Moxa stick cutting device with distance detection

A cutting device and distance detection technology, applied in metal processing and other directions, can solve the problems of low cutting efficiency, inability to automatically collect moxa sticks, different lengths, etc., to achieve the effect of convenient cutting processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

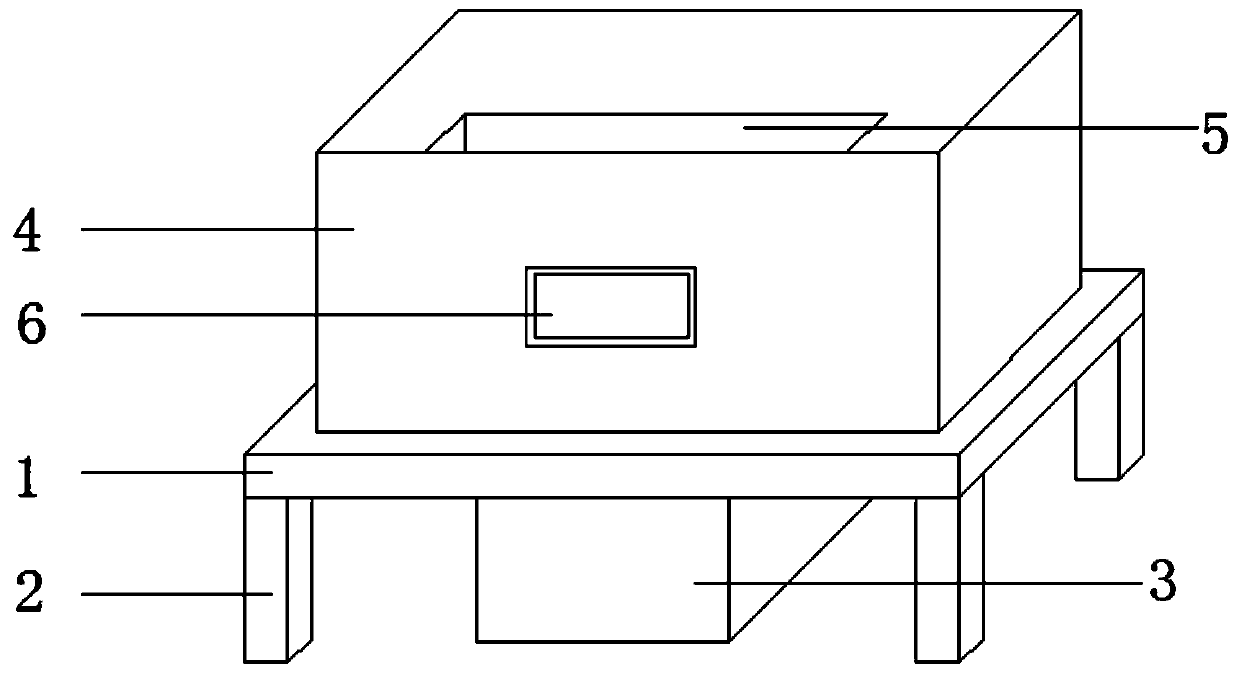

[0028] see figure 1 , 3 , 5, 6, a moxa stick cutting device with distance detection, including a distance sensor 12 and a base plate 1, the four corners of the lower surface of the base plate 1 are provided with legs 2, and the legs 2 are all fixed under the base plate 1 by screws, and the lower end surface of the base plate 1 The rear side is provided with a collection box 3, the collection box 3 is fixed under the base plate 1 by screws, a housing 4 is arranged in the middle of the upper surface of the base plate 1, the housing 4 is fixed on the base plate 1 by screws, and an inlet is provided in front of the front surface of the housing 4. Material opening 5, a control box 6 is arranged in the middle of the front surface of the casing 4, the control box 6 is fixed on the casing 4 by screws, a switch 7 is arranged on the front surface of the control box 6, the switch 7 is fixed on the control box 6 by screws, and the control A controller 8 is arranged inside the box 6, and ...

