Motor stator marking device with tracing function

A motor stator and marking device technology, which is applied in electromechanical devices, manufacturing motor generators, manufacturing stator/rotor bodies, etc., can solve problems affecting production, affecting stator electrical performance, scratches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

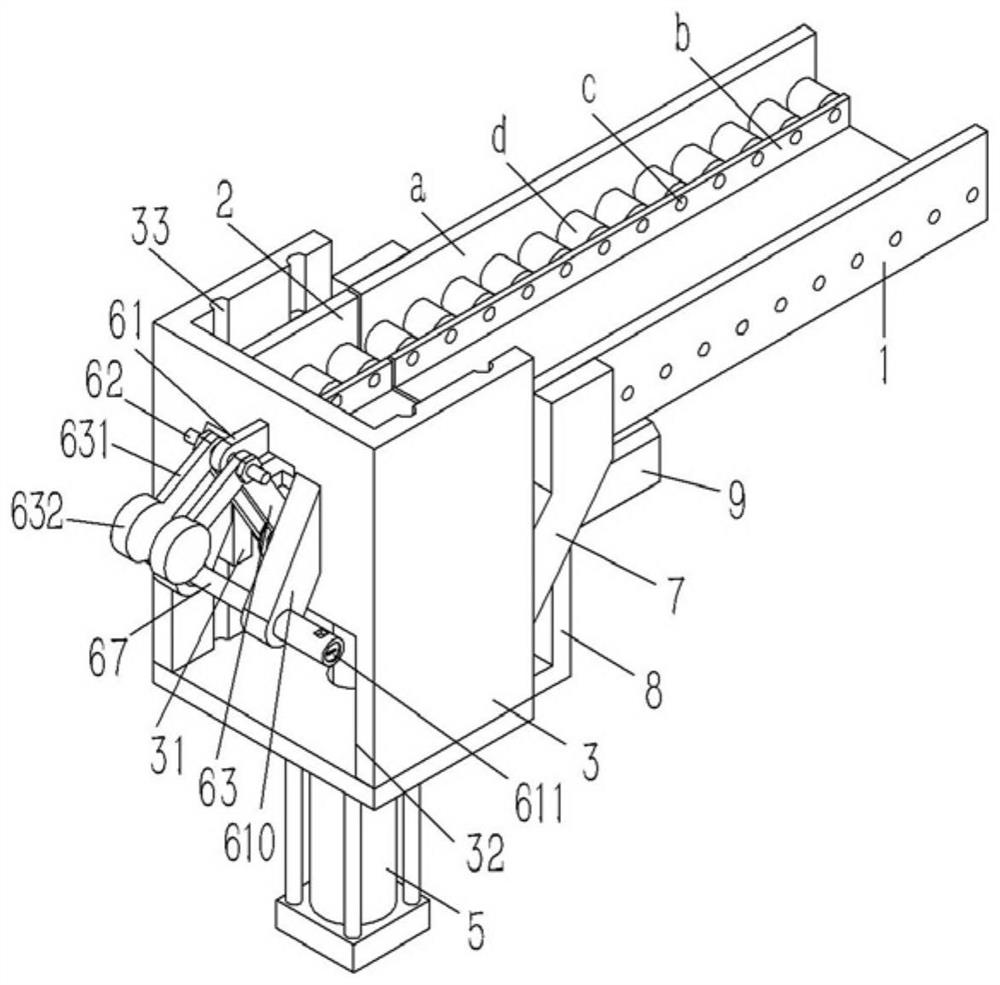

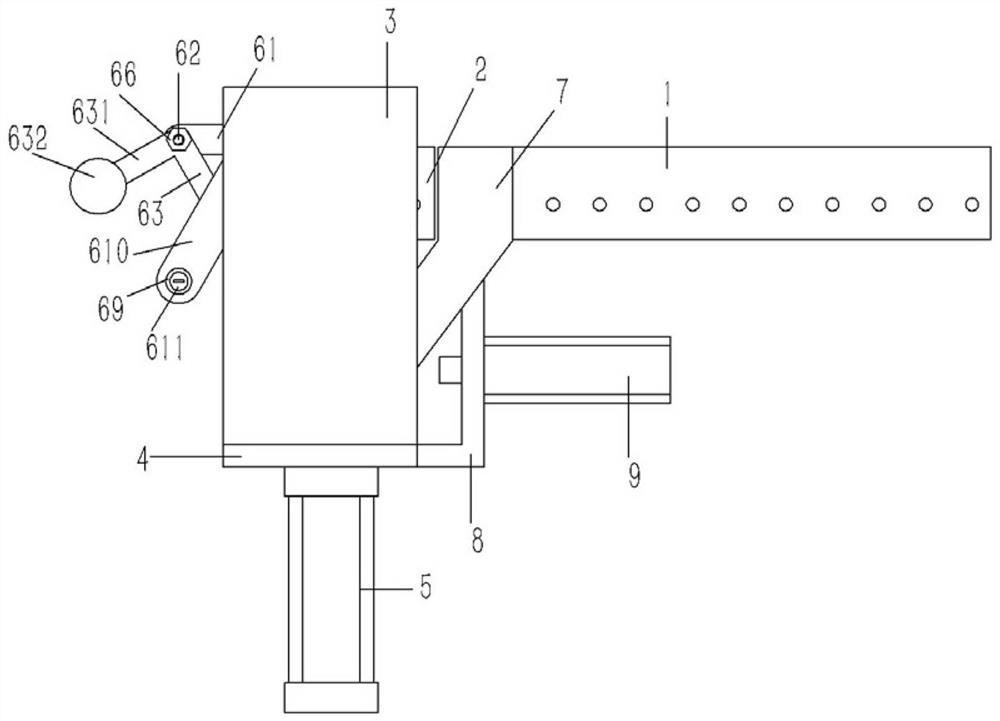

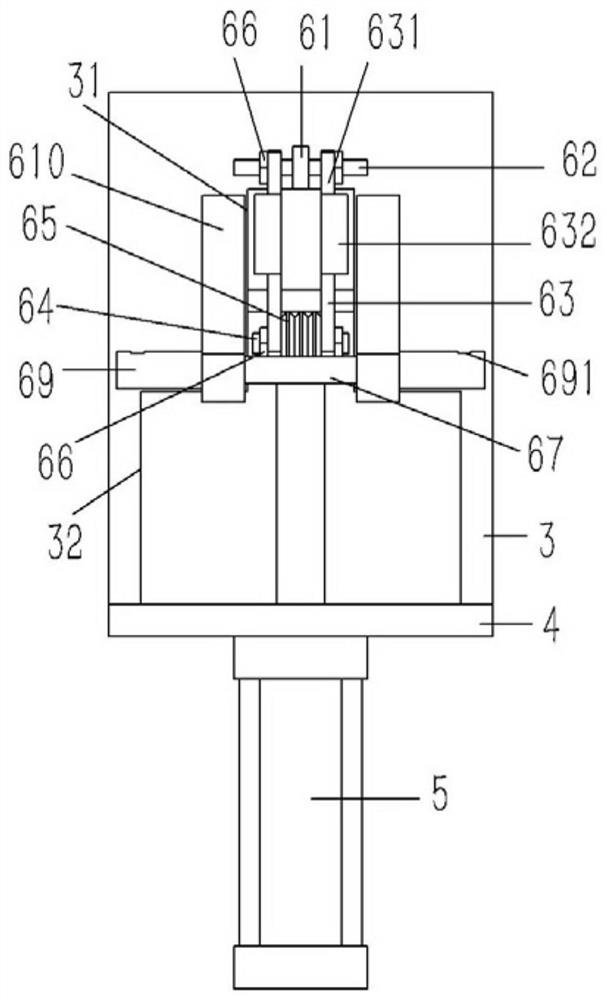

[0022]Example: SeeFigure 1 to 4As shown, a lifting slot rail 2 having a traceable function motor stator marker device, including a horizontal discharge rail 1, and an assembly tank rail 1, a lifting tank 2 inserted in a frame 3 of the "匚" glyph 3, The bottom plate 4 is fixed to the lower end surface of the frame 3, and the vertical lifting cylinder 5 is fixed to the bottom plate 4, and the piston rod of the lifting cylinder 5 is fixed to the lifting slot rail 2; the frame 3 offs from the discharge rail One side of the 1 side, the frame 3 is formed with a slot 31 opposite to the marking mechanism 6, and the lower end of the frame 3 is formed with the discharge port 32 in communication with the slot 31, below the discharge groove rail 1. A push cylinder 9 is provided with the discharge port 32, the pusher cylinder 9 is fixed to the cylinder bracket 8, and the cylinder bracket 8 is fixed to the bottom plate 4;

[0023]The labeling mechanism 6 includes an ear seat 61 fixed to the frame 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com