A self-cleaning pipeline filter device for water conservancy projects

A technology for water conservancy projects and filtration devices, applied in filtration and separation, fixed filter element filters, separation methods, etc., can solve the problems of manual disassembly and cleaning, inability to automatically clean and discharge impurities, troublesome use, etc., to avoid waste and increase filtration. effect, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

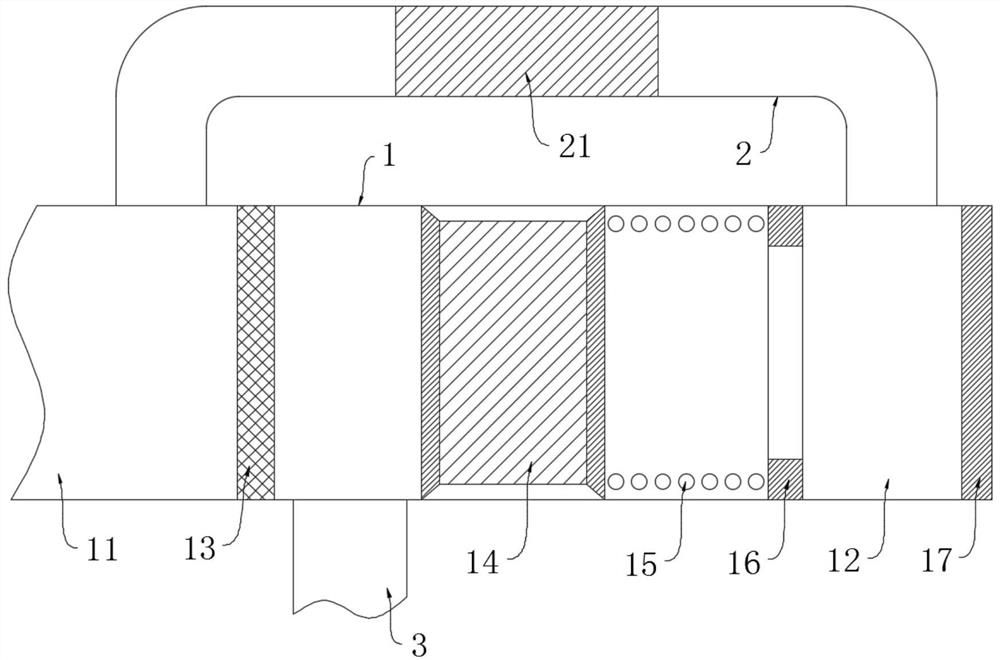

[0024] refer to figure 1 , a self-cleaning pipeline filter device for water conservancy projects, comprising a filter pipe 1, the filter pipe 1 includes a water inlet 11 and a sewage outlet 12, a slag discharge pipe 2 is installed on the side wall of the filter pipe 1, and a slag discharge pipe 2 is installed on the slag discharge pipe 2 A pressure valve 21, a filter screen 13 and a fixed ring 16 are installed on the inner wall of the filter pipe 1, and the filter screen 13 and the fixed ring 16 are both located between the two joints of the slag discharge pipe 2 and the filter pipe 1, and the fixed ring 16 is close to One end of filter screen 13 is equipped with spring 15, and spring 15 is equipped with piston 14 near one end of filter screen 13, and clear water pipe 3 is installed on the side wall of filter pipe 1, and sewage outlet 12 plugs are provided with pressure plug 17.

[0025] The clean water pipe 3 is located on the right side of the strainer 13, and the diameter o...

Embodiment 2

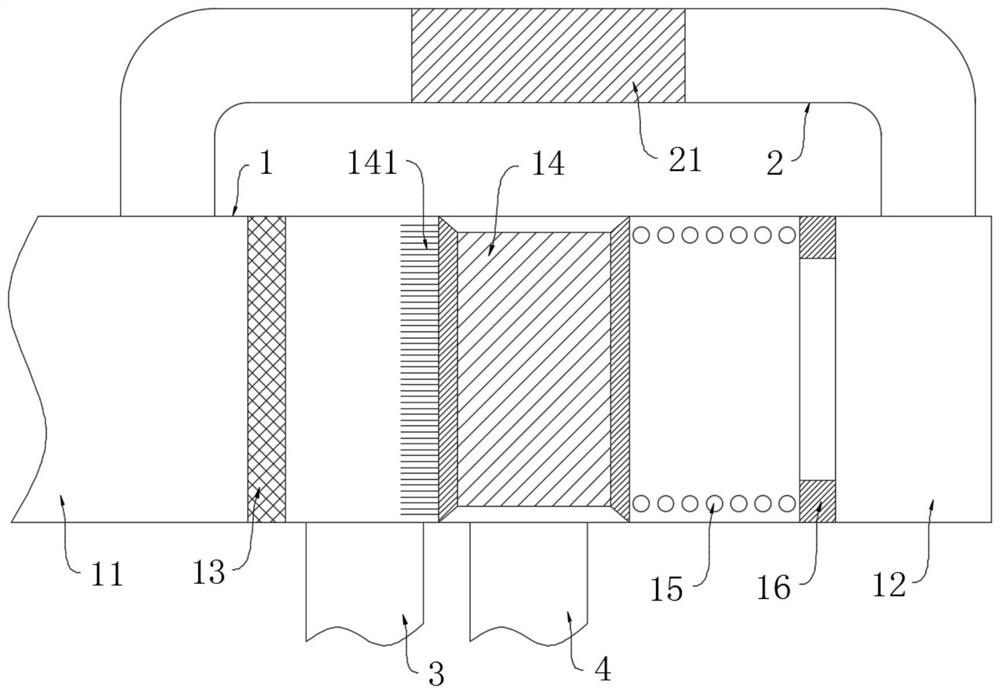

[0032] refer to figure 2 , a self-cleaning pipeline filter device for water conservancy projects, which is basically consistent with Embodiment 1, the difference is that:

[0033] The sewage outlet 12 is closed, the filter pipe 1 is located on one side of the clean water pipe 3 and a sewage pipe 4 is installed, and the diameter of the sewage pipe 4 is smaller than the length of the piston 14, and the length of the piston 14 is greater than the farthest distance from the filter screen 13 to the clean water pipe 3 And less than the shortest distance from the filter screen 13 to the sewage pipe 4, the end of the piston 14 near the filter screen 13 is equipped with a plurality of needles 141;

[0034]When the filter screen 13 is blocked by impurities, the water flows along the slag discharge pipe 2 to the sewage outlet 12. Since the sewage outlet 12 is closed, the water flow reverses in the filter pipe 1 to push the piston 14 to move to the filter screen 13 and open the sewage pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com