Patents

Literature

55results about How to "Prevent reverse flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

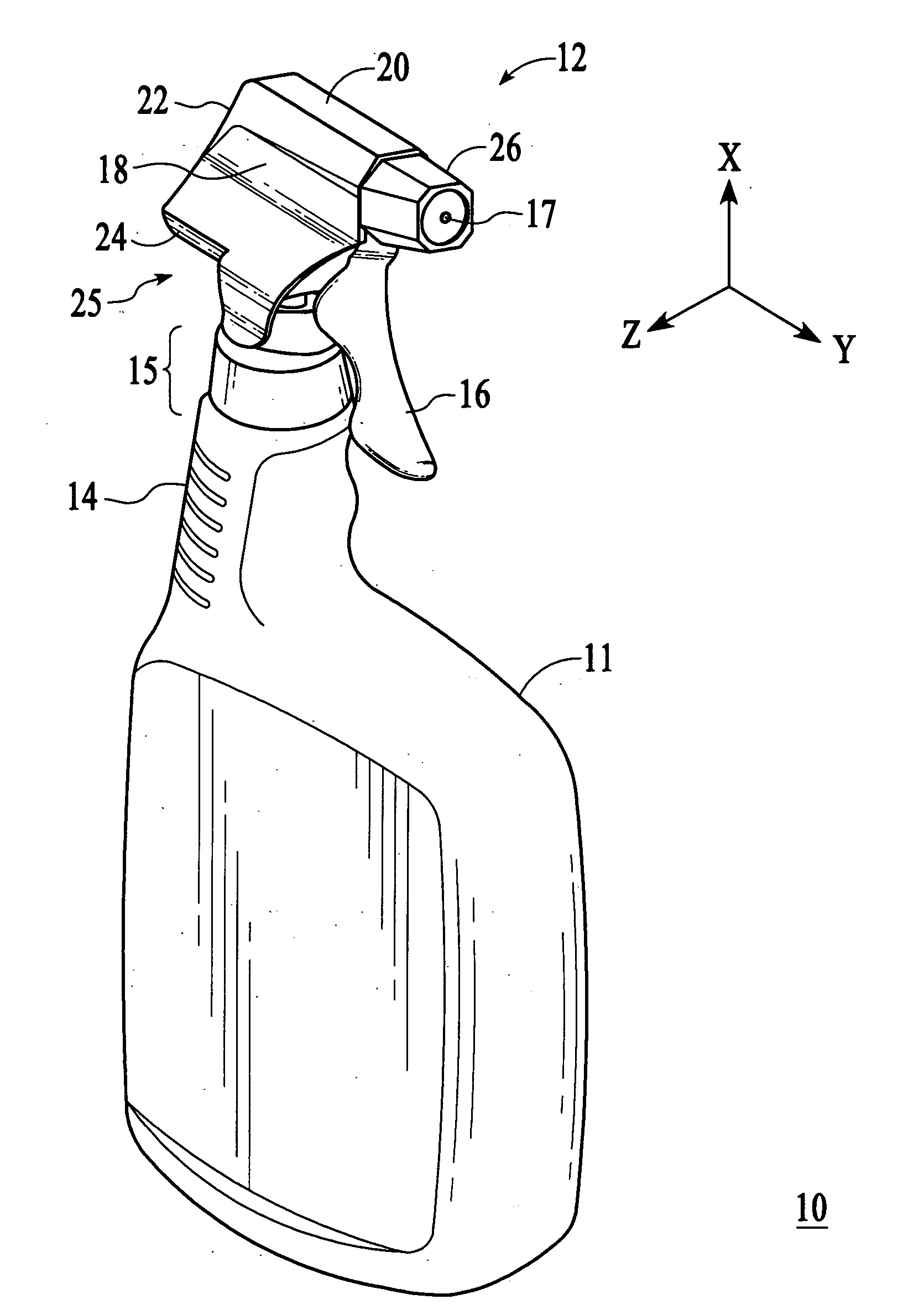

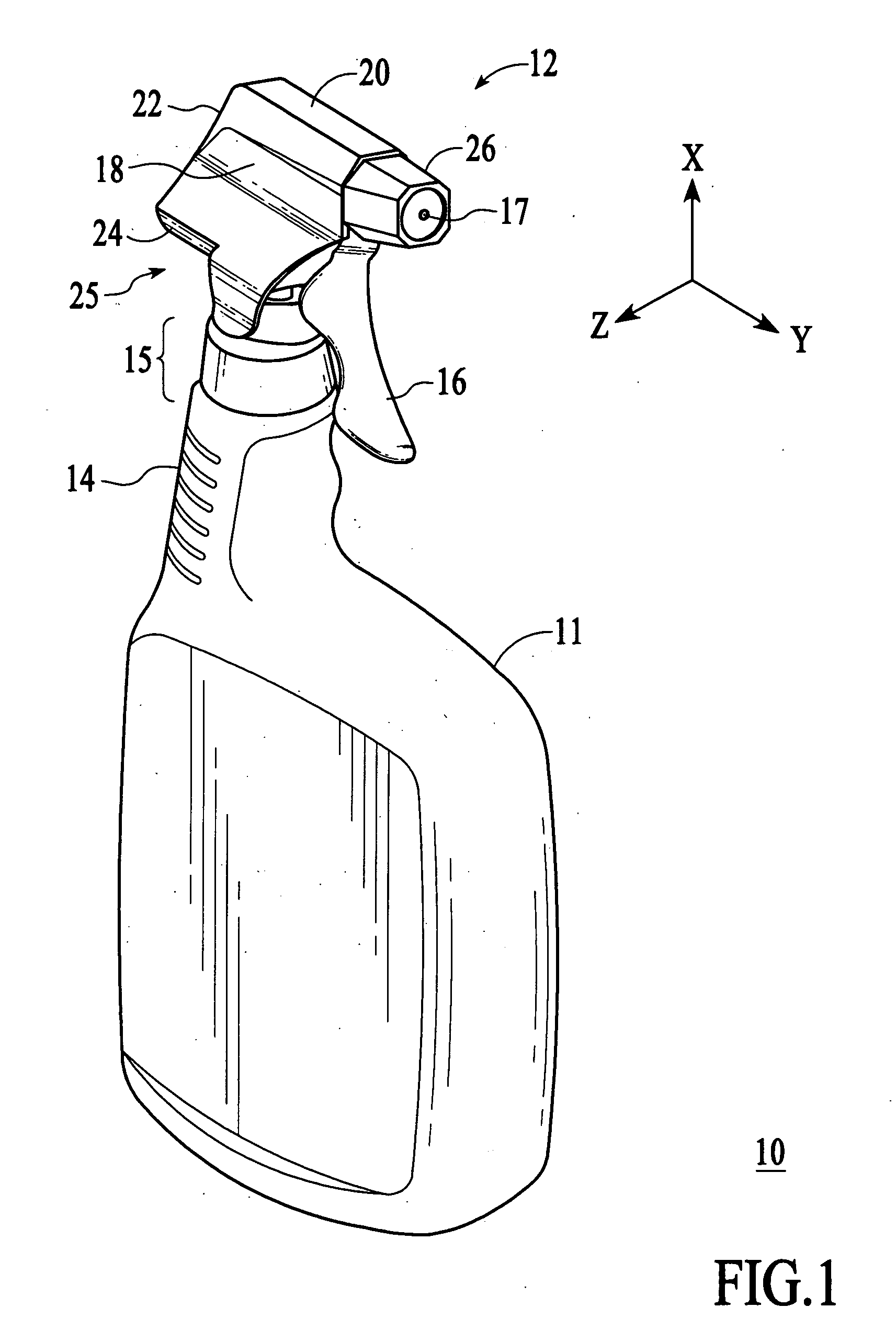

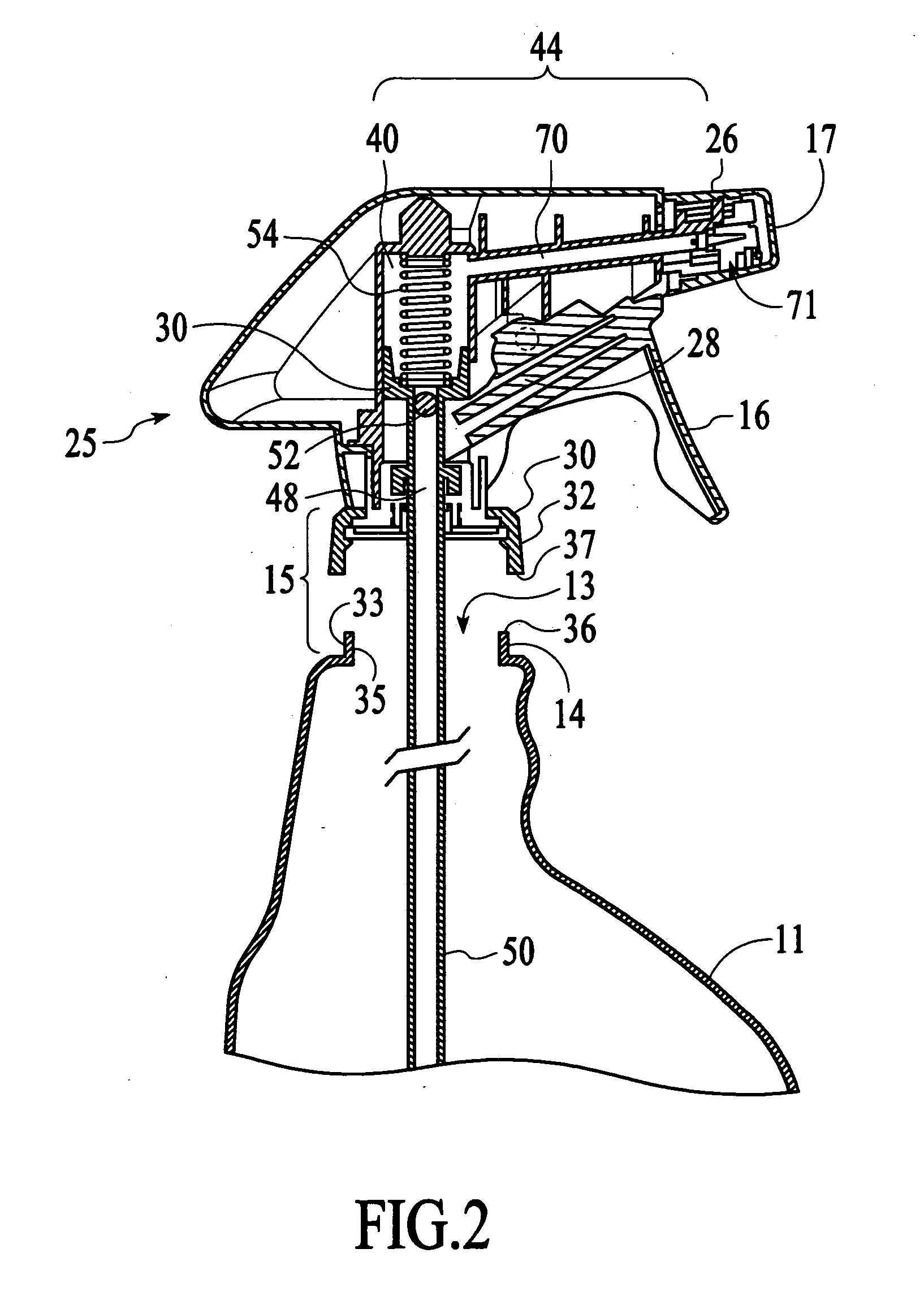

Modular sprayer

A liquid sprayer which may be removably attached to a liquid reservoir and thus readily interchangeable with a variety of liquid reservoirs. The sprayer includes a discharge nozzle, a manually or electrically powered pump and an actuation mechanism for the pump. The sprayer includes a quick-release coupling means for attaching the sprayer to a complementary quick-release coupling means fitted to the product reservoir. In some embodiments of the present invention, a signaling means on the reservoir communicates with a corresponding receiver means on the sprayer to provide information relating to the liquid contents of the reservoir so that the user will act on the information in a way that optimizes product safety, efficacy, convenience or combinations thereof. The information concerning the liquid may be conveyed to the user / consumer via the sprayer such that the user / consumer is part of the information / feedback loop, or the information may be communicated to the sprayer, which directly acts on the information without input from the consumer.

