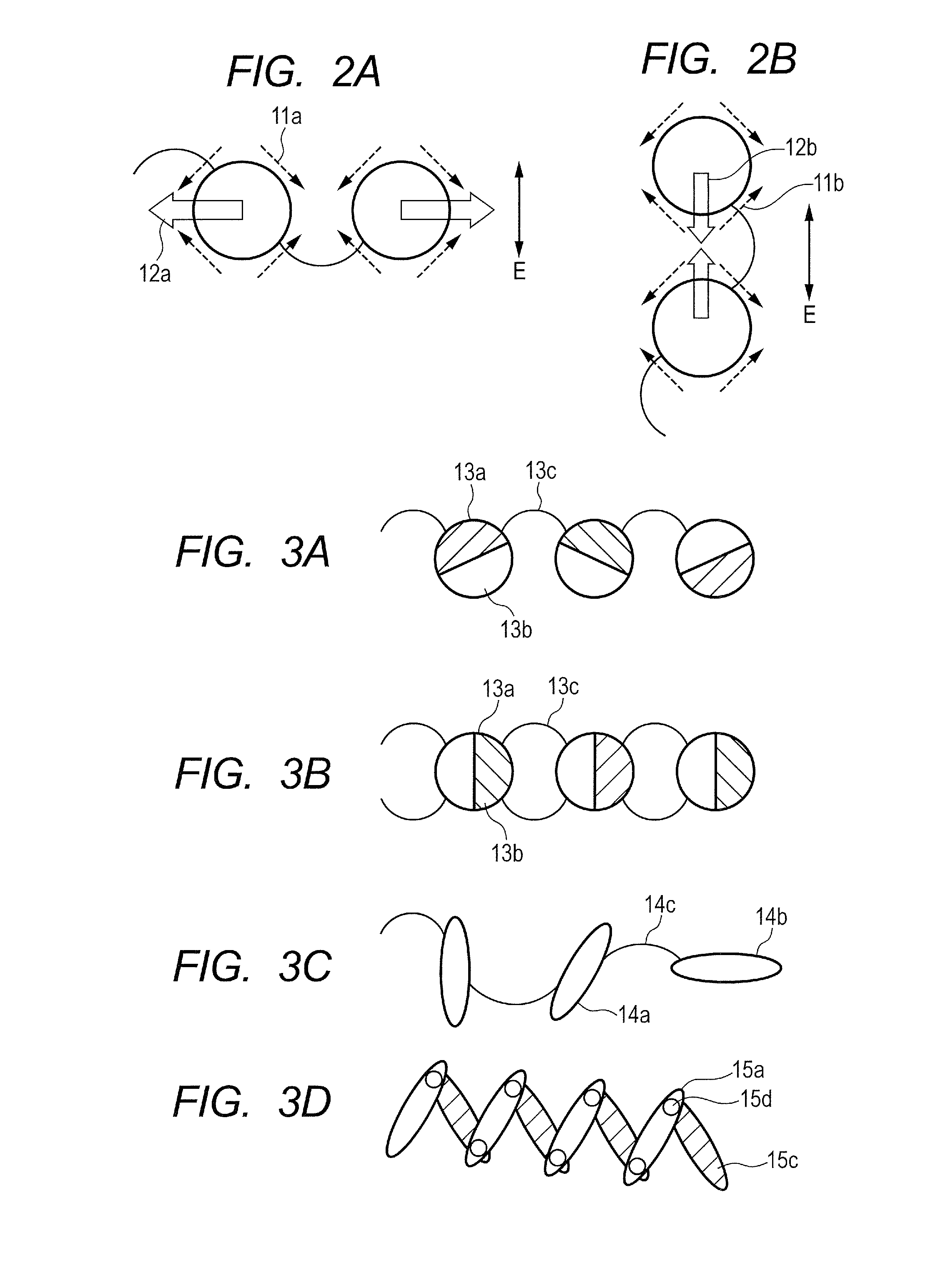

In a transfer system, transport beams are displaced in three types of motions, i.e. toward each other, along a longitudinal extension thereof for advancement, and up and down. Two of these types of motions are triggered by a double-function motor. Such a double-function motor includes a shaft, which simultaneously rotates and displaces back and forth in linear fashion along the longitudinal extension thereof.

Owner:SIEMENS AG

Efficient intelligent die cutting machine stable in performance

InactiveCN108015848AEasy to operateLow costMetal working apparatusFunction motorAgricultural engineering

The invention discloses an efficient intelligent die cutting machine stable in performance. The efficient intelligent die cutting machine comprises a supporting base, a second access box, a second adjustment valve, a second rotating shaft, a third rotating shaft, a first die cutting head, a second die cutting head, a rotator, a fixed valve and a multi-function motor. A first access box is arrangedon the upper side of the left end of the supporting base, and a first rotating shaft is installed on the inner side of the first access box. A first fine adjustment valve and a first adjustment valveare arranged on the left side of the second access box, and a working box is installed on the left side of the first adjustment valve. A working box is arranged on the right side of the second adjustment valve, and a second fine adjustment valve is installed on the lower side of the second adjustment valve. A first leveling roller is arranged on the right side of the second rotating shaft, and asecond leveling roller is installed on the right side of the first leveling roller. A fifth rotating shaft is arranged on the upper side of the multi-function motor, and an alarm monitor is installedon the upper left side of the fifth rotating shaft. The efficient intelligent die cutting machine stable in performance can be adjusted according to the operation requirements when used, operation isquicker, the overall structure is more stable, and running is smoother.

