A miniaturized functional fiber drawing equipment

A technology of functional fiber and equipment, which is applied in the field of miniaturized functional fiber drawing equipment, can solve problems such as the inability to meet the flexibility and diversity of optical fibers, and achieve the effect of simple configuration, less material consumption and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

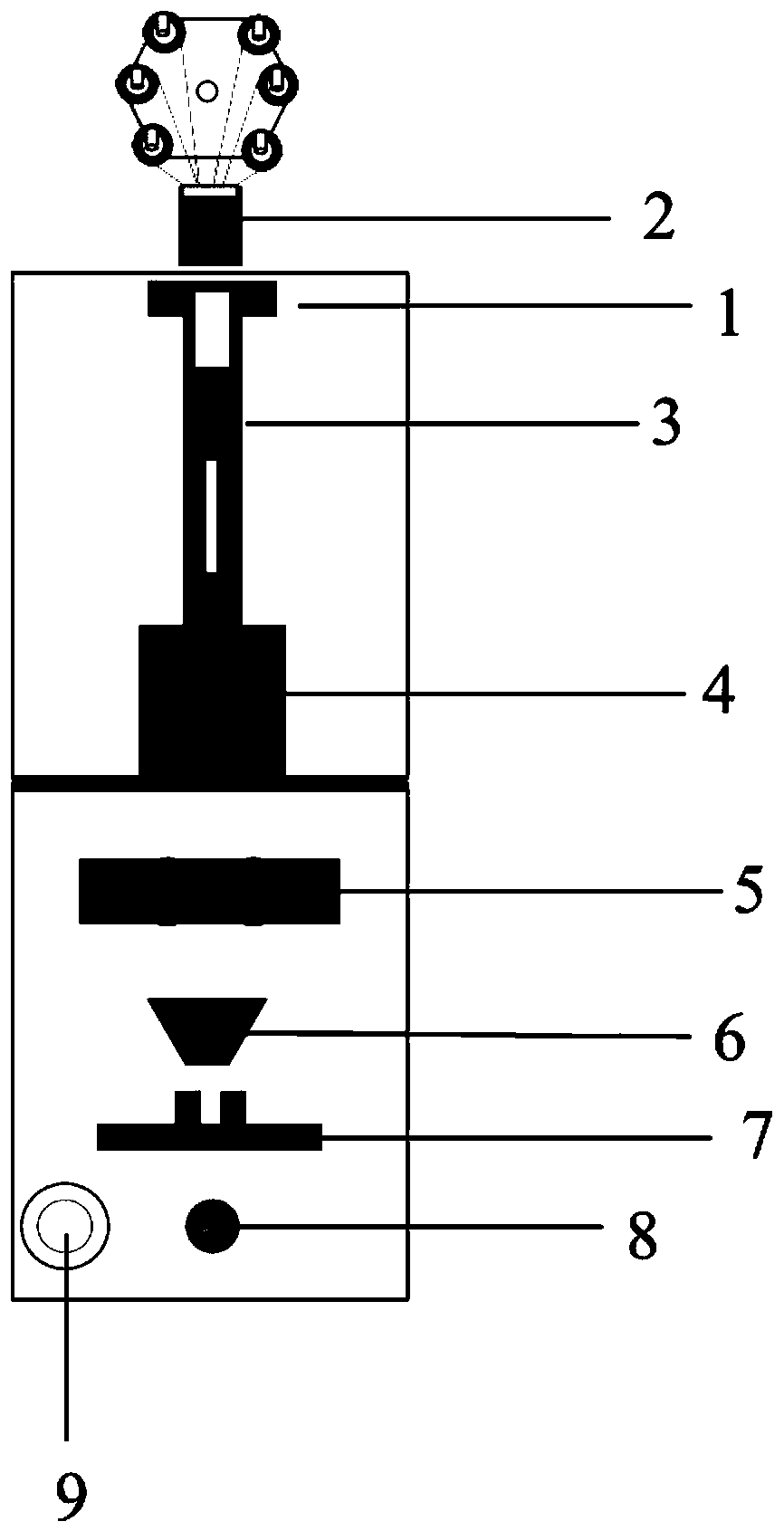

[0049] The functional fiber drawing equipment provided in this embodiment includes a metal frame 1 , a rod feeding device 3 , a heating furnace 4 , an auxiliary traction device 5 , a diameter measuring device 7 , a guide wheel 8 and a wire take-up device 9 .