Owner:THE CLOROX CO

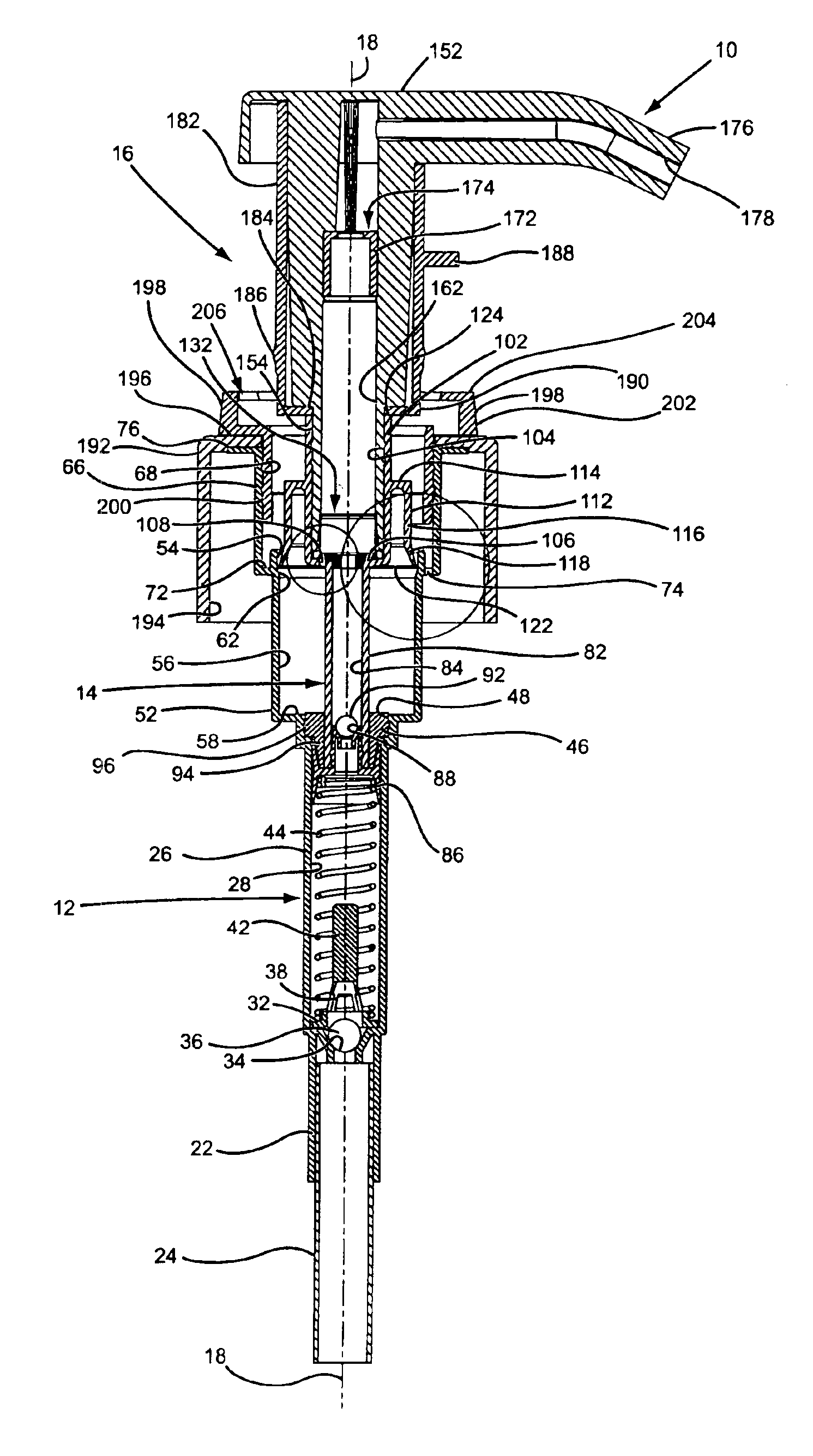

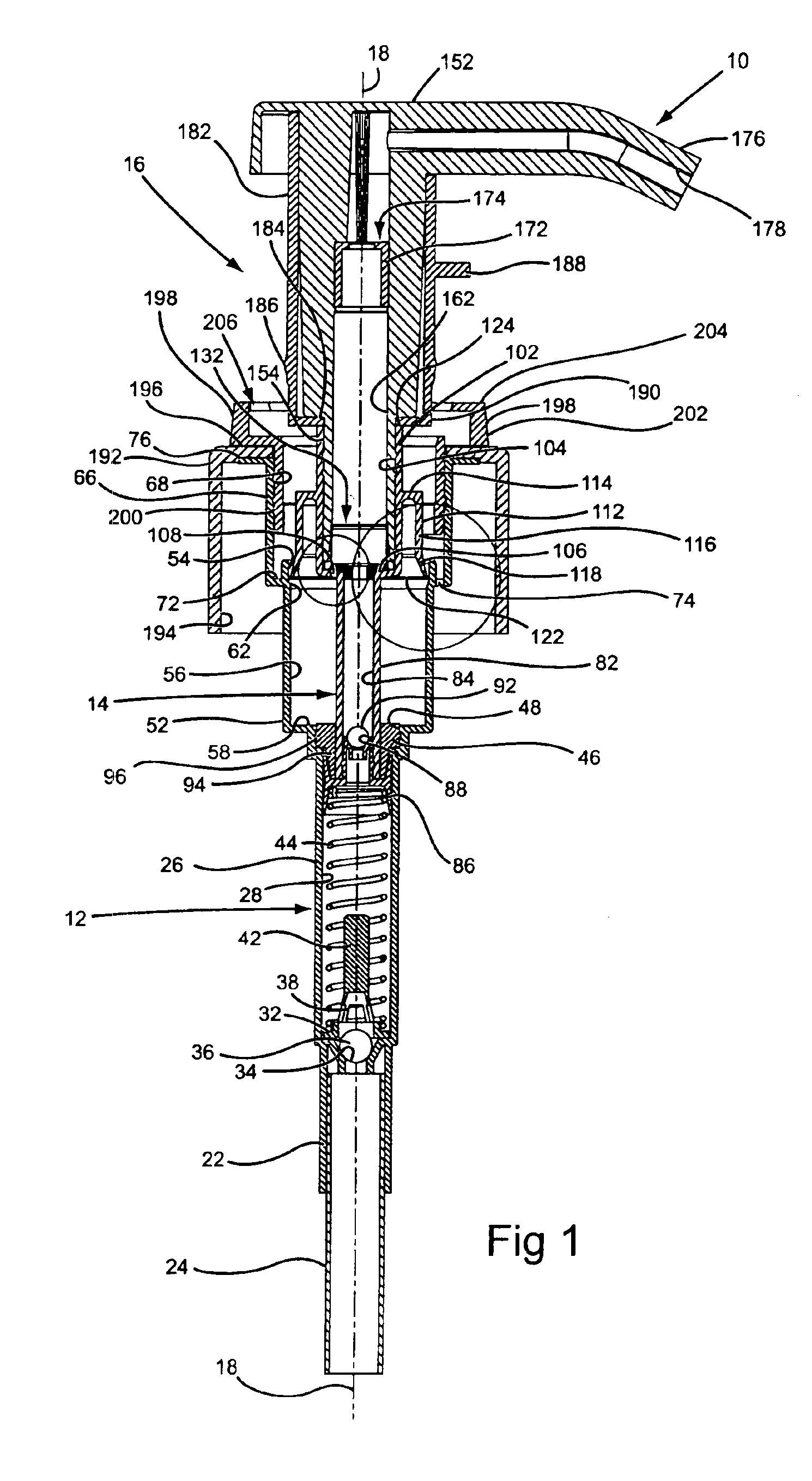

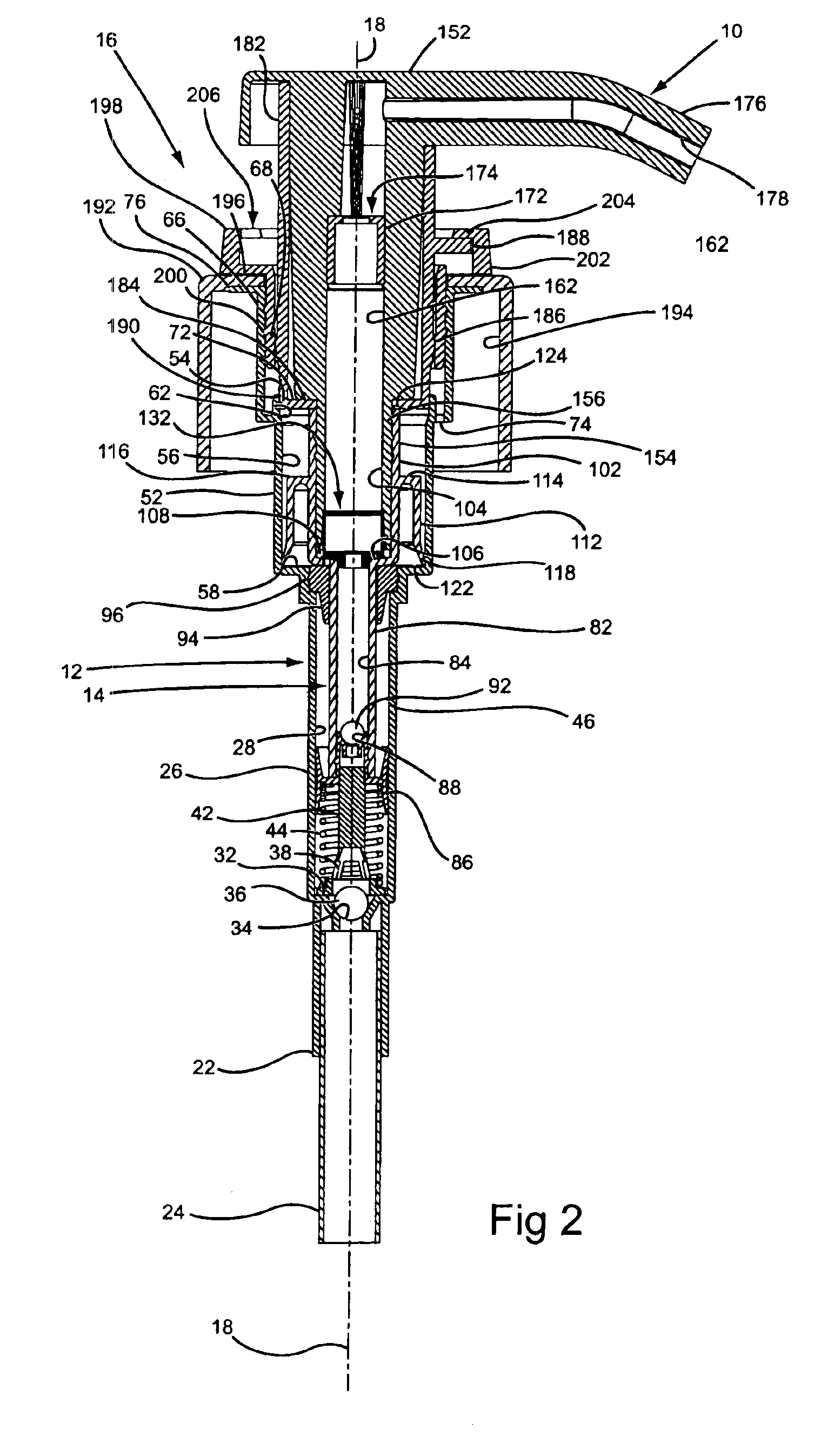

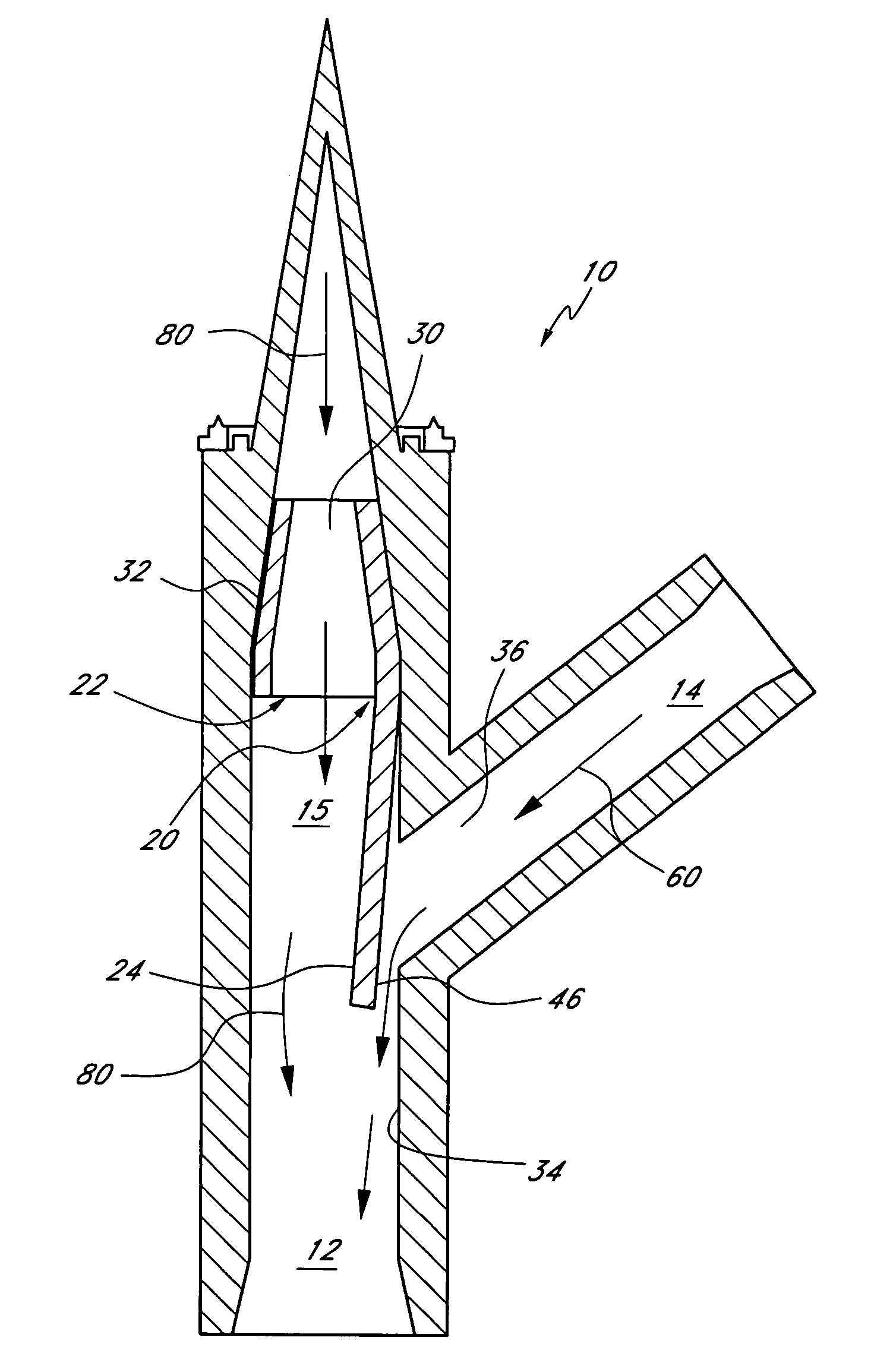

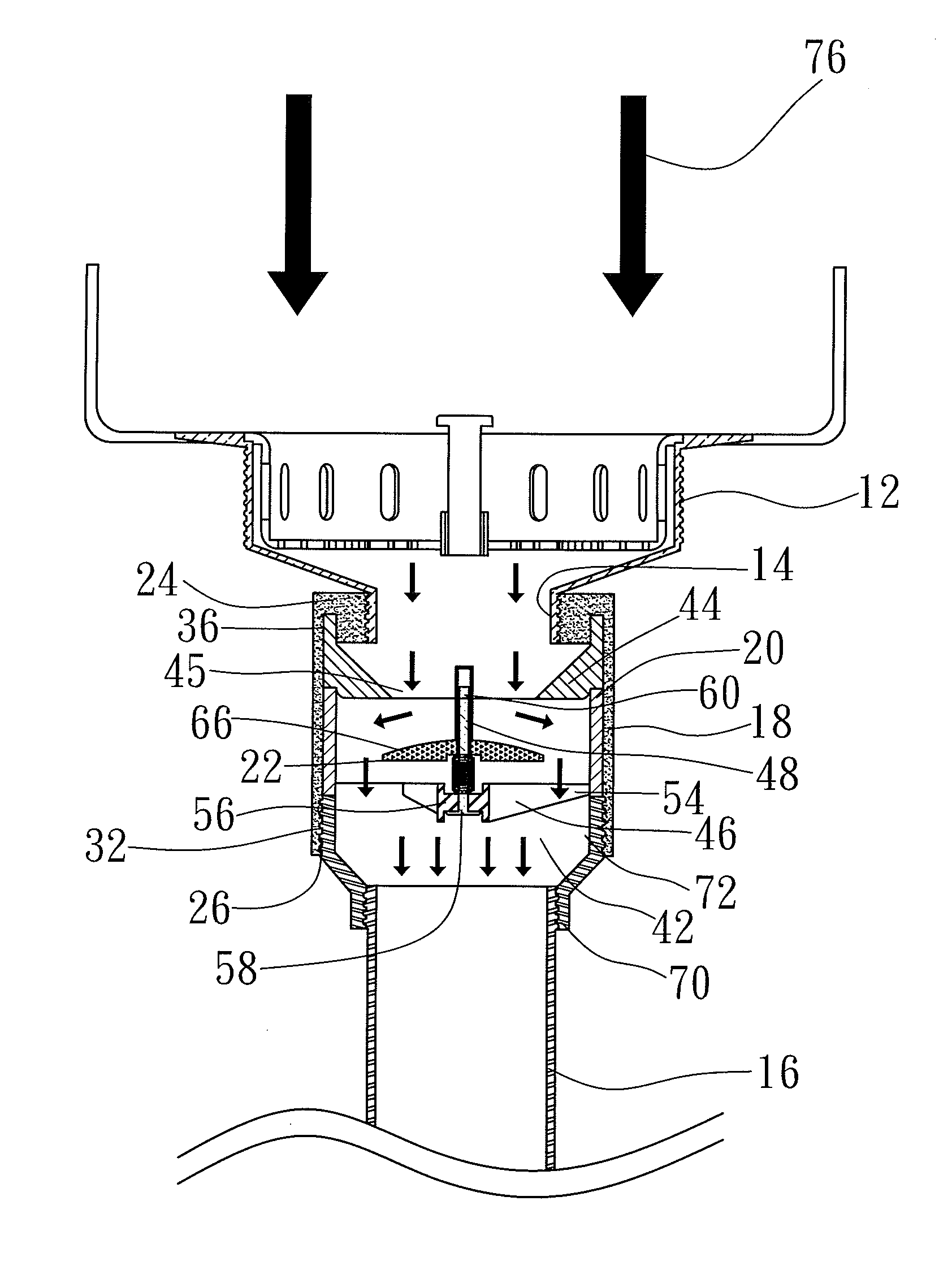

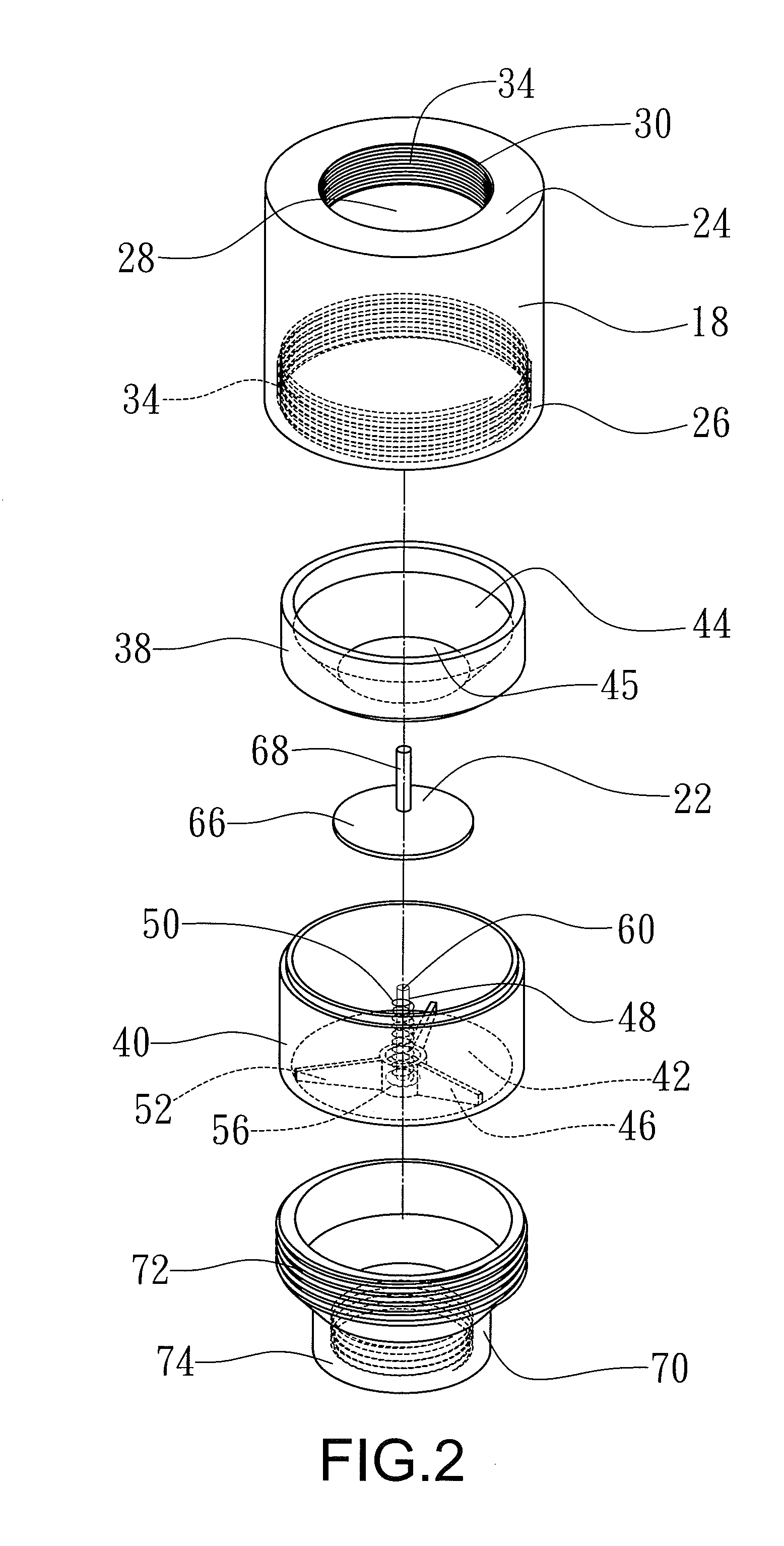

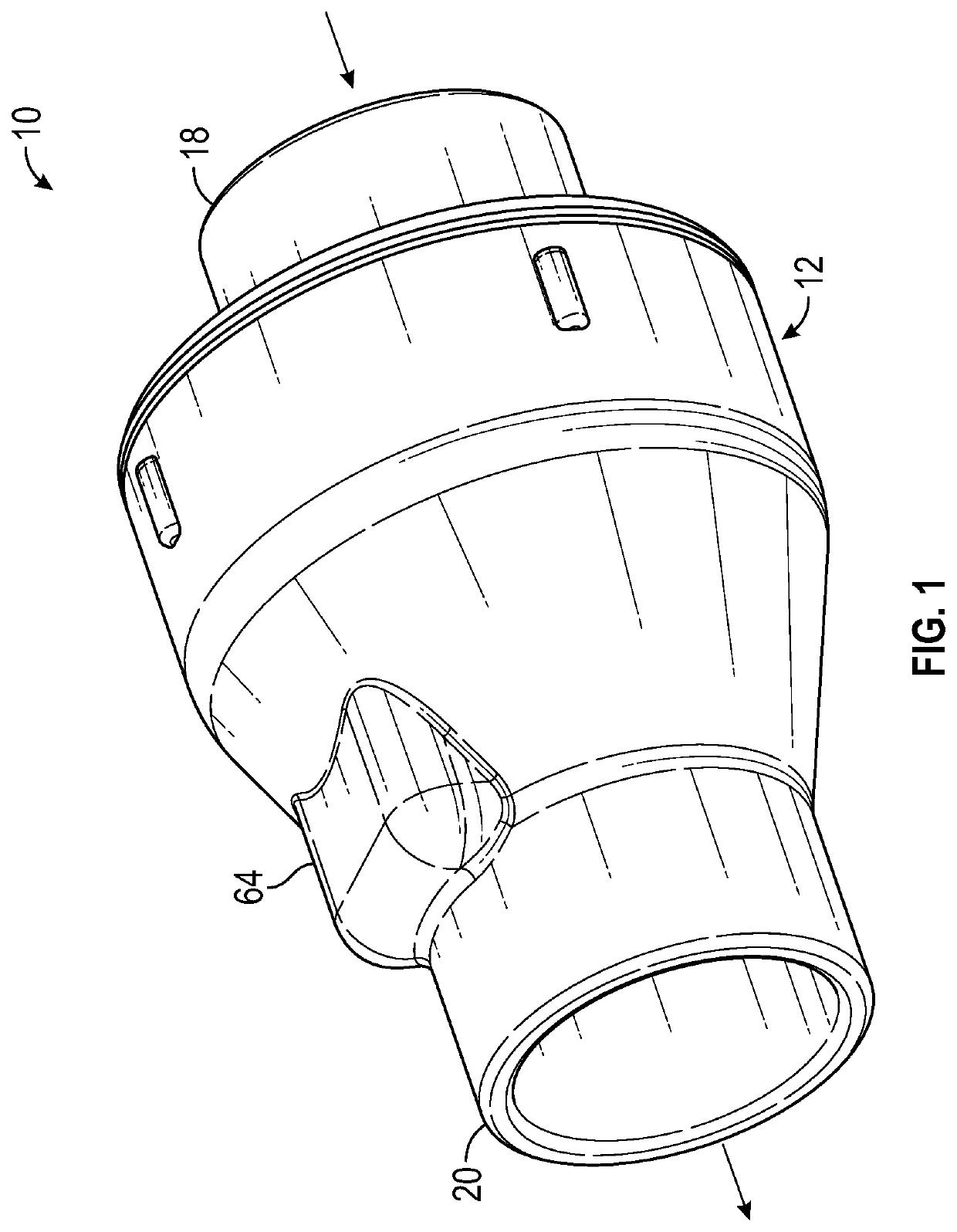

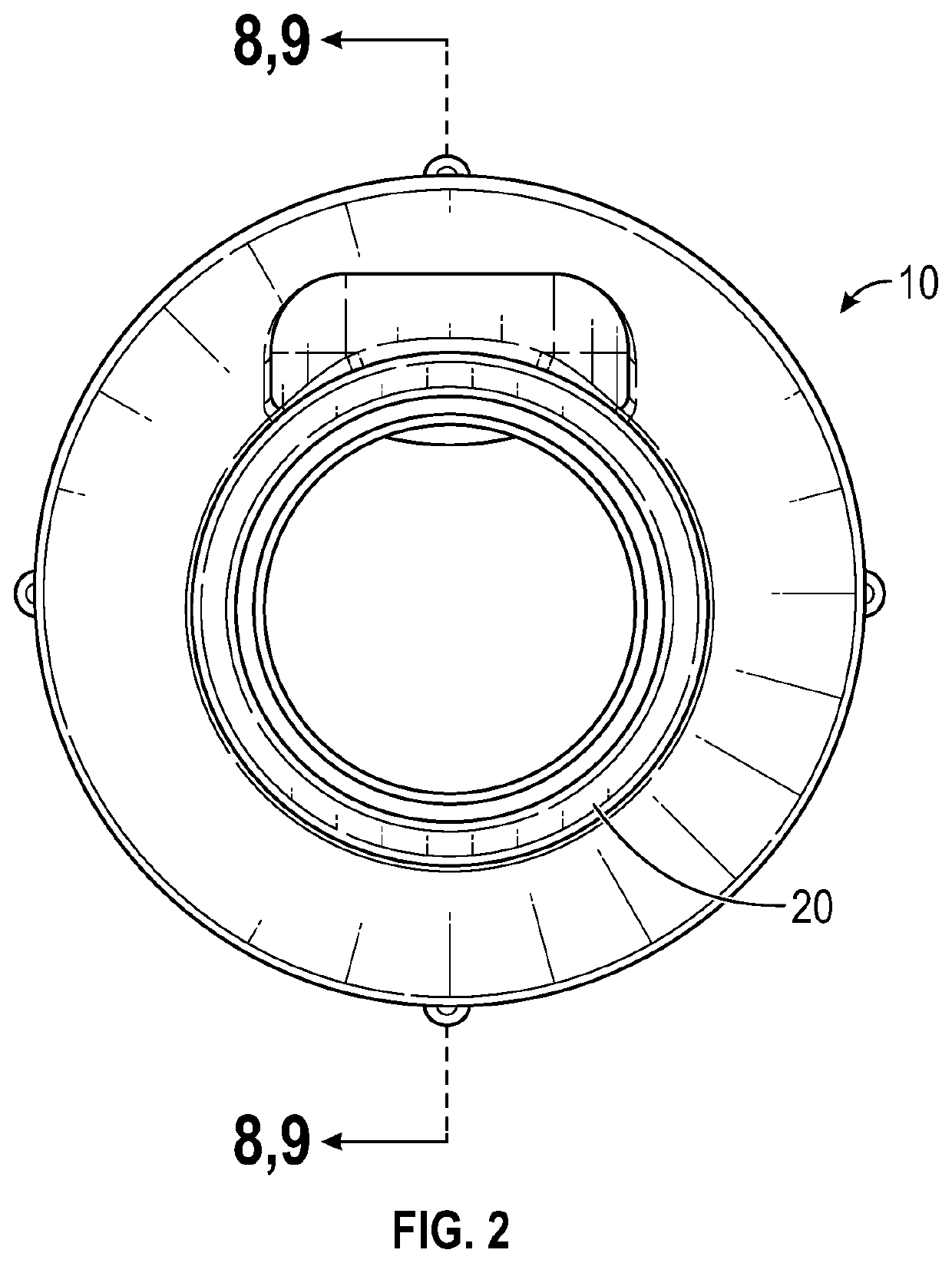

Foaming liquid dispenser

ActiveUS6923346B2Prevent reverse flowLarge interior diameterContracting/expanding measuring chambersClosuresEngineeringAir pump

A manually operated liquid foaming dispenser is attached to the top of a container of liquid and is manually vertically reciprocated to dispense the liquid from the container as a foam. The dispenser includes a liquid pump chamber and an air pump chamber that respectively pump liquid and air to a discharge passage of the pump where the liquid and air are mixed, generating the foam dispensed from the dispenser. The liquid dispenser is constructed with three biased closed valves that prevent leakage from a liquid container attached to the dispenser should the dispenser and container be positioned on their sides or be inverted.

Owner:WESTROCK DISPENSING SYST

Check valve for medical Y-site

ActiveUS20060173420A1Prevent reverse flowPreventing and minimizingCatheterIntravenous devicesCheck valveMedical treatment

A check valve for use in a Y-site in an infusion system comprises a fixation portion configured to retain the check valve in a common lumen of the Y-site, and a flap member extending axially from the fixation portion. The flap member has an outer surface, at least a portion of which is configured to engage an internal wall of the common lumen overlying an inlet from a main lumen. In one embodiment, the flap member comprises a pocket surrounding the hole and any burr extending from the wall adjacent the hole. In some embodiments, the flap member is resiliently biased towards a sealed position, and can flex to allow fluid flow from the main lumen to the common lumen.