Owner:TIANJIN LIANSEN PACKAGING PROD

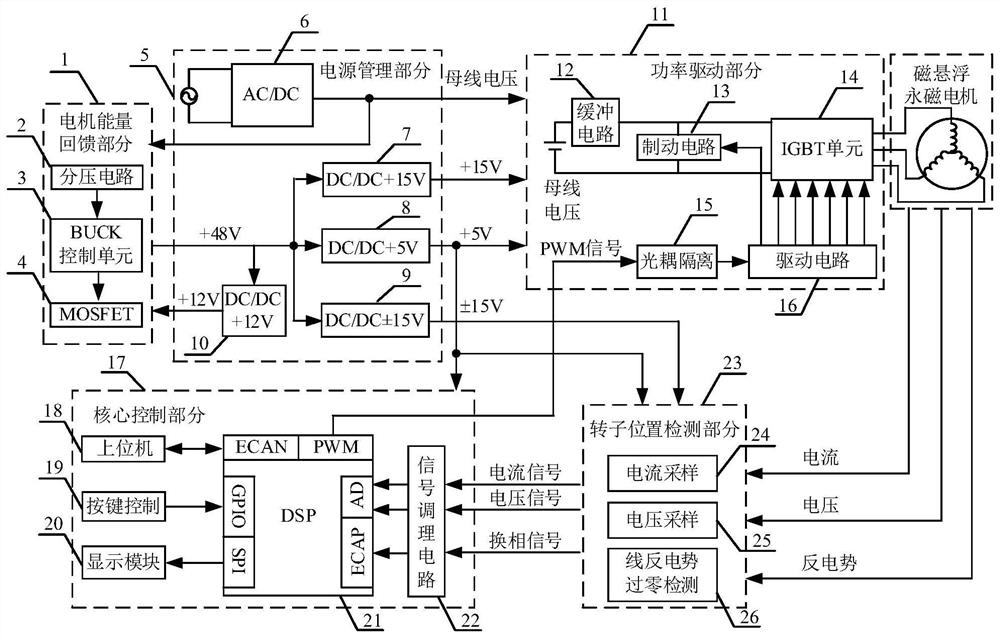

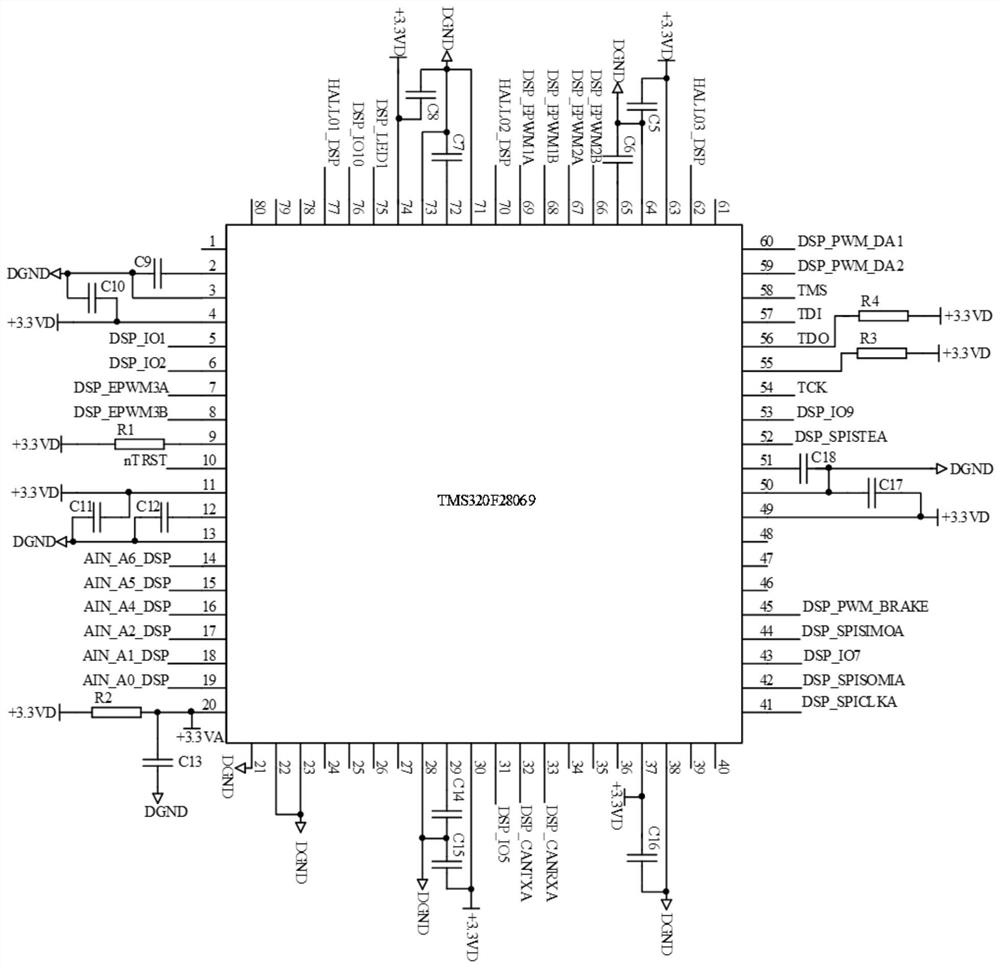

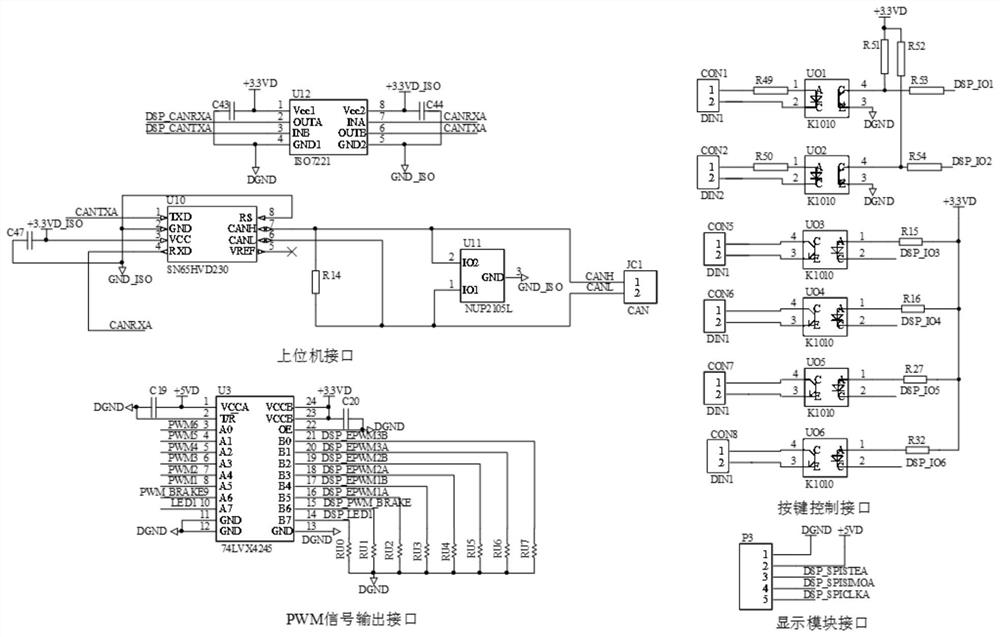

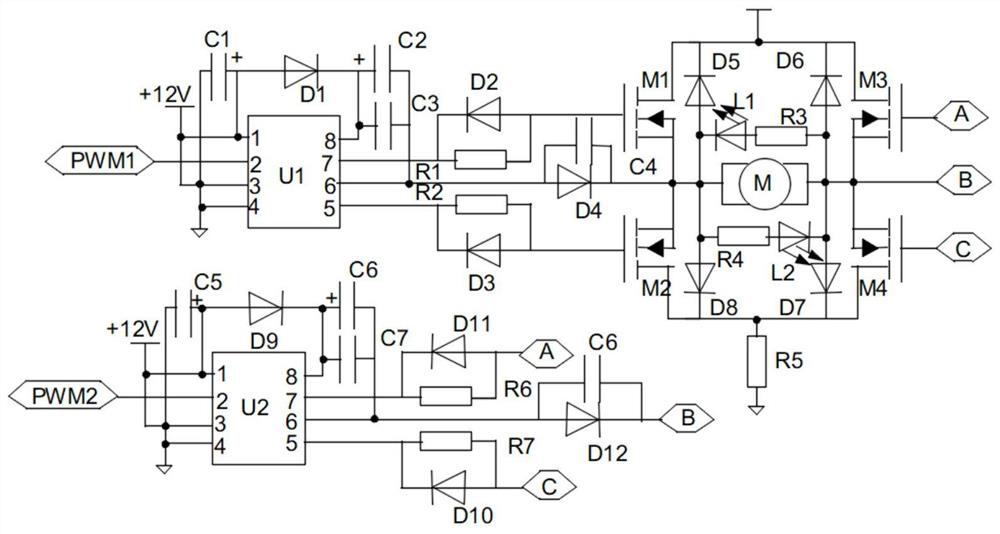

Square wave and sine wave integrated control system for magnetic suspension permanent magnet motor

ActiveCN112910363AHighly integratedReduce volumeGeneral control strategiesMotor parameters estimation/adaptationControl cellMagneto

The invention relates to a square wave and sine wave integrated control system for a magnetic suspension permanent magnet motor. The square wave and sine wave integrated control system comprises a core control part, a power driving part, a rotor position detection part, a motor energy feedback part and a power supply management part; the core control part comprises a DSP control unit, a signal input / output interface and a communication interface; the power driving part comprises an IGBT unit and a driving circuit, the rotor position detection part comprises a line counter electromotive force zero crossing point detection circuit and a voltage and current sampling circuit, the motor energy feedback part comprises a Buck control unit with wide voltage range input, and the power supply management part comprises an alternating current-to-direct current rectifier module and a direct