Main curvature calculation method for contact rolling path of planetary rolling column lead screw pair

A technology of planetary rollers and calculation methods, which is applied to complex mathematical operations, transmission devices, belts/chains/gears, etc., and can solve problems such as the accuracy of which needs to be verified, the structure of the planetary roller screw pair, and errors are not considered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

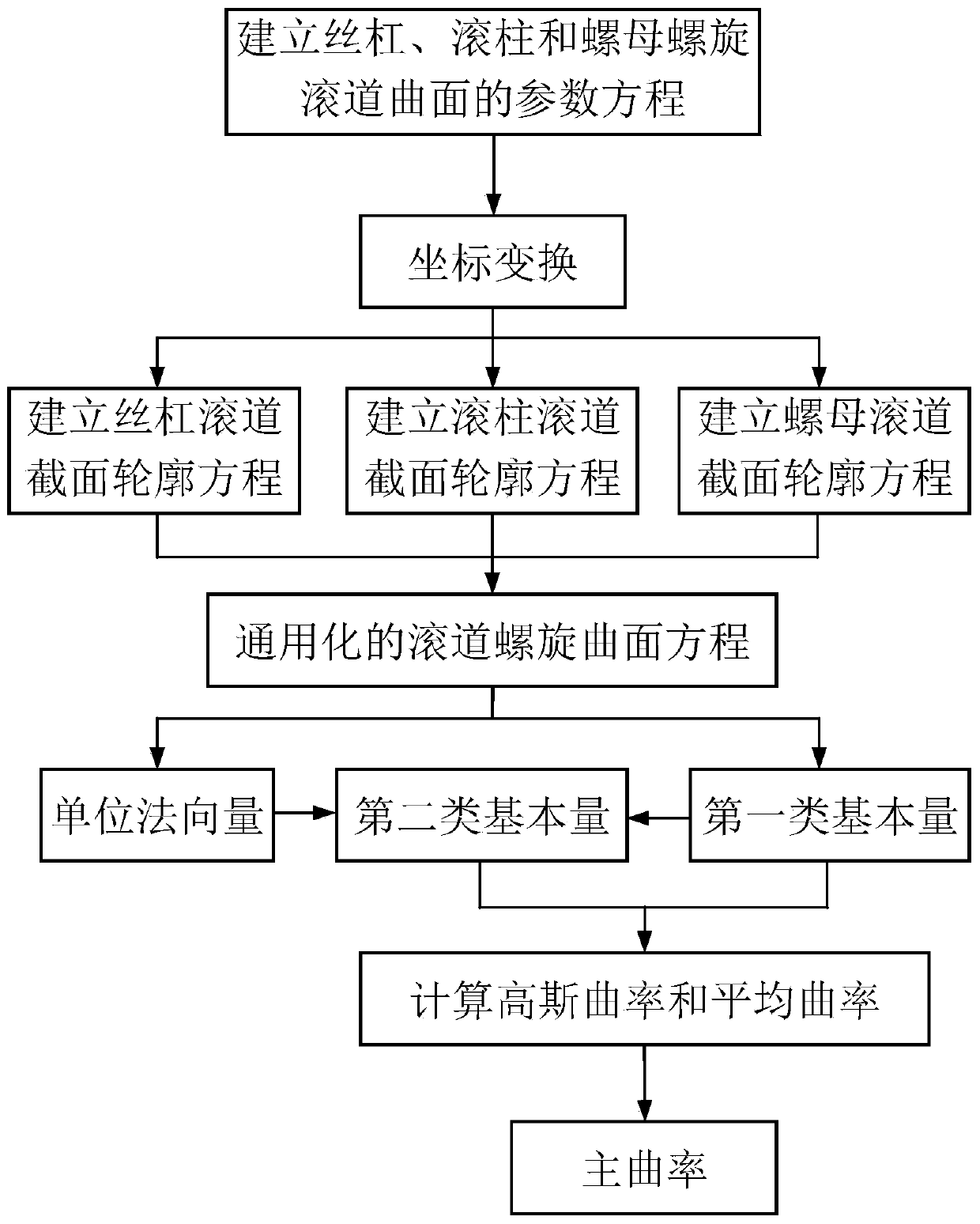

[0114] Such as figure 1 As shown, a method for calculating the main curvature of the contact raceway of a planetary roller screw pair includes the following steps:

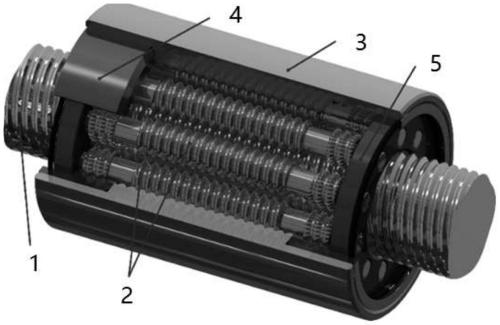

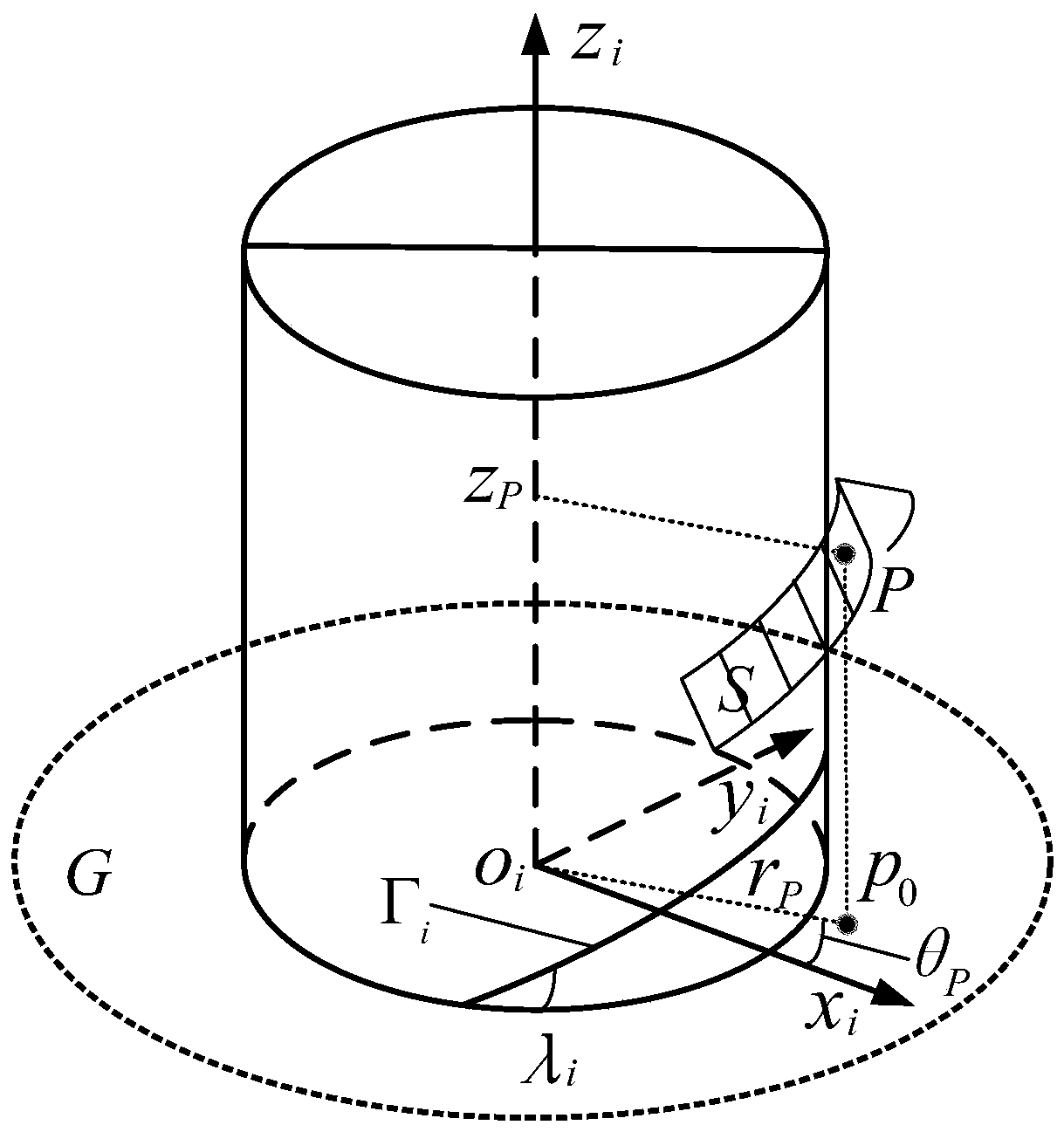

[0115] S1 planetary roller screw pair mainly includes screw 1, roller 2, nut 3, inner ring gear 4 and cage 5, such as figure 2 As shown, among them, the contact raceways of screw 1, roller 2 and nut 3 are used to transmit their motion and power. According to the characteristics of the spiral raceway surface of the screw 1, roller 2 and nut 3 in the planetary roller screw pair, for any point P on the spiral raceway surface S of the screw 1, roller 2 and nut 3, as image 3 As shown, the parametric equation of the spiral raceway surface is established, as shown in formula (Ⅰ):

[0116] F=[r P cosθ P , r P sinθ P , f(r P , θ P )], (r P , θ P )∈G(I);

[0117] Among them, r P and θ P is the parameter coordinate of the surface S, the plane o i x i the y i The polar coordinates of any point in the element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com