Owner:ICU MEDICAL INC

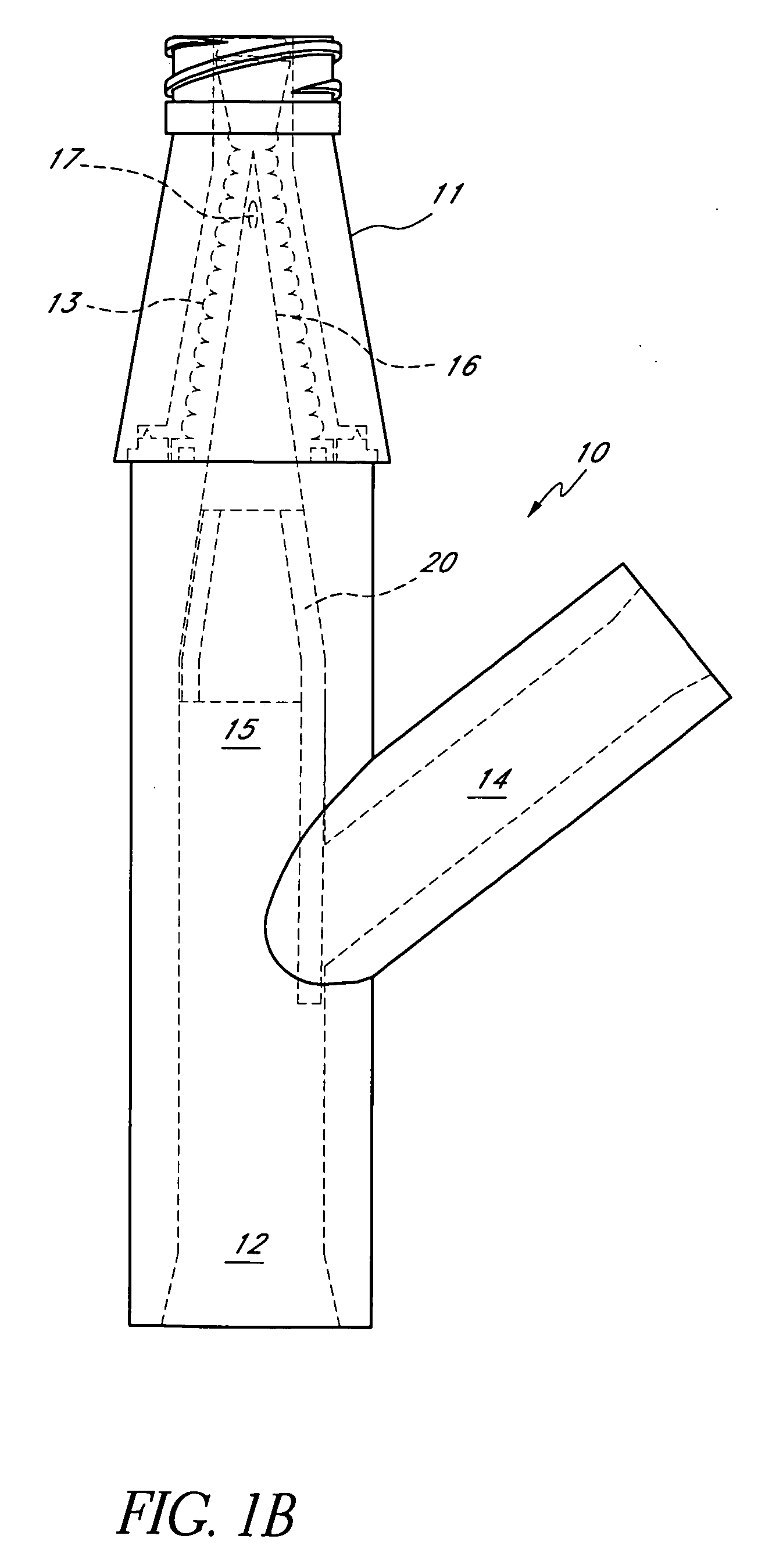

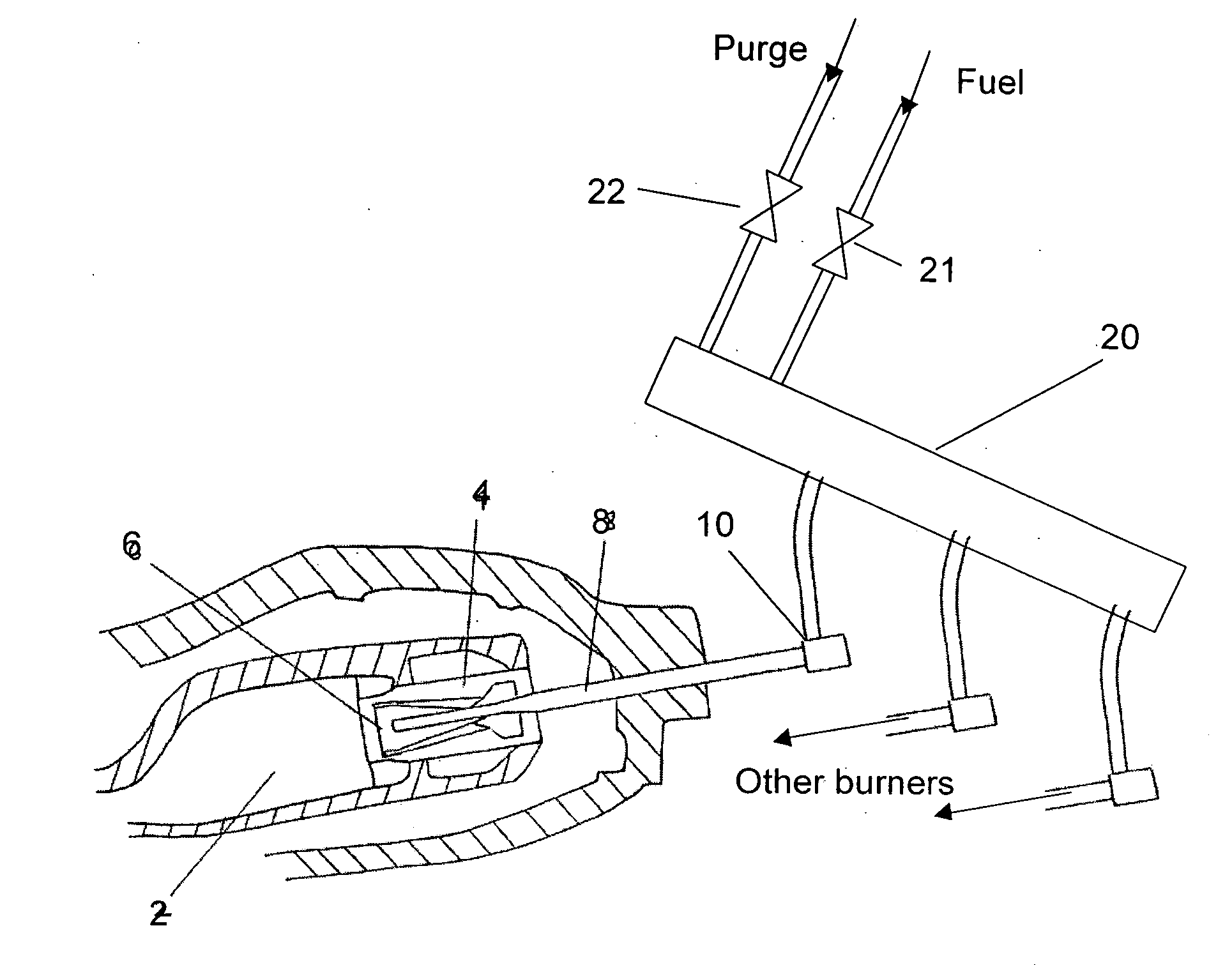

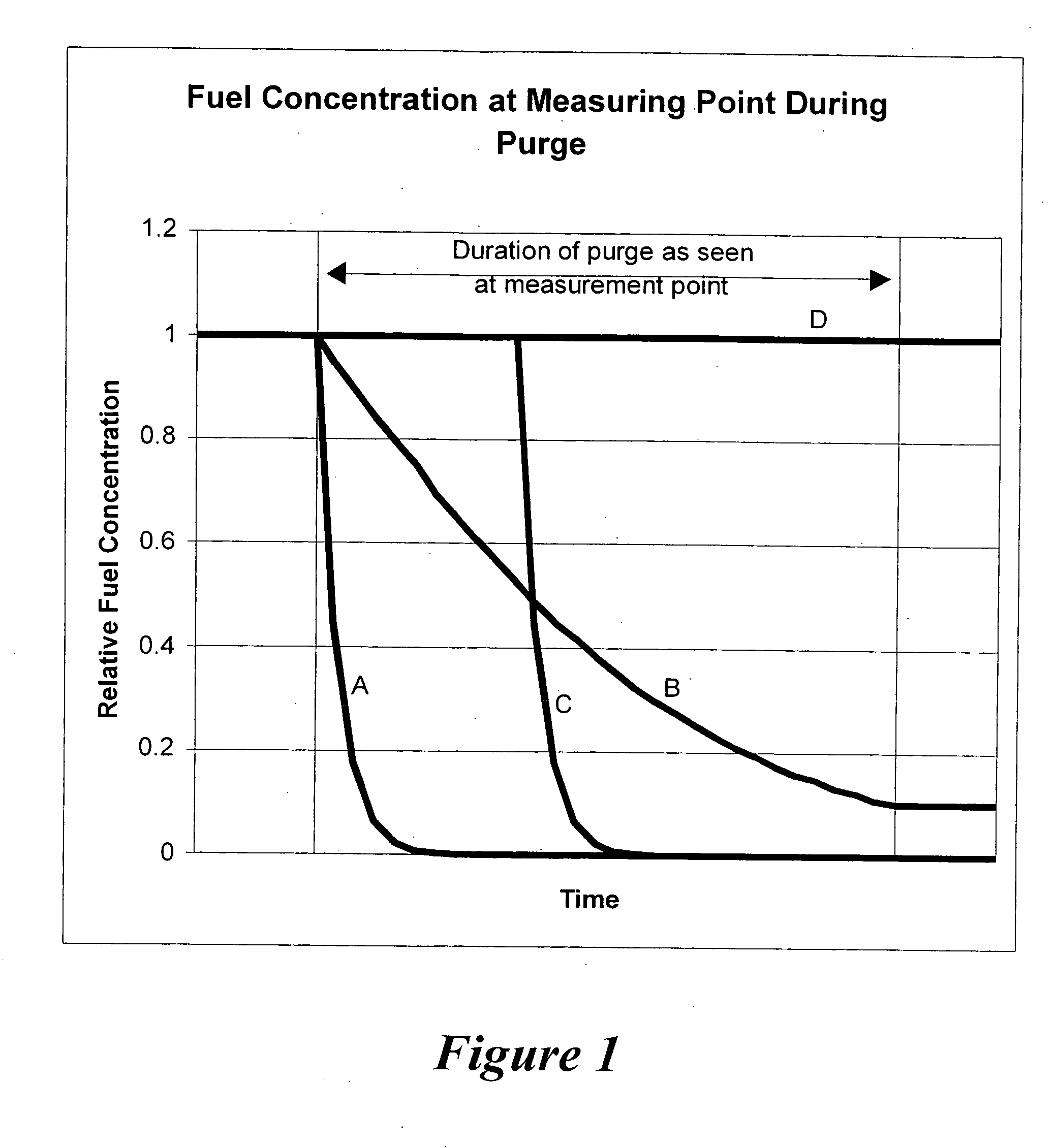

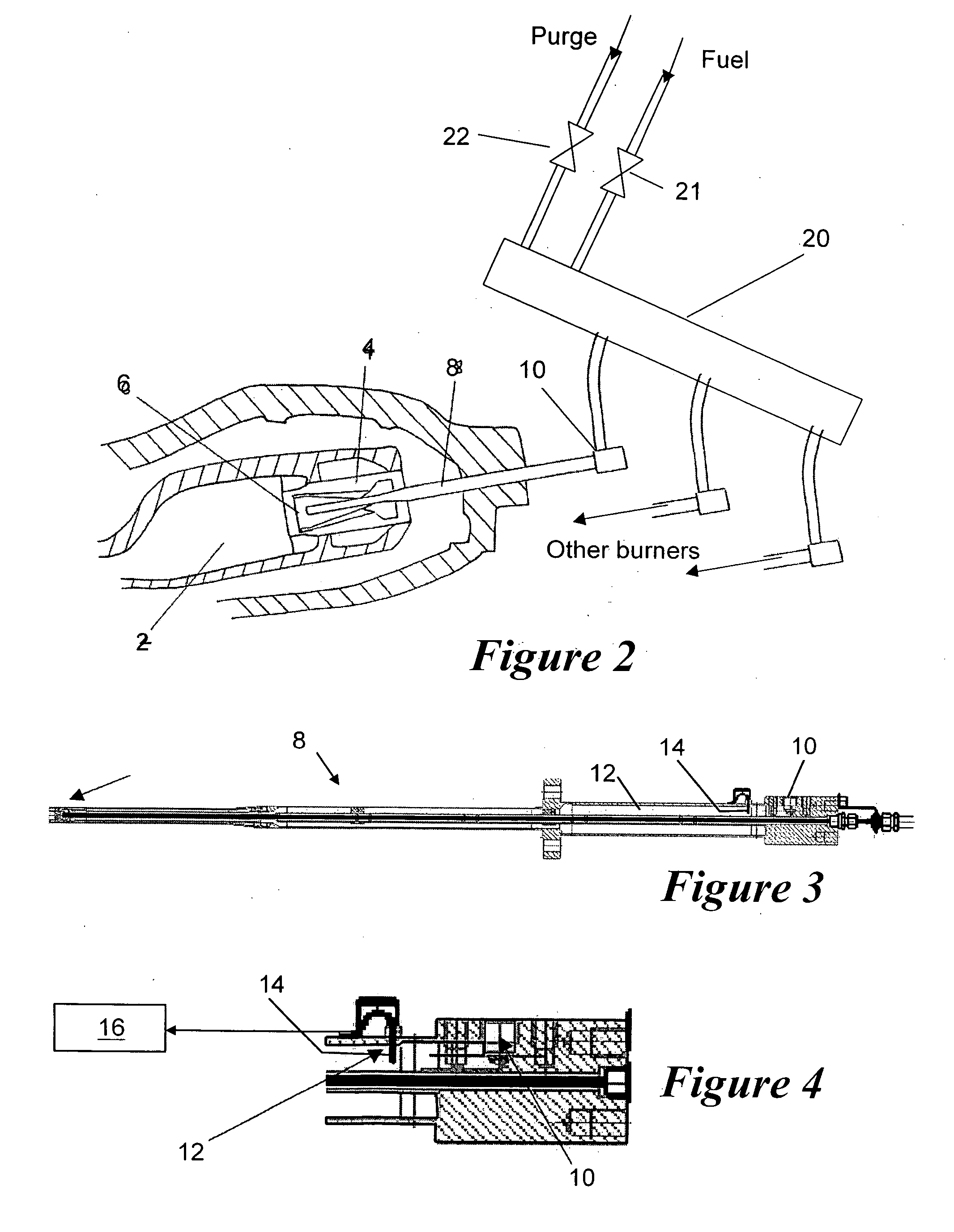

Fuel injection system and purging method

ActiveUS20060283193A1Prevent reverse flowReduce riskBurner safety arrangementsBurnersFuel supplyGas turbines

A fuel injection system has a fuel lance for supplying gaseous fuel to the burner of a gas turbine engine. The fuel lance includes a gas sensor that is used to monitor the concentration of the methane fuel inside the gas pilot channel of the fuel lance. The invention prevents overheating caused by the ignition of the methane fuel inside the fuel lance by monitoring the concentration of the methane fuel during the purge sequence and taking action if a critical fuel air mixture is reached.

Owner:ANSALDO ENERGIA SWITZERLAND AG

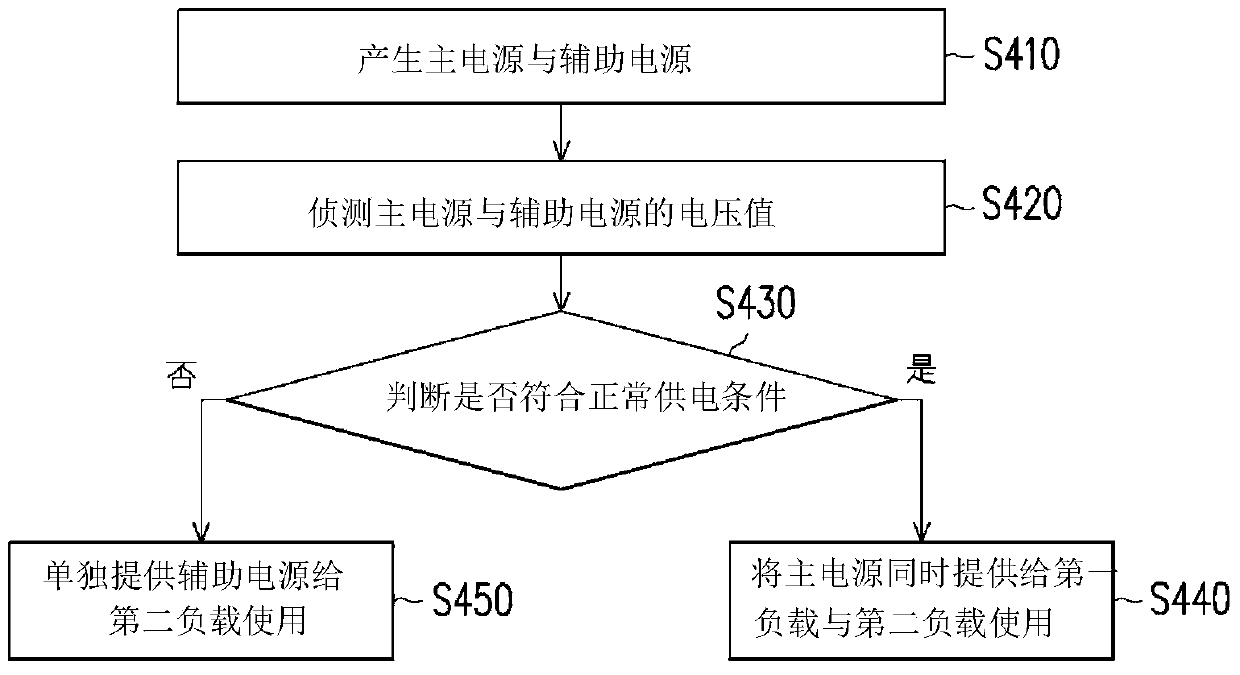

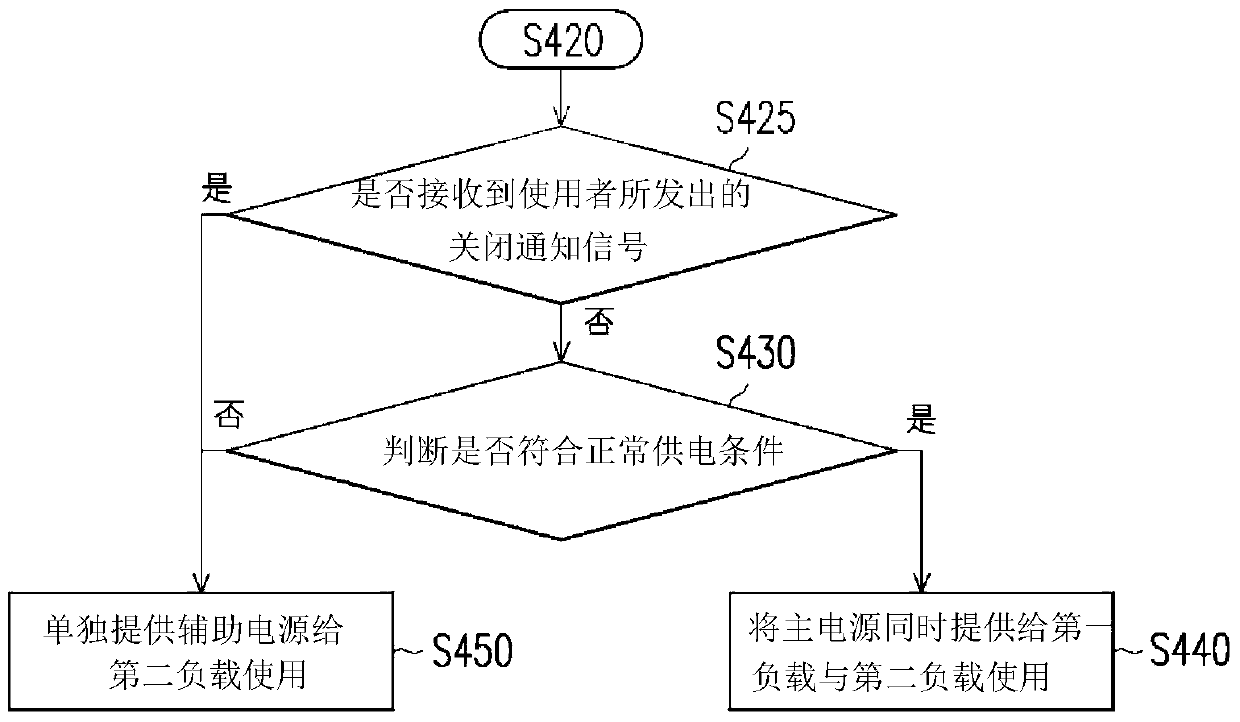

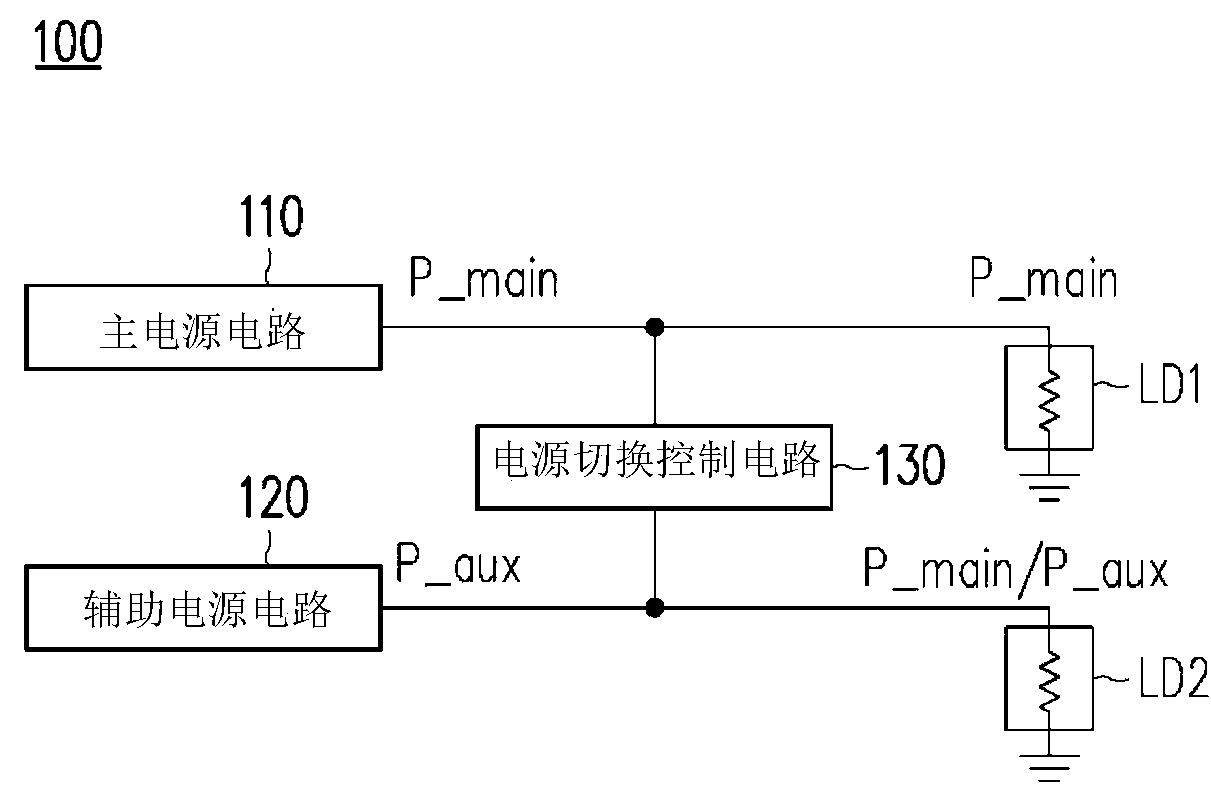

Apparatus and method for power supply

ActiveCN104731293AImprove conversion efficiencyAvoid damageVolume/mass flow measurementDc source parallel operationPower flowPower switching

An apparatus and a method for power supply are provided. The apparatus for power supply includes a main power circuit, an auxiliary power circuit and a power switching control circuit. The main power circuit is configured to generate a main power suitable to be provided to a first load and a second load for use. The auxiliary power circuit is configured to generate an auxiliary power suitable to be provided to the second load for use. The power switching control circuit is configured to detect a voltage difference between the main power and the auxiliary power and determine whether the apparatus meets a normal power supply condition, so as to select one of the main power and auxiliary power as a power source of the second load.

Owner:SPI ELECTRONICS

Self-cleaning pipeline filtering device for water conservancy project

ActiveCN111214876ANo need for manual disassembly and cleaningNo manual operationStationary filtering element filtersWater flowWater resources

The invention discloses a self-cleaning pipeline filtering device for a water conservancy project. The filtering device comprises a filter pipe, the filter pipe comprises a water inlet and a sewage port, a residue discharging pipe is mounted on the side wall of the filter pipe, a pressure valve is mounted on the residue discharging pipe, a filter screen and a fixing ring are mounted on the inner wall of the filter pipe, the filter screen and the fixing ring are both located between the two connecting positions of the residue discharging pipe and the filter pipe, a spring is mounted at the end,close to the filter screen, of the fixing ring, a piston is mounted at the end, close to the filter screen, of the spring, and a clear water pipe is mounted on the side wall of the filter pipe. The pressure of the residue discharging pipe is higher than that of the filter pipe after the filter screen is blocked, so that water flows along the residue discharging pipe to form negative pressure to peel off impurities on the filter screen; the clean water pipe is blocked through the piston to prevent sewage from entering, the clear water pipe and a blow-off pipe are arranged side by side, the clear water pipe can be closed to open the blow-off pipe to achieve self-cleaning when the filter screen is blocked, the self-cleaning speed is further increased through a pricking needle, and water resources are saved.