current-to-direct current power supply isolation module. According to the invention, two functions of square wave control and sine wave control are realized in the same hardware system, the integrated design is compact in structure, and the integration level of the motor control system is improved; functions are comprehensive, and reliability can be enhanced; the system is easy to debug and flexible to implement, and effectively widens the application range of a single-function motor control system.

Owner:BEIHANG UNIV

Polarizable connection structure and device including the same

InactiveUS20150034486A1Sludge treatmentPiezoelectric/electrostriction/magnetostriction machinesFunction motorEngineering

Provided is a device capable of functionalizing a micro-motion of a polarizable microstructure. A structure includes a plurality of polarizable structures, each having an electrically polarizable conductive part on a surface thereof, and a connector body having one of mobility and deformability, for connecting the plurality of polarizable structures to each other.

Owner:CANON KK

FLEX-NC control system

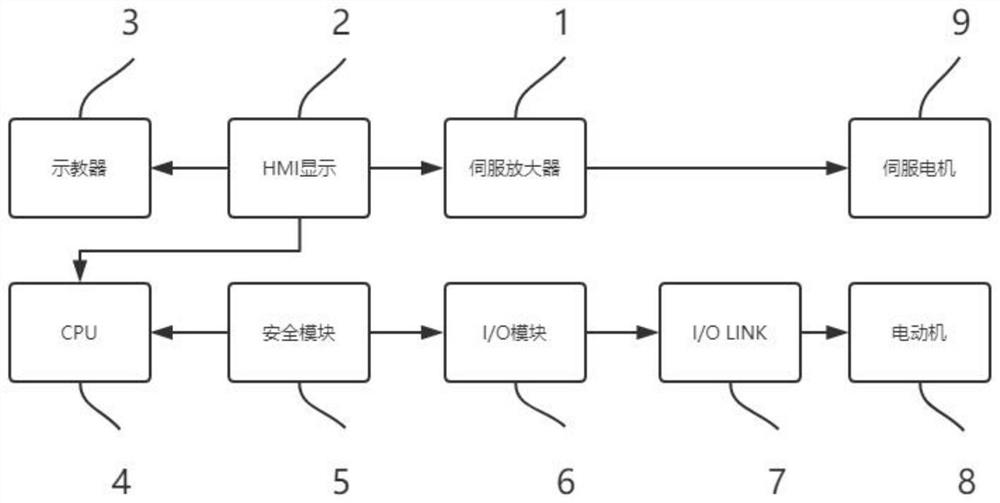

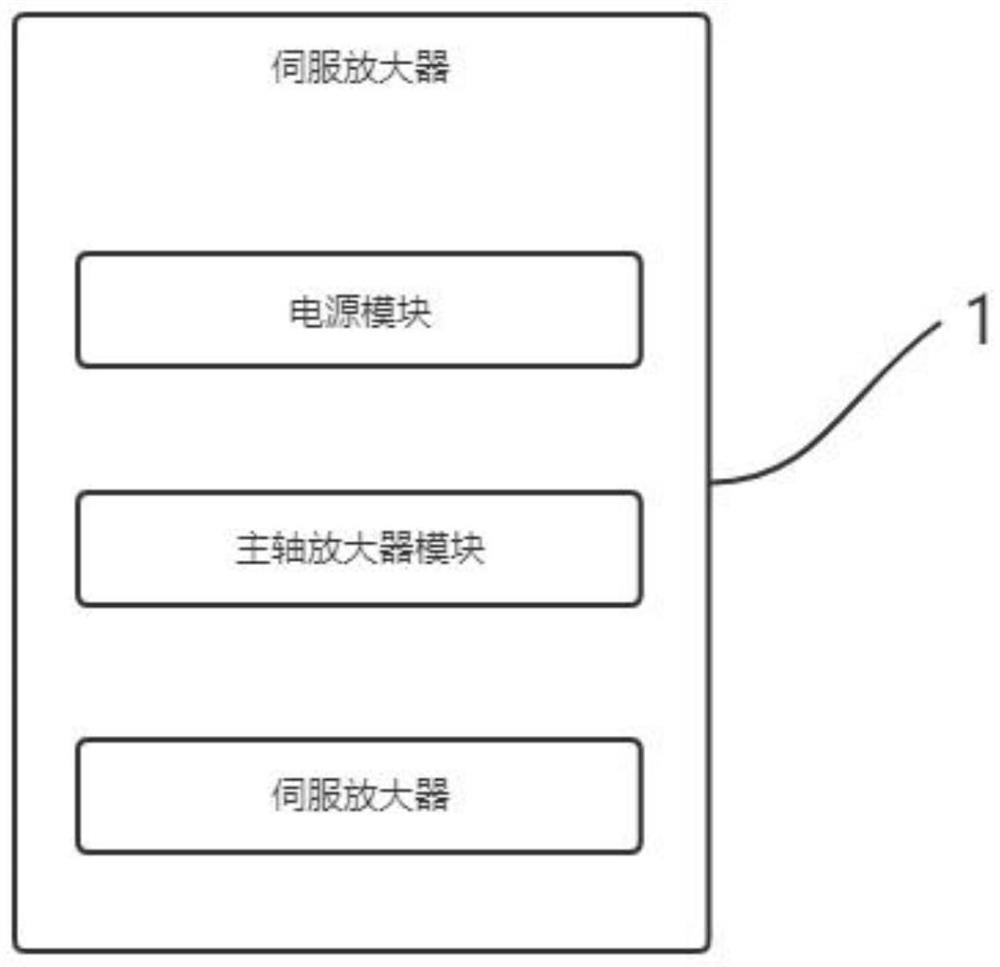

PendingCN113485253ARealize the whole process controlNot lostNumerical controlHuman–machine interfaceNetwork communication

