Method for sharing waterproof lamp shell by different optical systems

A technology for optical systems and lamps, which is applied in the direction of air-proof/waterproof devices, devices used in theaters and circuses, electric light sources, etc. It can solve the problems of moving the top lens of lamps, etc., and achieve the effect of saving product manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

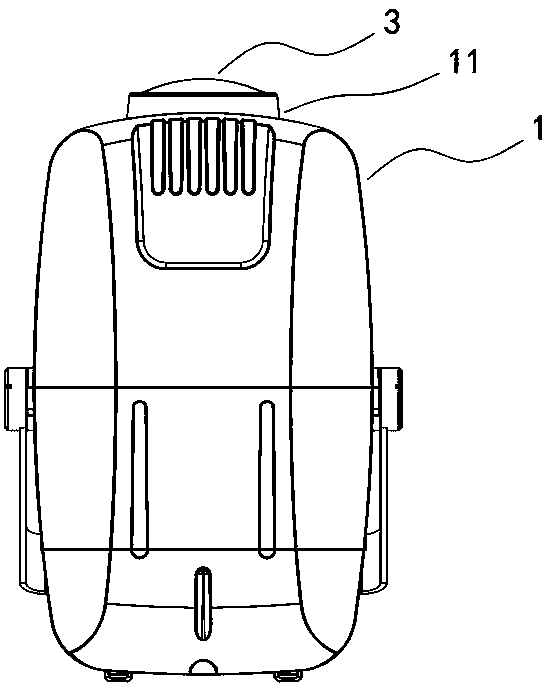

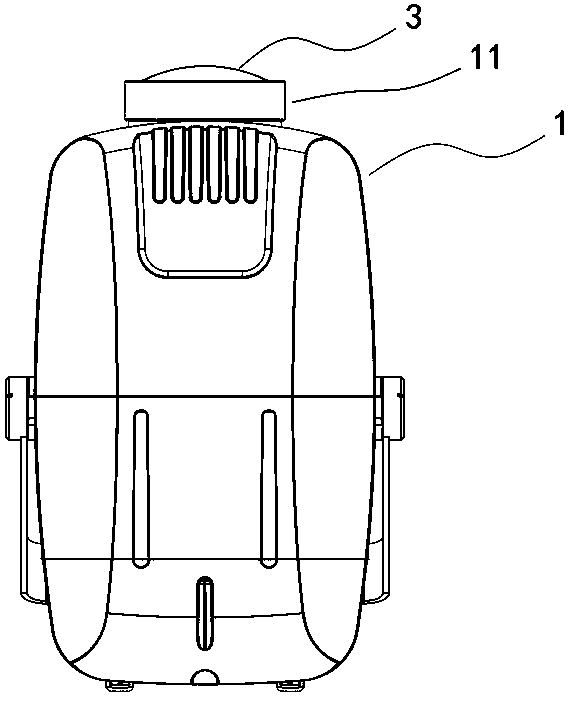

[0024] as attached figure 1 As shown, a method of sharing a set of waterproof lamp casings with different optical systems, the top of the waterproof lamp casing (1) includes an extension part (11) in the direction of light emission, and a light emission lens (3) is fixed on the extension part (11); when The optical system of this lamp becomes longer. If in order to change the lighting effect, the number of components of the original optical system needs to be increased or reduced, and the light-emitting lens (3) needs to be moved up to meet the new optical system, the existing waterproof lamp housing can be replaced. (1) Processing; the processing method is:

[0025] (1) Confirm whether the extension part (11) blocks light in the new optical system; if it blocks light, first process the extension part (11) to reduce the height of the extension part (11) to the state of not blocking light; if not If the light is blocked, proceed directly to step (2);

[0026] (2) According to...

Embodiment 2

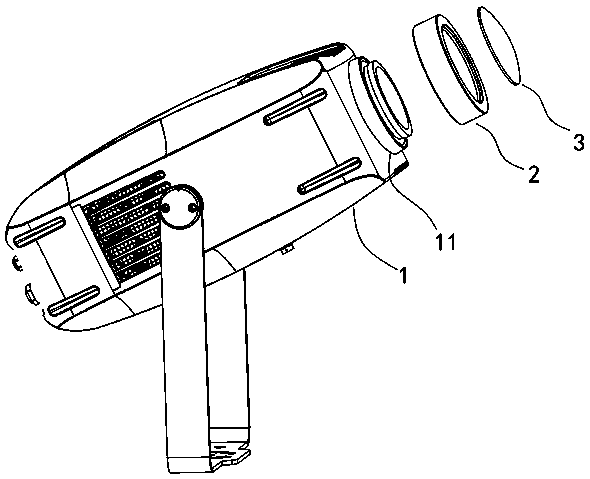

[0033] A method for sharing a set of waterproof lamp shells with different optical systems. The top of the waterproof lamp shell (1) includes an extension part (11) in the light emitting direction, and a light emitting lens (3) is fixed on the extension part (11); Initially, the waterproof lamp shell (1) was designed as a height-adjustable structure for the light-emitting lens (3). This design can avoid the need to increase or decrease the number of components of the original optical system in order to change the lighting effect, thereby changing the length of the optical system Sometimes, the original waterproof lighting shell cannot be shared, but a new mold must be opened. The height-adjustable design method of the light-emitting lens (3) is:

[0034] (1) The extension part (11) is designed as a hollow structure, and the outer wall of the extension part (11) is provided with screw teeth (12);

[0035] (2) Add a new lens cover (2), the inner wall of the lens cover (2) has s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com