Owner:郭新生

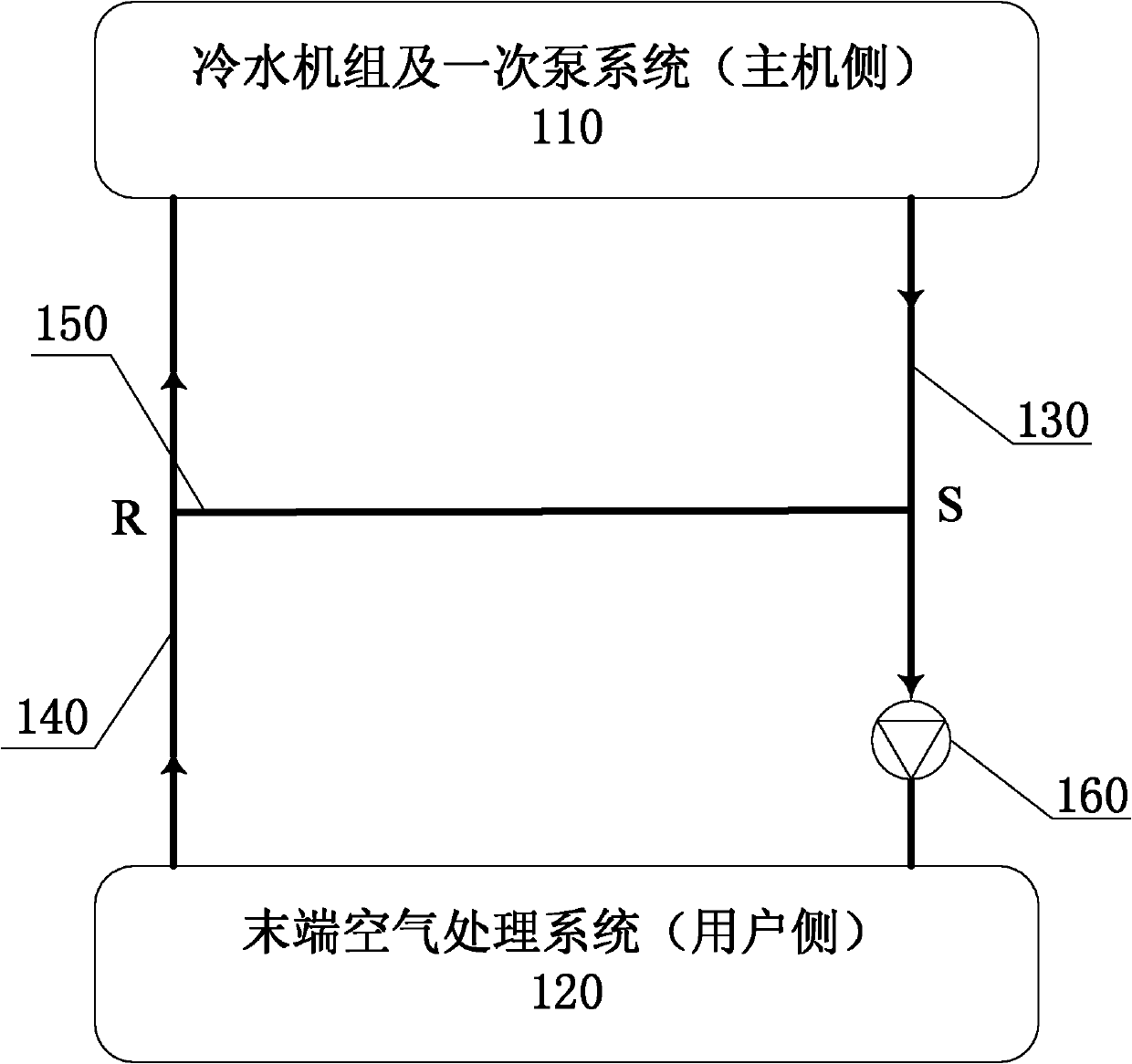

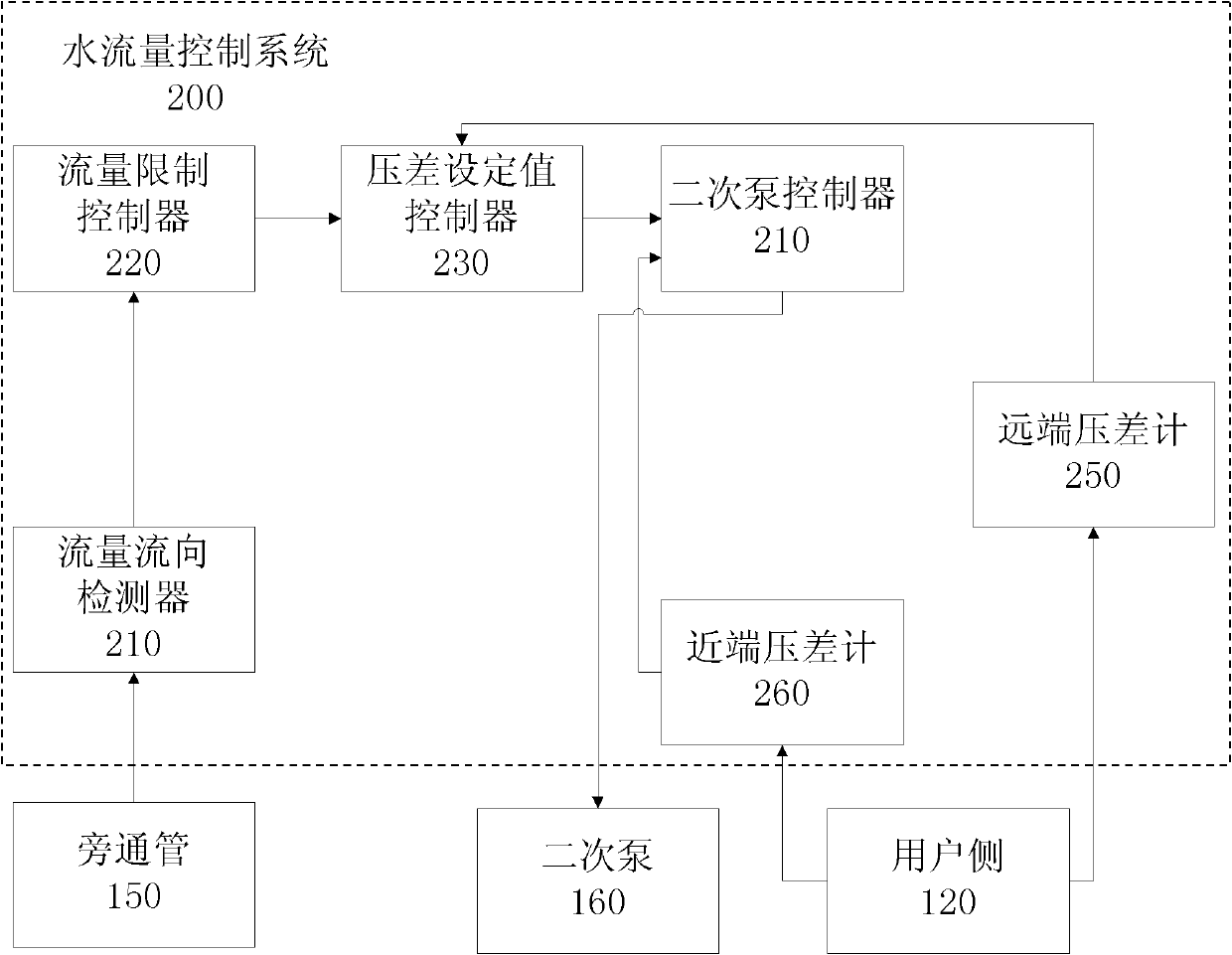

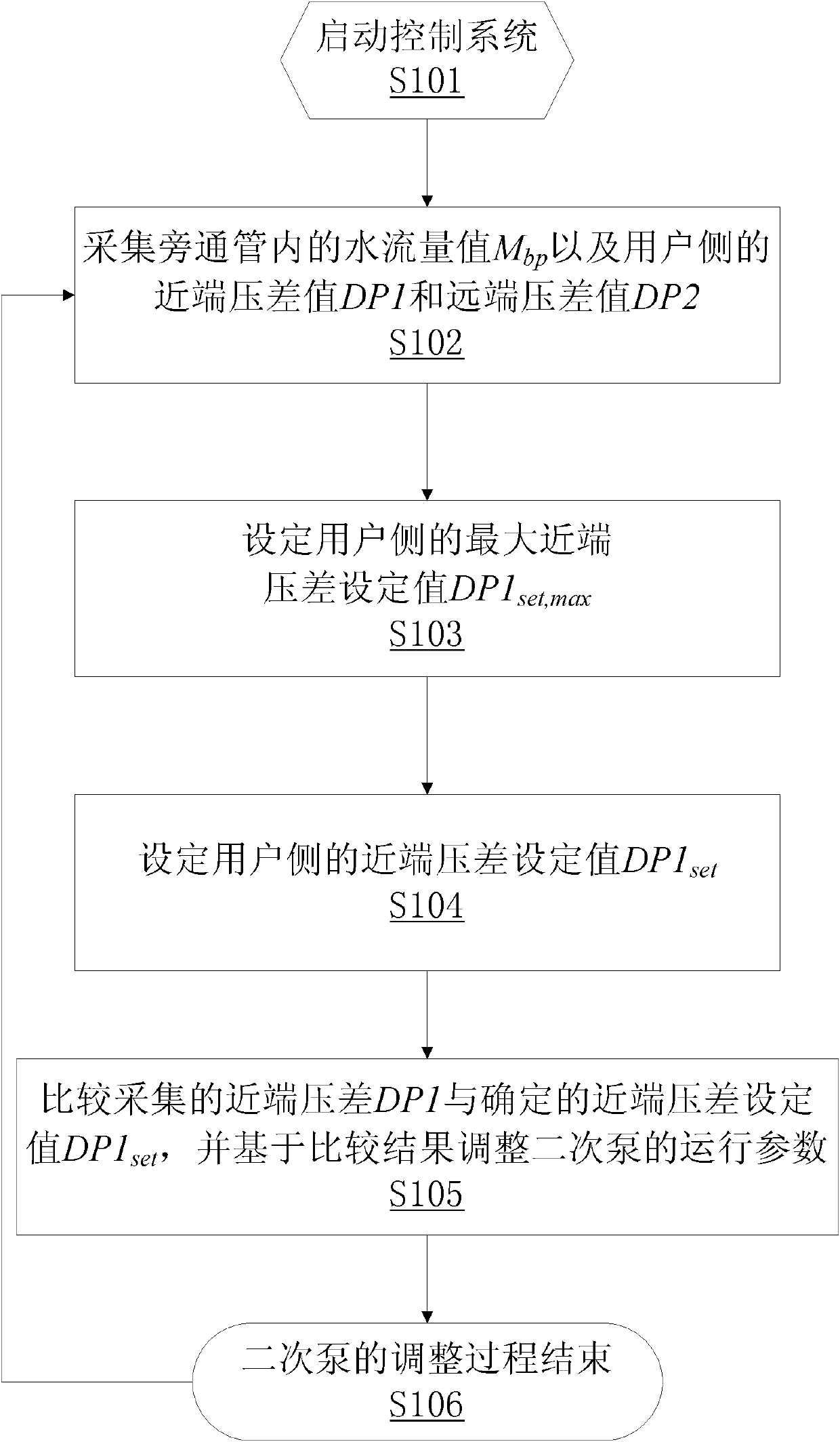

System and method for controlling water discharge

ActiveCN102889664APrevent reverse flowSpace heating and ventilation safety systemsLighting and heating apparatusWater dischargeControl system

The invention discloses a system and a method for controlling water discharge. The method for controlling water discharge comprises the following steps of: starting a water discharge control system; collecting a water discharge value inside a by-pass pipe in a secondary pump chilled water system of a central air conditioner, and a near-end pressure differential value and a far-end pressure differential value of a use side in the secondary pump chilled water system of the central air conditioner; determining the maximal near-end pressure differential set value of the user side; determining the near-end pressure differential set value of the user side; comparing the collected near-end pressure differential value with the determined near-end pressure differential set value, and adjusting operating parameters of the secondary pump on the basis of a comparison result, and finishing the adjusting process of the secondary pump. The operating parameters of the secondary pump can be adjusted by virtue of the system and the method for controlling water discharge, so that the water discharge in a water supply pipe of the user side in the chilled water system of the central air conditioner is adjusted; and the condition that the water discharge inside a water return pipe of the user side is not greater than that in the water supply pipe of a host side is ensured, and reverse backflow in the by-pass pipe is prevented finally.

Owner:THE HONG KONG POLYTECHNIC UNIV

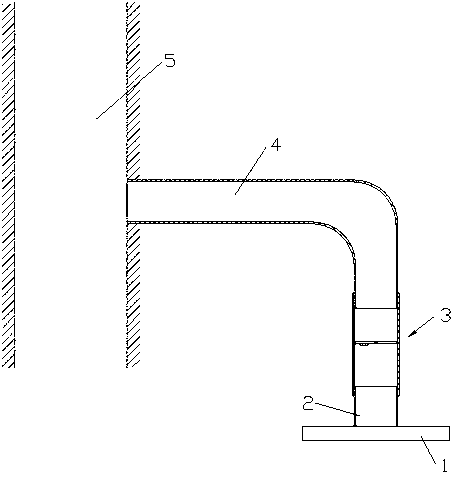

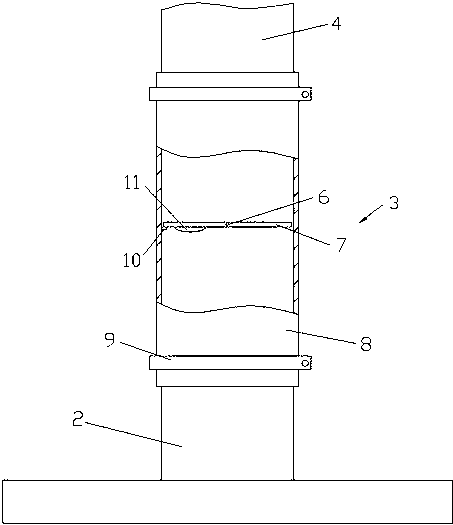

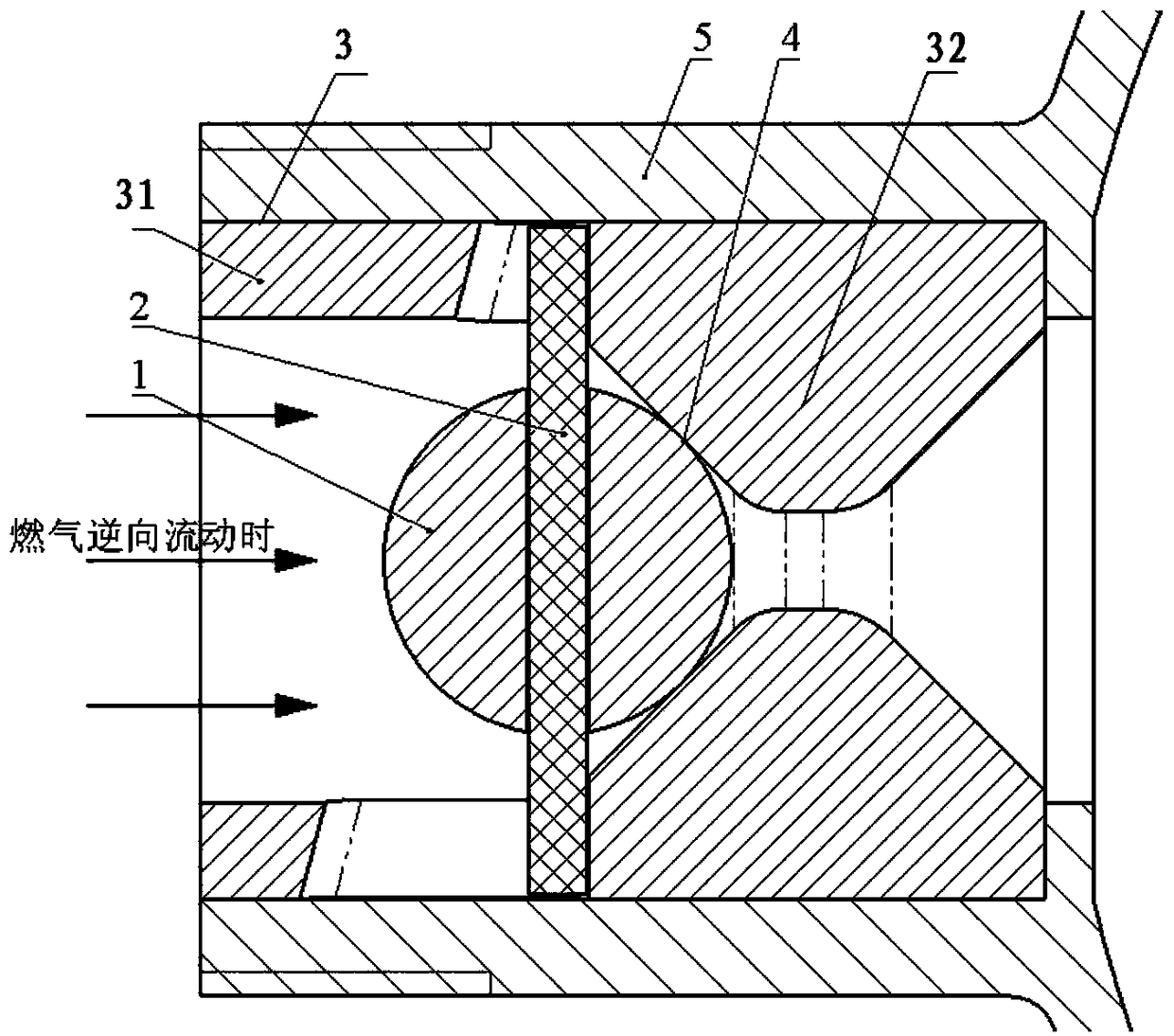

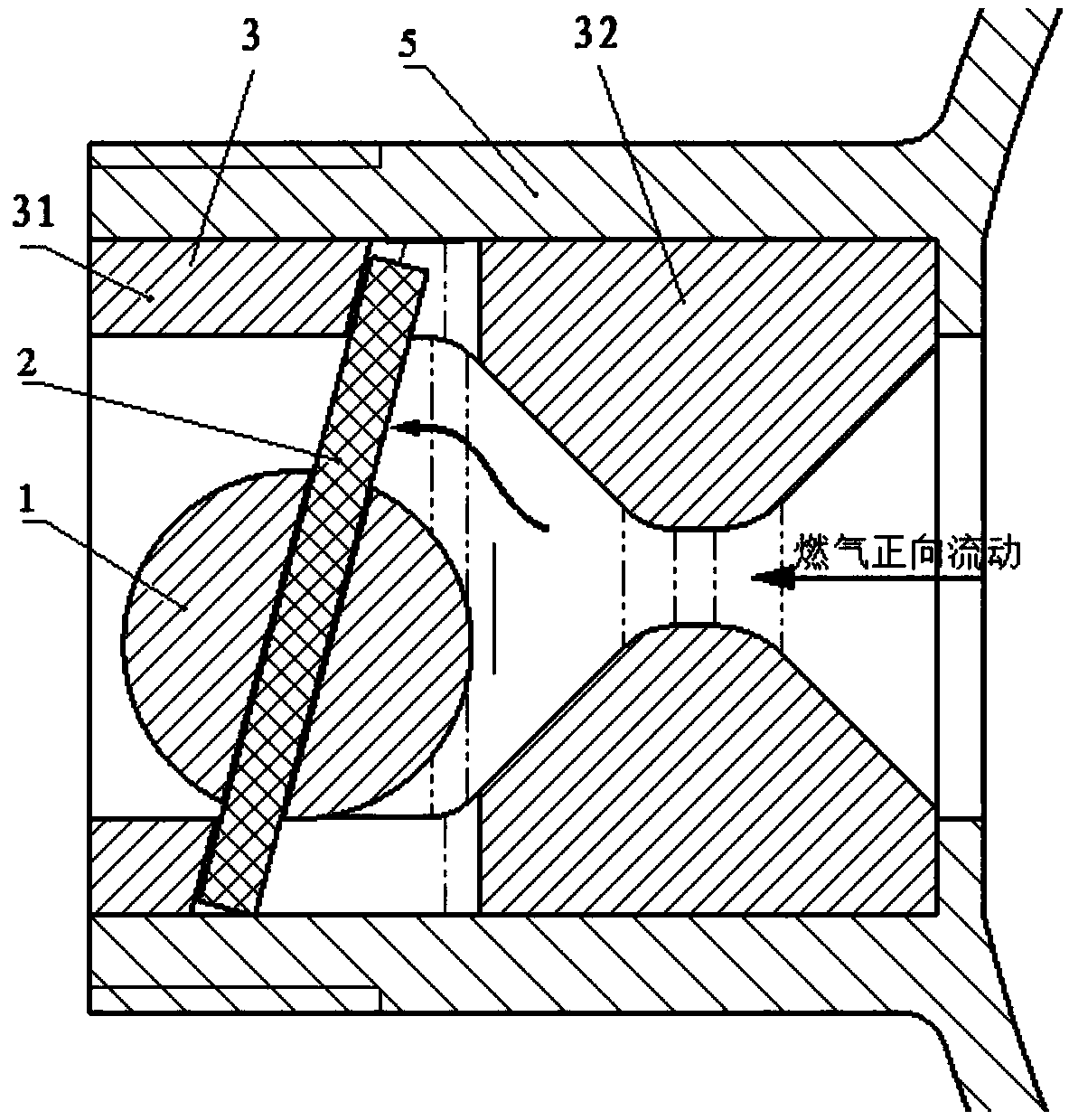

Kitchen lampblack discharge system

InactiveCN103123136APrevent reverse flowOpen flexibleDomestic stoves or rangesLighting and heating apparatusEnvironmental engineeringCheck valve

The invention provides a kitchen lampblack discharge system which has good effect and is convenient to maintain. The kitchen lampblack discharge system comprises a range hood, a check valve, a smoke discharge pipe and a public flue, wherein the smoke discharge pipe is directly and hermetically connected with the public flue, the check valve comprises a vertical pipe which is internally provided with a circular valve plate, the valve plate is rotatably supported on the pipe wall of the vertical pipe by virtue of a transverse shaft which radially penetrates through the valve plate, and the pipe wall of the vertical pipe is provided with a blocking point; when the valve plate is in a horizontal state, the edge of the valve plate is depressed on the blocking point, a weight gain plate is fixed on the valve plate which is located above the blocking point and is close to the blocking point, the upper end and lower end of the vertical pipe are respectively sleeved on the lower end of the smoke discharge pipe and the air outlet of the range hood. In the invention, the check valve is additionally arranged between the air outlet of the range hood and the smoke discharge pipe, and the check valve is connected with the air outlet of the range hood and the smoke discharge pipe in a dismountable way, so as to be convenient to dismount and clean.