Owner:吉林省百浪汽车装备技术有限公司

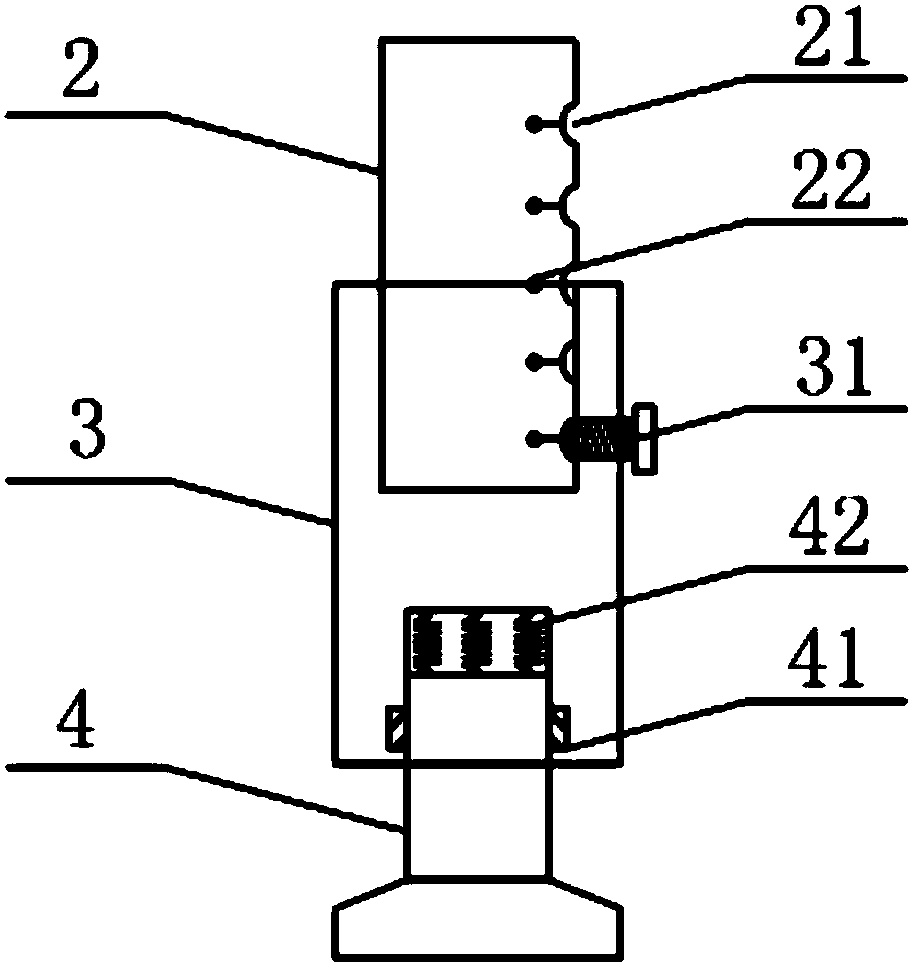

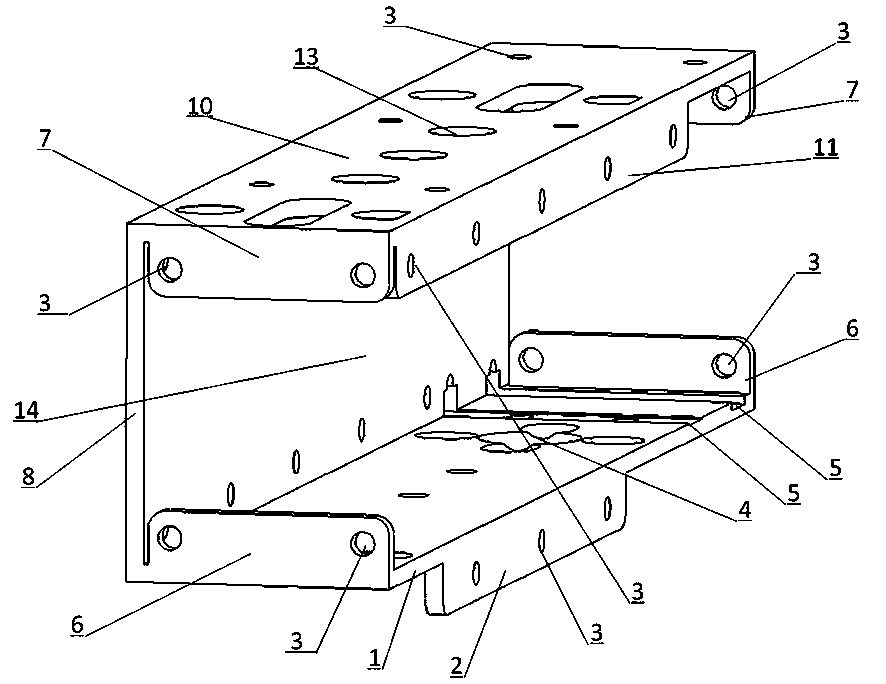

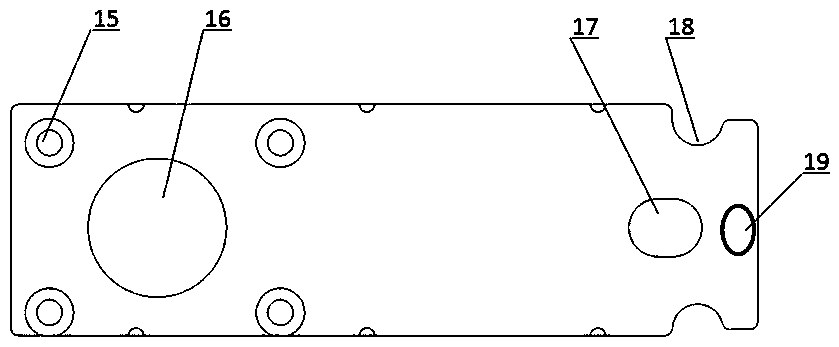

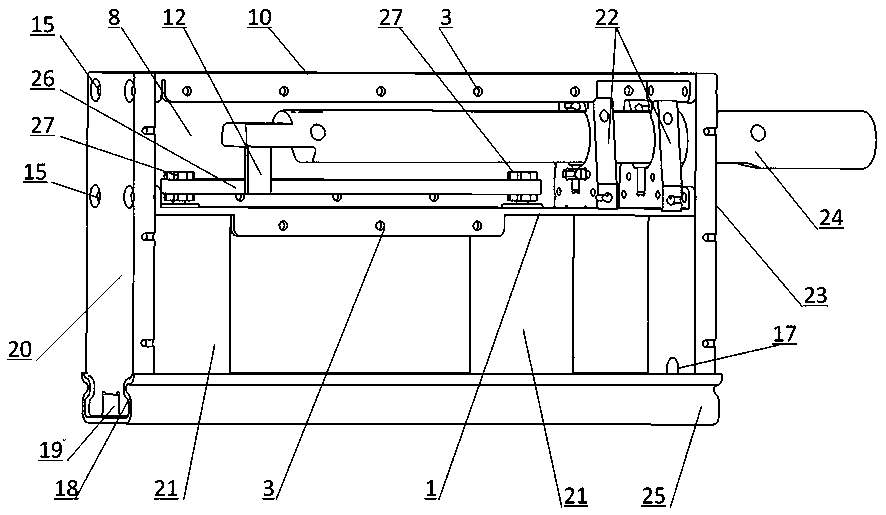

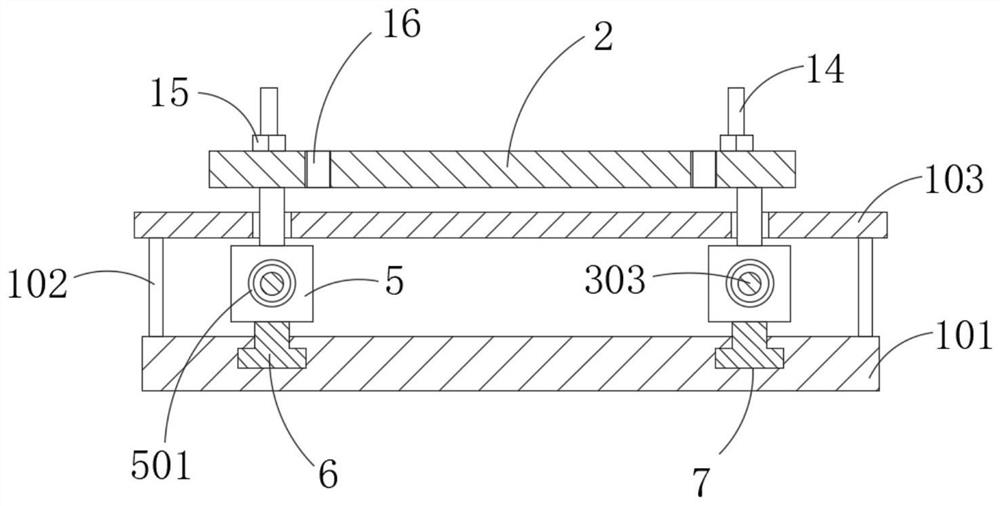

Multifunctional motor support

The present invention provides a multifunctional motor support. The multifunctional motor support comprises: a bottom shell, wherein the edge of the end face of the bottom shell is folded, the edges of the end faces of a middle shell, a top shell and a top shell are folded, the edge of the side of the top shell is folded; and an inner cavity; a motor is arranged on the outer surface of the bottomshell; a slideway is arranged on the inner surface of the bottom shell, the bottom shell side surface folded edge and the top shell side surface folded edge are used for placing a circuit board and astructural member, the bottom shell end surface folded edge and the top shell end surface folded edge are used for placing a baffle plate, and the inner cavity of the support is used for accommodatingthe slideway, a sliding rod, a transmission belt and a transmission mechanism; the inner cavity is formed by sequentially surrounding four sides of the bottom shell, the middle shell, the top shell and the top shell side folded edge, a gap is reserved between the top shell side folded edge and the bottom shell, the gap is used for placing the circuit board and a structural member, and when the circuit board is not needed, only the structural member is placed in the gap.

