Self-locking structure of stator protector and plastic package motor

A self-locking structure and protector technology, applied in structural connection, electrical components, electromechanical devices, etc., can solve problems such as product quality problems, low operation efficiency, product quality errors, etc., to reduce product manufacturing costs, improve production efficiency, The effect of eliminating product quality defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present application is further described in conjunction with the following examples.

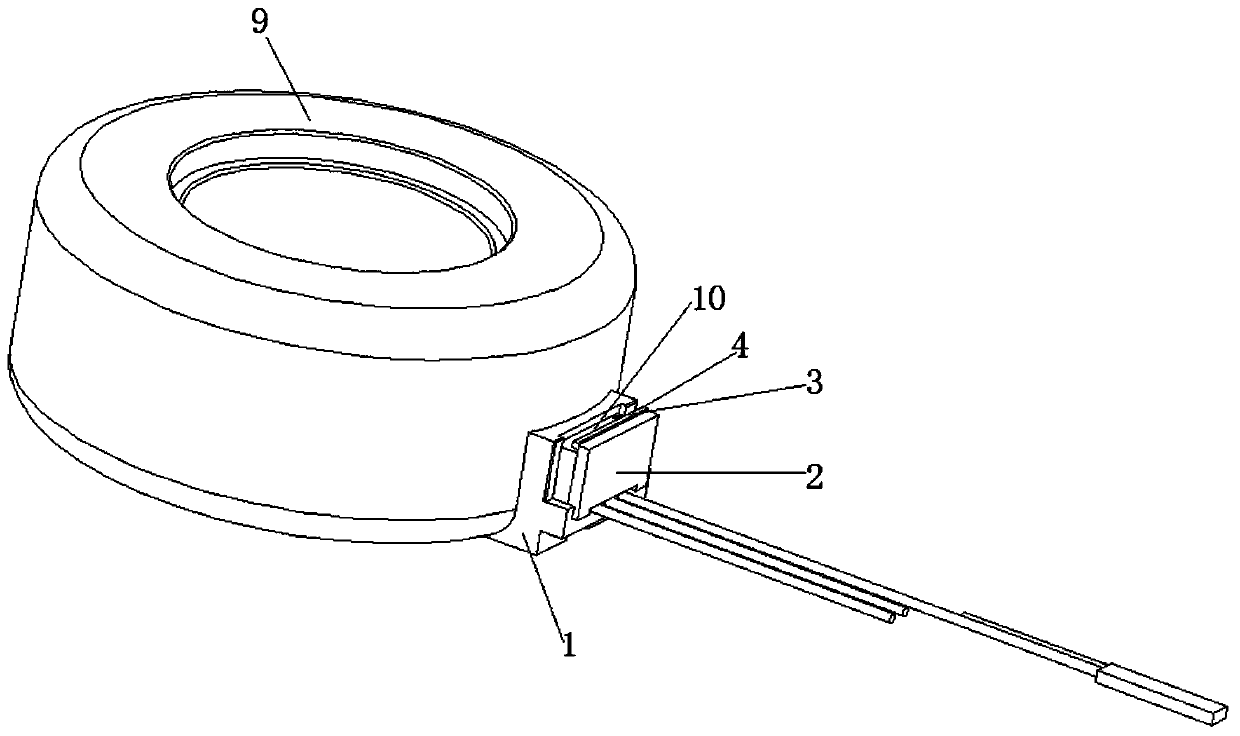

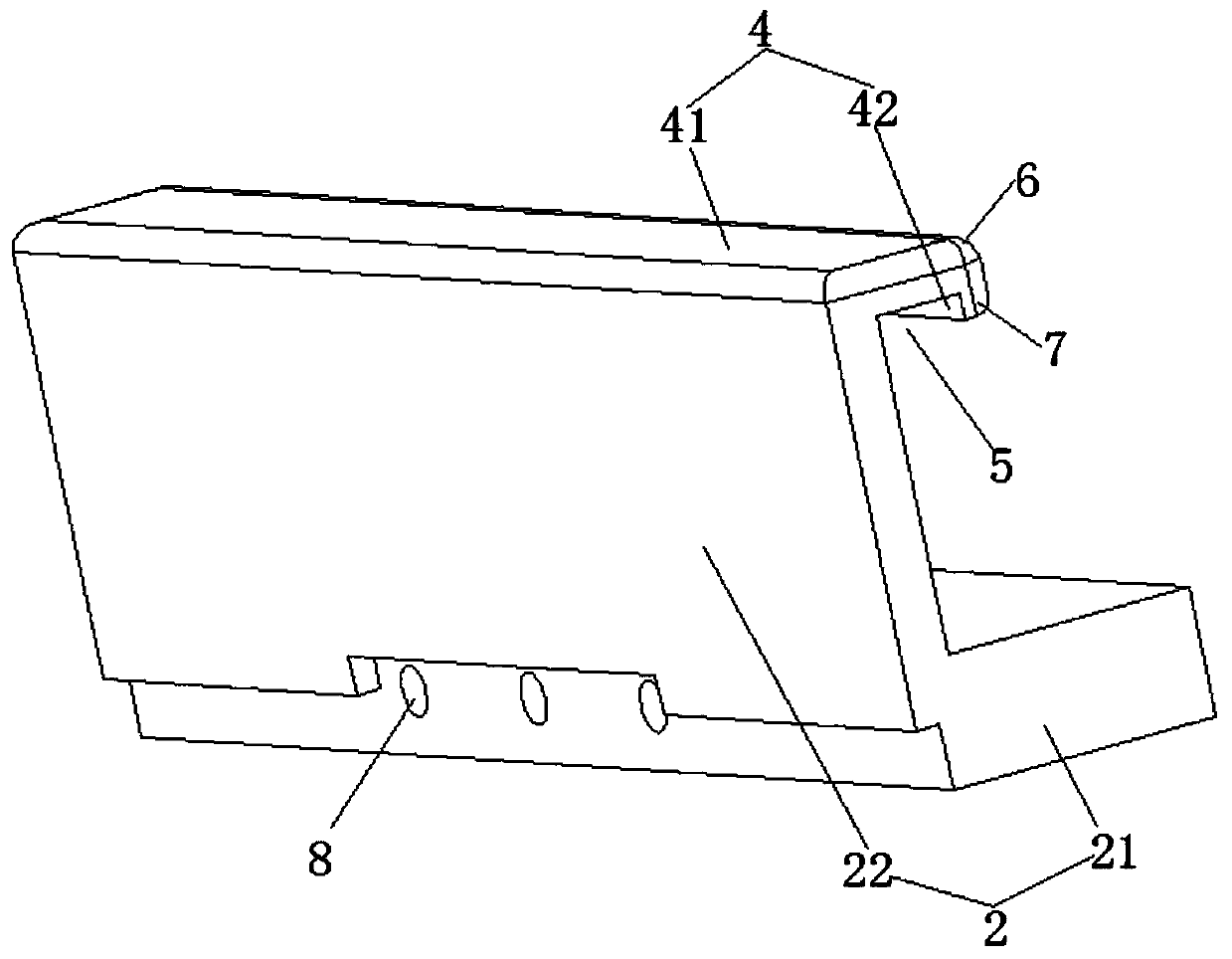

[0029] Such as Figure 1 to Figure 2 , a stator protector self-locking structure, including a stator boss 1, a protective baffle 2 and a self-locking clip 4. Wherein, the protective baffle 2 is arranged on the stator boss 1 and forms a mounting groove 3 for placing the stator protector 10 with the stator boss 1; the self-locking clip 4 is arranged on the protective baffle 2; the self-locking part 4 locks and fixes the stator protector 10 after the stator protector 10 is inserted into the installation groove 3 .

[0030] The self-locking structure of the stator protector is provided with a self-locking clip 4 on the protective baffle 2, and the stator protector 10 is embedded in the installation groove 3 from top to bottom to ensure that the stator protector 10 is installed without displacement. The self-locking clip part 4 locks and fixes the stator protector 10, restricting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com