Owner:王惠蕾

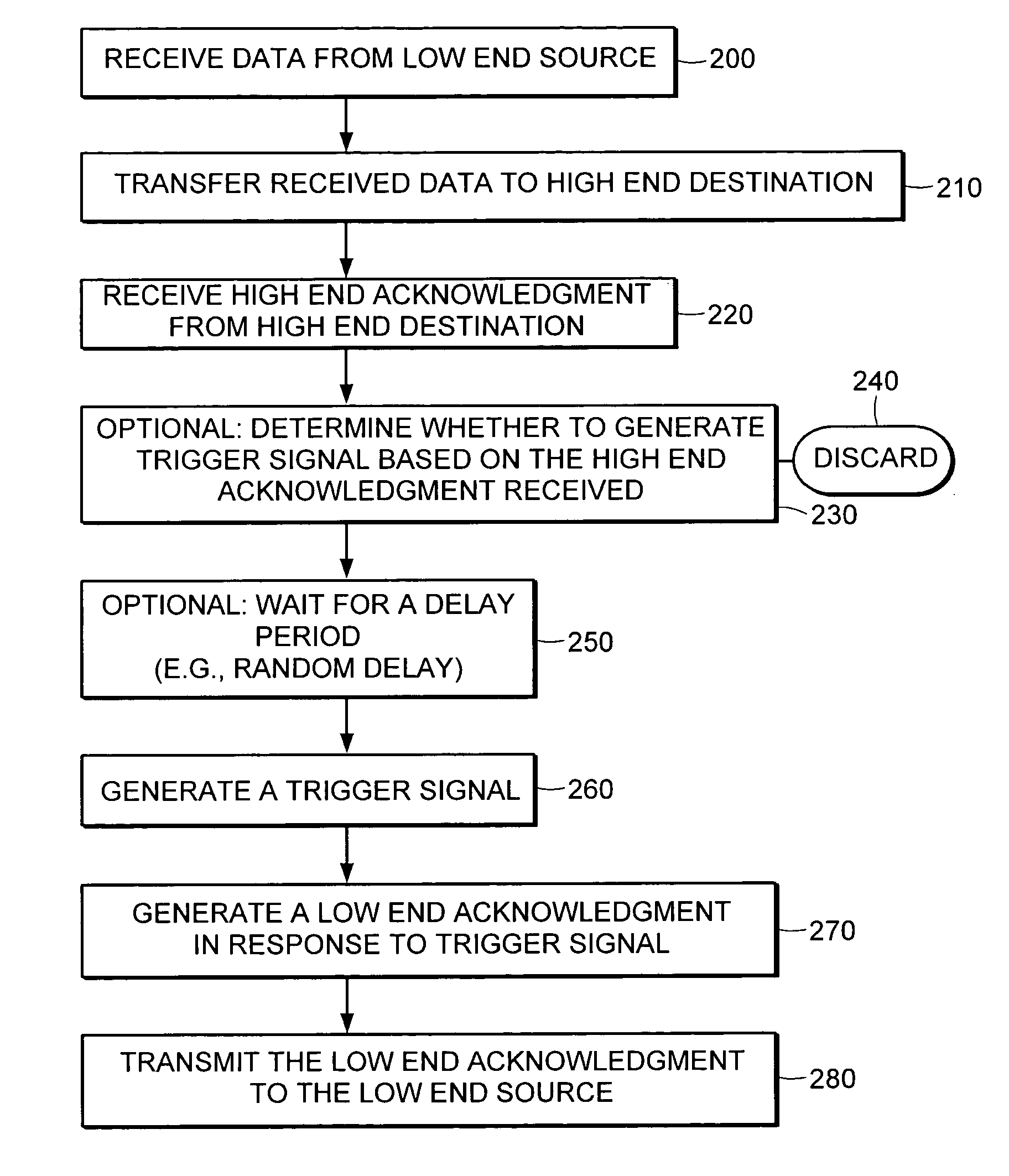

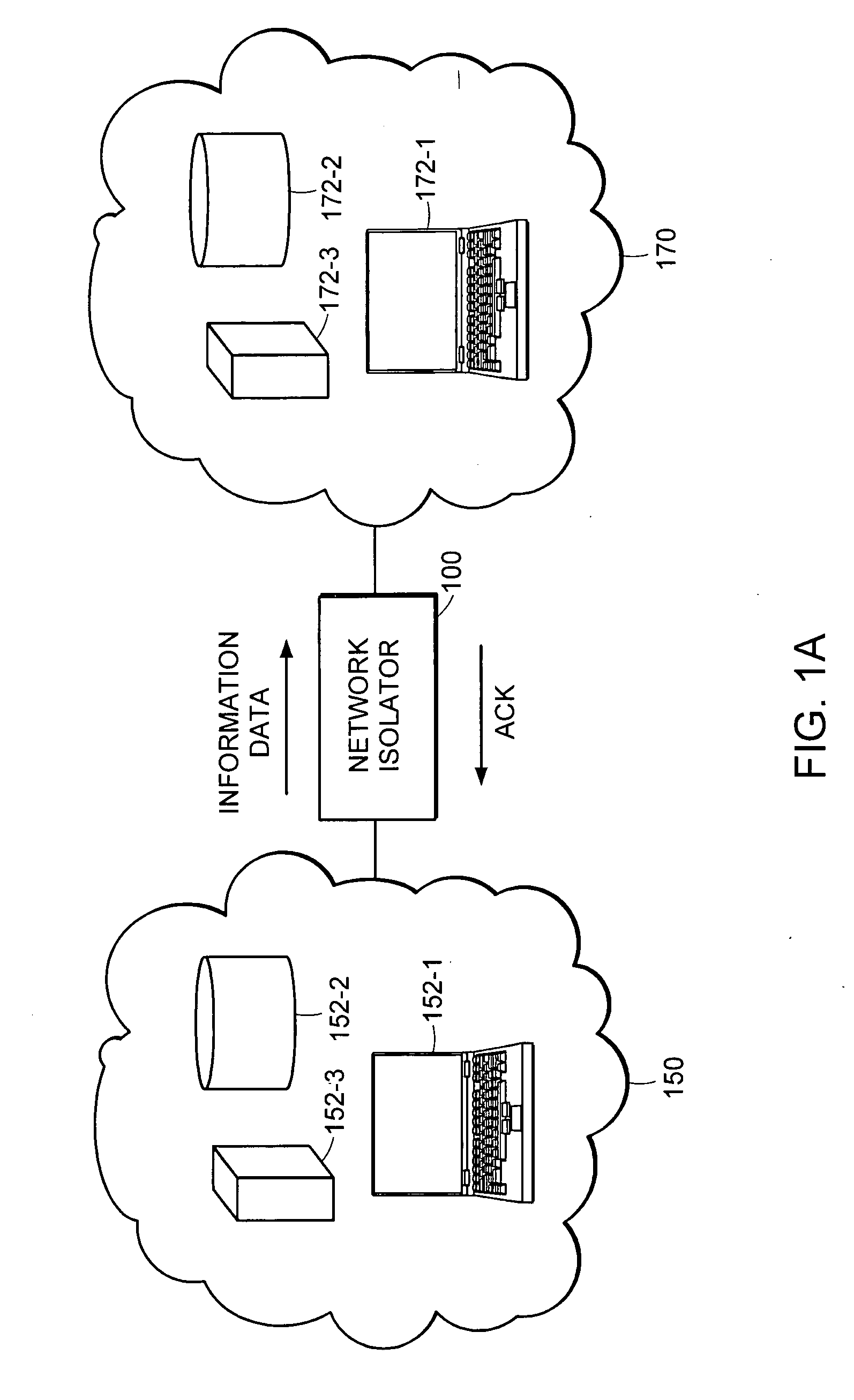

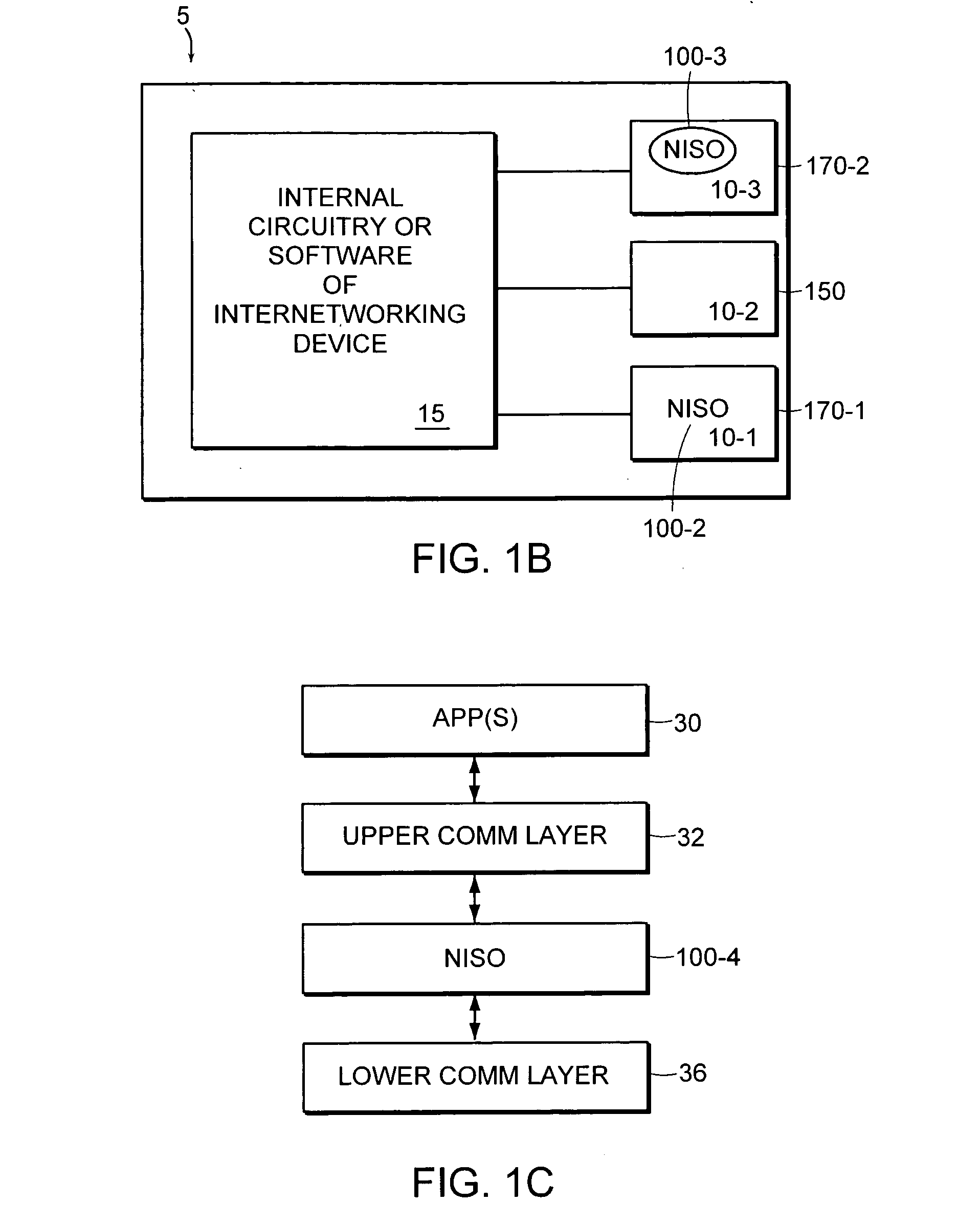

Low-to-high information security protection mechanism

InactiveUS20050044407A1Prevent reverse flowPrevent backflowDigital data processing detailsMultiple digital computer combinationsProtection mechanismPayload

A system and method for communicating data from a low security assurance source to a high security assurance destination in which information data is transferred from the low end source to the high end destination, but acknowledgments from the high end destination are not directly returned back to the originating source. Rather, receipt of an acknowledgment from a high end destination triggers the generation of a new acknowledgment which is then transmitted back to the originating low end source to acknowledge receipt of the information data. The low end acknowledgment may be generated from an acknowledgment template in which the data payload is empty.

Owner:MASSACHUSETTS INST OF TECH

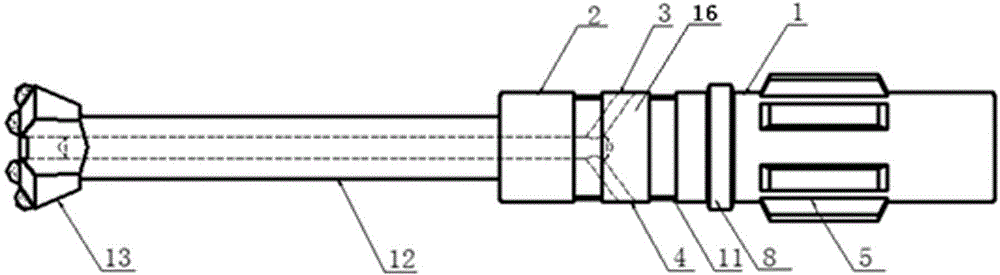

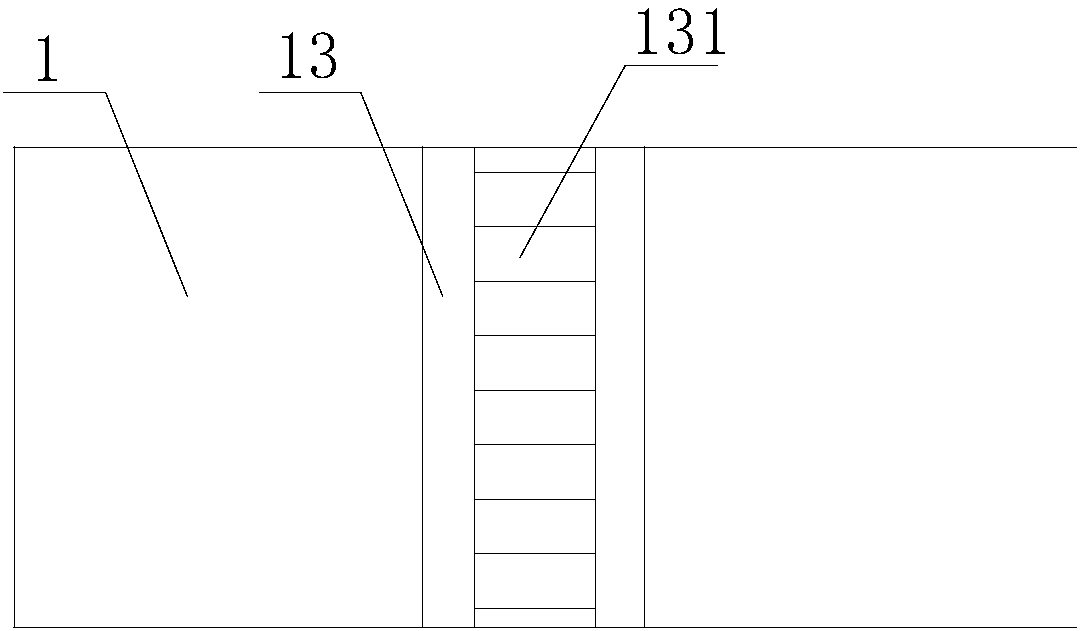

Blast furnace tap hole apparatus

ActiveCN103981314AAvoid breakingReduce assembly partsBlast furnace componentsBlast furnace detailsScrew threadDrill bit

The invention provides a blast furnace tap hole apparatus. The apparatus comprises a drilling rod, a connecting sleeve and a bit shank which are sequentially connected; the drilling rod has a through hole, a drill bit is welded to one end of the drilling rod, the other end of the drilling rod has a threaded connection with the connecting sleeve, a sealing sleeve is arranged between the connecting sleeve and the bit shank, and the connecting sleeve, the sealing sleeve and the bit shank form one body; the sealing sleeve is provided with a wind inlet and a water inlet, and the wind inlet and the water inlet are connected with the through hole respectively; and one end of the bit shank far from the sealing sleeve is provided with a stern notch, the middle portion of the bit shank is provided with a spline, and the spline and the bit shank form one body. The bit shank, the connecting sleeve and the sealing sleeve are designed to form one body, so the assembling part and the connecting portion are reduced, and the fracture of the weak link of a fitting connection is avoided; and the tail end of the bit shank is provided with the impact stern notch, so when an opening machine impacter impacts, an impact tail portion is difficult to impact and damage, and the service life of a connecting mechanism is prolonged.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

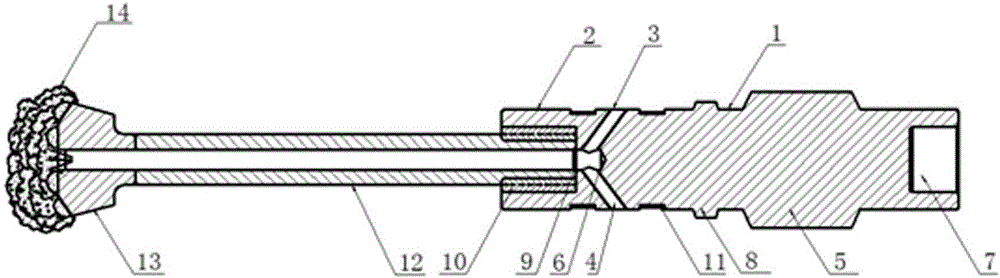

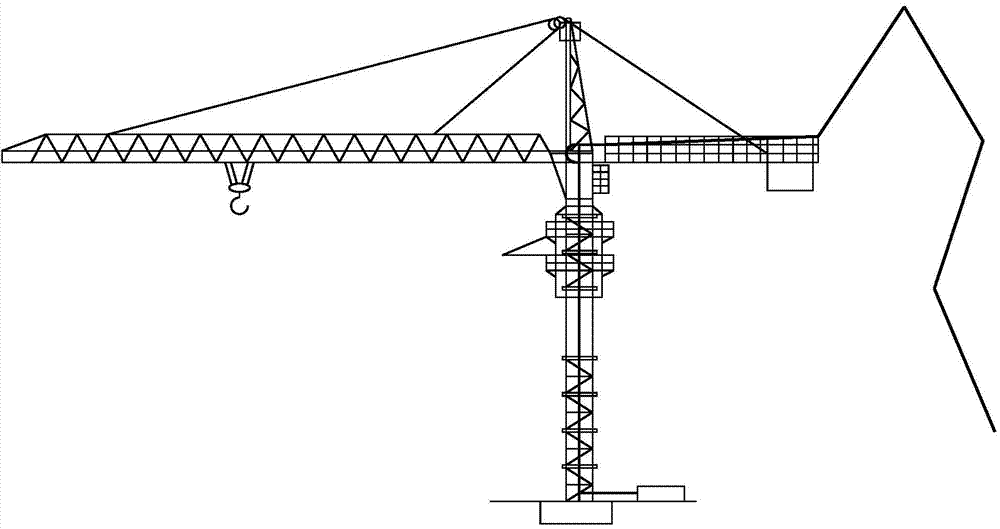

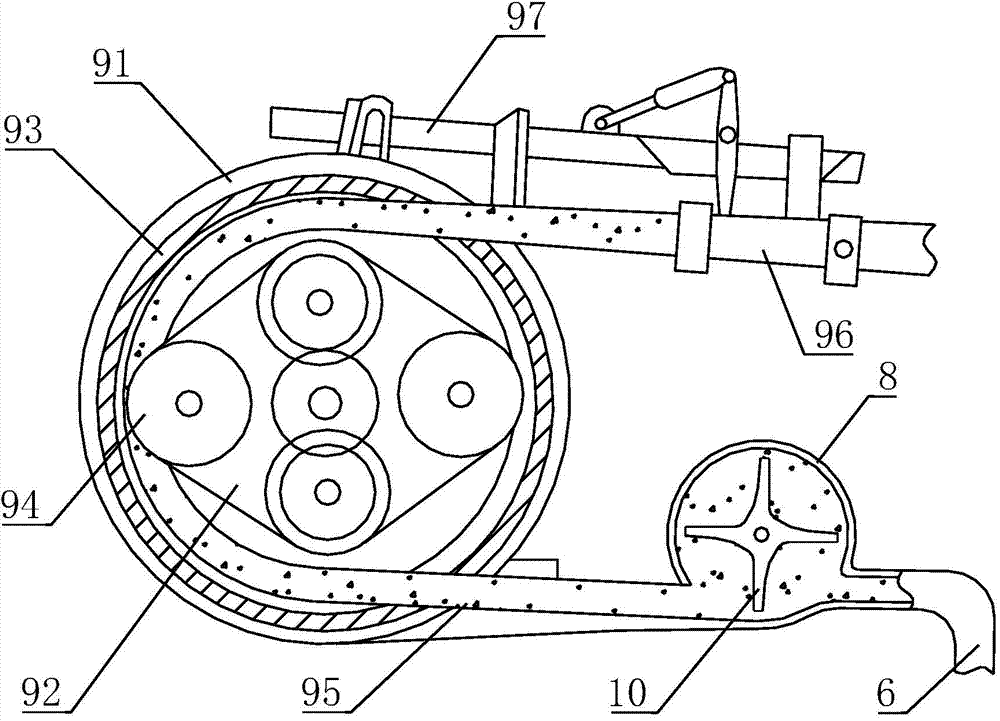

Tower crane type concrete delivery device

The invention relates to a tower crane type concrete delivery device which comprises a tower truss, a tower cap, a lifting arm, a balance arm, a delivery pump, a delivery pipe and an arm frame, wherein the tower cap is arranged on the upper end of the tower truss; the lifting arm and the balance arm are horizontally connected with the upper end of the tower truss through rotating discs; the arm frame is arranged on the balance arm in a folded way, the input end of the arm frame is connected with the output end of the delivery pump through the delivery pipe fixed on the tower truss, and the delivery pump is arranged outside a base of the tower truss; the delivery pipe is provided with an accelerating pump used for accelerating the flow of a concrete material. According to the tower crane type concrete delivery device, the arranged tower truss serves as a support and guide structure of the delivery pipe, so that the height of a delivered material can be increased, and the synchronous adjustment of the height is carried out along the lifting of the tower truss; in addition, the arm frame is arranged on the balance arm, under a general condition, extra weight counterbalance is unnecessary, additionally, the height is changed with the height of the tower truss, and the output end of the arm frame is positioned above a pouring part all the time, so that the stability of the pitch number of the arm frame can be kept, the height is increased, the cost is less increased, and high working efficiency and low cost are achieved.