Owner:马丽娟

Motor stator marking device with tracing function

The invention discloses a motor stator marking device with a tracing function, and the device comprises a horizontal discharge grooved rail and a lifting grooved rail at one end of the discharge grooved rail, the lifting grooved rail is inserted into a [-shaped frame, a bottom plate is fixed on the lower end surface of the frame, and a vertical lifting air cylinder is fixed on the bottom plate; a piston rod of the lifting air cylinder penetrates through the bottom plate and is fixed on the lifting grooved rail; a marking mechanism is arranged on the side, deviating from the discharge grooved rail, of the frame, an inserting groove opposite to a marking mechanism is formed in the frame, a discharging port communicated with the inserting groove is formed in the lower end of the frame, a pushing air cylinder opposite to the discharging port is arranged below the discharge grooved rail, the pushing air cylinder is fixed to an air cylinder support, and the air cylinder support is fixed to the bottom plate.

Owner:咸宁恒舟信息科技有限公司

New energy pure electric vehicle driving motor

ActiveCN112531950AExtended service lifeWith shock absorption functionElectric machinesSupports/enclosures/casingsNew energyAir spring

Owner:重庆市小电天体新能源汽车有限公司

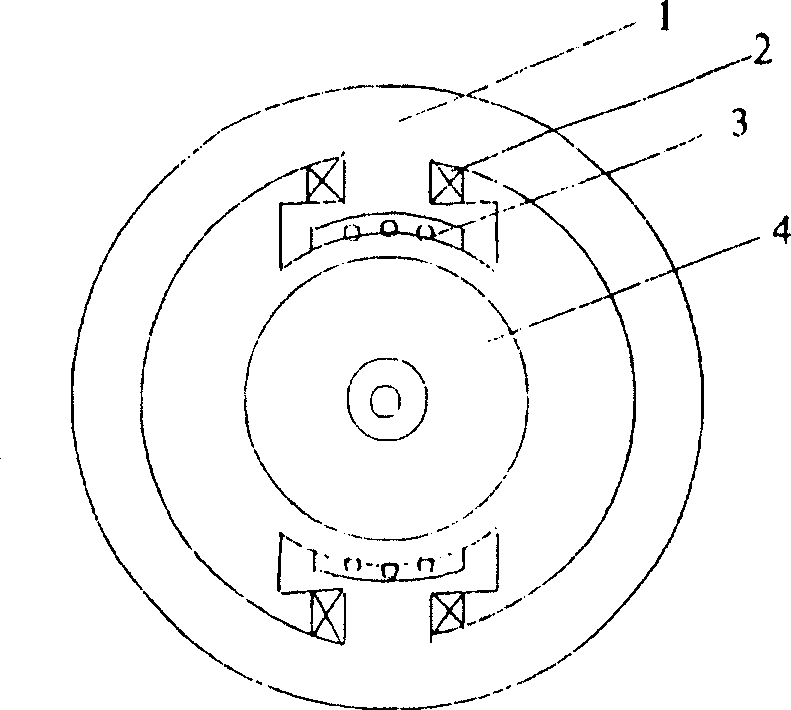

Multi-function motor

InactiveCN101154830ASimple structureSimple speed regulationMagnetic circuit rotating partsMagnetic circuit stationary partsSoft magnetFunction motor

