Transverse partition plate of column and column with same

A technology for diaphragms and columns, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of welding deformation of steel pipes, difficulty in ensuring the straightness of columns, etc., achieve uniform force on the whole, ensure the compactness of columns, and have a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

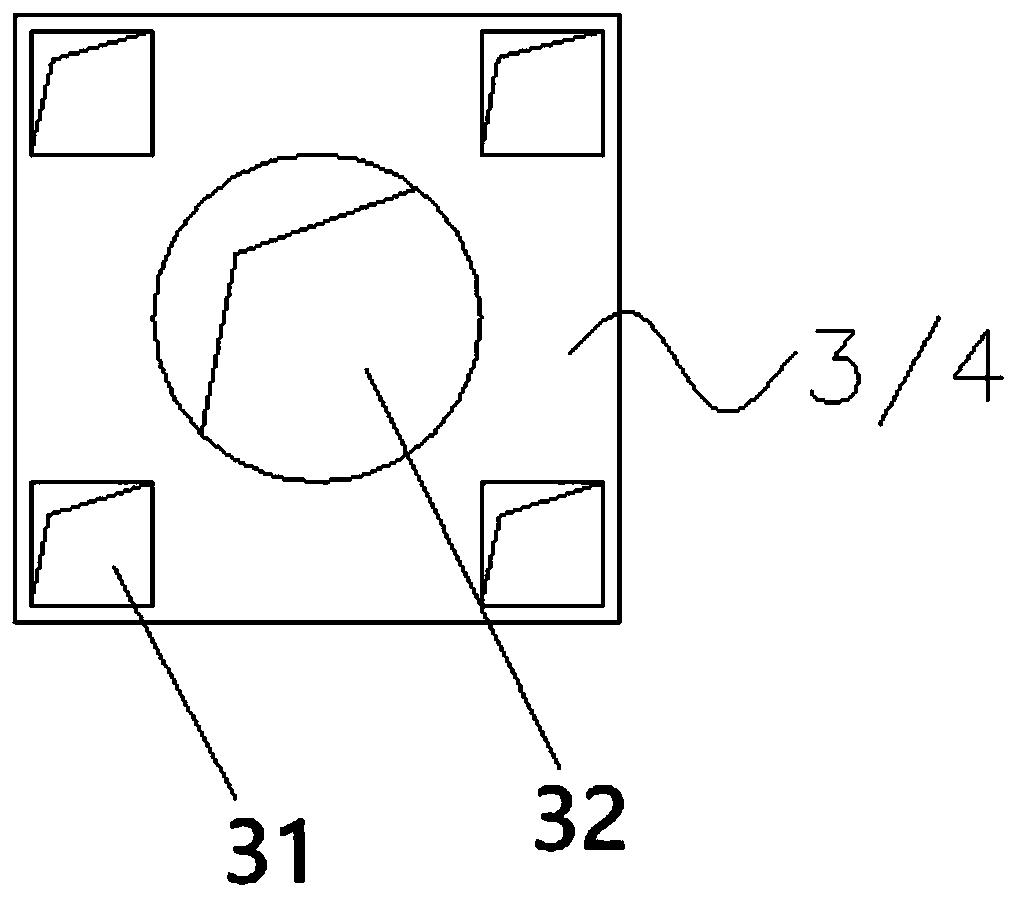

[0029] Such as figure 1 As shown, the present invention proposes a diaphragm 3 / 4 of a column, and the diaphragm 3 / 4 is preset with a through hole 32 for pouring concrete and a hole 31 for passing through a steel pipe.