Owner:吴春生

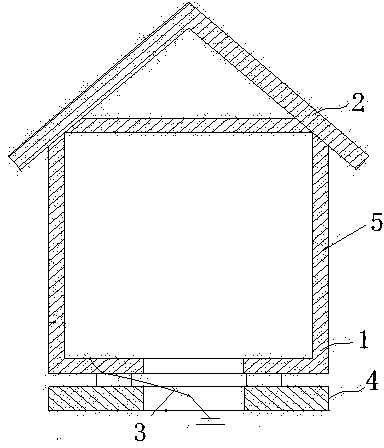

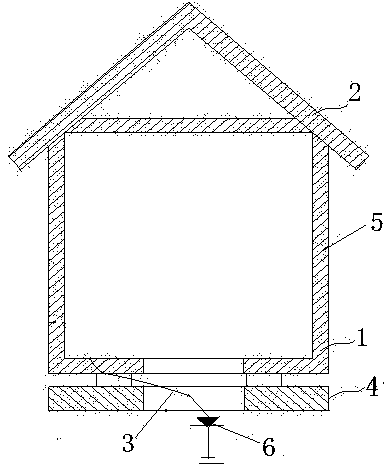

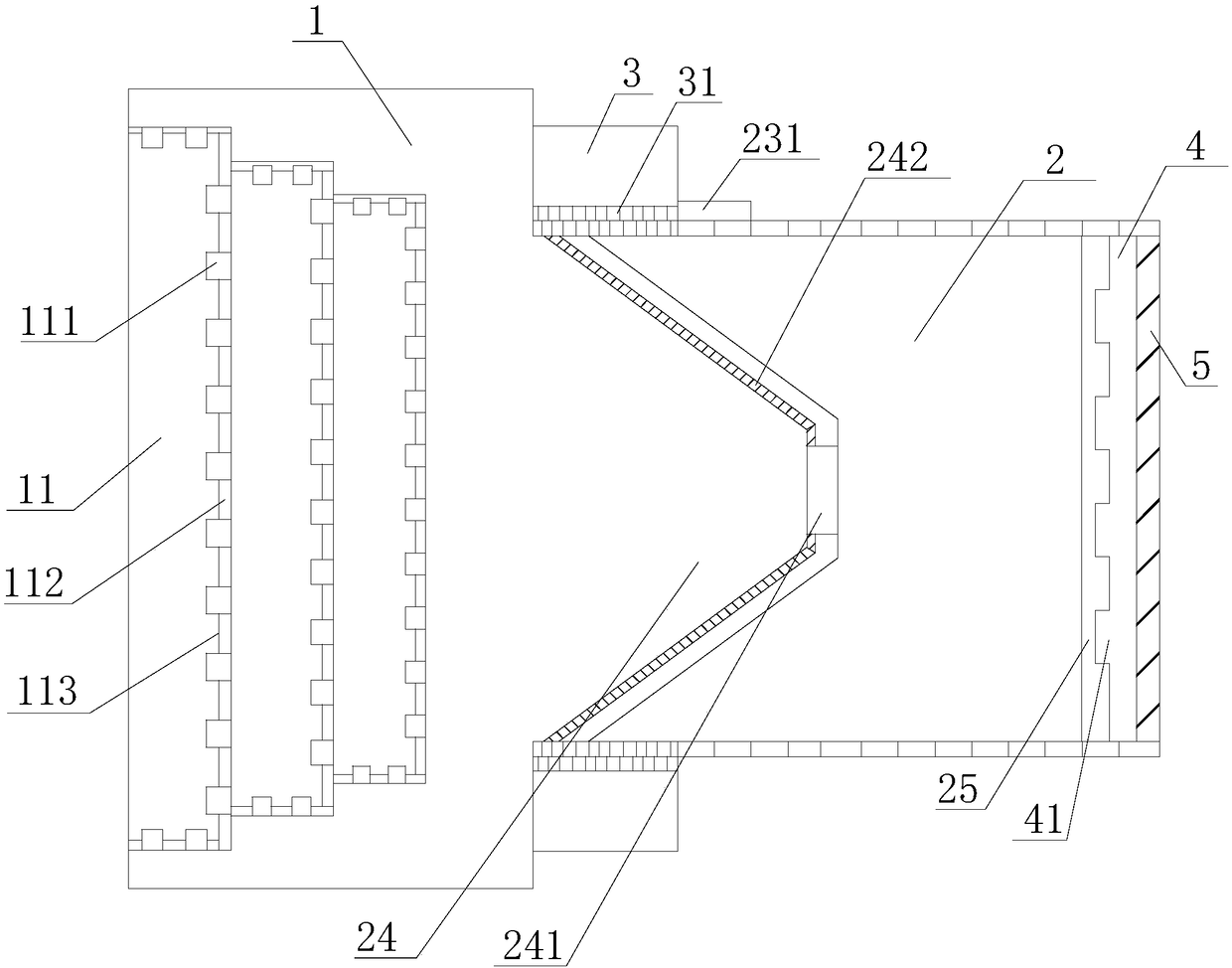

Safety electrical distribution box

InactiveCN104332839APrevent the ground current from flowing reversely to the top of the distribution box shellEliminate electric shock accidentsEarthing arrangementsSubstation/switching arrangement casingsCushionElectricity

The invention relates to a safety electrical distribution box. The safety electrical distribution box comprises a rectangular box body (5), wherein a tapered cover plate (2) is arranged on the rectangular box body (5); a through hole for a wire to pass through is formed in the lower surface of the rectangular box body (5) and an insulating cushion (4) is also arranged on the lower surface of the rectangular box body (5); the safety electrical distribution box is characterized in that a ground wire (3) is additionally arranged at the bottom of the rectangular box body (5), and the ground wire (3) is connected to the bottom of the rectangular box body (5) and used for immediately guiding static electricity on the distribution box into the ground for releasing. The safety electrical distribution box has the advantages that the current of the ground wire flows back to the housing of the distribution box by use of the one-way channel characteristic of a diode (6), and the electric shock accident caused by the charged ground wire is thoroughly eliminated.

Owner:STATE GRID CORP OF CHINA +2

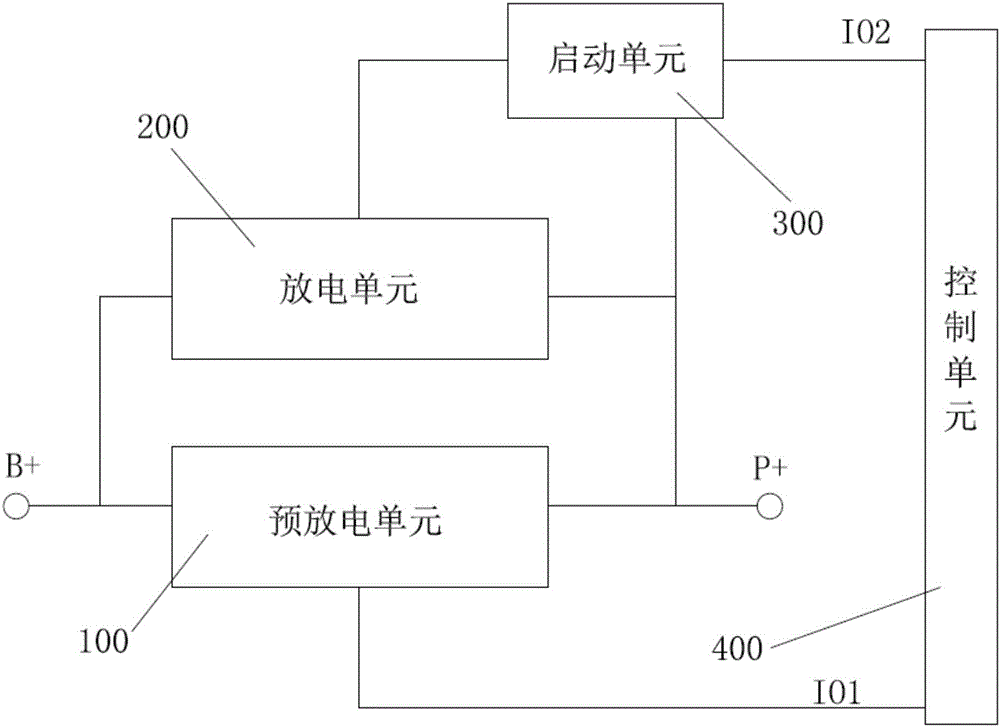

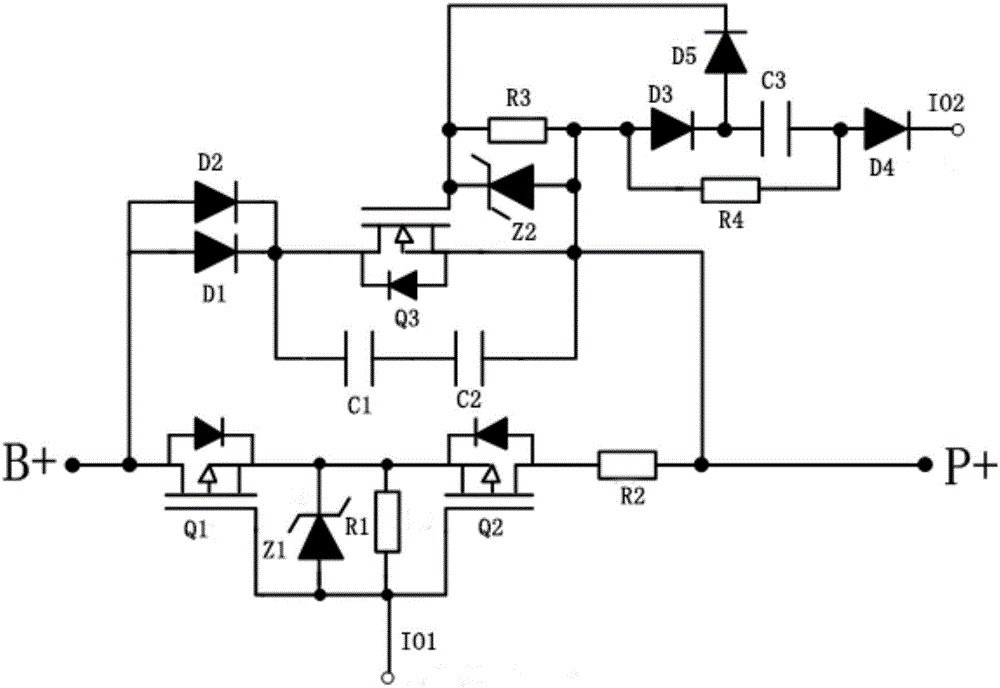

Battery discharging control circuit

InactiveCN107528368AAchieve safe dischargeSwitch back and forthElectric powerSafety/protection circuitsInput controlEngineering

A discharge control circuit for a battery pack, comprising: a pre-discharge unit, a discharge unit, a start unit and a control unit, the input end of the pre-discharge unit is connected to the total positive end of the battery pack, the output end is connected to an external load, the input control end is connected to the control The first output control terminal of the unit is connected; the input terminal of the discharge unit is connected to the total positive terminal of the battery pack, the input control terminal is connected to the output control terminal of the starting unit, and the output terminal is connected to an external load; the first input control terminal of the starting unit It is connected with the output terminal of the discharge unit, and the second input control terminal is connected with the second output control terminal of the control unit. The control unit of the present invention controls the power MOS tube to disconnect and start the pre-discharge unit and the discharge unit, starts the pre-discharge unit to work at the moment of discharge, uses the power resistance of the pre-discharge unit to absorb the peak current, and then disconnects the pre-discharge unit to start the discharge unit , to realize the safe discharge of the battery pack to the external load.