A multifunctional motor comprises a stator and a rotor, wherein, the rotor is made of soft magnet, and the stator is made of soft magnet or permanent magnet, a coil is also included, a stator generates an exciting magnetic field to cause the rotor to be magnetized, and a magnetic field is generated, then the rotor actually becomes a magnet with two poles, after the coil in the stator is electrified, the stator and the rotor are provided with an interaction with electromagnetic force, as the coil is fixed, the rotor has to rotate, and as core bodies of the rotor are continuous, the rotor keeps on rotating. The invention has the advantages of simple structure, complete symmetry, reverse direction, easy speed regulation and high torque, moreover, a magnetic circuit of the stator is made of soft magnet, alternating current or direct current can be simultaneously used, if the rotor is driven to rotate by an external force, a generator is provided.

Owner:TIANJIN DEXIN ELECTRIC MACHINERY

A Zynq-based multi-axis multifunctional motor position decoding system

ActiveCN110752798BReduce the burden onImprove real-time performanceElectronic commutatorsComputer architectureEngineering

Owner:HUNAN HYFLEX TECH

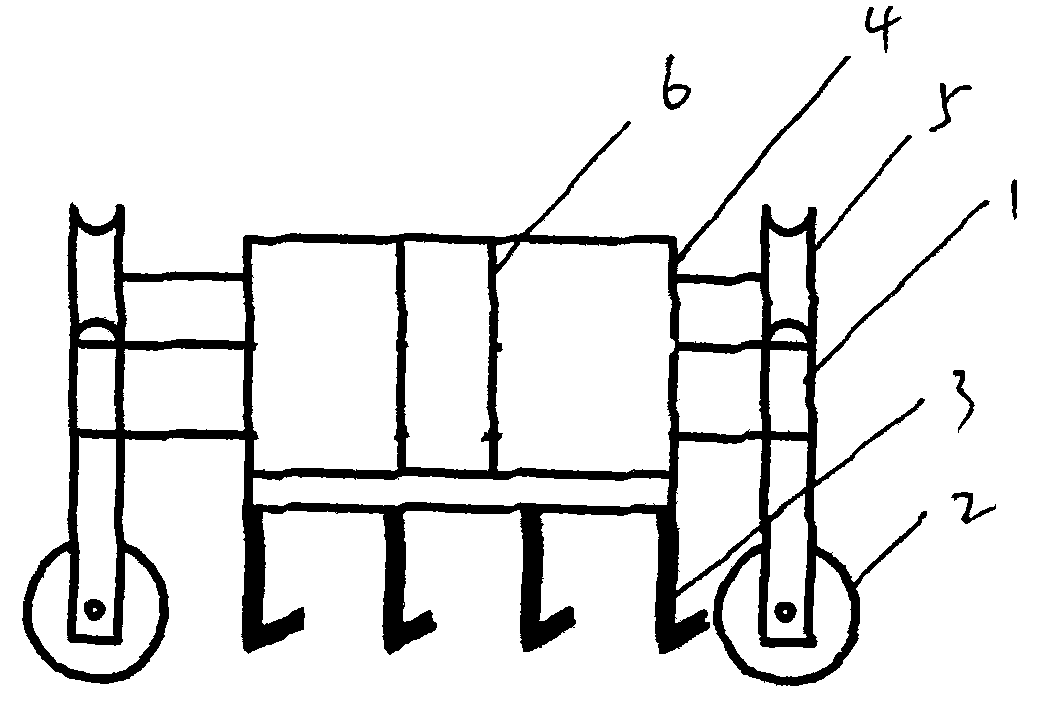

Full-function motor-driven tiller

InactiveCN101849449ASimple structureLow costAgricultural machinesPloughsFunction motorAgricultural engineering

The invention provides a full-function motor-driven tiller comprising a rack. Two sides of the rack are provided with travelling wheels, and the middle of the rack is provided with two moving furrow plough devices; each moving furrow plough device comprises a plowshare, a hydraulic lifter and electric wheels arranged on chutes at the front side and the rear side of the rack, wherein the plowshare is connected with a lifting shaft in the hydraulic lifter which is connected with the electronic wheels at the front side and the rear side of the rack; and two plowshares on two moving furrow plough devices have opposite direction. The invention has the characteristics of simple structure, low construction cost, high ploughing speed, favourable ploughing effect and the like.

Owner:吴小云

Motor base with functions of sound insulation, convenient fixation and tensioning of driving chain

PendingCN114465408AConvenience guaranteedGuaranteed accuracySupports/enclosures/casingsClassical mechanicsElectric machinery

The invention discloses a motor base with a soundproof and convenient-to-fix driving chain tensioning function, which comprises a movable bottom support and a motor mounting plate, the movable bottom support comprises a bottom plate and a stand column, the stand column is fixedly mounted on the upper surface of the bottom plate, a supporting plate is fixedly mounted at the top end of the stand column, and the motor mounting plate is slidably mounted on the upper surface of the supporting plate. A driving assembly is arranged between the movable bottom support and the motor mounting plate, the motor mounting plate and the driving assembly are detachably and fixedly connected, an elastic adjusting assembly and a rotary adjusting rod are arranged on one side of the motor mounting plate, and due to the fact that the adjusting rod is in threaded connection with the interior of an adjusting base, the rotary adjusting rod drives a second connecting block to move; the distance between the first connecting block and the second connecting block is changed, so that the two-way tensioning effect on the installed motor and the motor installation plate is achieved, on one hand, it is guaranteed that after the motor is installed above the motor installation plate, certain friction force is kept, and therefore convenience and accuracy during adjustment of the motor base are guaranteed.

