Production process and preparation method of wood-plastic product with natural wood grains on whole body

A wood-plastic product, a natural technology, applied in the production process and preparation field of wood-plastic products with natural wood grain throughout, can solve the problems of uneven surface, poor applicability, and single wood texture of wood-plastic boards, and achieve Increase the process and processing costs, avoid the effect of toxic and harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

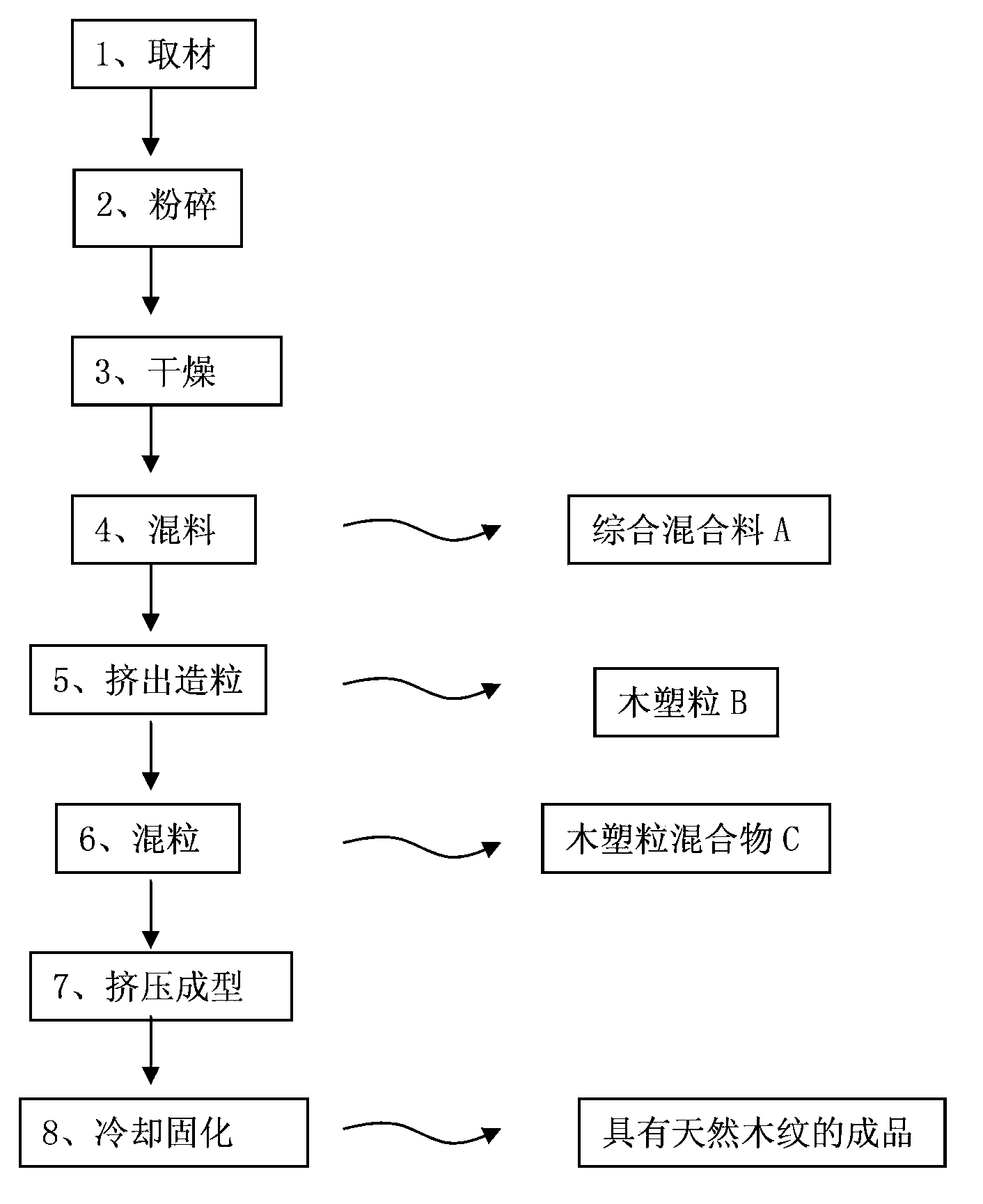

Method used

Image

Examples

example 1

[0030] Example 1: Wood-plastic products imitating cedar wood grain

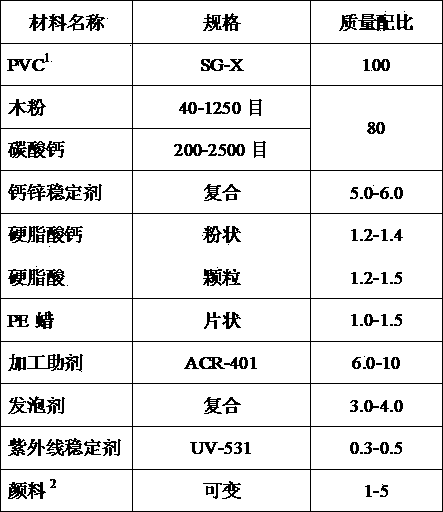

[0031] Table 2: Raw material ratio table

[0032]

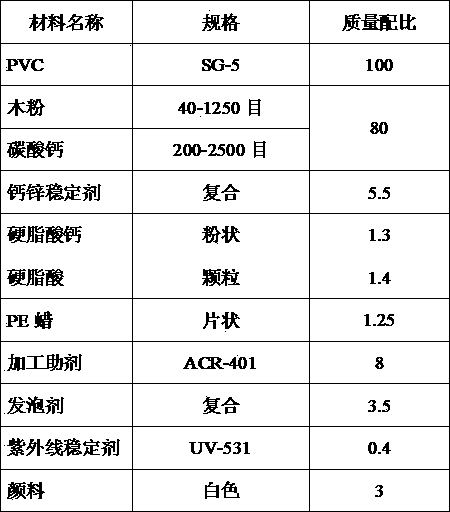

[0033] Table 3: Raw material ratio table

[0034]

[0035] Table 4: Raw material ratio table

[0036]

[0037] Table 5: Raw material ratio table

[0038]

[0039] According to the raw material ratio tables in Table 2, Table 3, Table 4 and Table 5, the ingredients were mixed, and then they were mixed and extruded to obtain white particles, yellow particles (2 specifications) and orange particles respectively. The four kinds of particles are mixed according to the mass ratio of 11:0.1:0.1:0.2, and then extruded to obtain a wood-plastic product imitating cedar wood grain.

example 2

[0040] Example 2: Wood-plastic products imitating red cherry wood grain

[0041] Table 6: Raw material ratio table

[0042]

[0043] Table 7: Raw material ratio table

[0044]

[0045] Table 8: Raw material ratio table

[0046]

[0047] Table 9: Raw material ratio table

[0048]

[0049] According to the raw material ratio tables in Table 6, Table 7, Table 8 and Table 9, the ingredients were mixed, and then they were mixed and extruded to obtain white particles, yellow particles and red particles (2 specifications). The four kinds of particles were mixed according to the mass ratio of 10: 2: 1: 2, and then extruded to obtain wood-plastic products imitating red cherry wood grain.

example 3

[0050] Example 3: Wood-plastic products imitating the wood grain of golden sandalwood

[0051] Table 10: Raw material ratio table

[0052]

[0053] Table 11: Raw material ratio table

[0054]

[0055] Table 12: Raw material ratio table

[0056]

[0057] Batching was performed according to the raw material ratio tables in Table 10, Table 11 and Table 12, and then they were mixed and extruded to obtain white particles, yellow particles and orange particles respectively. The three kinds of particles are mixed according to the mass ratio of 6: 2: 2.5, and then extruded to obtain wood-plastic products imitating the wood grain of golden sandalwood.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com