Owner:HUIZHOU BNET TECH CO LTD

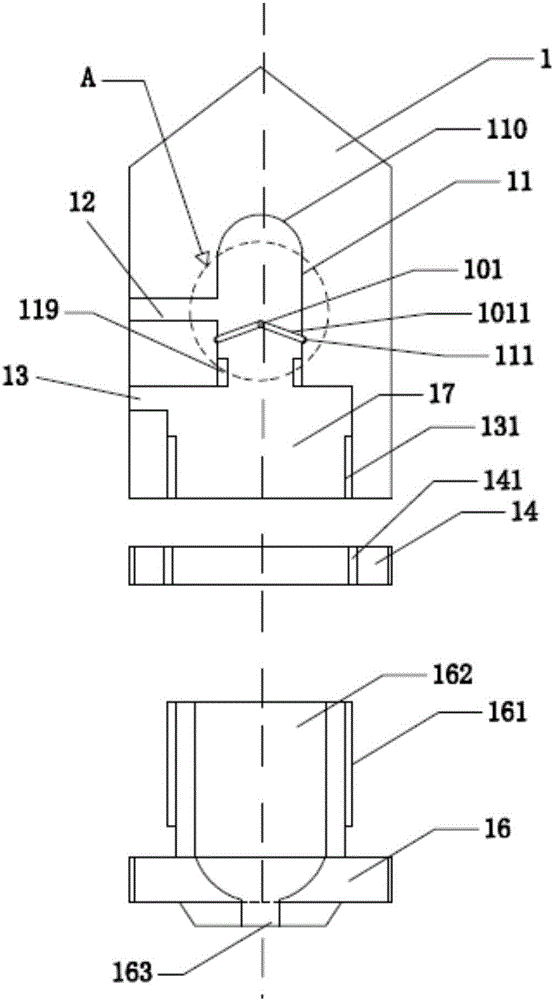

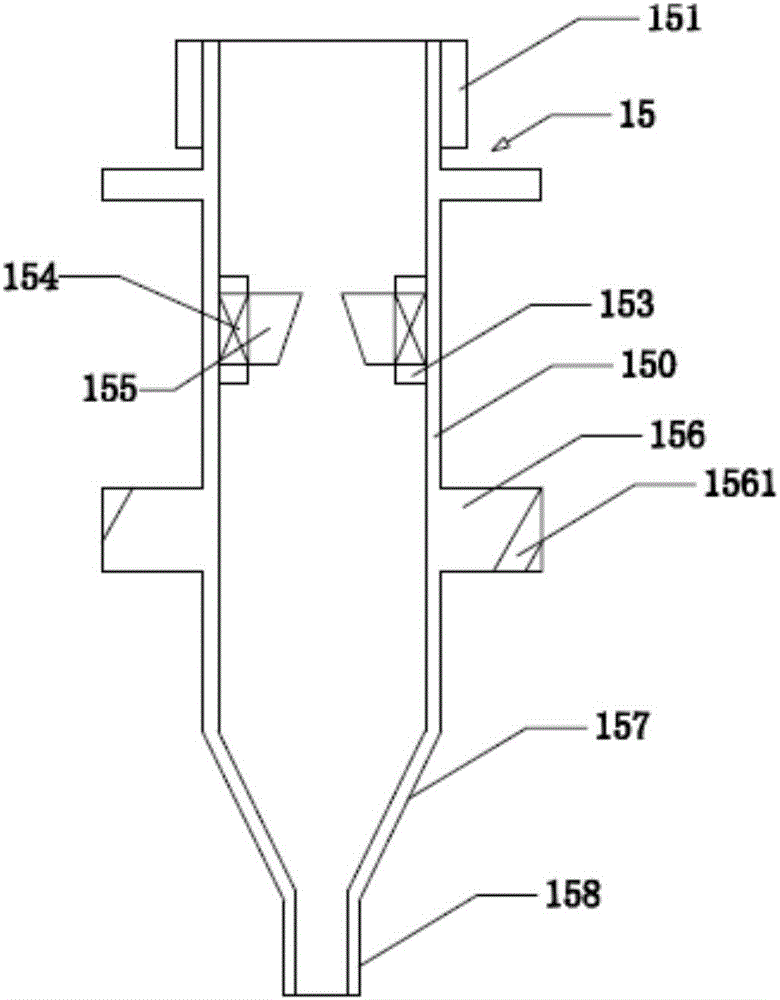

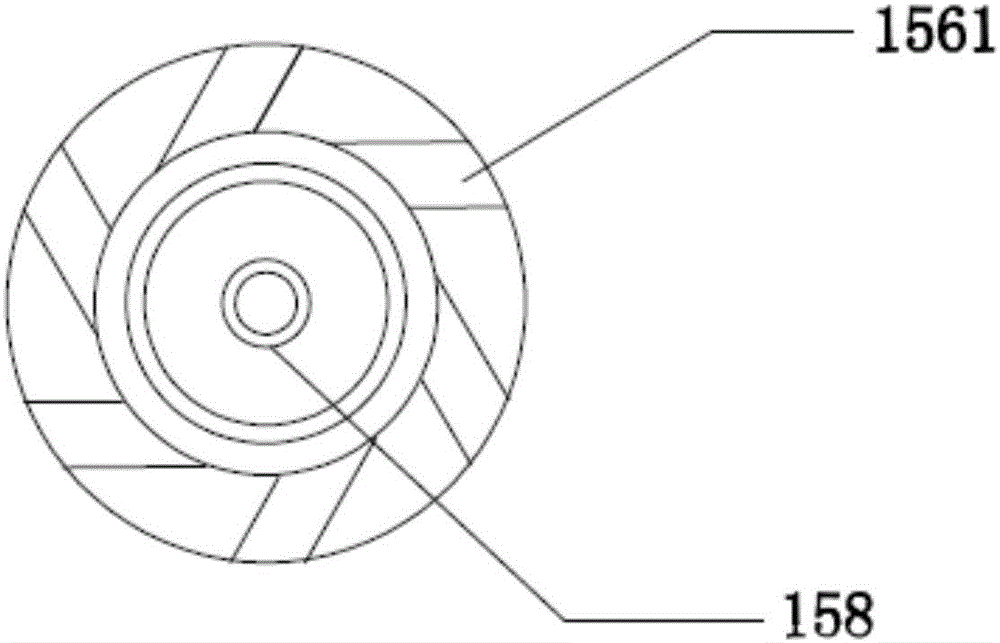

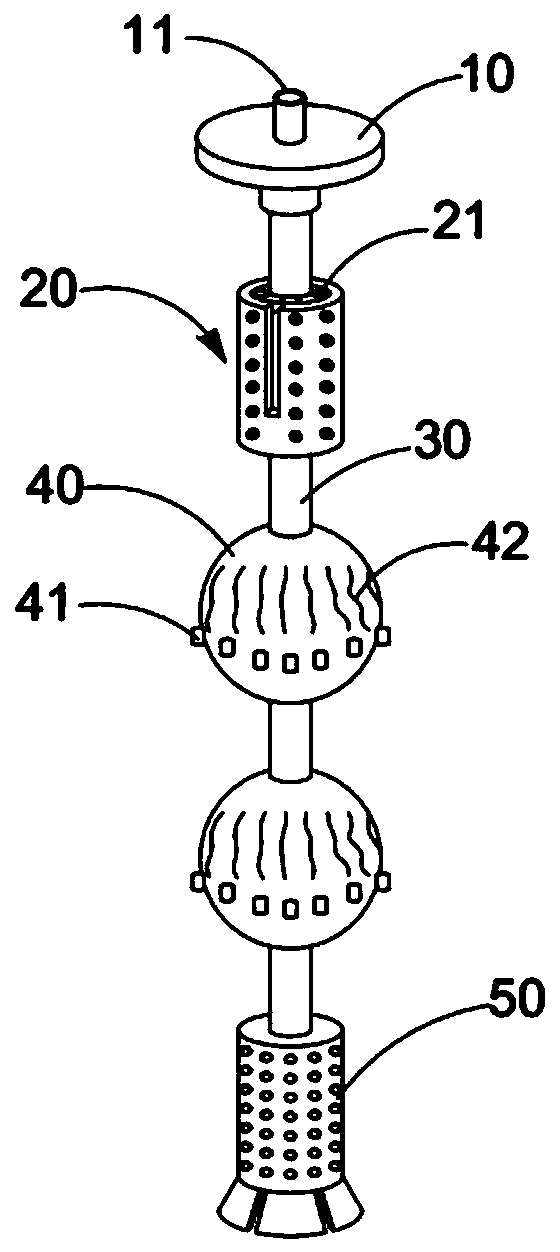

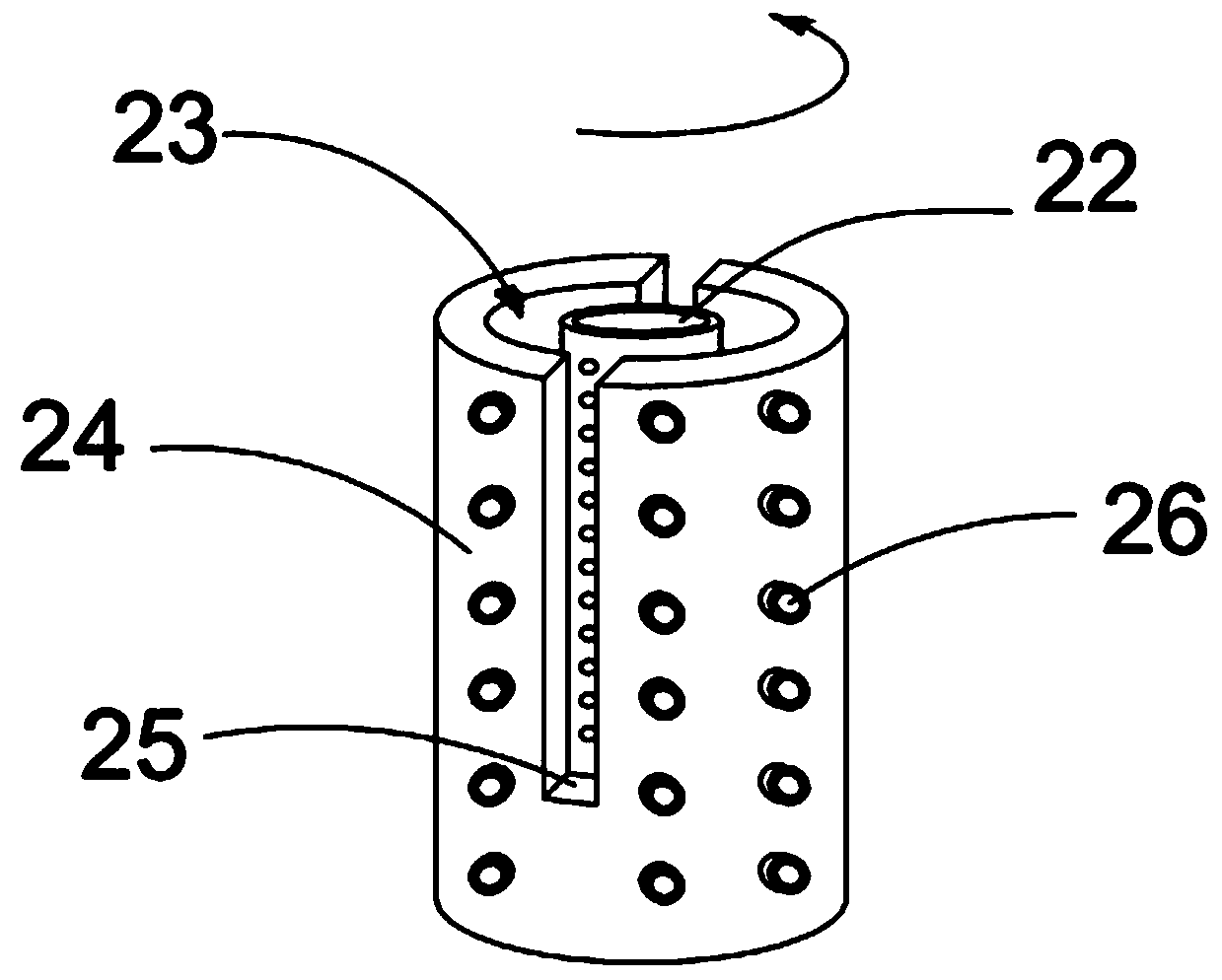

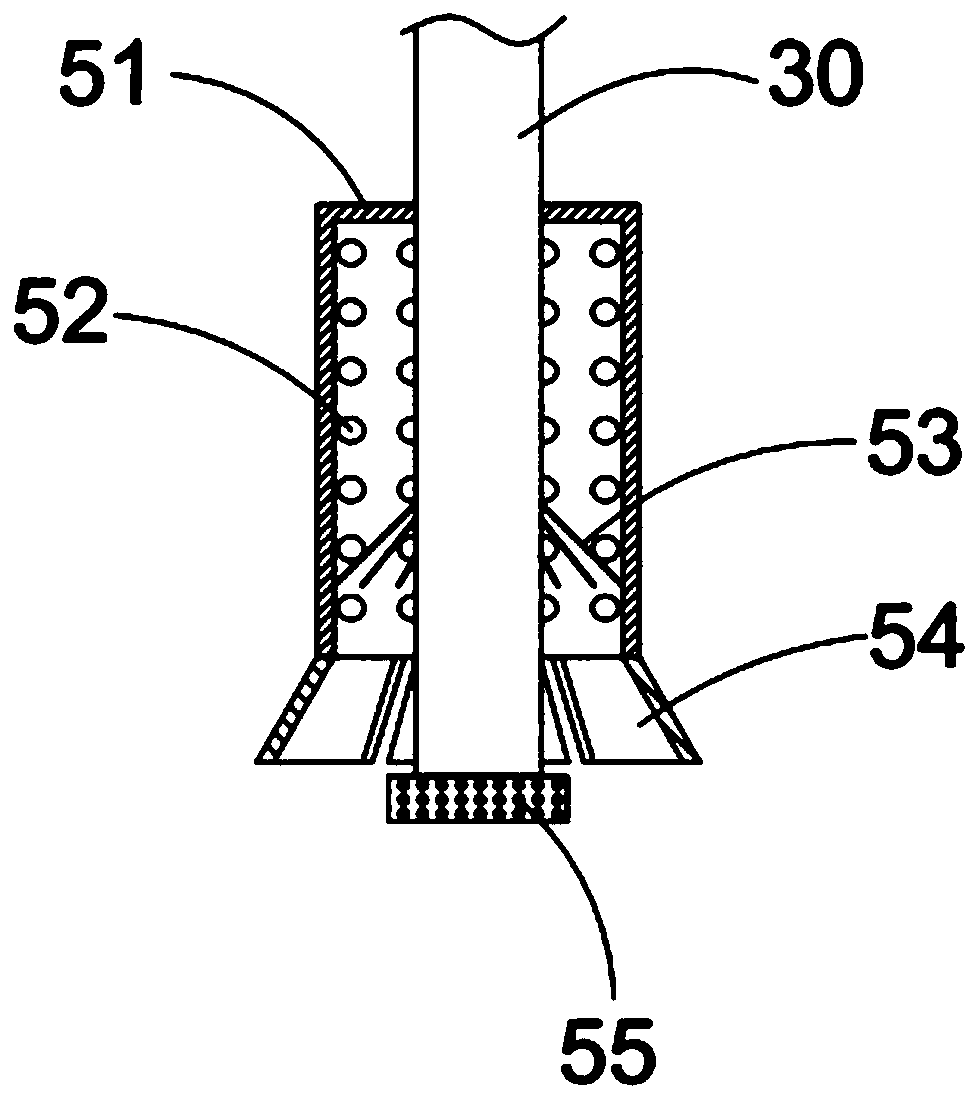

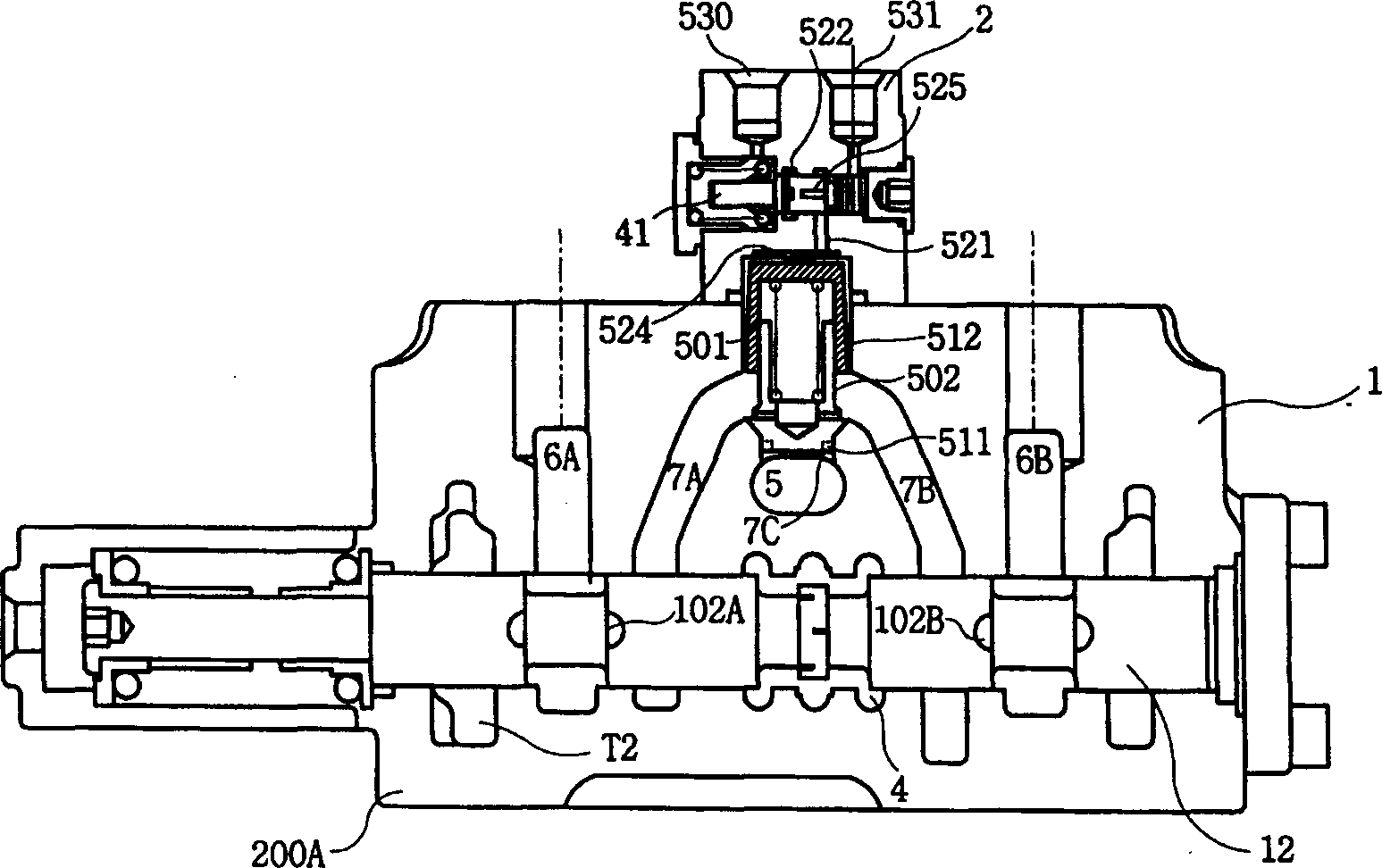

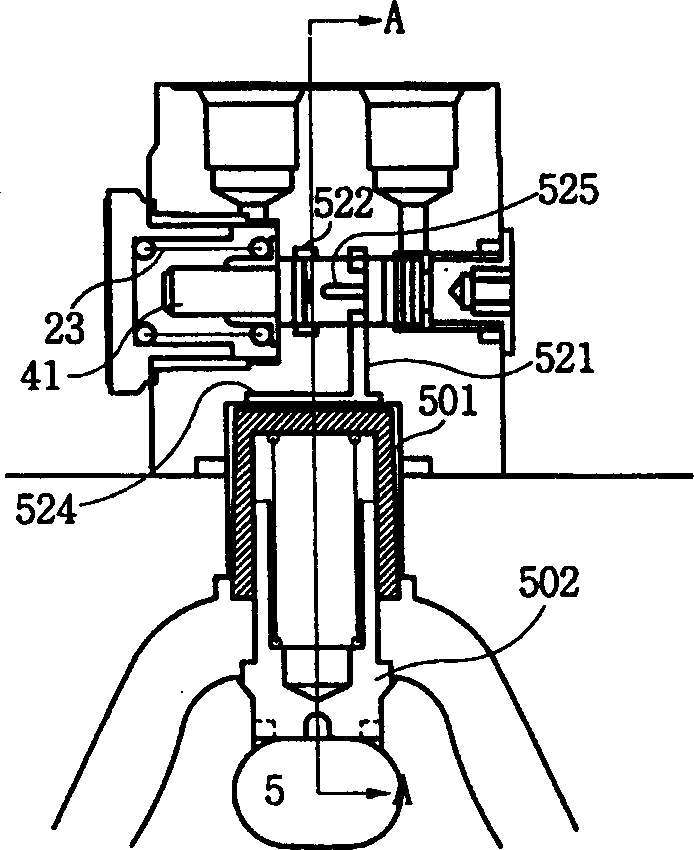

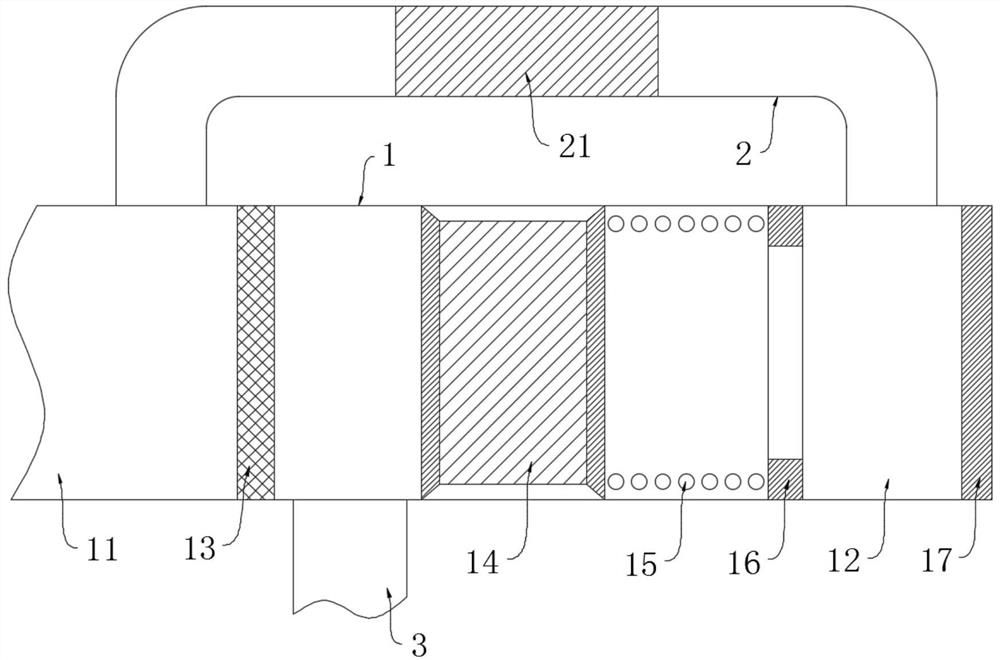

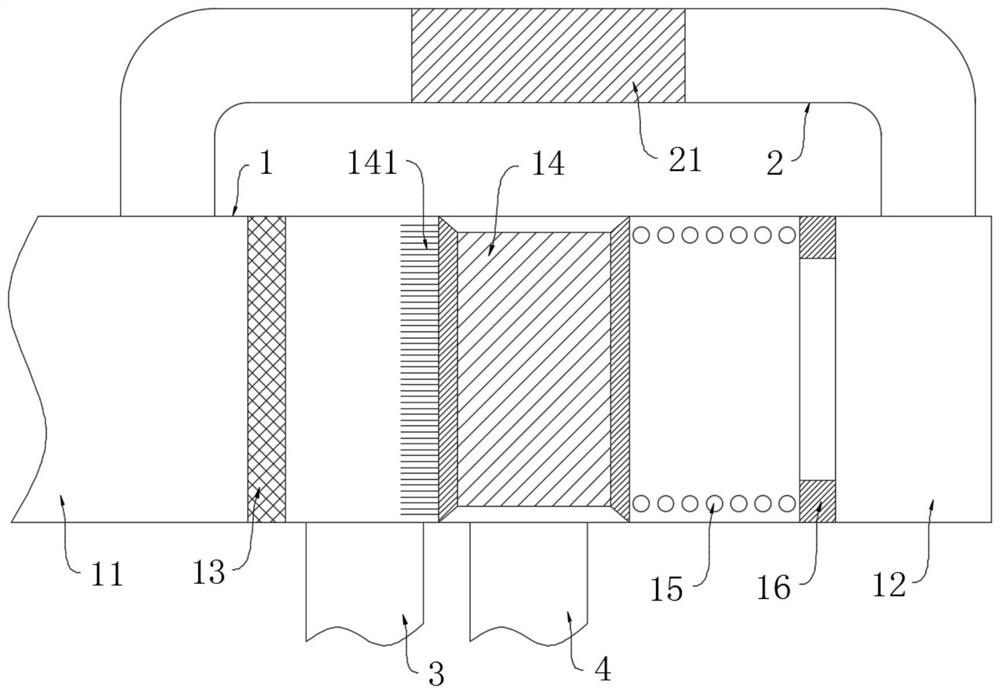

Spray drying gun head assembly

PendingCN106733279AImprove stabilityPrevent reverse flowSpray nozzlesLiquid spraying apparatusSpray nozzleStops device

The invention provides a spray drying gun head assembly which comprises a spraying nozzle fixing head, an adjusting ring, an adjusting cover and a spraying nozzle. The spraying nozzle comprises a barrel and a convex extending ring, the convex extending ring is provided with a plurality of rotational flow channels, a through hole is formed in the bottom of the adjusting cover, and a liquid inlet and an air inlet are formed in the side portion of the spraying nozzle fixing head; a first cavity and a second cavity which are through are formed inside the spraying nozzle fixing head, the liquid inlet is communicated with the first cavity, the air inlet is communicated with the second cavity, and a radial shrinkage part and a spraying pipe are formed in the tail end of the barrel; the spraying pipe penetrates the through hole, and an annular gap is formed between the spraying pipe and the through hole; and a reverse stopping device is arranged in the first cavity to prevent back flow of the liquid to the liquid inlet. In the spray drying gun head assembly, the reverse stopping device is arranged in a liquid conveying channel, and therefore the liquid and air mixing efficiency is improved, air can be effectively prevented from reversely flowing into the liquid channel, and the atomization effect is improved.

Owner:SHENZHEN SUNEVAP TECH

Pipeline dirt removal device used for civil engineering

The invention discloses a pipeline dirt removal device used for civil engineering, and belongs to the technical field of pipeline cleaning. The pipeline dirt removal device comprises a water deliverypipe and a collection assembly. The collection assembly is mounted at one end of the water delivery pipe, and the other end of the water delivery pipe is connected with a water delivery port. A scraping assembly and a cleaning assembly are sequentially mounted on the portion, behind the collection assembly, of the water delivery pipe, wherein the cleaning assembly comprises an inner pipe connectedwith the water delivery pipe in a sleeved mode, the inner pipe is connected with a rotatable outer pipe through a bearing, water outflow pipe orifices are uniformly distributed in the surface of theouter pipe and the surface of the inner pipe, and the water outlet ends of the water outflow pipe orifices are convex. Water outlets corresponding to the water outflow pipe orifices in position are formed in the outer surface of the joint of the water delivery pipe and the inner pipe. The pipeline dirt removal device has the advantages that the interior of curved pipelines can be cleaned, solids,grease, dirt and the like in the pipelines can be removed, and the cleaning efficiency is high.

Owner:ZHEJIANG OCEAN UNIV

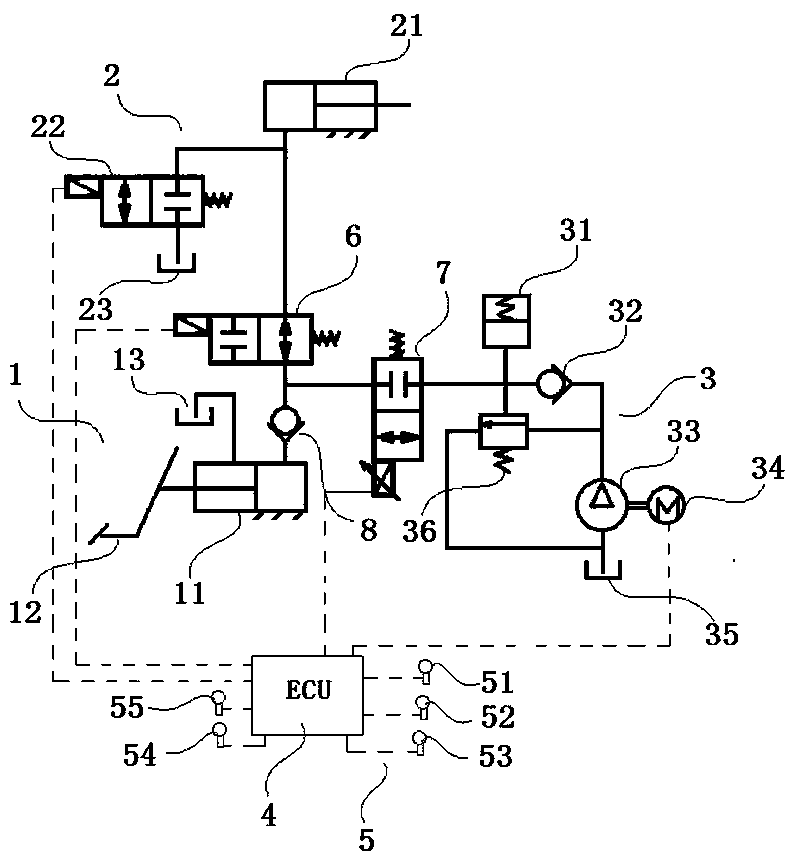

Automatic automobile brake hydraulic control system and automobile with same

The invention relates to the technical field of automobiles, in particular to an automatic automobile brake hydraulic control system which comprises a brake main cylinder assembly, a brake wheel cylinder assembly, an energy storage assembly, an electric control unit, an information acquisition assembly, a first electromagnetic valve and a second electromagnetic valve. An oil outlet of the brake main cylinder assembly is communicated with an oil inlet of the first electromagnetic valve, an oil outlet of the first electromagnetic valve is communicated with an oil inlet of the brake wheel cylinder assembly, an oil outlet of the energy storage assembly is communicated with an oil inlet of the second electromagnetic valve, an oil outlet of the second electromagnetic valve is communicated with the oil inlet of the first electromagnetic valve, and the energy storage assembly, the brake wheel cylinder assembly, the first electromagnetic valve, the second electromagnetic valve and the information acquisition assembly are electrically connected with the electric control unit. The automatic automobile brake hydraulic control system has the advantages that the automatic automobile brake hydraulic control system is improved on the basis of the traditional anti-lock brake system (ABS) hydraulic control systems, oil circuits are simple, and the automatic automobile brake hydraulic control system and an automobile with the automatic automobile brake hydraulic control system have conventional brake, anti-lock brake system and automatic brake functions.

