Full-function motor-driven tiller

A tiller, full-function technology, applied in the field of full-function electric tillers, can solve the problems of unfavorable seedling growth, uneven field, slow tillage speed, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

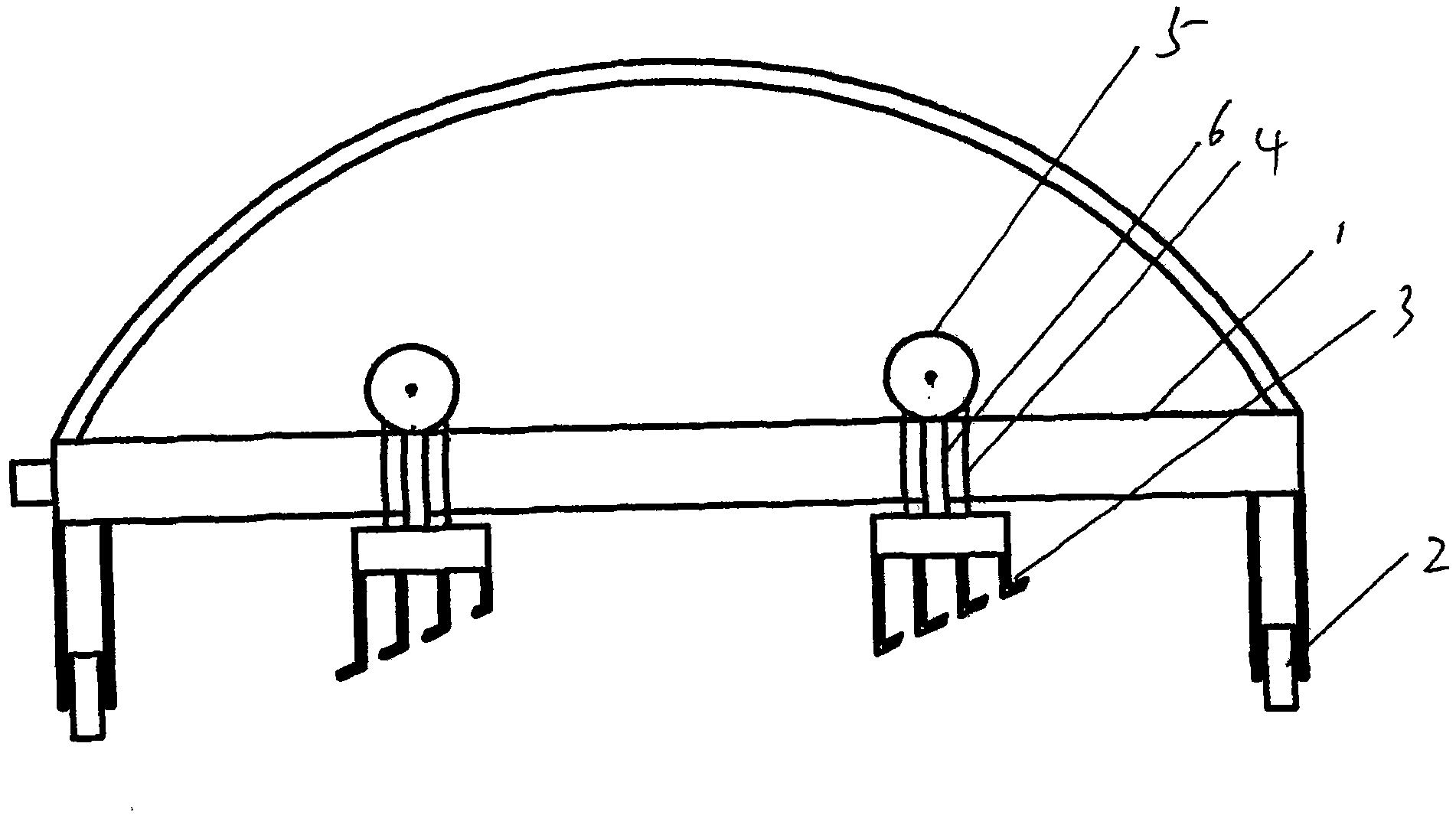

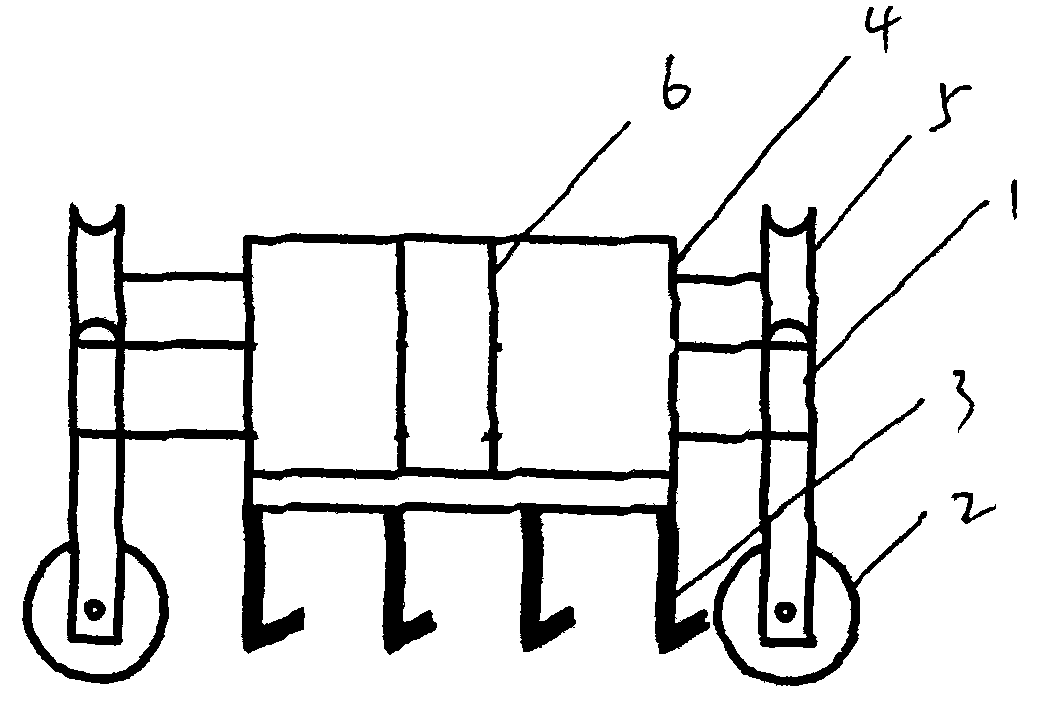

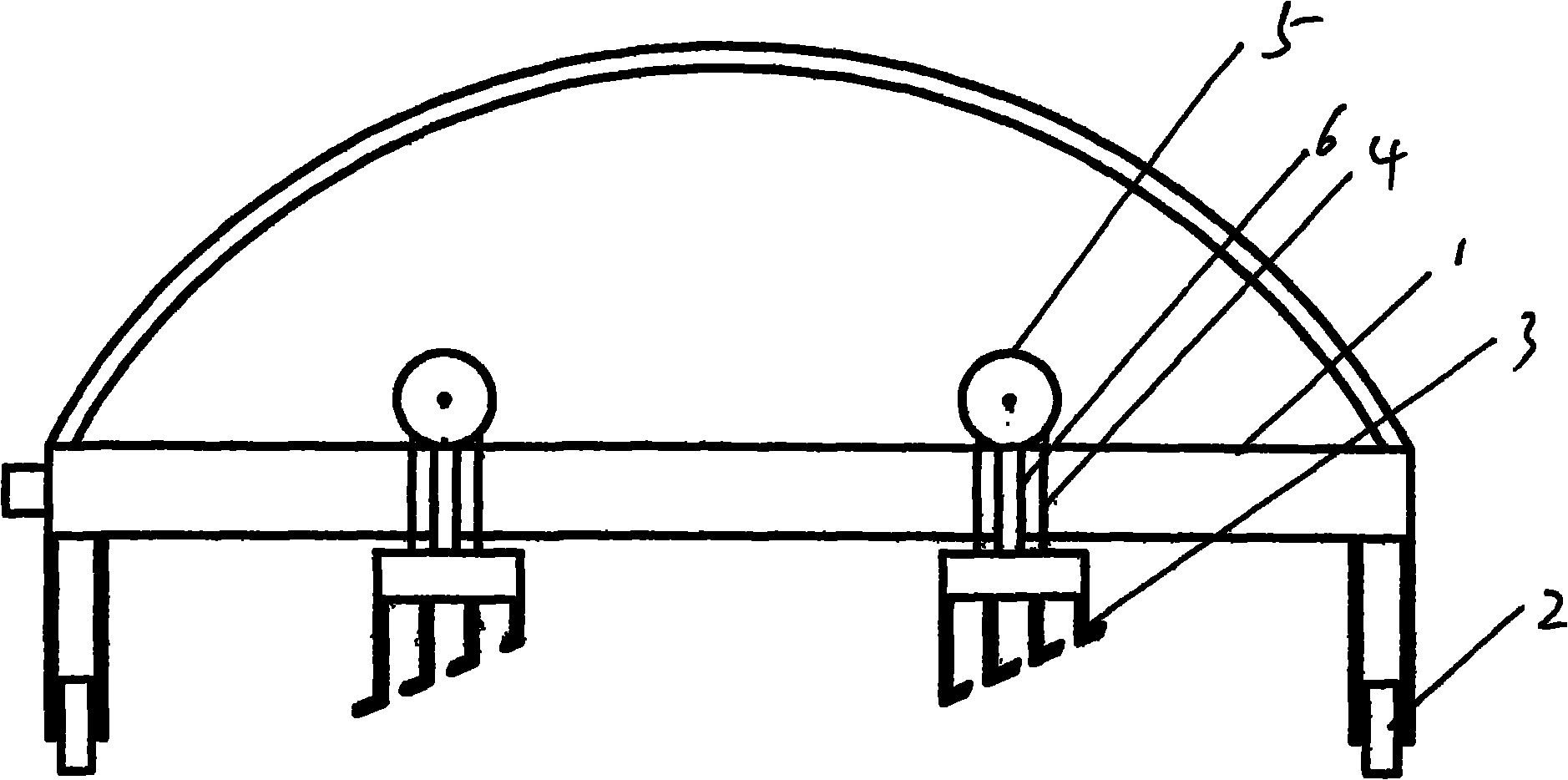

[0009] control figure 1 , figure 2 As can be seen, the present invention comprises frame 1, and the two sides of frame 1 are provided with traveling wheel 2, and described traveling wheel 2 can be driven by electric motor to walk, also is provided with two movable share plows in frame 1 middle part, described movable share The plow includes a plowshare 3, a hydraulic lifter 4, and electric wheels 5 arranged on the chutes at the front and rear sides of the frame. The plowshare 3 is connected to the lifting shaft 6 inside the hydraulic lifter 4, and the hydraulic lifter controls its movement. up or down. The hydraulic lifter 4 is connected to the electric wheels 5 on the front and rear sides of the frame, and the electric wheels 5 drive it to move left and right and drive the plowshares to move left and right. The two plowshares on the two moving plowshares are just in opposite directions. , one for plowing while moving forward, and one for plowing while going backward.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com