Special operating platform for glass rod cutting

A technology for operating platforms and glass rods, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as waste of raw materials, long billets, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

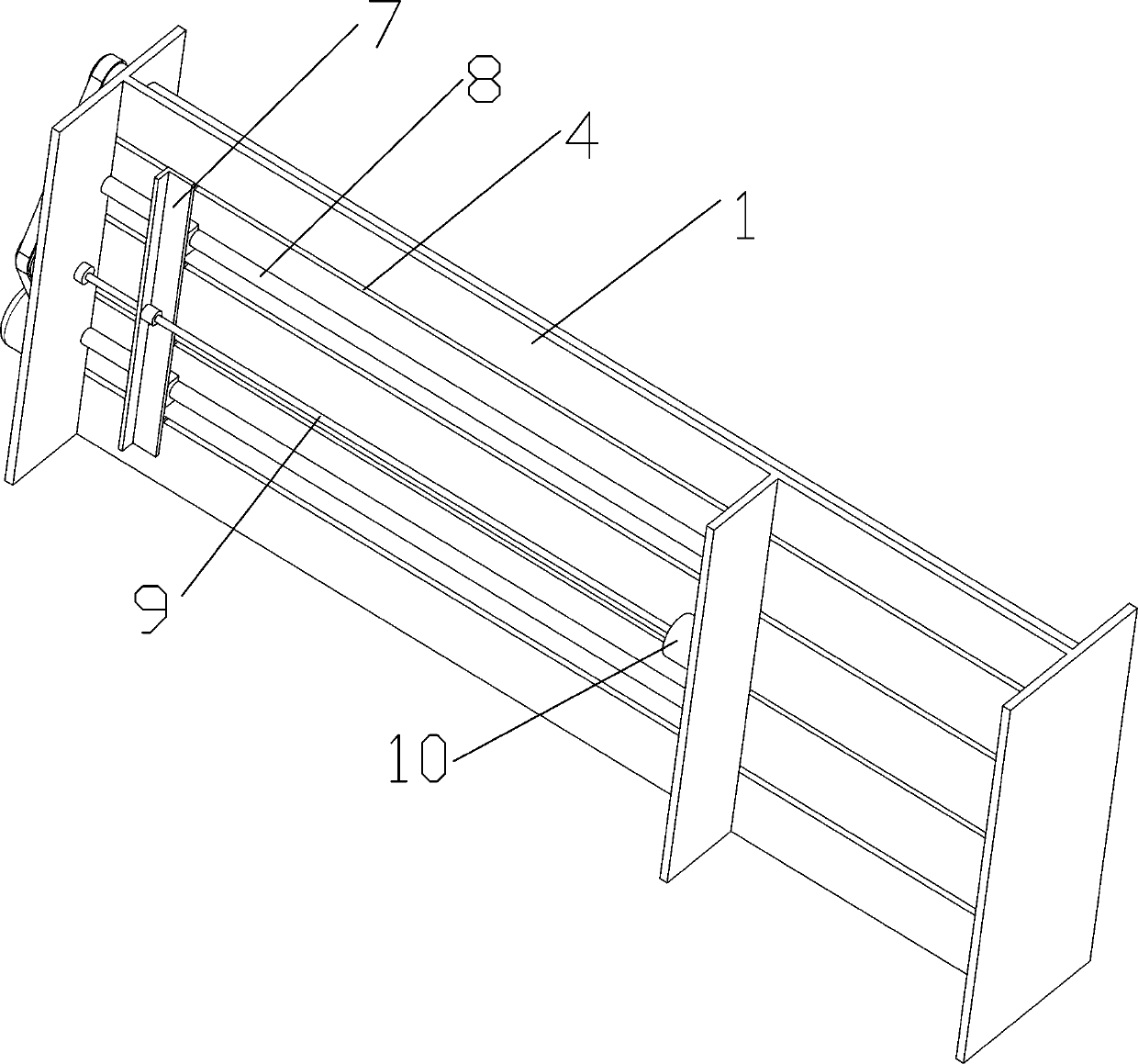

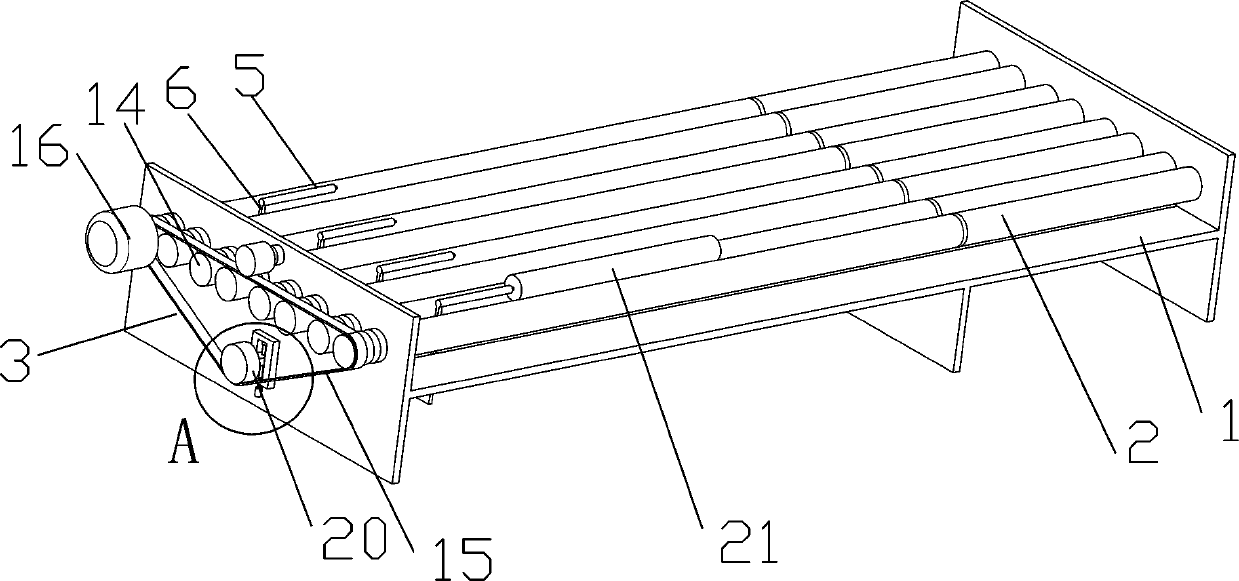

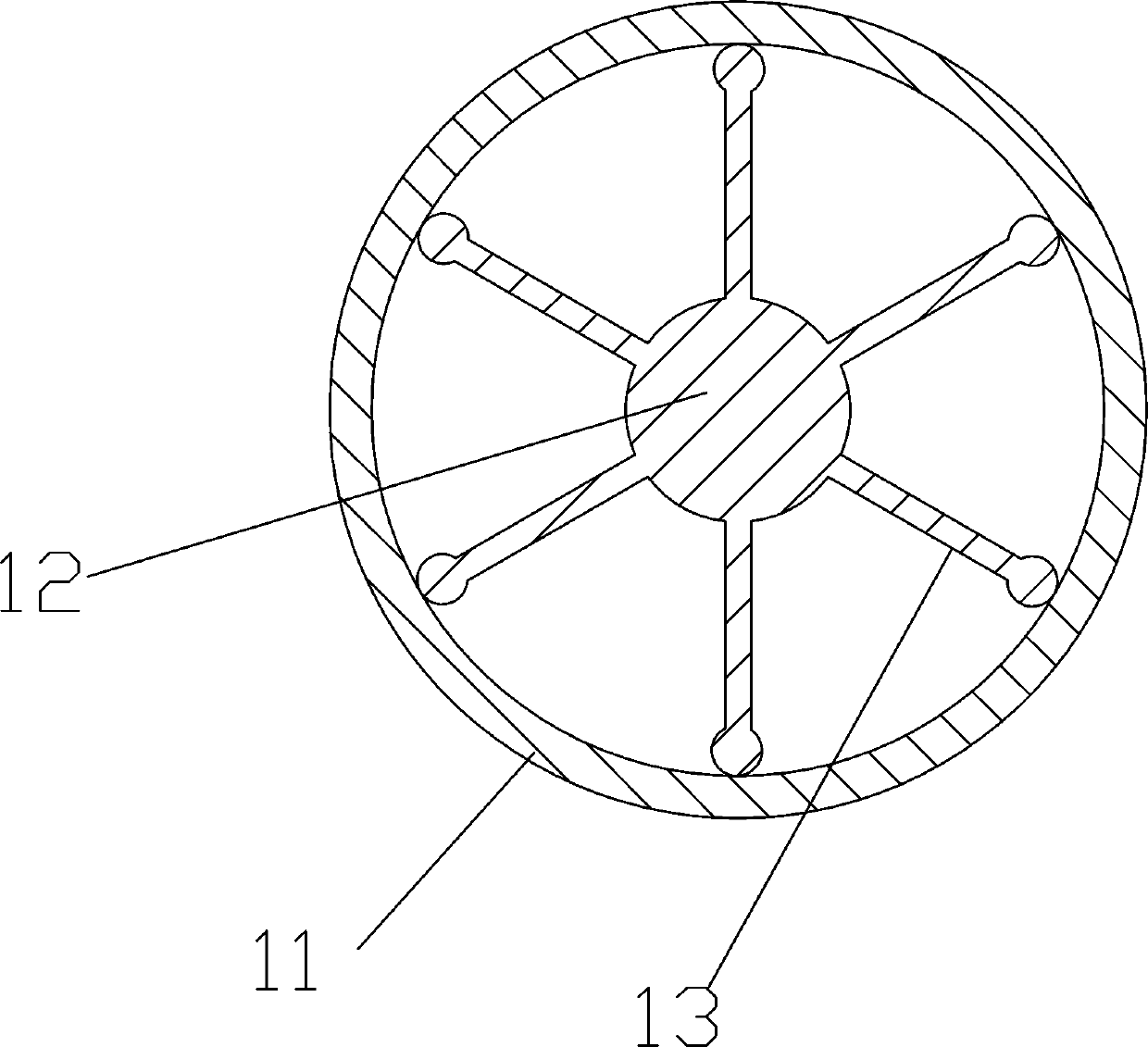

[0020] like Figure 1-2 As shown, a special operating platform for cutting glass rods includes a platform 1. The platform 1 includes a front and rear base, and a horizontal support plate is provided between the front and rear bases. The support plate is provided with four slots 4 at intervals along the length direction. . Correspondingly, there are four sets of pairs of rotating rollers 2 above the support plate. The two ends of the rotating rollers 2 are rotatably connected to the base through bearings. There is a gap between the pairs of rotating rollers 2. 4 is right. The ejector rod 5 is located above the gap of the rotating roller 2, and the lower end is connected with the slide plate 7 through the connecting rod 6. The slide plate 7 is provided with two slide blocks, and the slide blocks are provided with a chute, and the chute is connected with the slide rail 8 at the bottom of the platform 1. Clearance fit. The slide rail 8 not only ensures that the slide plate 7 sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com