Fabricated wall surface leveling mounting structure

An installation structure and prefabricated technology, used in building construction, covering/lining, construction, etc., can solve the problems of unstable overall structure, high requirements on wall flatness, affecting decoration effect and quality, etc. The effect of leveling work, improving the quality of decoration, and improving the effect of decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

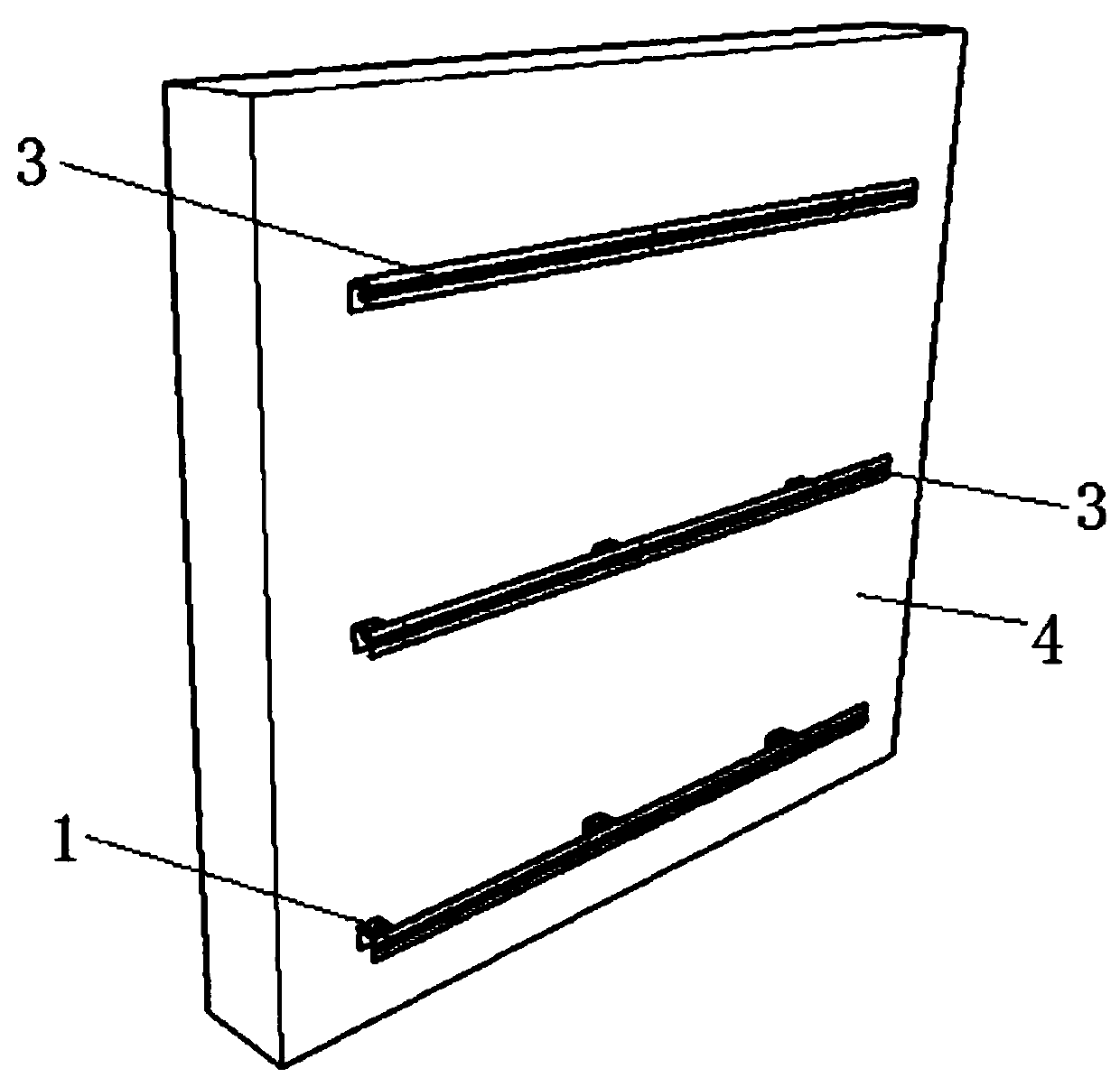

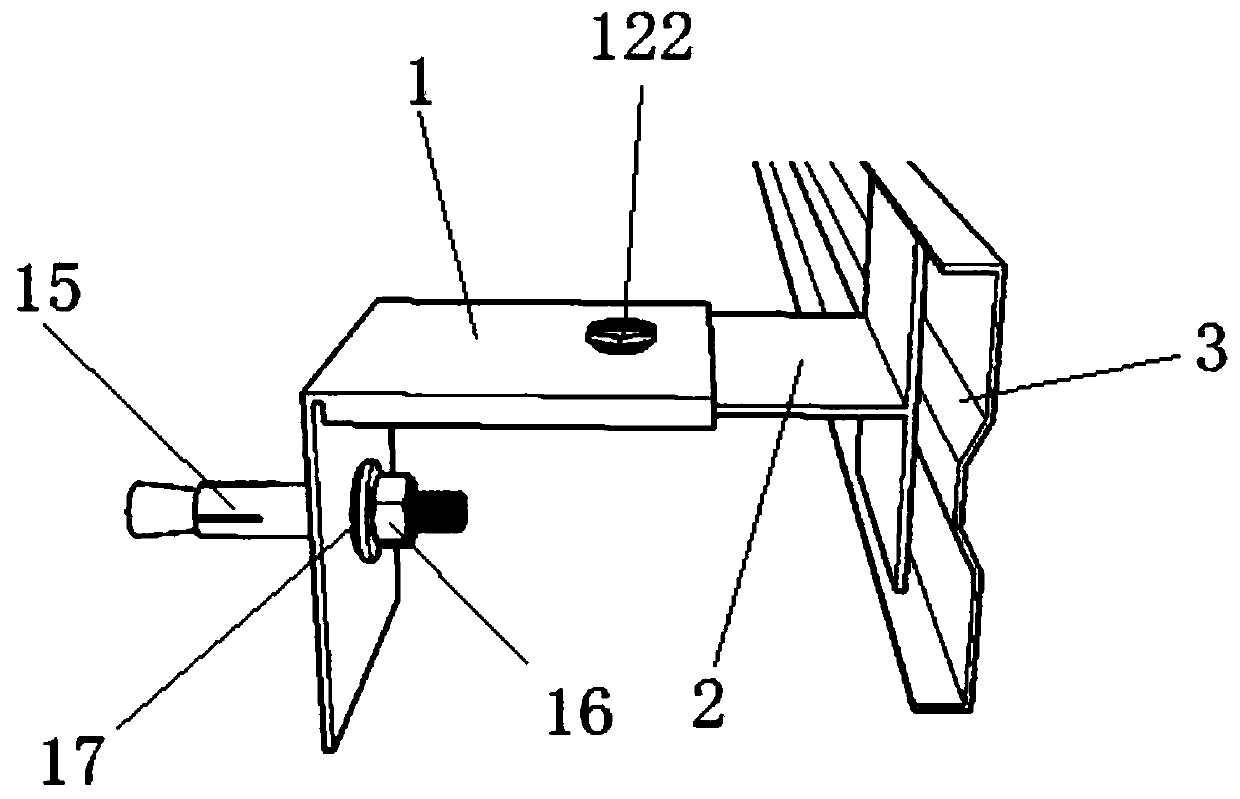

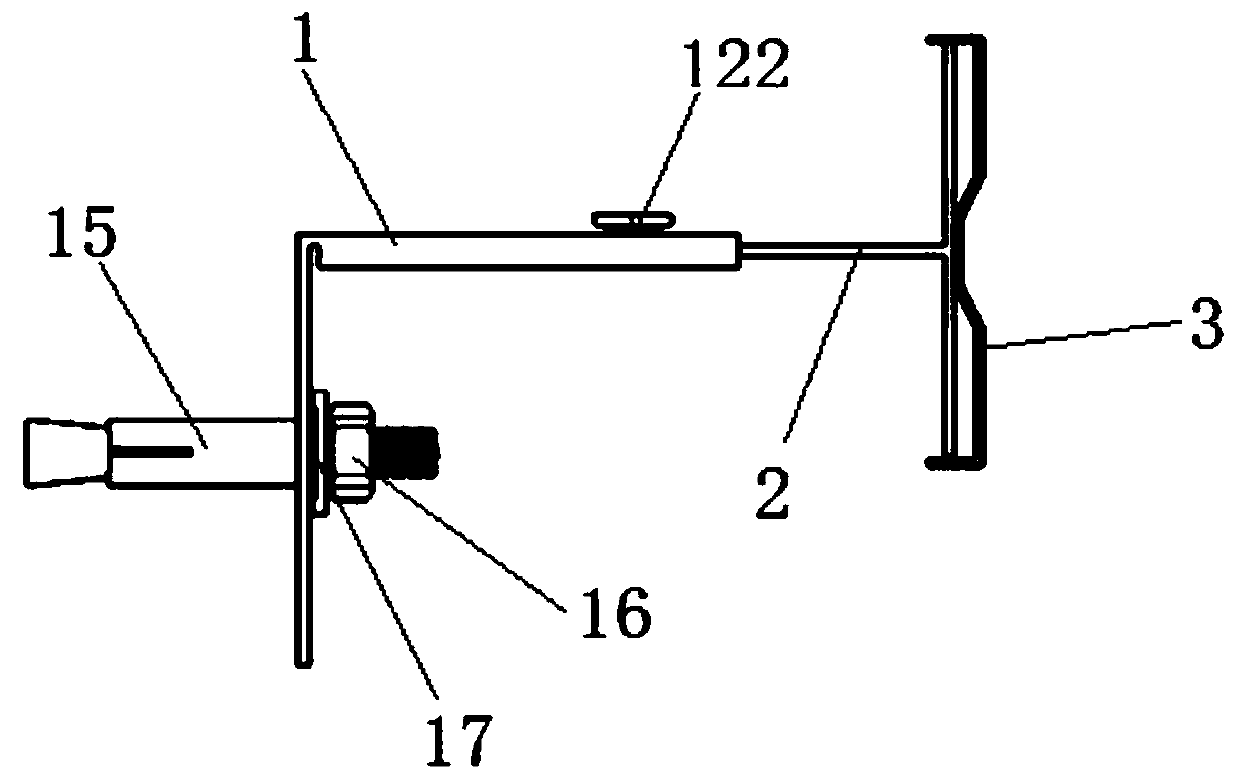

[0036] see Figure 1 to Figure 5 , the figure shows a prefabricated wall leveling installation structure provided by Embodiment 1 of the present invention, which includes a plurality of leveling installation mechanisms, and the leveling installation mechanism includes: a hook 1, which includes a first connecting plate 11 and the second connecting plate 12 connected thereto, the first connecting plate 11 and the second connecting plate 12 are perpendicular, and a connecting groove 13 is provided below the second connecting plate 12; the first connecting