Large-deformation water stop device and gate valve

A water stop device and large deformation technology, applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve problems such as the inability to adapt to the large deformation requirements of the gate, the separation of water stop parts, and water leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

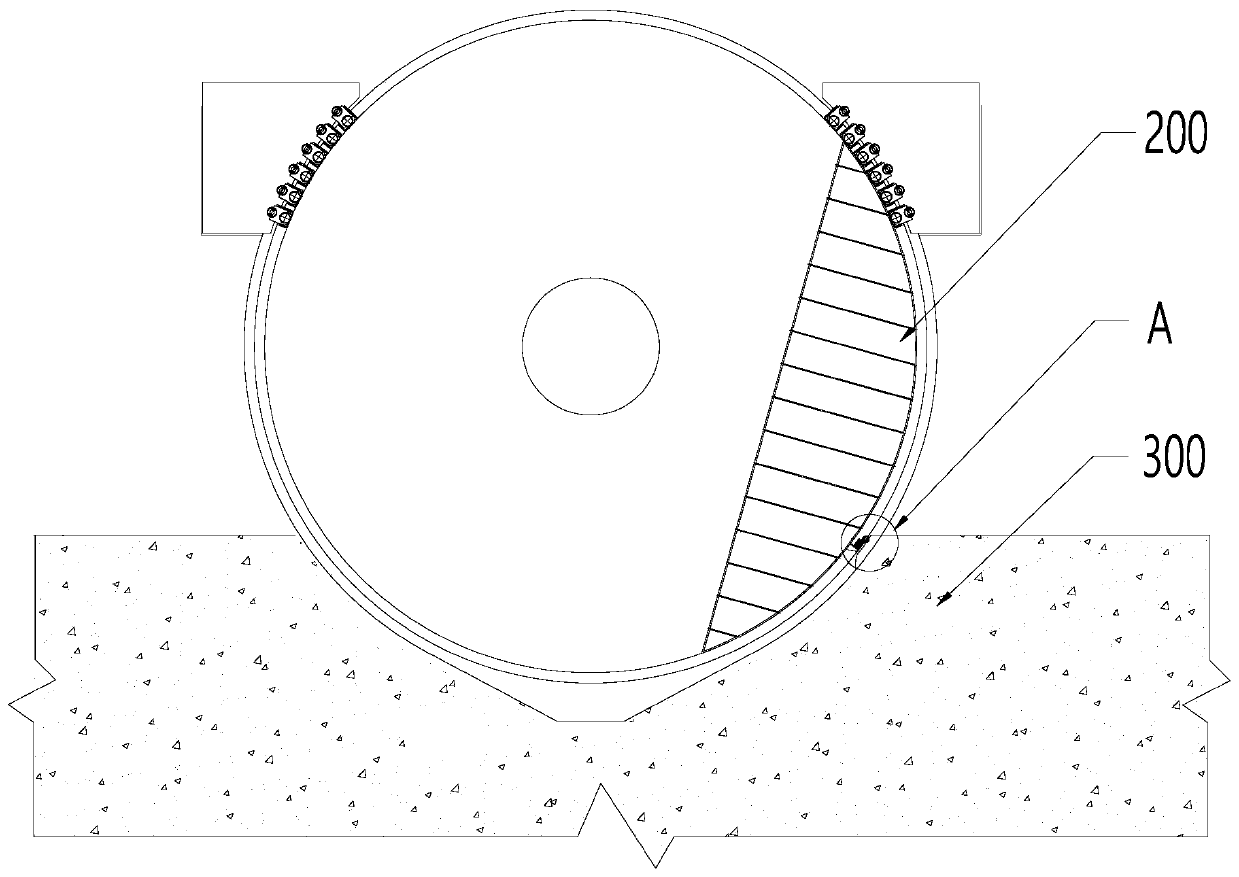

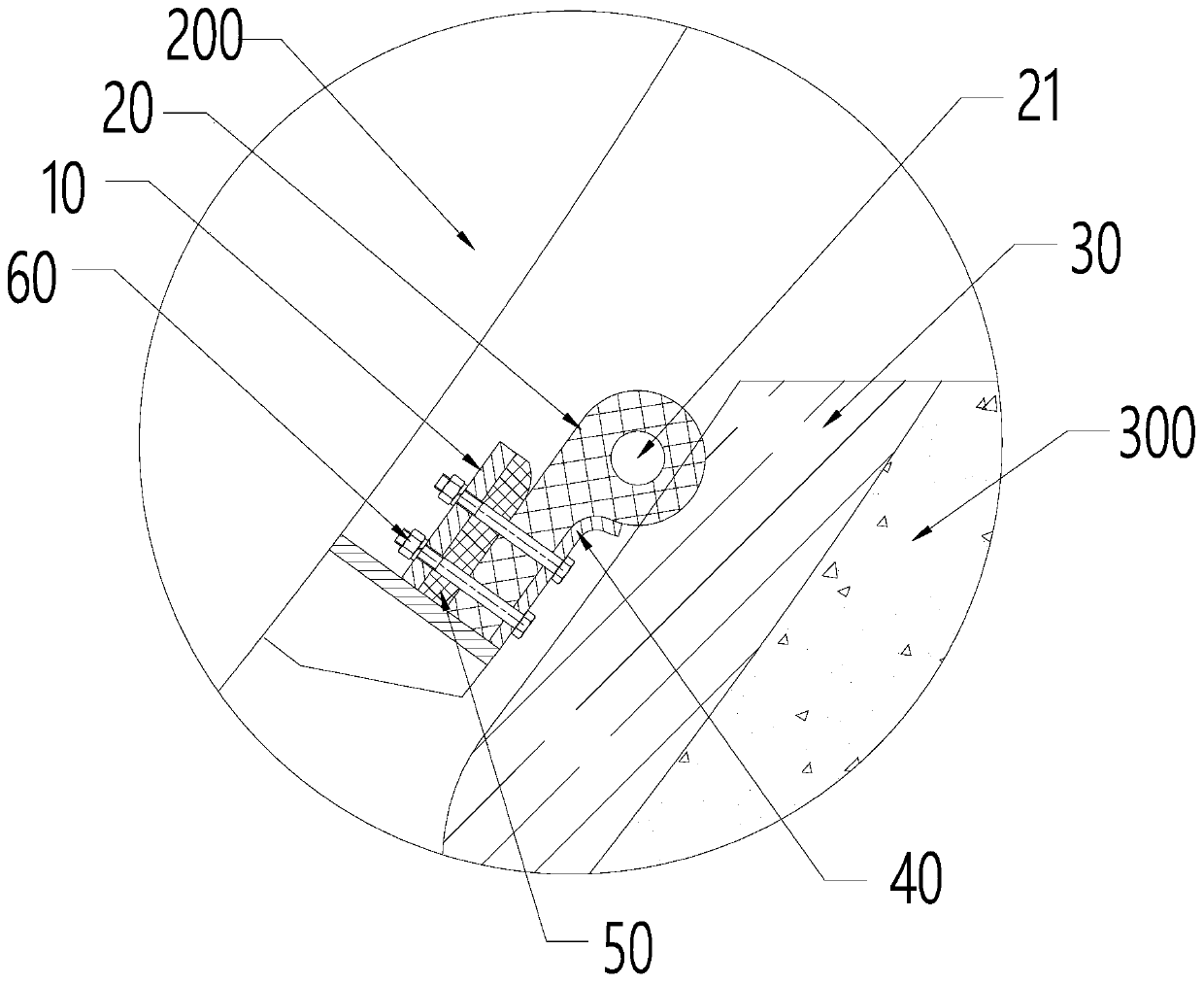

[0039] Such as Figure 1-Figure 5 As shown, this embodiment provides a large deformation water stop device, including: a bracket 10, a flexible water stop 20 and a water stop embedded part 30, the flexible water stop 20 is installed on the bracket 10, and the bracket 10 is used to connect with the gate The water-stop embedded part 30 is set relative to the gate, and the water-stop embedded part 30 is embedded in the bottom sill 300 of the gate system. There is a gap between the water-stop embedded part 30 and the gate. When the gate 200 is closed, the flexible water-stop part 20 It is located between the gate 200 and the water-stop embedded part 30 .

[0040] The flexible water stop 20 includes a first section 22 and a second section 23 connected to each other, the thickness of the first section 22 is greater than the thickness of the second section 23, the first section 22 is provided with a through hole 21 along the length direction, the first section 22 The maximum thickne...

no. 2 example

[0062] A gate system includes a gate and the large-deformation water-stop device provided in the above-mentioned first embodiment, and the bracket in the large-deformation water-stop device is connected to the gate.

