Motor end cover drilling device with cooling function

A technology of motor end cover and drilling device, which is applied in boring/drilling, drilling/drilling equipment, manufacturing tools, etc. Fast and convenient, improve safety, adjust the effect of flexible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

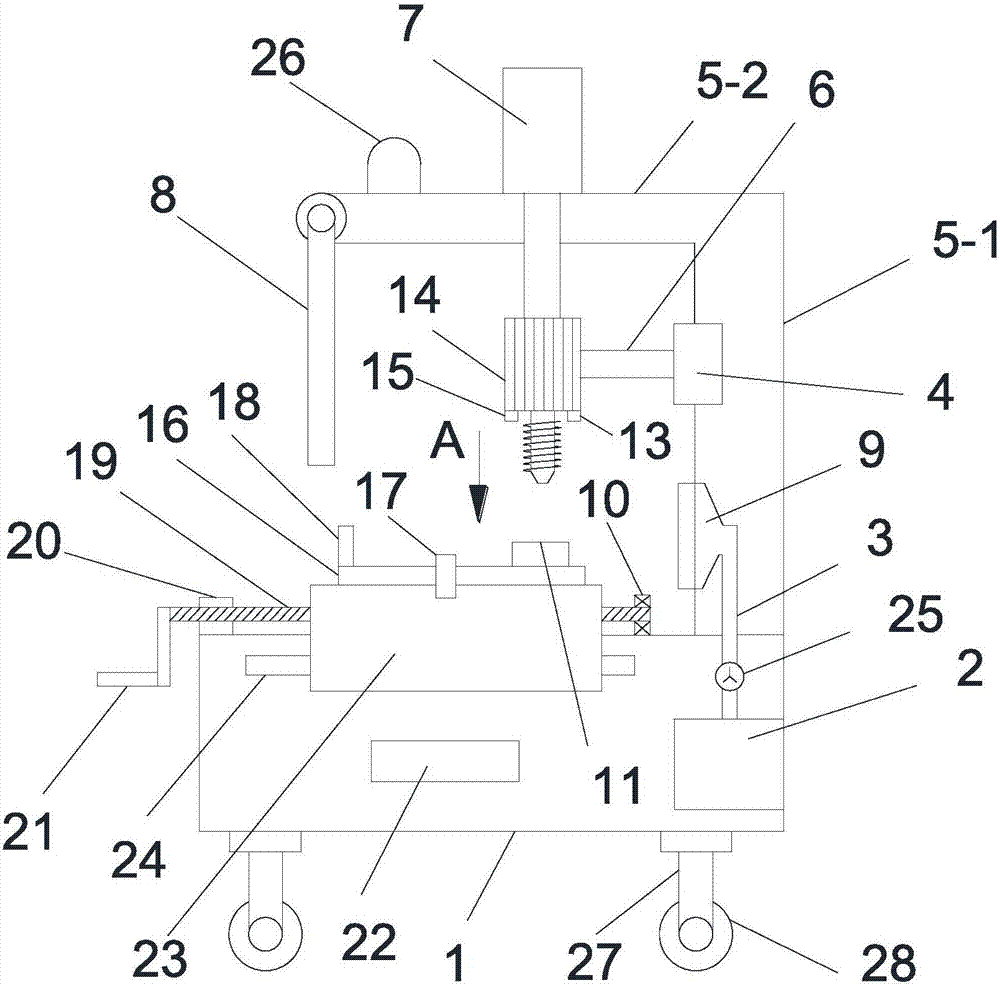

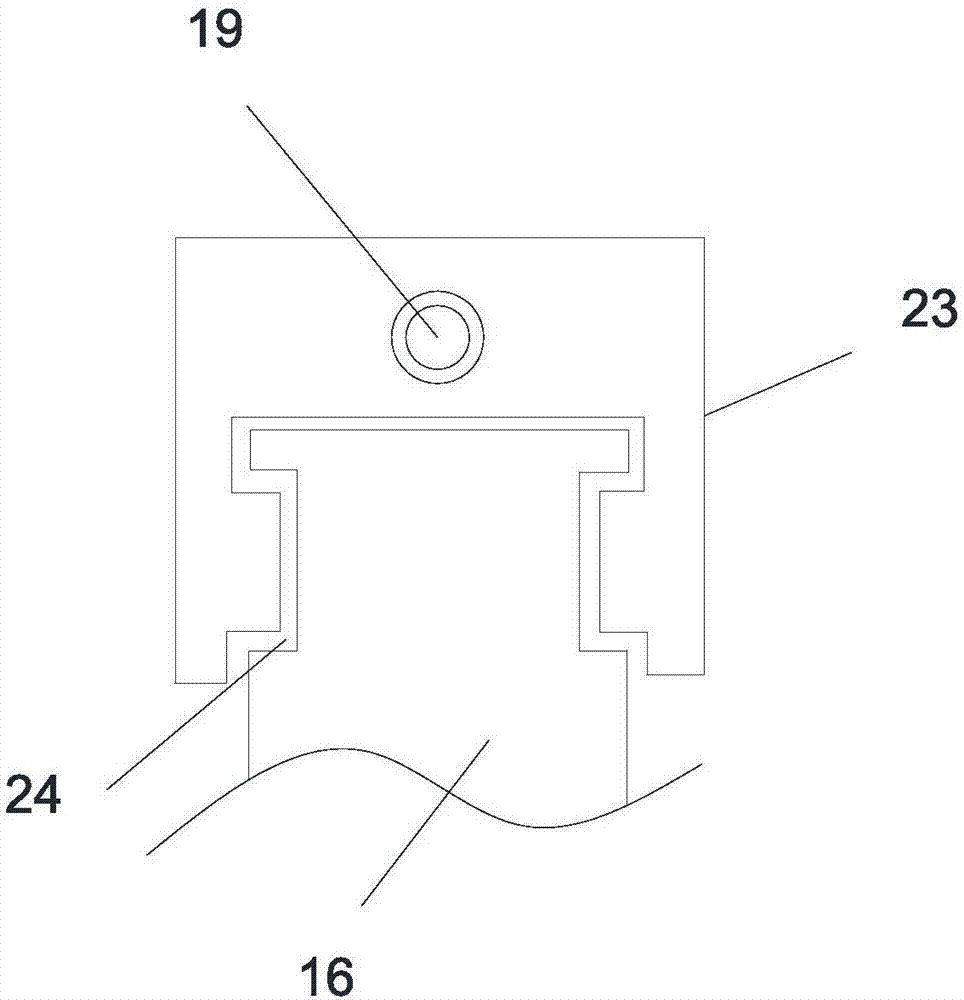

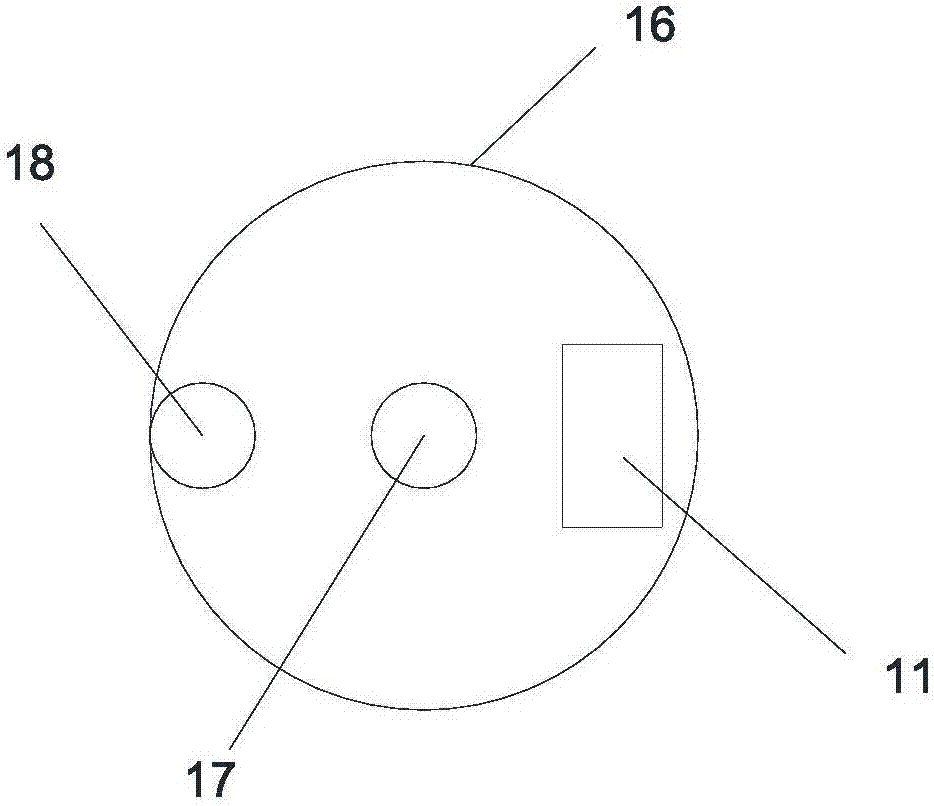

[0021] see Figure 1-4 , a motor end cover drilling device with a cooling function, comprising a base 1, a frame is provided on the base 1, the frame includes a vertical frame 5-1 and a horizontal support 5-2, and the horizontal support 5-2 The electric hydraulic cylinder 7 is installed upside down, and the bottom of the electric hydraulic cylinder 7 is fixedly equipped with a drill bit seat 14. The drill bit seat 14 is provided with a drill bit 12, and the lower part of the drill bit seat 14 is fixedly installed with a temperature sensor 13 and a distance sensor 15. The drill bit seat 14 The right side is fixedly equipped with a connecting rod 6, and the right end of the connecting rod 6 is welded and fixed with a limit slider 4, and the limit slider 4 is slidably installed on the vertical frame 5-1; the side of the base 1 is provided with a slideway 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com