a current transformer

A current transformer, high potential technology, applied in the direction of inductors, circuits, transformers, etc., can solve the problems of long intermediate potential shielding length, poor electric field improvement effect of current transformers, coaxial grounding pipes, etc., to simplify assembly operations , The effect of eliminating assembly operation and good shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

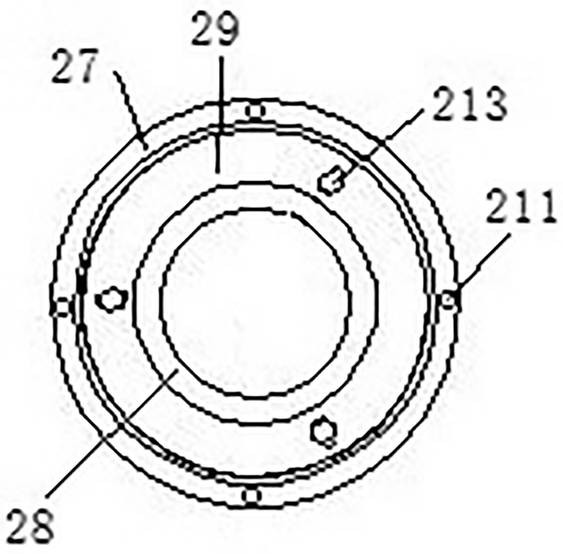

[0034] Specific embodiment 1 of the current transformer of the present invention: as figure 2 As shown, it includes a base 21, a sleeve 22, and a cylinder 23. The sleeve 22 is vertically fixed on the base 21. The cylinder 23 is located at one end of the sleeve 22 facing away from the base 21, and its axis is the same as that of the sleeve 22. Vertically, the cylinder body 23 is provided with a secondary coil 24, the secondary coil is wrapped with a secondary coil shielding cylinder 25, the lower part of the secondary coil shielding cylinder 25 is fixed with a shielding cover 216, and the middle part of the shielding cover 216 is provided with a spring finger.

[0035] The casing 22 is provided with a grounding pipe 26, the grounding pipe 26 is connected to the base 21 by metal bolts through the flange at the lower end, and the upper end is inserted into the spring contact finger provided in the middle of the shielding case 216 to conduct conductive connection with the shieldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com