A hydraulic underwater stirring device

A stirring device and hydraulic technology, which is applied in biochemical cleaning devices, enzymatic/microbiological devices, biomass post-processing, etc., can solve the problems of waste of the environment and pollution of the reaction solution, minimize the dead angle of stirring, and reduce the failure rate. , to avoid the effect of crusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

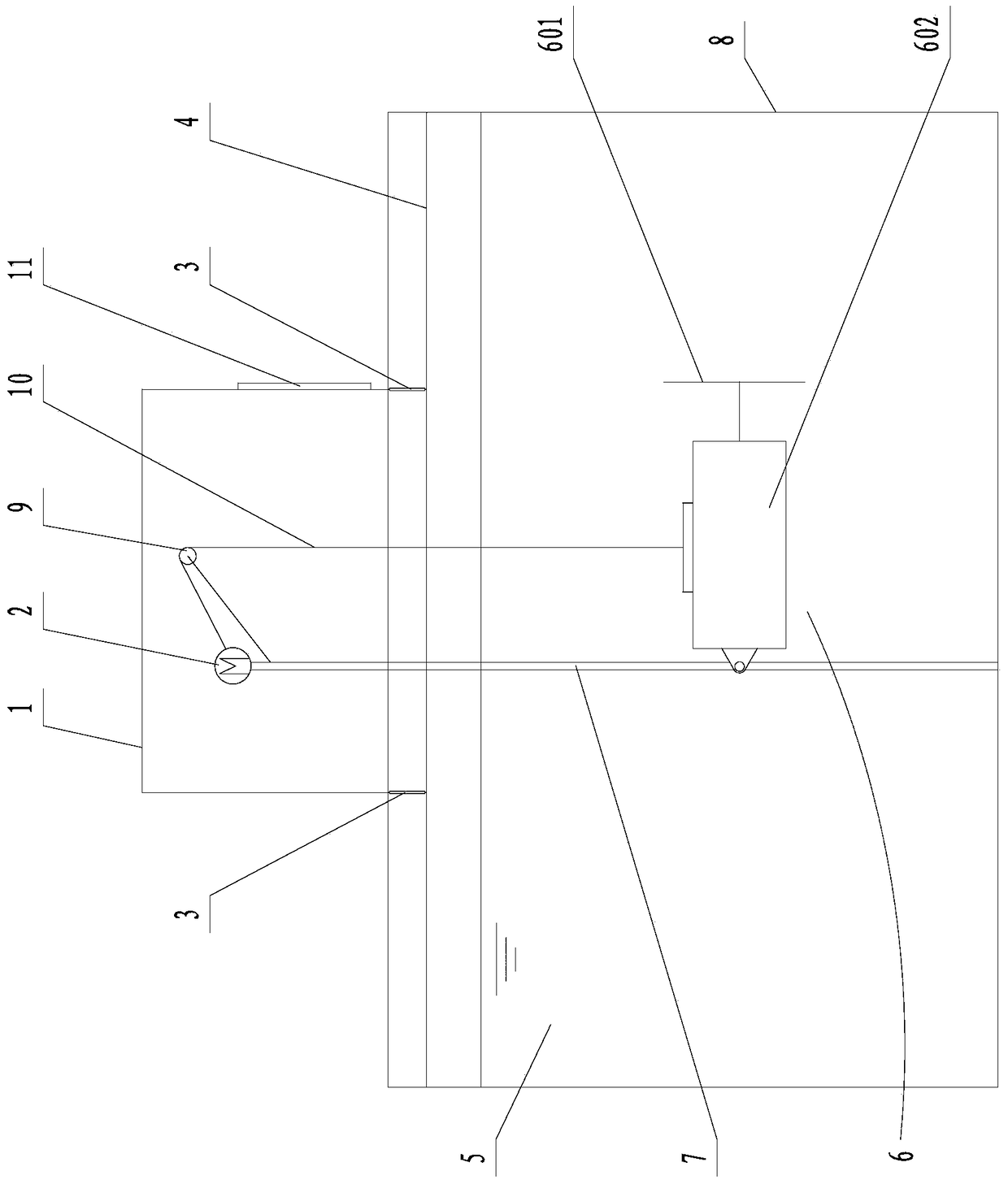

[0016] Such as figure 1 As shown, the present invention includes a sealed box 1, a motor 2, a telescopic hydraulic cylinder 3, a gas protection curtain 4, a stirring body 6, a supporting column 7, a reactor 8, a pulley 9 and a traction rope 10, wherein the reactor 8 is filled with fermentation Liquid 5, the fermented liquid 5 of the present invention can be anaerobic fermentation raw materials such as livestock manure, agricultural waste (straw) or industrial waste (distiller's grains).

[0017] The top of the reactor 8 has a hole, and a telescopic hydraulic cylinder 3 is installed on the lower surface of the top; there are two telescopic hydraulic cylinders 3 of the present invention, and one end of each telescopic hydraulic cylinder 3 is fixed on the lower surface of the reactor 8 top. One end is an output end, and a gas protection curtain 4 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com