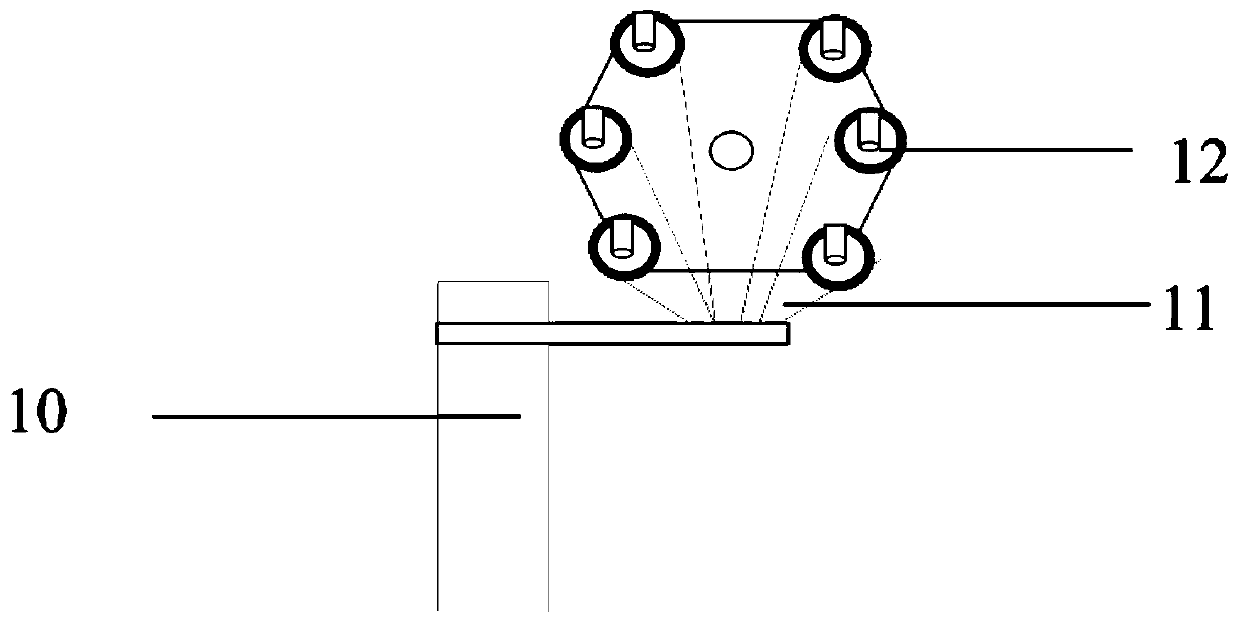

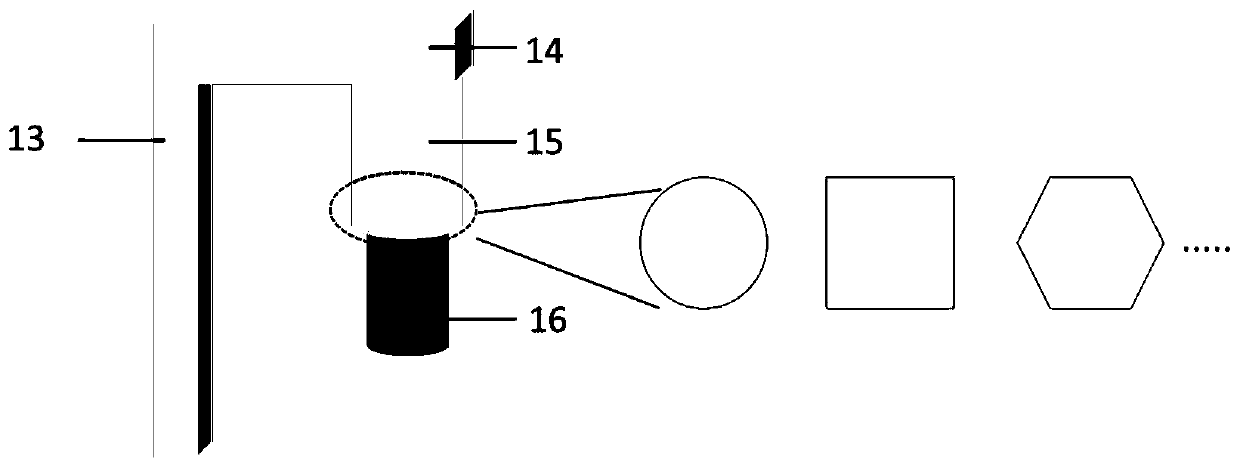

[0050] The rod feeding device 3 consists of three parts: a mechanical sliding track 13, a metal tail handle 14 and a chuck sleeve 15, the mechanical sliding track 13 is fixed on the top of one side of the metal frame 1, and one end of the metal tail handle 14 is fixed on the mechanical sliding track 13 , the metal tail handle 14 can be driven by a servo motor to slide vertically up and down on the mechanical sliding track 13, and the other end of the metal tail handle 14 is fixed with a chuck sleeve 15 of the preform rod. The chuck sleeve 15 is circular in shape, and one section of the chuck sleeve 15 adopts a top wire to lock the preform. The diameter of the collet sleeve 15 is 35 mm, which can hold the preform rod with...

Embodiment 2

[0053] The functional fiber drawing equipment provided in this embodiment includes a metal frame 1 , a rod feeding device 3 , a heating furnace 4 , an auxiliary traction device 5 , a diameter measuring device 7 , a guide wheel 8 and a wire take-up device 9 .

[0054] The rod feeding device 2 consists of three parts: a mechanical sliding track 13, a metal tail handle 14 and a collet sleeve 15, the mechanical sliding track 13 is fixed on the top of one side of the metal frame 1, and one end of the metal tail handle 14 is fixed on the mechanical sliding track 13 , the metal tail handle 14 can be driven by a