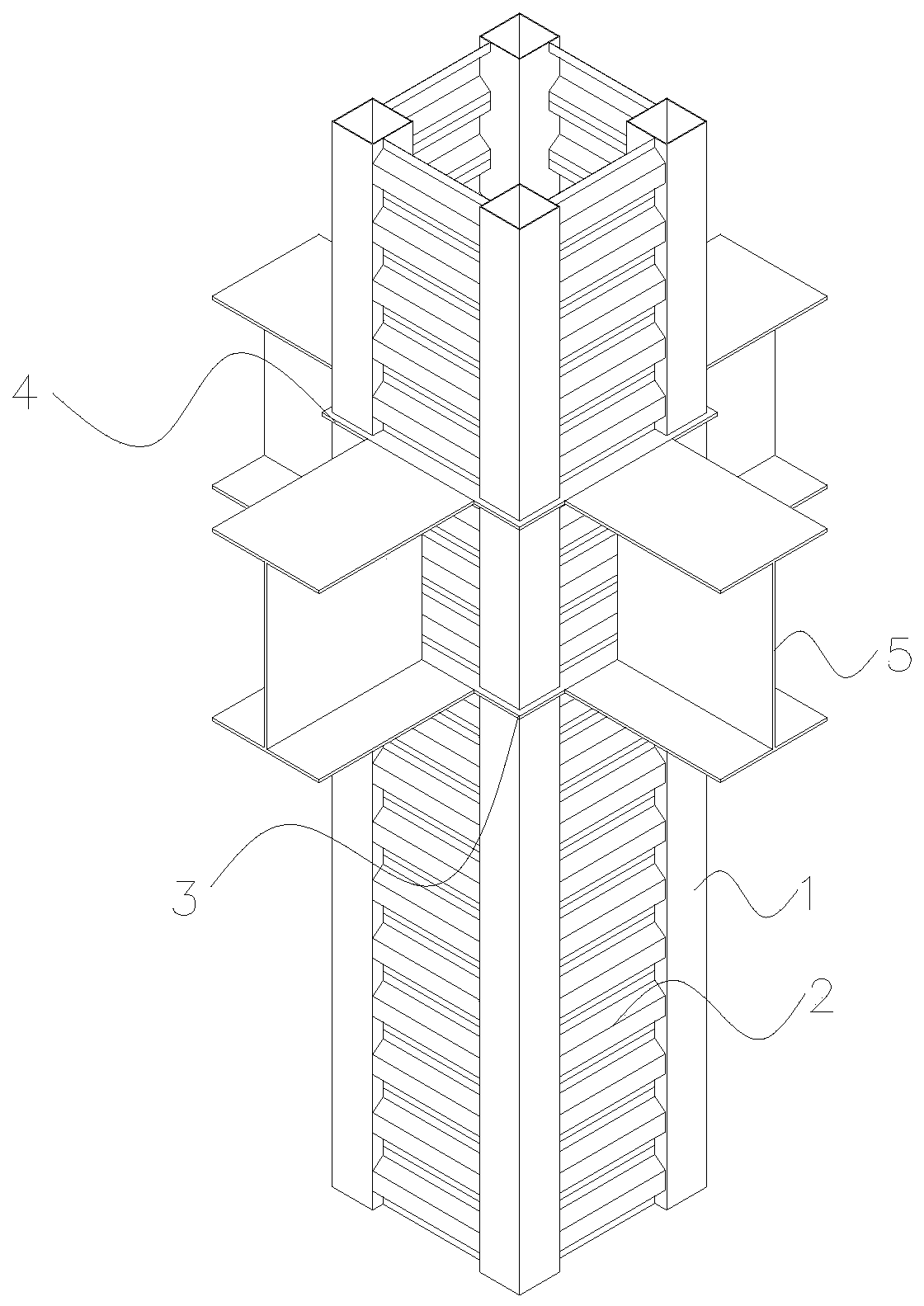

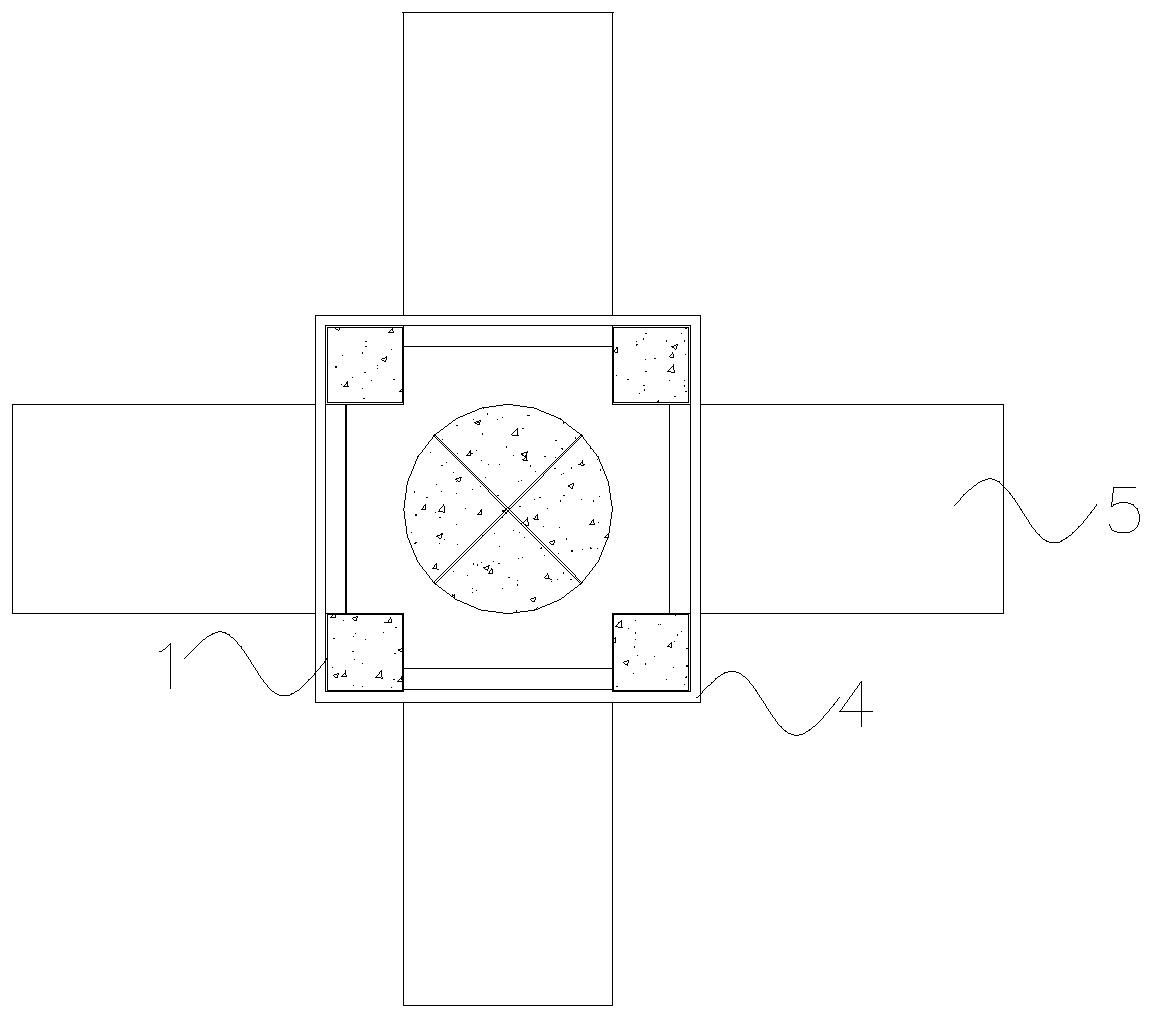

[0030] Such as figure 2 with image 3 As shown, it is a column with the above-mentioned diaphragm 3 / 4, including multiple sets of diaphragms 3 / 4 and the column body; each group of diaphragms 3 / 4 includes an upper diaphragm 4 and a lower diaphragm 3; The upper transverse diaphragm 4 and the lower transverse diaphragm 3 are arranged in parallel in relative up and down positions;

[0031] The column body includes side plates 2 and a plurality of corner steel pipes 1; a side plate 2 is connected between adjacent corner steel tubes 1 to form a column, and the corner steel tubes 1 and side plates 2 are connected by welding, which can To ensure the airtightness of the column as a whole, and in this embodiment, the side plate 2 is a corrugated web, and a flat side ...

Embodiment 2

[0043] Such as Figure 4 , Figure 5 with Image 6 As shown, the overall structure of embodiment 2 is roughly the same as that of embodiment 1, and the same parts will not be repeated here, and the difference technical features are as follows: Figure 5 with Image 6 As shown, the external beam 5 outside the column is not perpendicular to the column; therefore, the present invention adopts Figure 4 For the diaphragm 3 / 4 of other structures shown, the diaphragm 3 / 4 adopts a polygonal shape. In this embodiment, a pentagonal shape is adopted, so that one side of the diaphragm 3 / 4 is not perpendicular to the normal The external beam 5 can be smoothly lapped. According to the overlapping condition of the external beam 5 required in the actual scene, the shape of the 3 / 4 of the diaphragm can be adjusted accordingly, and the extension angle of the outer edge of the 3 / 4 of the diaphragm can be adjusted to further realize the connection between the diaphragm and the external beam....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com