Embodiment 2

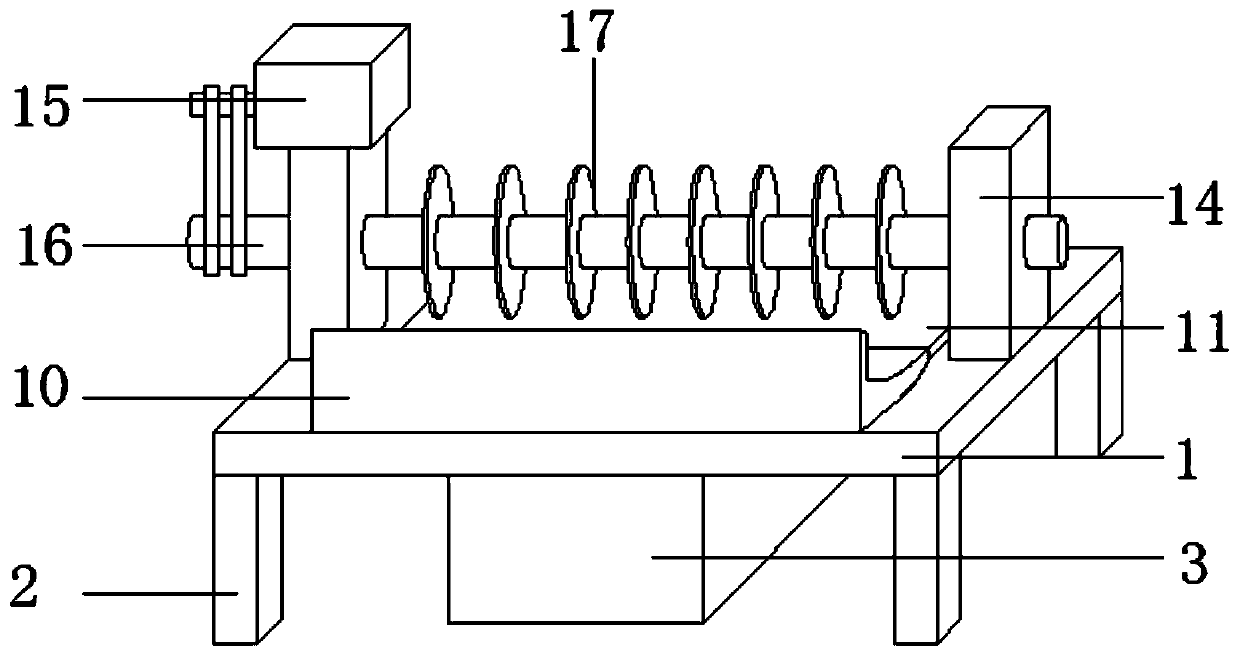

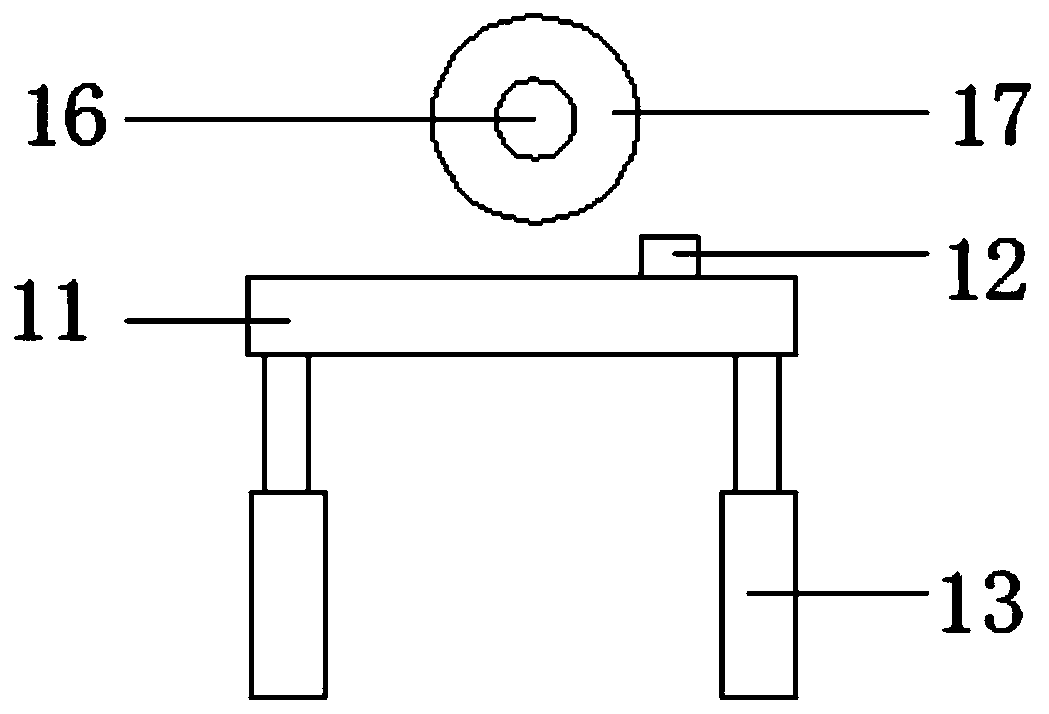

[0030] see figure 1 , 2 , a moxa stick cutting device with distance detection, a discharge port 18 is provided on the rear side of the upper surface of the bottom plate 1, and fixing frames 14 are arranged on the left and right sides of the upper surface of the bottom plate 1, and the fixing frames 14 are all fixed on the bottom plate 1 by welding , the left side of the upper surface of the fixed frame 14 is provided with a motor 15, the model of the motor 15: 192ZDC, the motor 15 is fixed on the fixed frame 14 by screws, the inner side of the fixed frame 14 is provided with a cutting shaft 16, and the cutting shaft 16 is set in the fixed frame 14, Cutting shaft 16 surface is provided with cutting tool 17 successively from left to right, and cutting tool 17 is all sleeved and fixed on cutting shaft 16, and the rotating shaft of motor 15 is sleeved on cutting shaft 16 by two hinges, and the rotating shaft of motor 15 and cutting There are two connecting grooves on the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com