Secondary mold stripping mechanism for automotive interior trim injection mold

A technology for automotive interior parts and injection molds, which is used in household components, household appliances, other household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

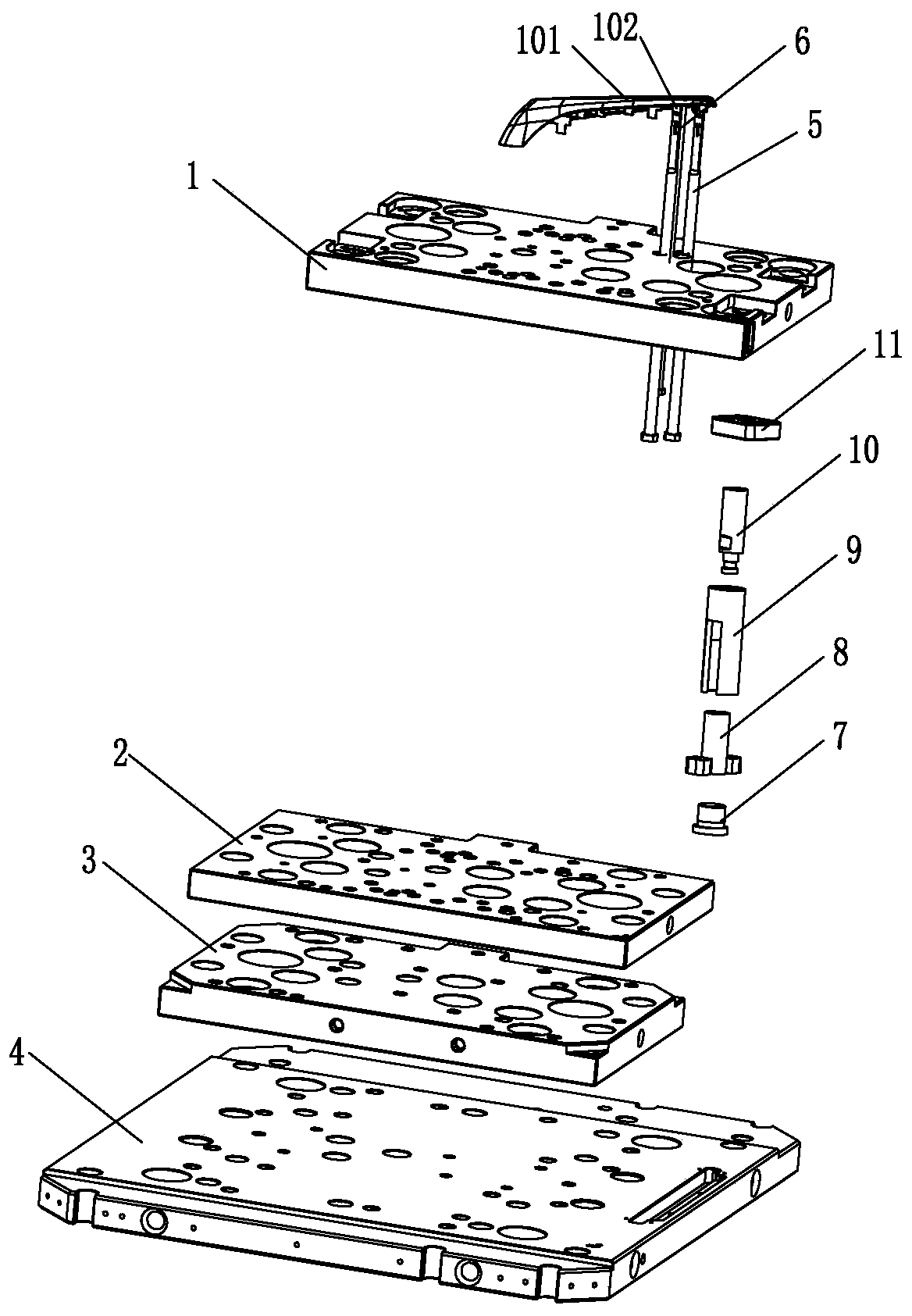

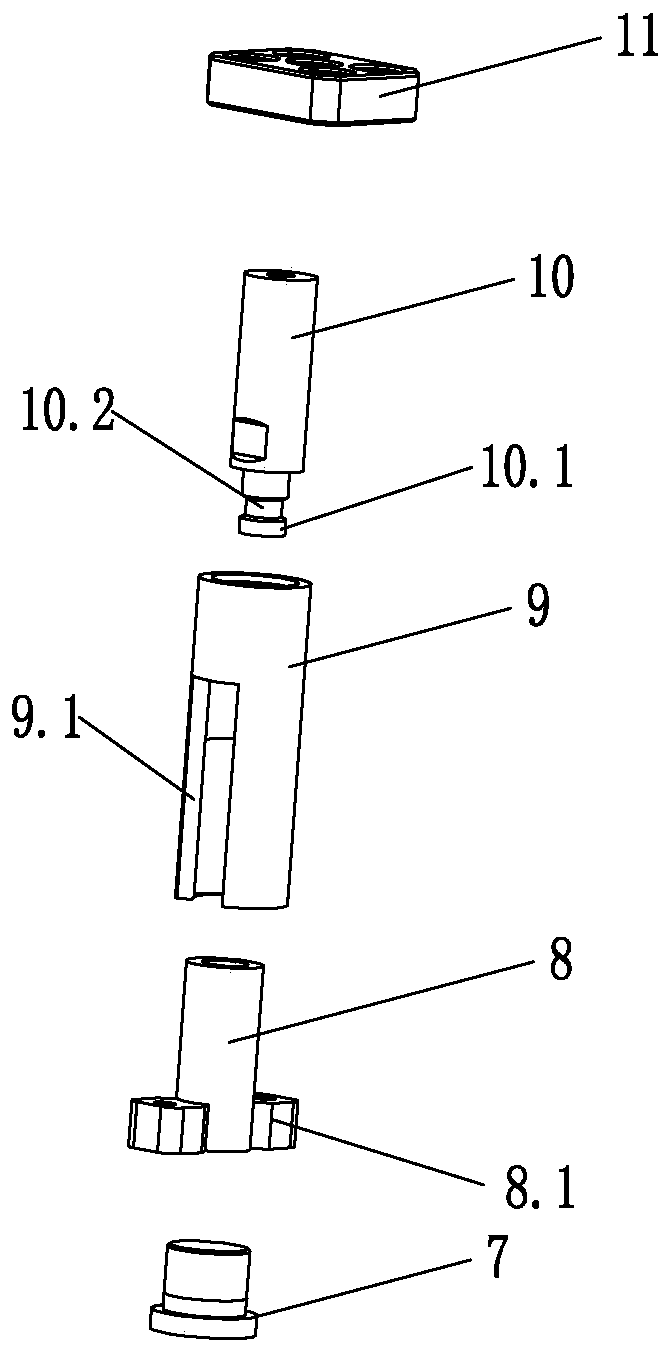

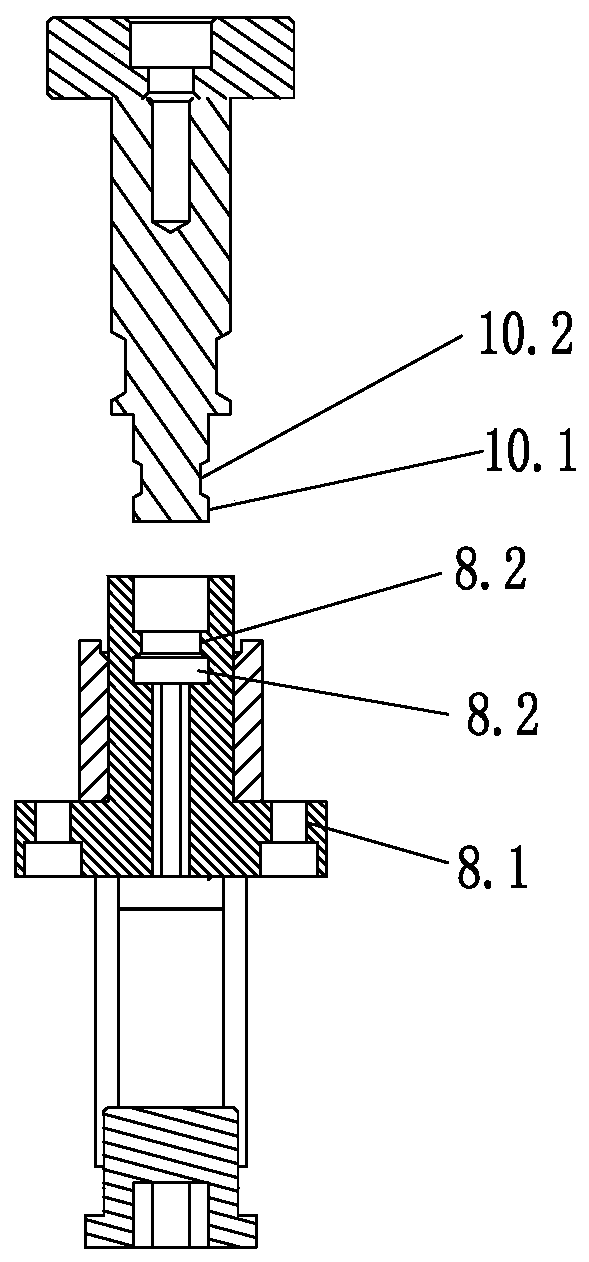

[0018] Such as figure 1 As shown, a secondary demoulding mechanism of an injection mold for automotive interior parts of the present invention includes a first ejector plate 1, a second ejector plate 2, a third ejector plate 3, a base plate 4 and a plurality of first ejector pins 5 , the first ejector plate 1, the second ejector plate 2, and the third ejector plate 3 are sequentially located on the bottom plate 4 from top to bottom, and the bottom end of each first ejector rod 5 passes through the hole of the second ejector plate 2 and The axial limit is between the second ejector plate 2 and the third ejector plate 3, and the top end passes through the first ejector plate 1 and B plate,

[0019] The secondary demoulding mechanism of the injection mold for automotive interior parts of the present invention also includes a second ejector rod 6 , a base 7 , a sliding seat 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com