servo motor to slide vertically up and down on the mechanical sliding track 13, and the other end of the metal tail handle 14 is fixed with a chuck sleeve 15 of the preform rod. The chuck sleeve 15 is circular in shape, and one section of the chuck sleeve 15 adopts a top wire to lock the preform. The diameter of the collet sleeve 15 is 15 mm, which can hold the preform rod wit...

Embodiment 3

[0058] The functional fiber drawing equipment provided in this embodiment includes a metal frame 1 , a rod feeding device 3 , a heating furnace 4 , an auxiliary pulling device 5 , a coating device 6 , a diameter measuring device 7 , a guide wheel 8 and a wire take-up device 9 .

[0059] The rod feeding device 2 consists of three parts: a mechanical sliding track 13, a metal tail handle 14 and a collet sleeve 15, the mechanical sliding track 13 is fixed on the top of one side of the metal frame 1, and one end of the metal tail handle 14 is fixed on the mechanical sliding track 13 , the metal tail handle 14 can be driven by a servo motor to slide vertically up and down on the mechanical sliding track 13, and the other end of the metal tail handle 14 is fixed with a chuck sleeve 15 of the preform rod. The chuck sleeve 15 is circular in shape, and one section of the chuck sleeve 15 adopts a top wire to lock the preform. The diameter of the collet sleeve 15 is 35 mm, which can hold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com