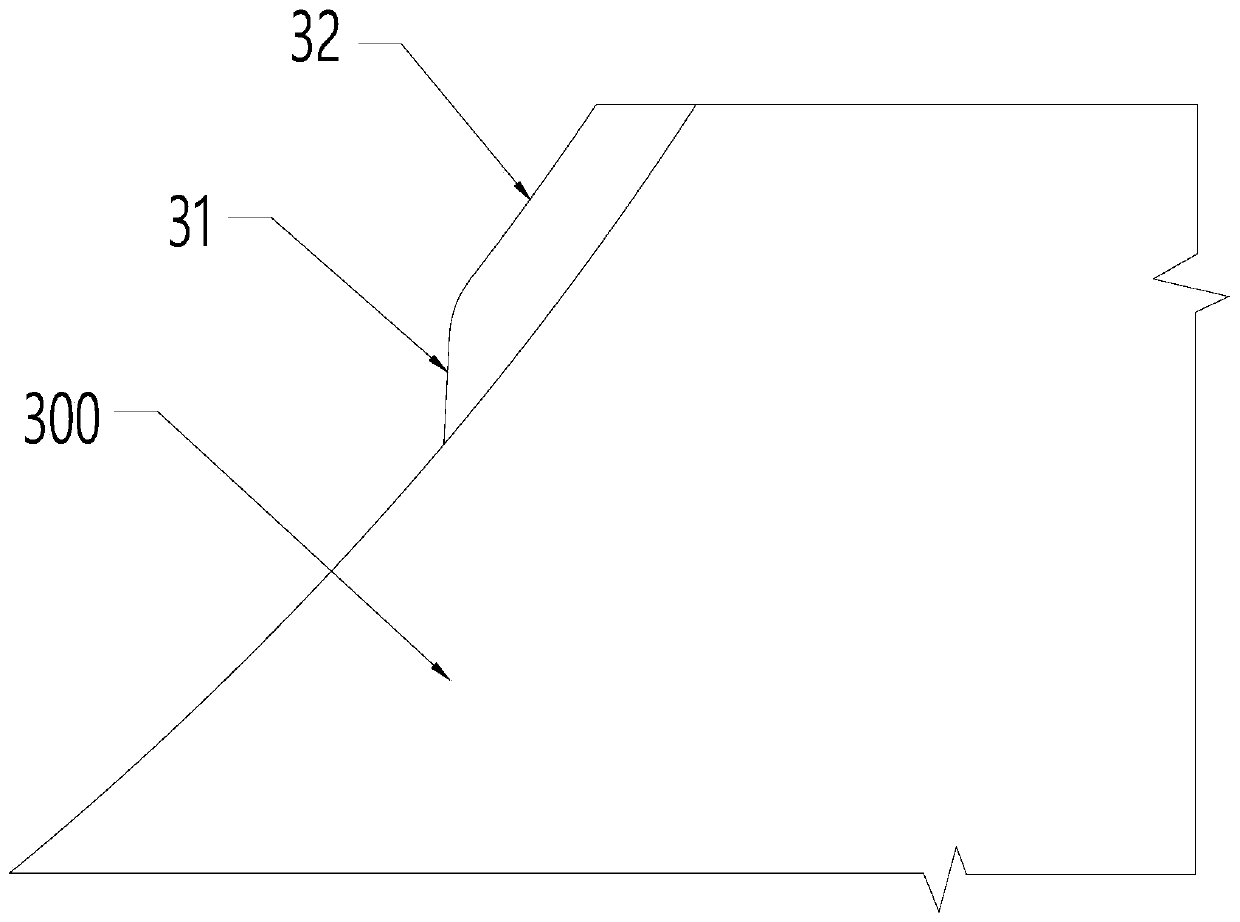

[0063] Further, the gate system also includes a sill 300, which is located at the bottom of the gate, and the sill 300 includes a concrete structure layer, and the water-stop embedment 30 is pre-embedded in the concrete structure layer of the sill 300, and the water-stop embedment 30 Part of the area protrudes outside the concrete structure layer so as to be in contact with the flexible water stop 20. When the gate is in the open state, the flexible water-stop member 20 is separated from the water-stop embedded member 30; when the gate is in the closed state, part of the gate protrudes from the bottom sill 300, and the flexible water-stop member 20 is in contact with the water-stop embedded member 30 to realize the water-stop seal. water.

[0064] Furthermore, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com