An edge strip embossing robot equipment and embossing method

An edge banding and robot technology is applied in the field of edge banding embossing, which can solve the problems of heavy equipment and increased production cost of equipment, and achieve the effects of low replacement cost, simple structure, and reduced burden on the overall quality of the equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

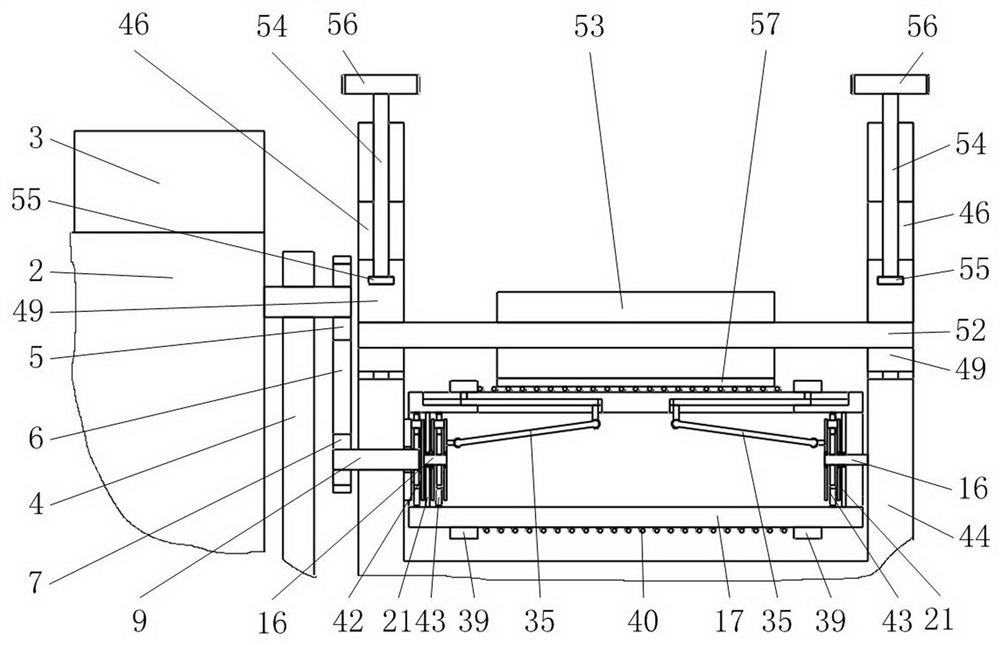

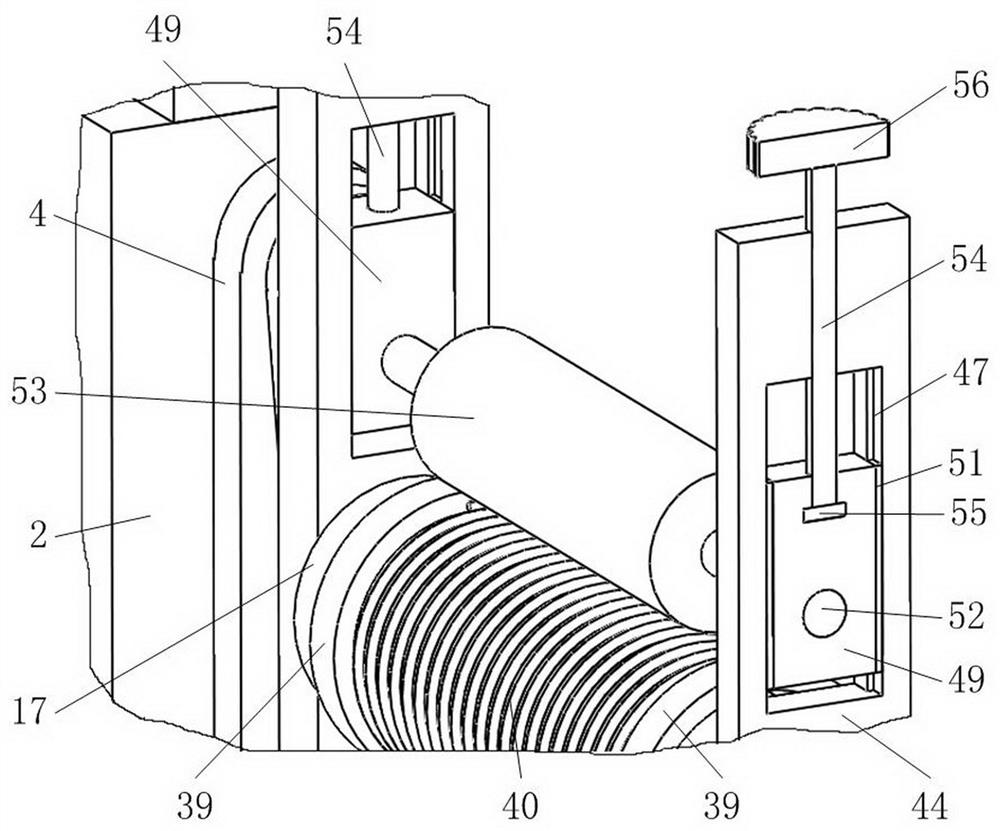

[0033] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

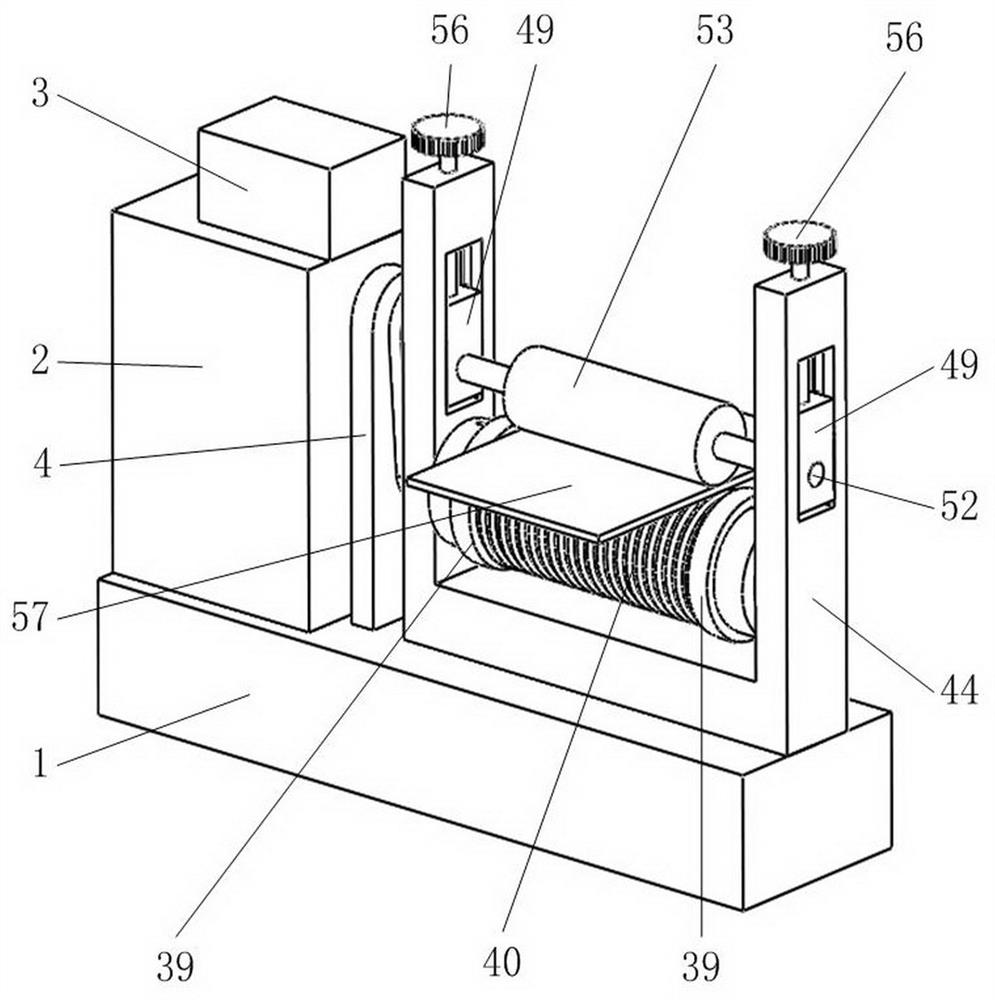

[0034] Such as figure 1 , 2 As shown, it includes an electric drive module 2, a roller mechanism 8, a roller B53, and a U-shaped seat 44, among which figure 1 , 2, 3, the roller mechanism 8 driven by the electric drive module 2 is installed between the two U-shaped seats 44; the driven roller B53 that can manually adjust the height up and down is installed between the two U-shaped seats 44, And the roller B53 is located directly above the roller mechanism 8; the roller mechanism 8 cooperates with the roller B53, and the roller mechanism 8 embosses the lower surface of the edge strip 57 passing between the roller mechanism 8 and the roller B53, The embossed lines on the edge ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com