Combined structure of rotor short-circuit ring and its processing method

A rotor short circuit and combined structure technology, applied in the magnetic circuit shape/style/structure, manufacturing stator/rotor body, magnetic circuit rotating parts, etc. Stability and other issues to achieve the effect of overcoming trouble and trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In the following, please refer to the relevant drawings to further describe the rotor short-circuit ring combination structure and the embodiment of the processing method of the present invention. In order to facilitate the understanding of the embodiments of the present invention, the same components are described below with the same reference numerals.

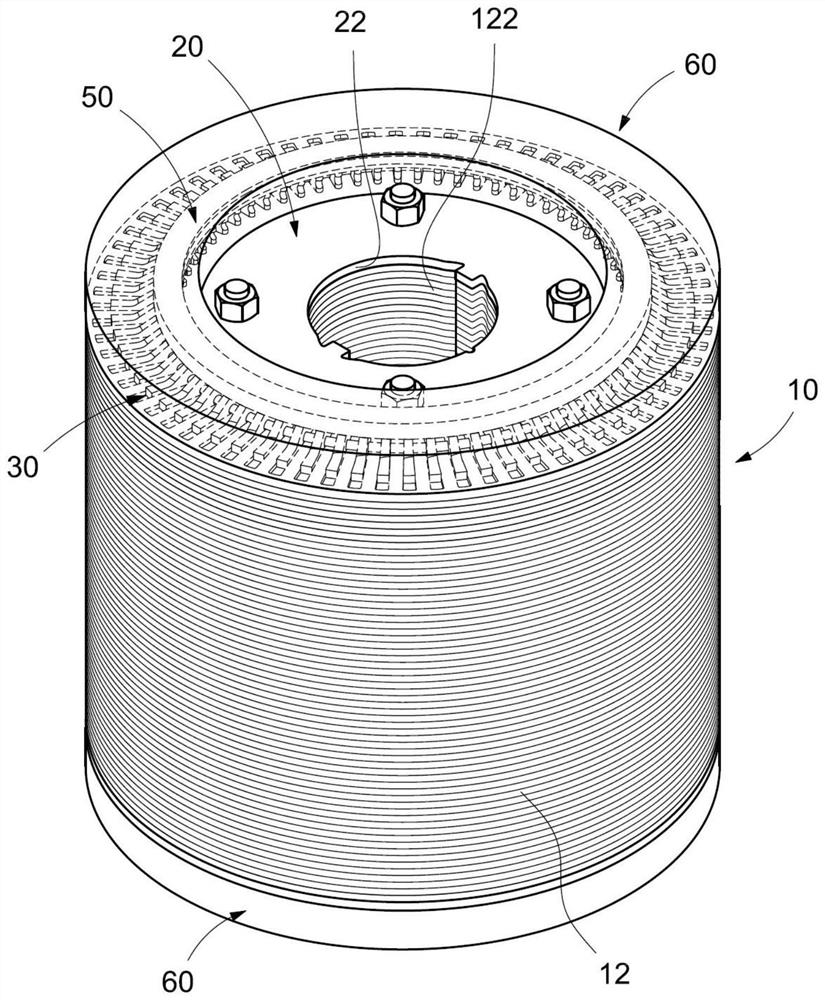

