Cloth clip on cloth stretching frame

A technology of stretch cloth and cloth clip, which is applied in the field of quilting machines, can solve problems such as interference and trouble, and achieve the effect of facilitating structural adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

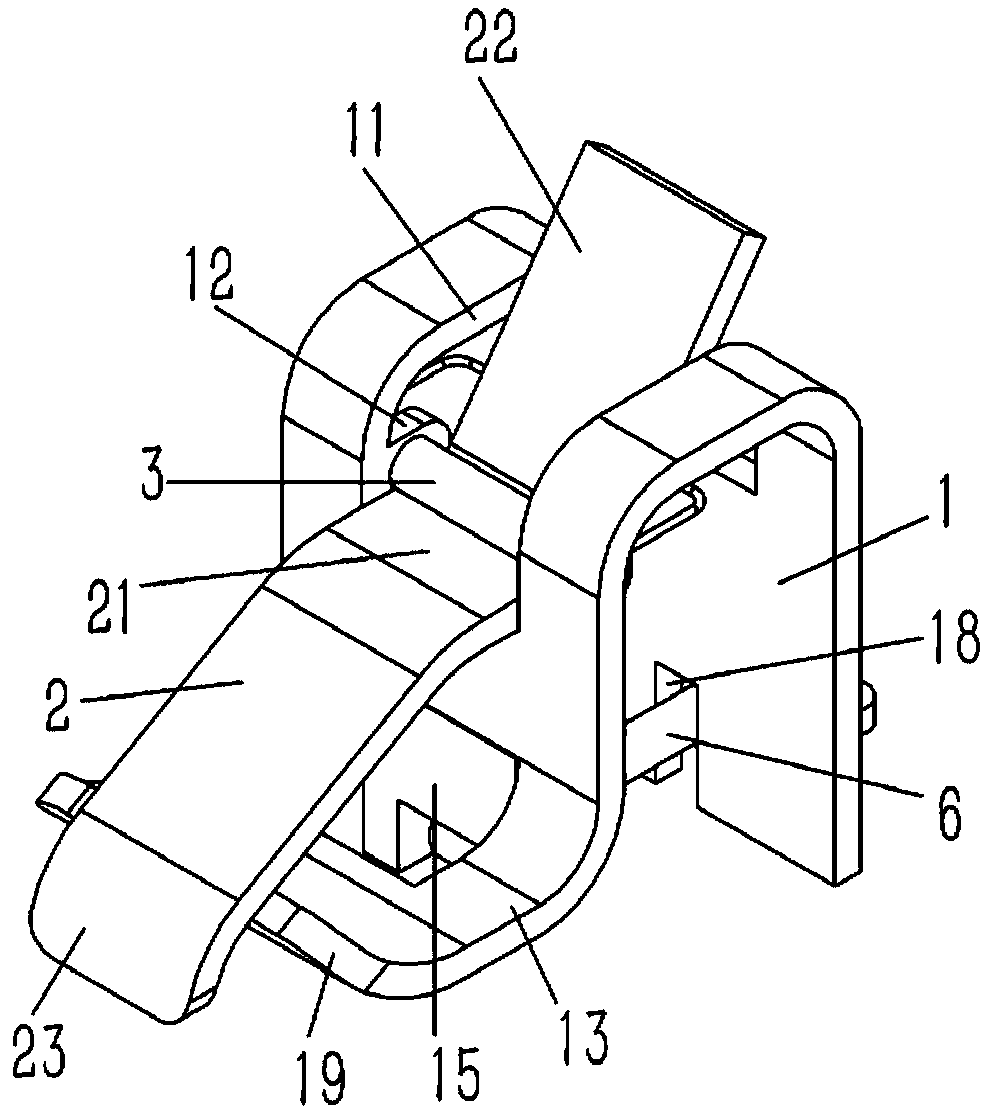

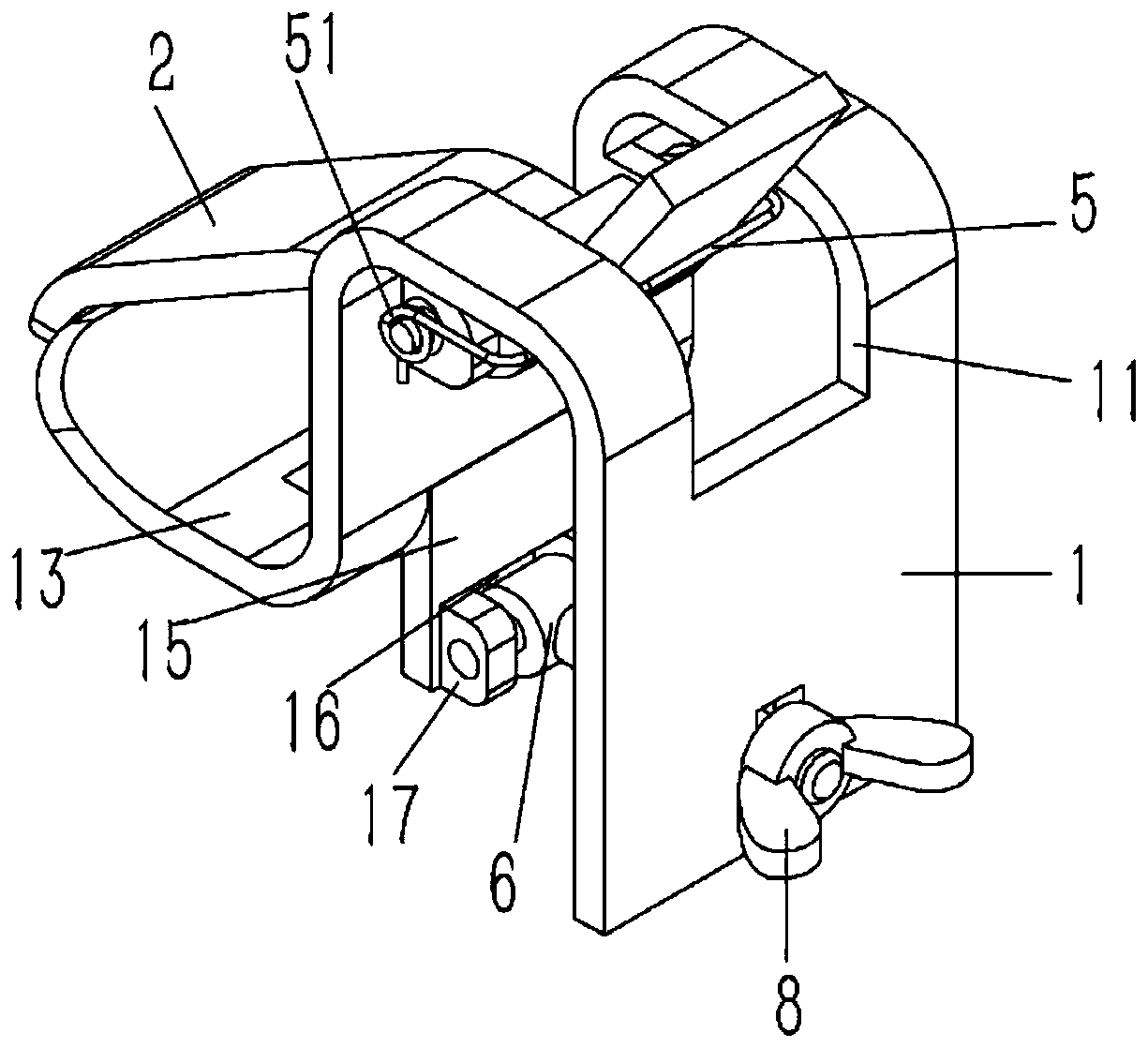

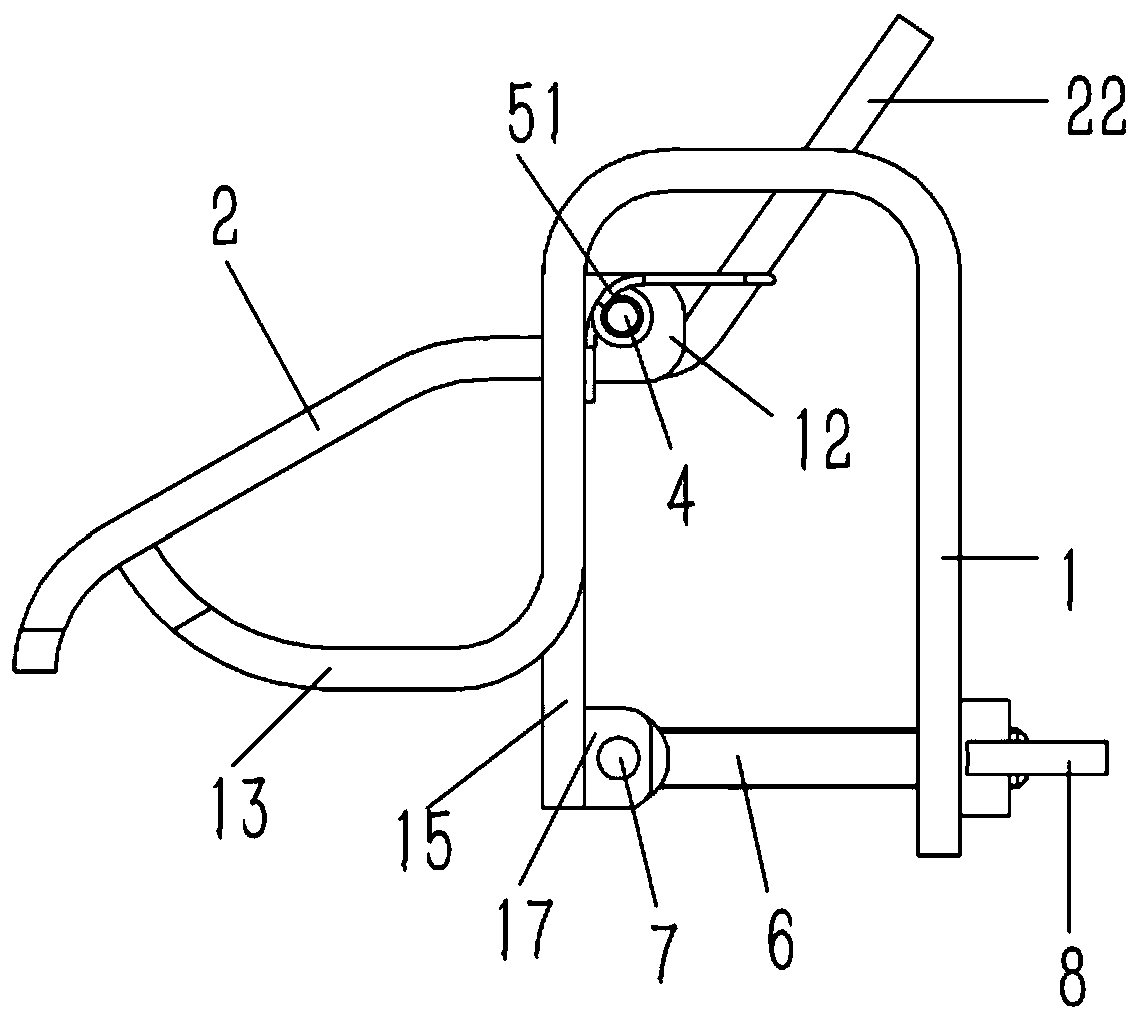

[0020] Example: see Figures 1 to 4 As shown, a cloth clip on a stretcher frame includes a "冂"-shaped support plate 1, the support plate 1 is composed of a vertical front panel, a rear panel and a horizontal top plate, and the side edge of the front end of the support plate 1 is curved A horizontal lower splint 13 is folded, and the upper end of the support plate 1 is formed with a first slot 11 that runs through the front and rear end faces of the support plate 1. The front panel of the support plate 1 on both sides of the first slot 11 is bent and formed with a rearward Extended first lug 12; the upper side of the lower splint 13 is provided with an oblique upper splint 2, the upper end of the upper splint 2 is formed with a horizontal transition plate 21, and the rear end of the transition plate 21 is formed with an oblique pressure plate 22 , the pressing plate 22 and the transition plate 21 are all inserted in the first slot 11 of the support plate 1, and the upper end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com