Thermal supplying apparatus with co-shaft of three device connected directly and its use

A coaxial technology of heat, electricity and cooling, which is used in mufflers, exhaust devices, energy-saving heating/cooling, etc., to achieve the effect of being conducive to serialization and optimized operation adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

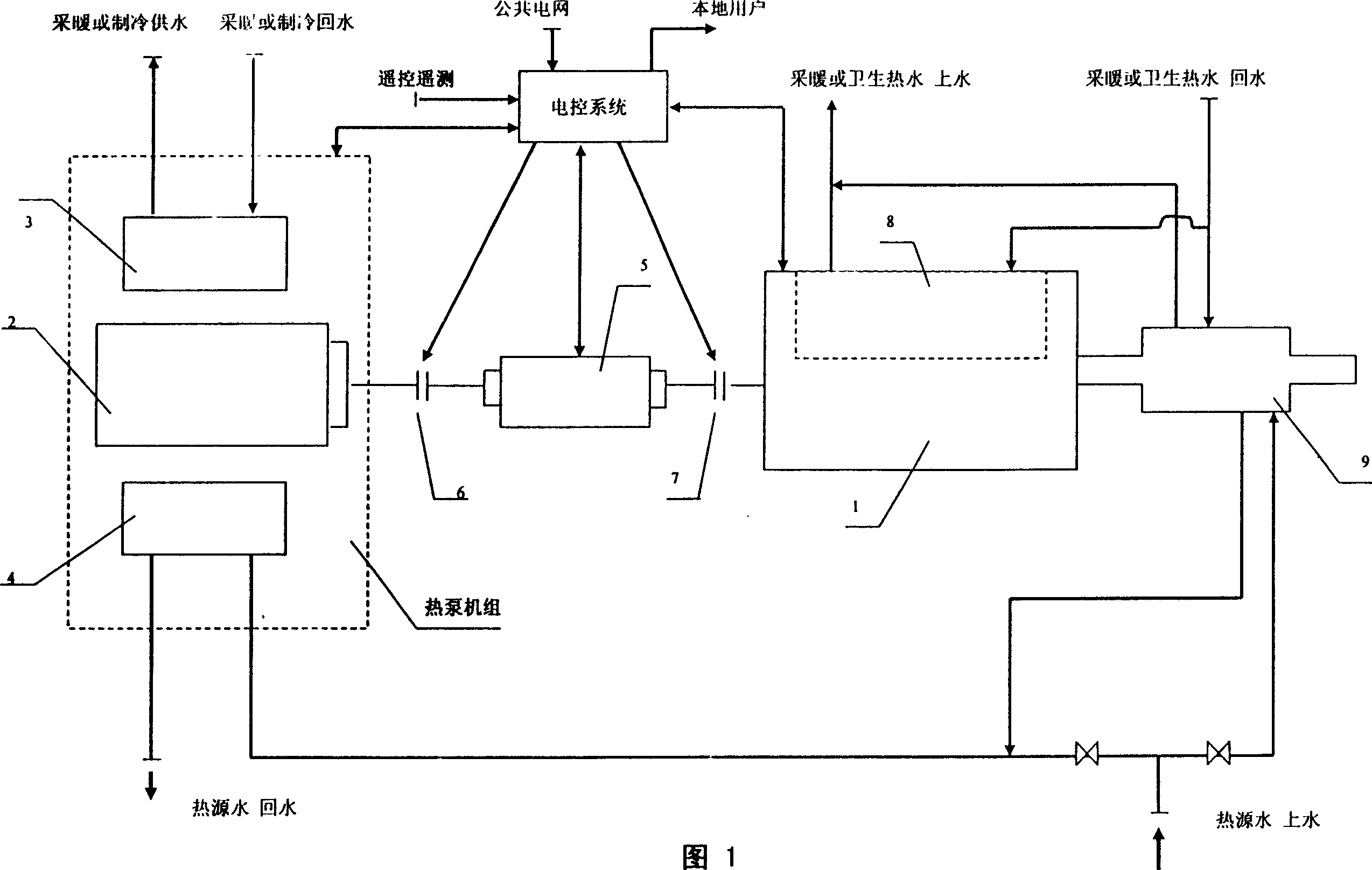

[0012] The three-machine coaxial direct-coupled thermoelectric-cooling device of the present invention includes an engine, a generator, a heat pump unit and an electric control system, as shown in Fig. 1, and is characterized in that the two ends of the dual-purpose motor 5 output shafts, and the clutches 6, 7 The engine 1 and the heat pump compressor 2 are respectively connected to the same shaft to form a direct connection of three machines. Dual-purpose motor links to each other with engine 1 with one end clutch 7. The clutch 6 at the other end is connected with the compressor 2 of the heat pump, and the dual-purpose motor 5 is connected with the power grid through the electric control system. The electronic control system accepts the input of the public power grid and the input of remote control and telemetry, and maintains two-way communication with the engine 1, the dual-purpose motor 5, and the heat pump unit, and outputs power supply to local users, and outputs control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com