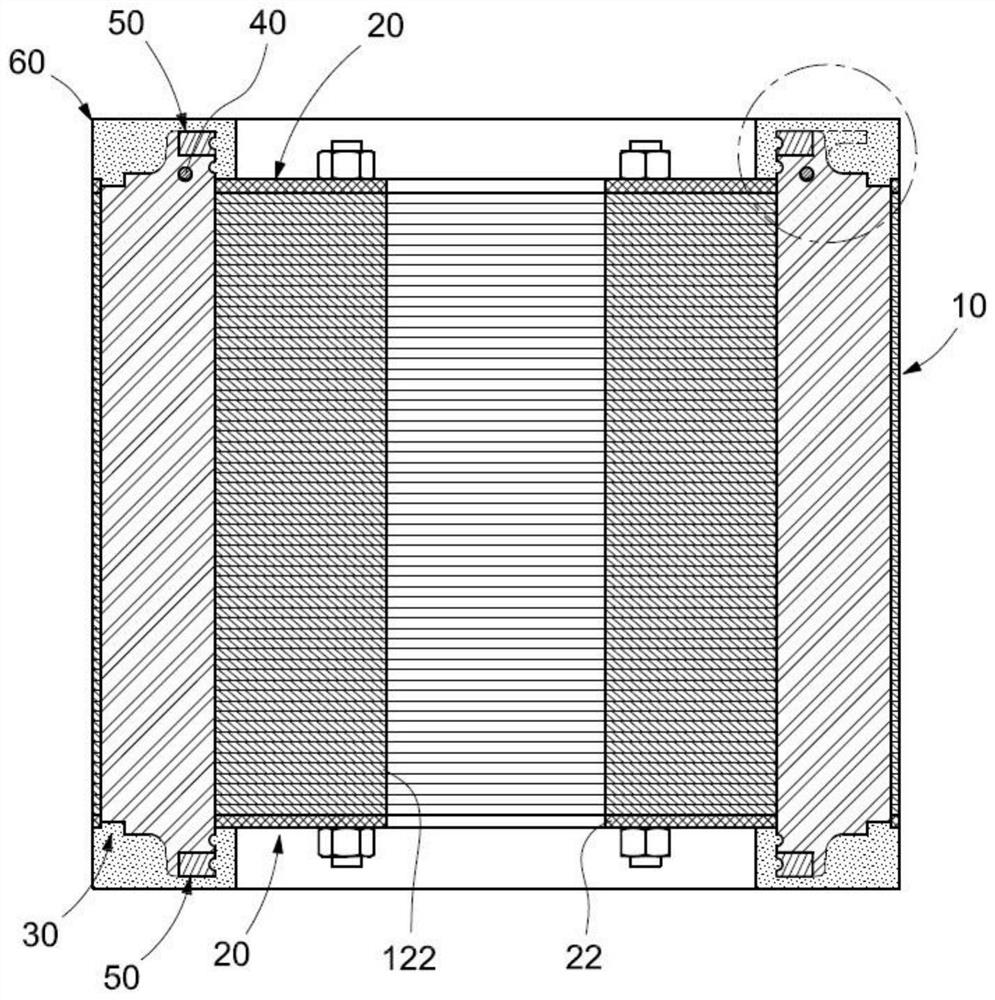

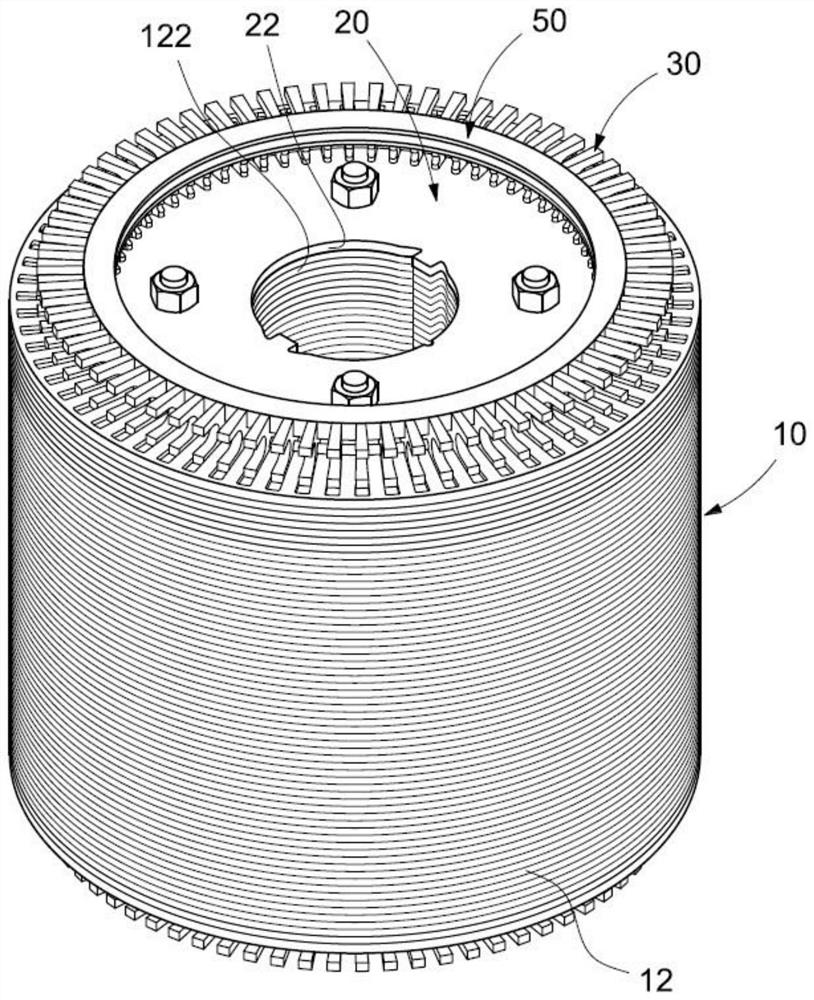

[0044] see Figures 1 to 2 As shown, the rotor short-circuit ring combination structure of the present invention includes a rotor core 10, two porous ring sheets 20, a plurality of conductive copper sheets 30, a line ring 40, two true rings 50, and two short-circuit rings 60, wherein:

[0045] above rotor core 10, see Figures 3 to 5 As shown, a plurality of silicon steel sheets 12 are stacked to form a columnar outline; wherein, each silicon steel sheet 12 has an iron core shaft hole 122 , a plurality of copper sheet insertion holes 124 , and a plurality of iron core through holes 126 .

[0046] The core shaft hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com