plate 11 is fixed to the wall 4; The telescopic connector 2 includes a telescopic connecting plate 21 and a articulated plate 22, the telescopic connecting plate 21 is inserted in the connecting groove 13, and the telescopic connecting plate 21 and the articulated plate 22 are perpendicular; the keel 3 has a side shape of “M ” type, the keel 3 is clamped and fixedly connected with the hitch plate 22; each keel 3 is installed wit...

Embodiment 2

[0044] see Figure 2 to Figure 4 , the figure shows a prefabricated wall leveling installation structure provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the second Both sides of the bottom of the connecting plate 12 are symmetrically provided with "L"-shaped side ears 14, and the side ears 14 and the second connecting plate 12 form a connecting groove 13; the second connecting plate 12 is provided with a locking hole 121, and the locking hole 121 is provided with The locking screw 122 is threadedly connected with the locking hole 121 . Through the setting of the above structure, the second connecting plate 12 and the telescopic connecting plate 21 can be quickly connected, and the telescopic connecting plate 12 can be firmly screwed through the locking hole 121 and the locking screw 122, thereby further improving the connection strength between t...

Embodiment 3

[0046] see Figure 6 to Figure 8 , the figure shows a prefabricated wall leveling installation structure provided by the third embodiment of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: side ears 14 Positioning grooves 141 are evenly distributed on the top, and the bottom of the free end of the telescopic connecting plate 21 is provided with positioning protrusions 211, and the positioning protrusions 211 are snapped into the positioning grooves 141; The shape and size match; the thickness of the positioning protrusion 211 is smaller than the thickness of the side ear 141 , and the overall thickness of the telescopic connecting plate 21 and the positioning protrusion 211 is less than the depth of the connection groove 13 . Through the setting of the above-mentioned structure and the setting of the positioning groove 141, the telescopic connecting plate 21 can be position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com