Owner:上海杰堂环保科技有限公司

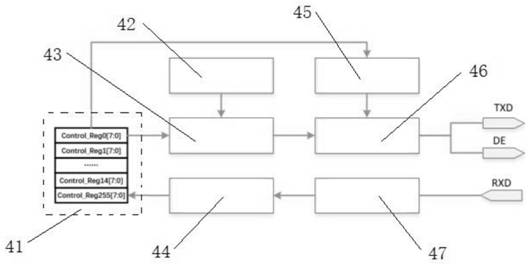

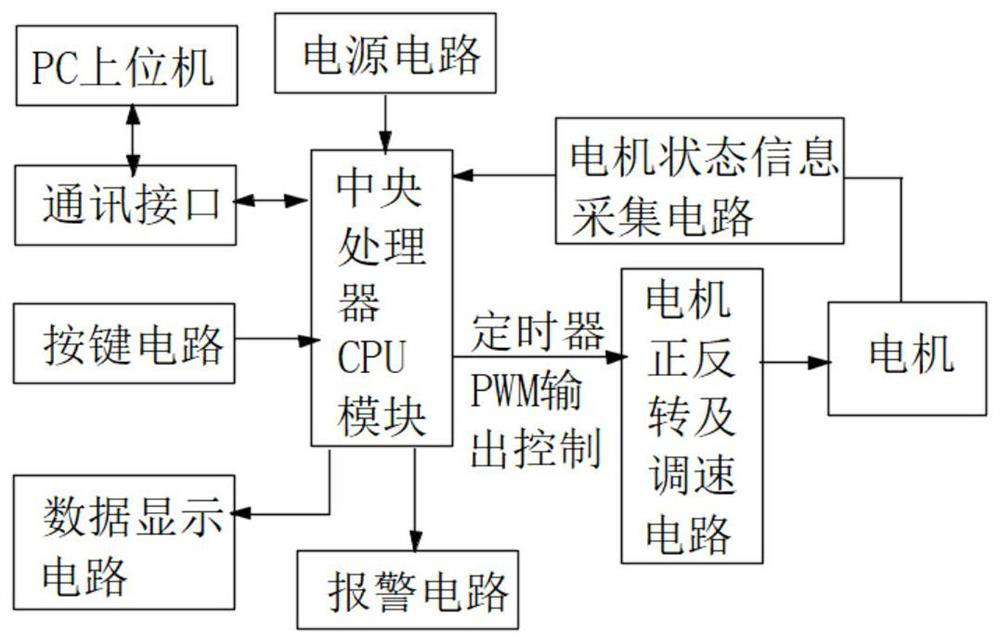

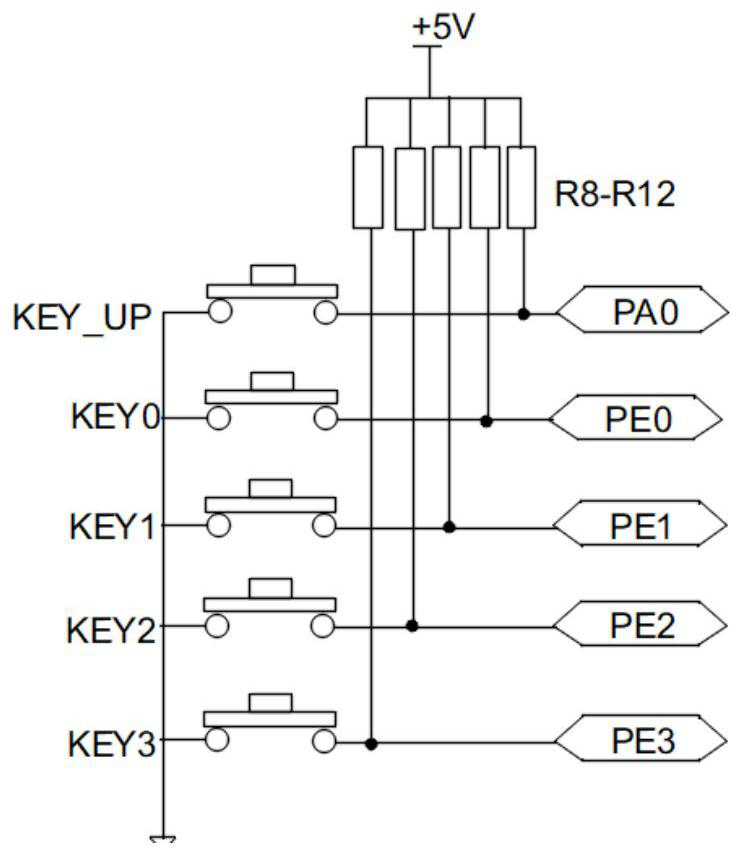

Multifunctional motor controller

InactiveCN113162492AMultifunctional motor control implementationAdjustable speedDC motor rotation controlData displayMicrocontroller

The invention discloses a multifunctional motor controller, which comprises a PC (Personal Computer) upper computer, a communication interface, a key circuit, a power supply circuit, a central processing unit (CPU) module, a data display circuit, an alarm circuit, a motor positive and negative rotation and speed regulation circuit, a motor and a motor state information acquisition circuit. The PC upper computer carries out instruction sending and information receiving on the CPU through the communication interface. The key circuit is used for function selection, the CPU module is used for controlling the operation of the whole circuit, the data display circuit is used for displaying the rotating speed of the motor, the alarm circuit is used for alarming, the motor positive and negative rotation and speed regulation circuit is used for controlling the operation of different functions of the motor, and the motor state information acquisition circuit is used for protecting the motor. According to the multifunctional motor controller, positive and negative rotation control is conducted on the motor through the microcontroller, the rotating speed of the motor can be adjusted, the multifunctional control over the motor is achieved, the high-precision control over the motor is achieved through the motor driver, and the motor is protected through the real-time information collection of the motor.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

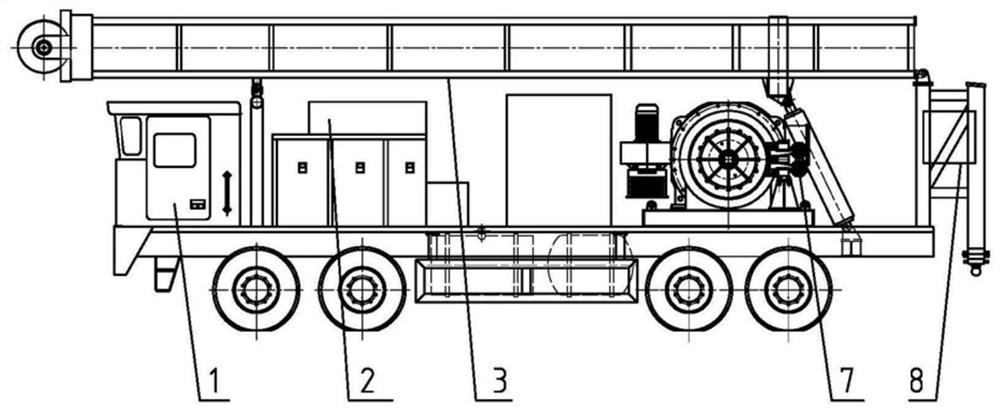

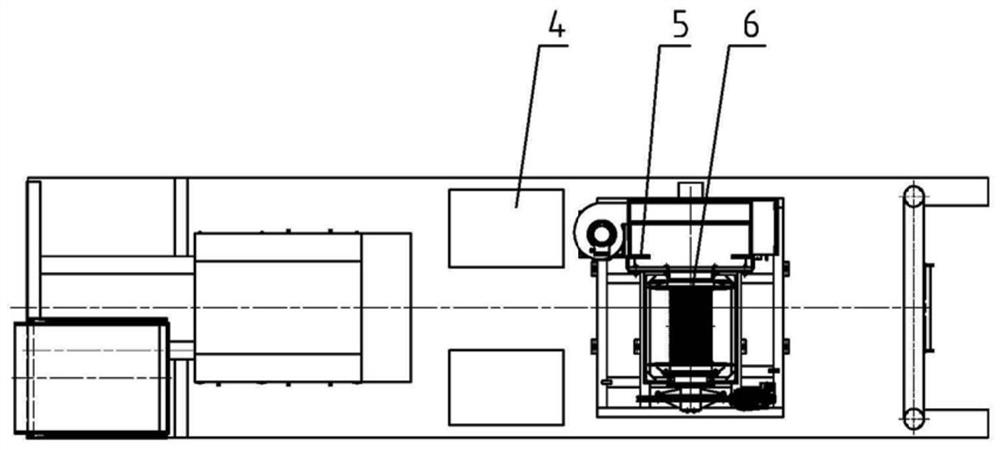

Direct-driven electric workover rig

PendingCN111622687ACompact structureSimple structureDrilling rodsDrilling casingsElectric machineFrequency conversion

The invention provides a direct-driven electric workover rig. In the technical scheme, the direct-driven electric workover rig adopts the transmission mode that an AC variable frequency disk type motor directly drives a roller body and is simple in transmission and compact in structure. A winch brake system realizes the four-quadrant operation and zero-velocity load hovering function of the motorin a brake unit and brake resistor combined energy consumption brake mode. The motor can operate stably at low velocity. An energy consumption brake of a winch driving a motor frequency conversion system serves as a main brake of the winch. An auxiliary brake of the winch adopts a pneumatic control disk type brake so as to prolong the service life of brake pads and relieve the maintenance workload. A direct driven mode is adopted in the direct-driven electric workover rig, the structure of the workover rig can be simplified, and the overall weight can be reduced. Meanwhile, the direct-driven electric workover rig can be directly connected with the disk type motor, the installation size is reduced, and the transmission efficiency is improved. Through combination of the energy consumption brake and the pneumatic control disk type brake, energy consumption can be better reduced, and the braking performance can be improved.

Owner:TIANJIN DONG FANG XIAN KE GASOLINEEUM MACHINERY

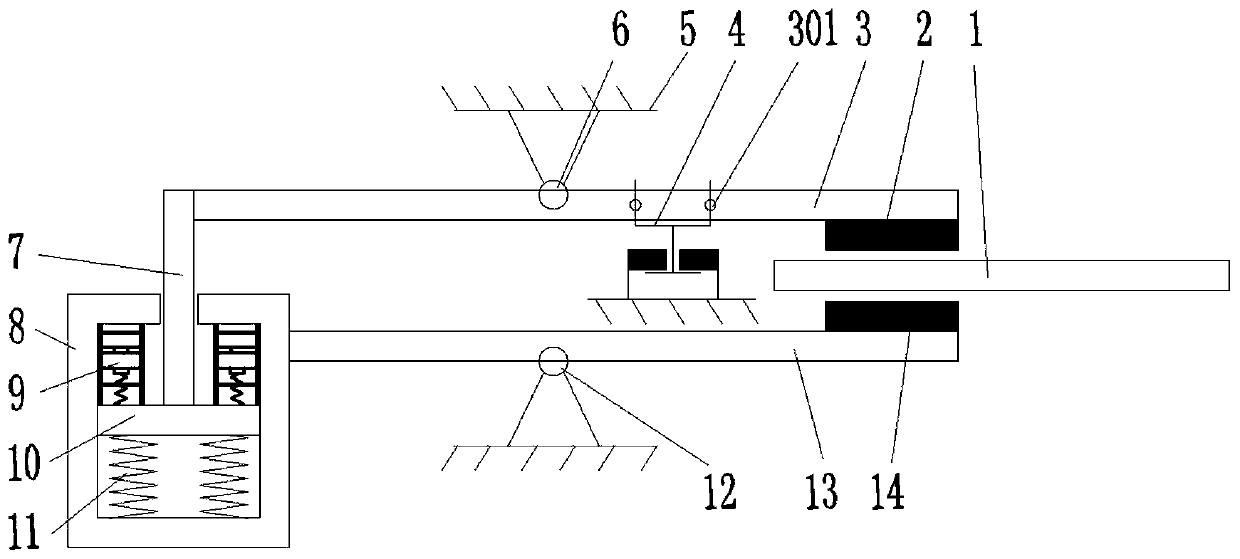

An electromechanical brake inlay with parking function

ActiveCN109505893BMeet the needs of power failure protectionHigh strengthAxially engaging brakesBraking action transmissionElectric machineryFunction motor

The present invention relates to an electromechanical braking inlay with a parking function, includes including a braking inlay module, an electromechanical braking module, a disc spring parking module, and a motor release module, where the braking inlay module includes an upper friction plate, an active pendulum rod, a housing, an active pendulum rod hinge, a passive pendulum rod hinge, a passive pendulum rod, and a lower friction plate, the electromechanical braking module implements conversion from rotary motion to linear movement, the disc spring parking module includes a piston push rod, a braking housing, a push plate, and a disc spring, the motor release module functions to cooperate with parking, braking release, routine braking and motor release by controlling the timing of insertion into the fork block hole, combination setting of the electromechanical braking module and the disc spring implements functions of parking, braking release, and routine braking, and setting of the motor release module implements the function of motor release, meeting a requirement for power-off protection while improving strength of a system, and providing a new method for application of an electromechanical braking technology to important braking situations

Owner:ANHUI UNIV OF SCI & TECH

Multifunctional motor base

PendingCN114039450AInstalled and disassembledEasy to change the transmission directionSupports/enclosures/casingsElectric machineFunction motor

The invention discloses a multifunctional motor base. The motor base comprises a base, and a movable plate and an L-shaped fixed plate which are fixed on the base. The movable plate and the L-shaped fixed plate are hinged through a hinge, a motor base is arranged on the movable plate, a motor is arranged in the motor base, two sides of the motor base are respectively provided with a heat dissipation groove, one end of the motor base is provided with a shaft hole, fixing holes are formed in the periphery of the shaft hole, a limiting fixing plate is arranged at the other end of the motor base, a locking plate is arranged at the position, above one side of the shaft hole, of the motor base, and when the motor base rotates by 90 degrees to be perpendicular to the base, the locking plate is matched with a locking mechanism on an L-shaped fixing plate. The use state of the novel multifunctional motor base can be adjusted according to requirements, the internal motor can be horizontally or vertically arranged, the transmission direction can be conveniently changed, and the novel multifunctional motor base is stable in overall structure, convenient to mount and dismount and suitable for application and popularization.

Owner:泰信电机(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com