Owner:LINGNAN NORMAL UNIV

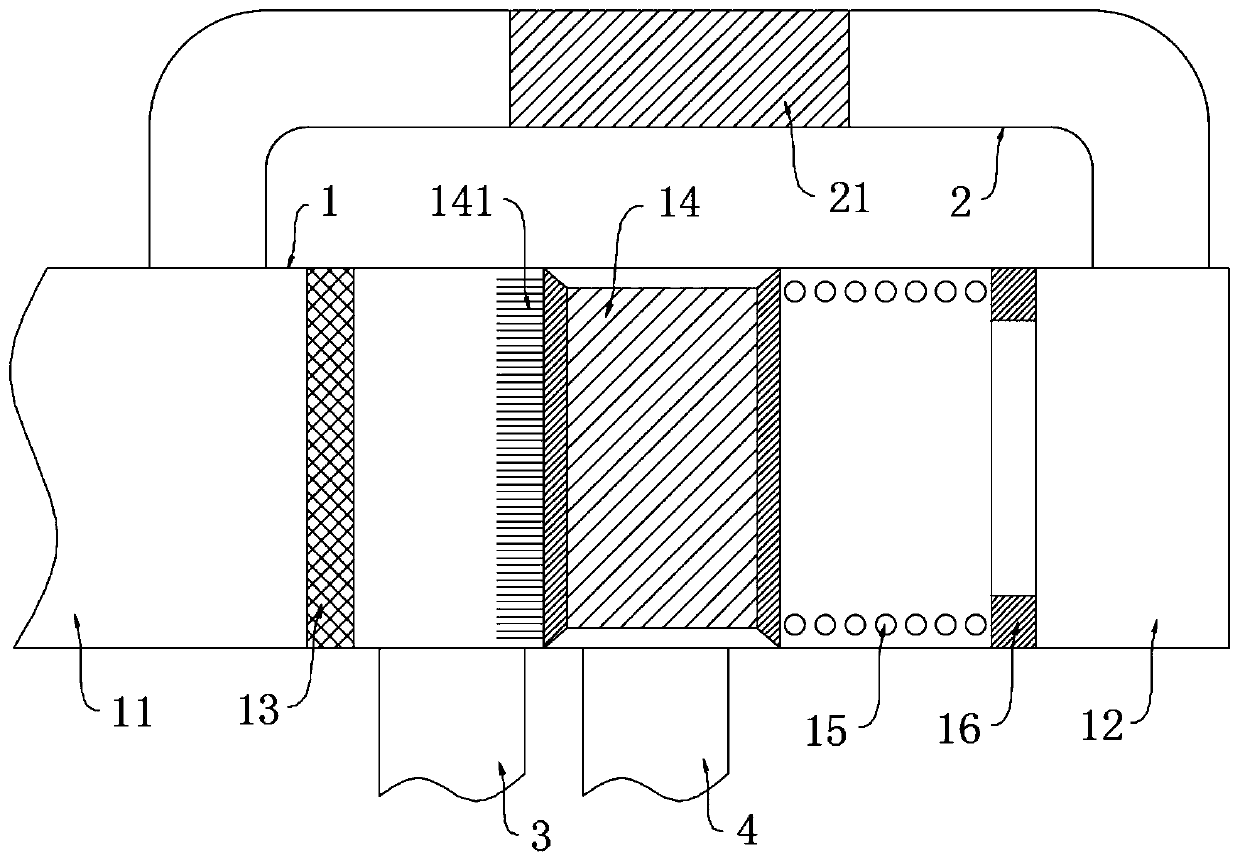

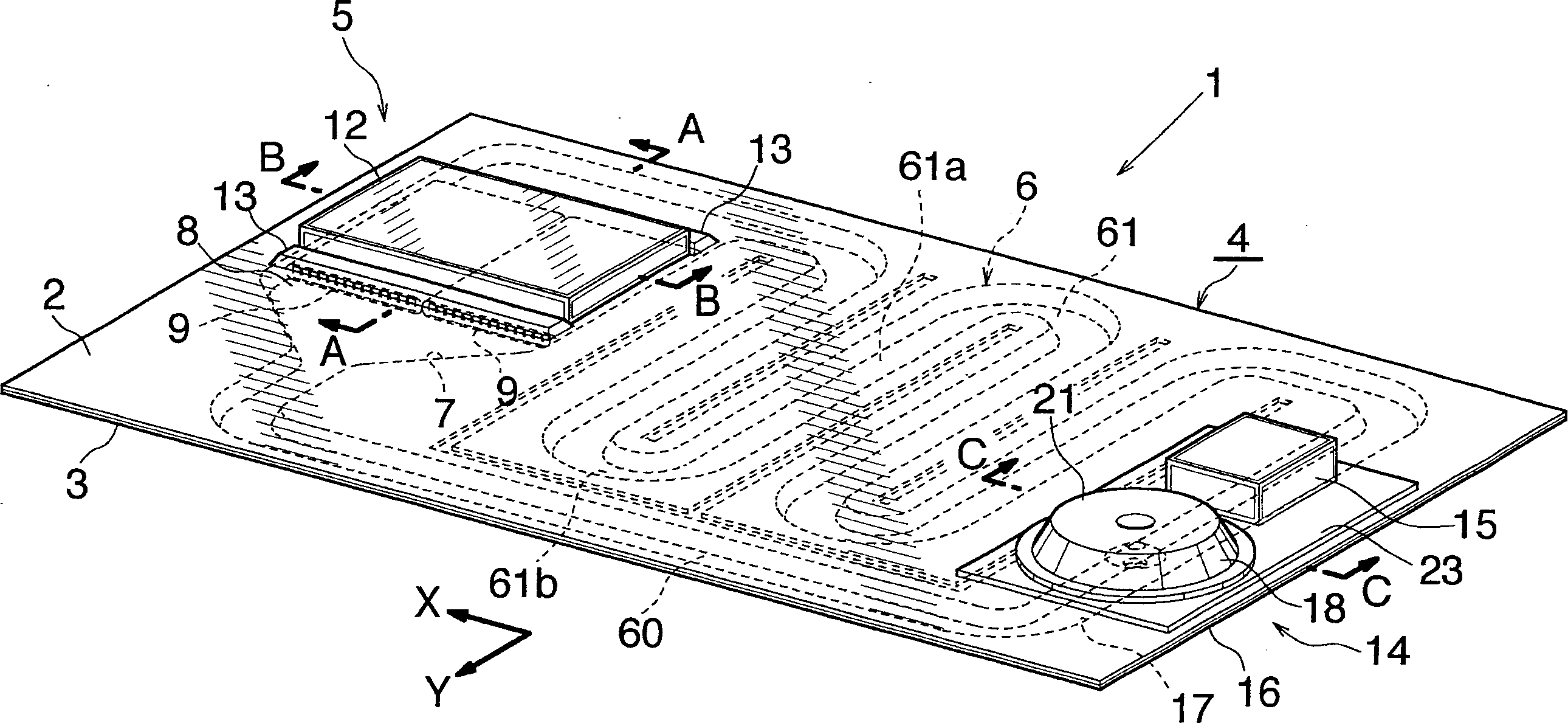

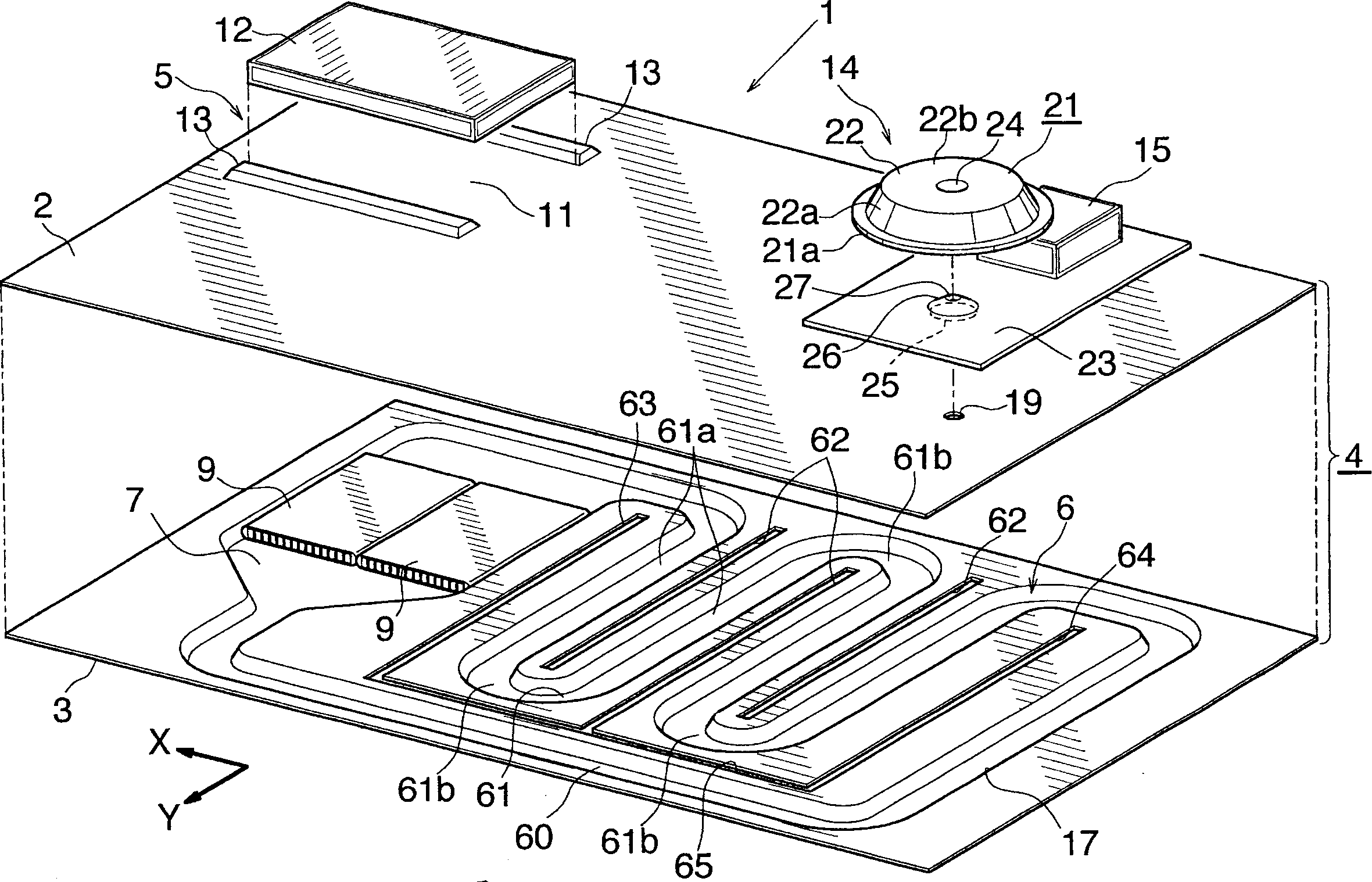

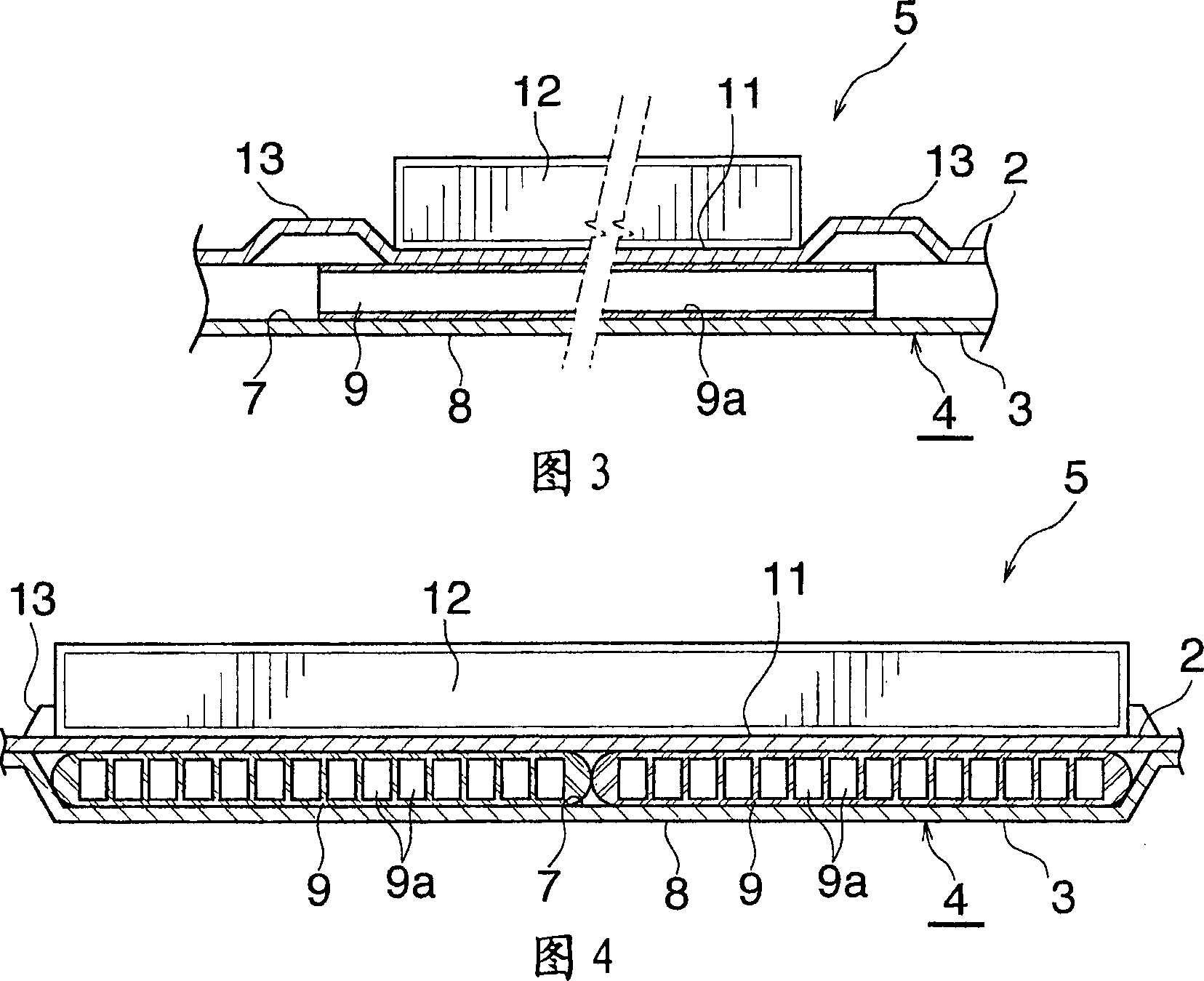

Expansion tank device, process for fabricating expansion tank device, and liquid cooling radiator

InactiveCN1878996AAvoid breakingImprove cooling efficiencyLighting and heating apparatusSemiconductor/solid-state device detailsExpansion tankCooling fluid

An expansion tank device 14 comprises a tank installation base 16 having a cooling liquid channel 17 and an expansion tank 18 provided on the upper surface of the installation base 16. The base 16 has a communication hole 19 for holding space above the upper surface thereof in communication with the cooling liquid channel 17. The expansion tank 18 has a tank main body 21 including an upwardly bulging portion 22 having an opening at its lower end, and a bottom plate 23 joined to the lower end of the tank main body 21 for closing the lower-end opening of the bulging portion 22 and joined to the upper surface of the tank installation base 16. The bottom plate 23 is provided at a portion thereof corresponding to the communication hole 19 with a through hole 25 communicating with the communication hole 19. The bottom plate 23 is provided with a baffle plate 26 formed along the entire circumference of the inner peripheral edge thereof defining the through hole 25 and slanting upwardly toward the center of the through hole 25. The expansion tank device 14 removes the air in the cooling liquid from the circulating system, precludes the system from breaking and prevents the decrease in the amount of cooling liquid within the circulating system.

Owner:SHOWA DENKO KK +1

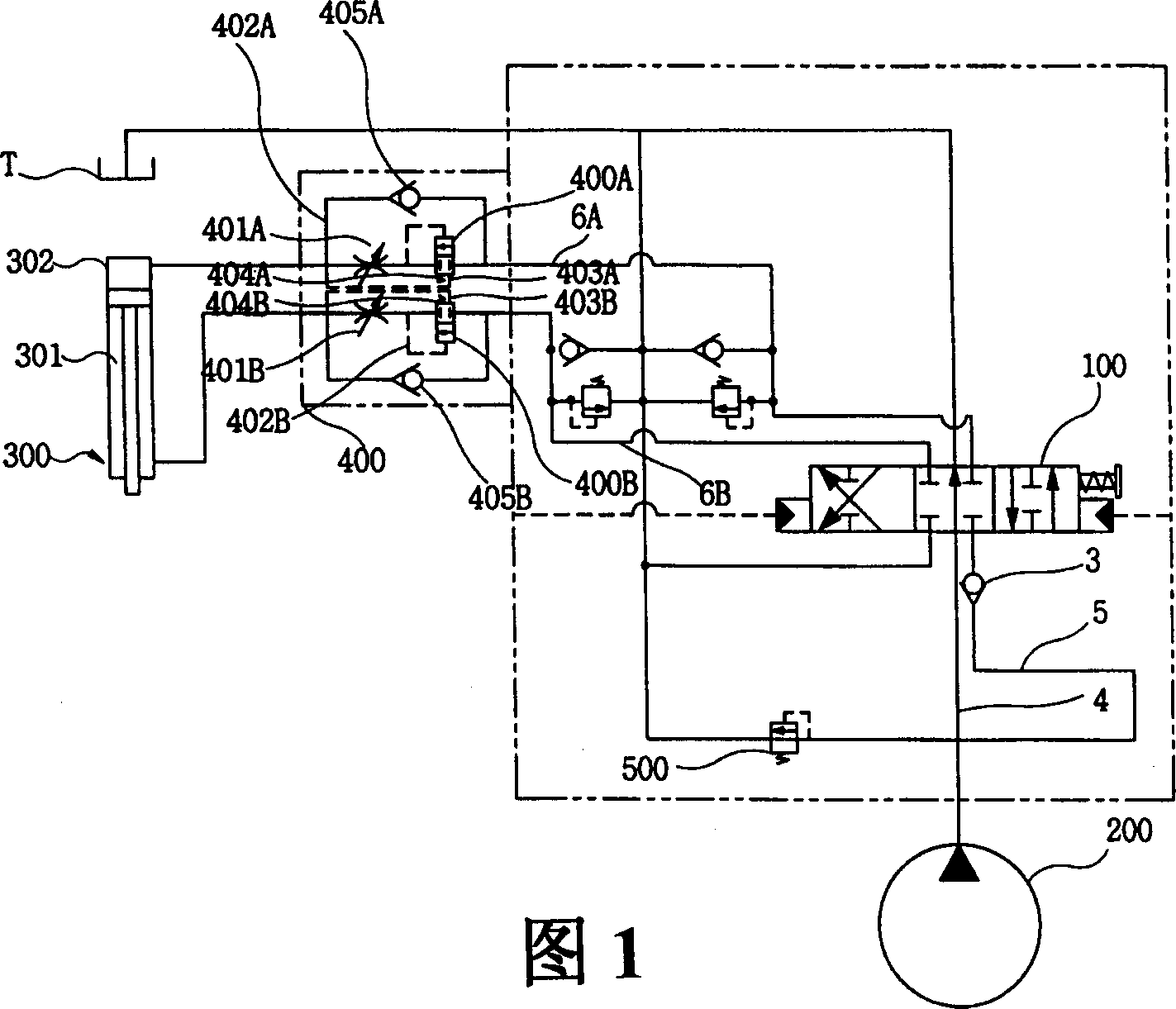

Hydraulic changeable controller for heavy construction equipment

InactiveCN1427185APrevent reverse flowServomotor componentsServomotorsHydraulic pumpControl variable

Hydraulic changeable controller for heavy construction equipment is disclosed. A seat valve element provided in an oil passage between a pump path and a feeder path for controlling the amount of oil to be supplied to a variable throttle and auxiliarily controlling the amount of oil flowing into a load path comprises a first seat valve having a control variable throttle to be displaced with a difference between the loading pressure of the load path and pressure on the discharge side of a hydraulic pump for changing an opening area ranging from the pump path to the feeder path with the displacement, a second seat valve having a pilot control variable throttle to be displaced with respective to the first seat valve for determining the displacement of the first seat valve and changing the opening area with the displacement, and a pilot spool having a pilot variable throttle for determining the displacement of the pilot control variable throttle of the second seat valve during change-over.

Owner:SAMSUNG HEAVY IND CO LTD

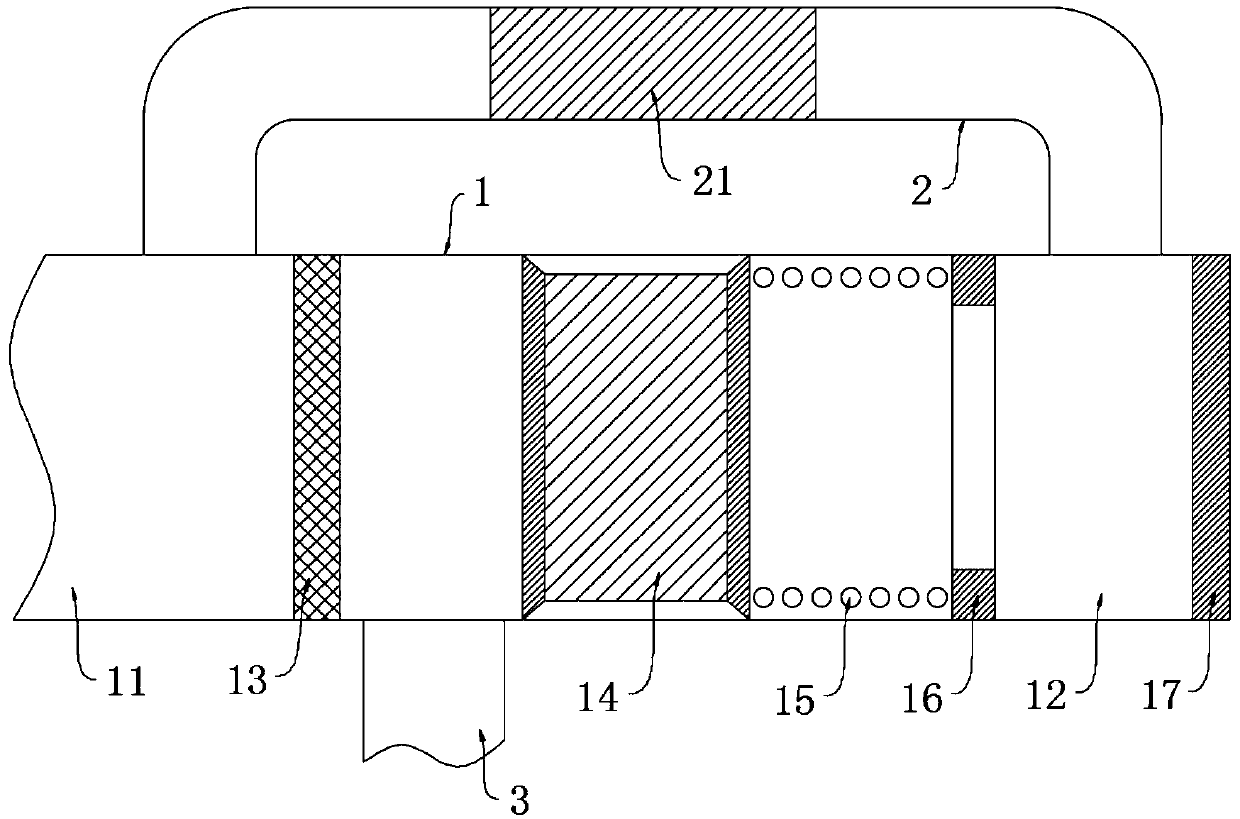

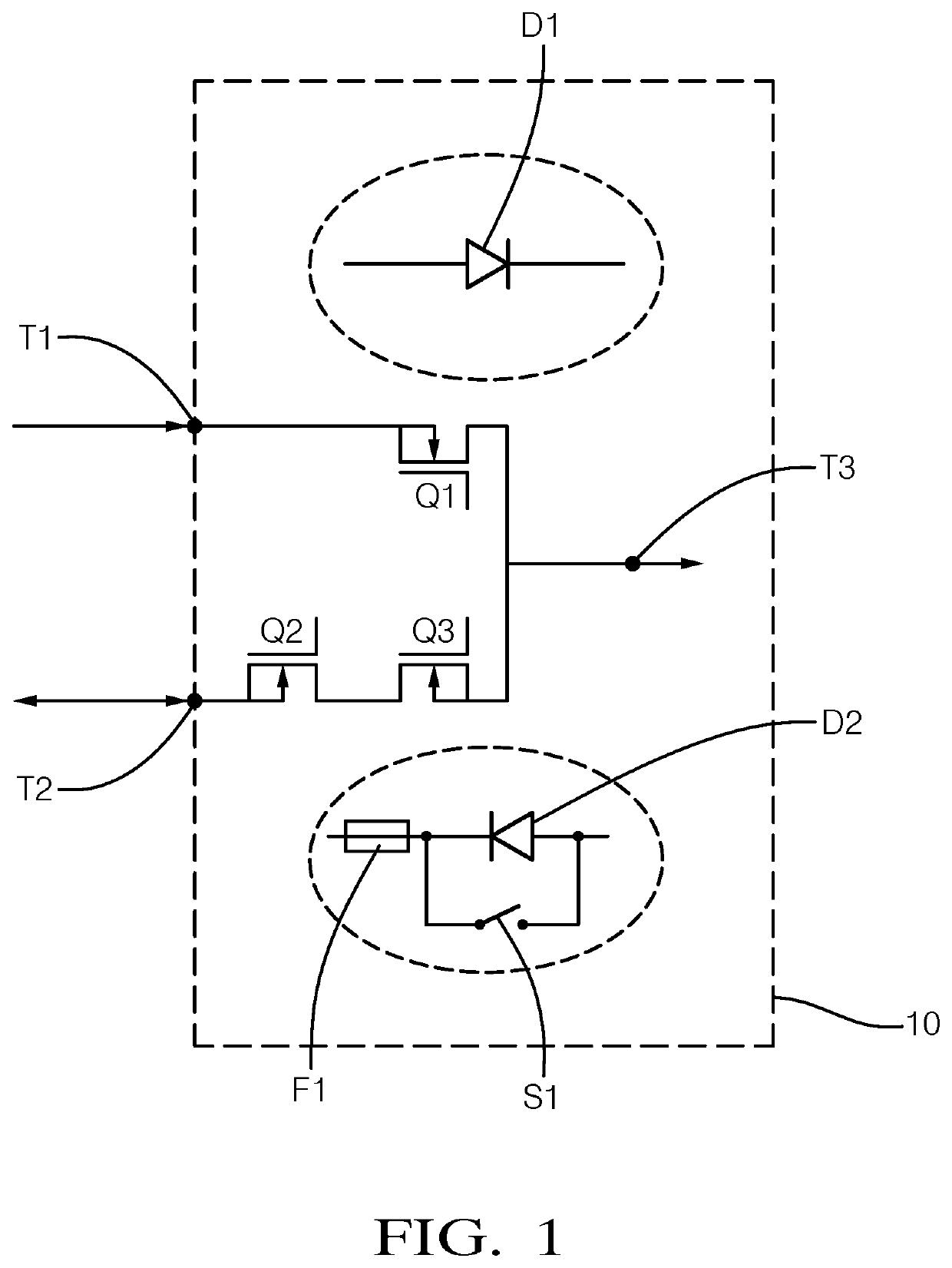

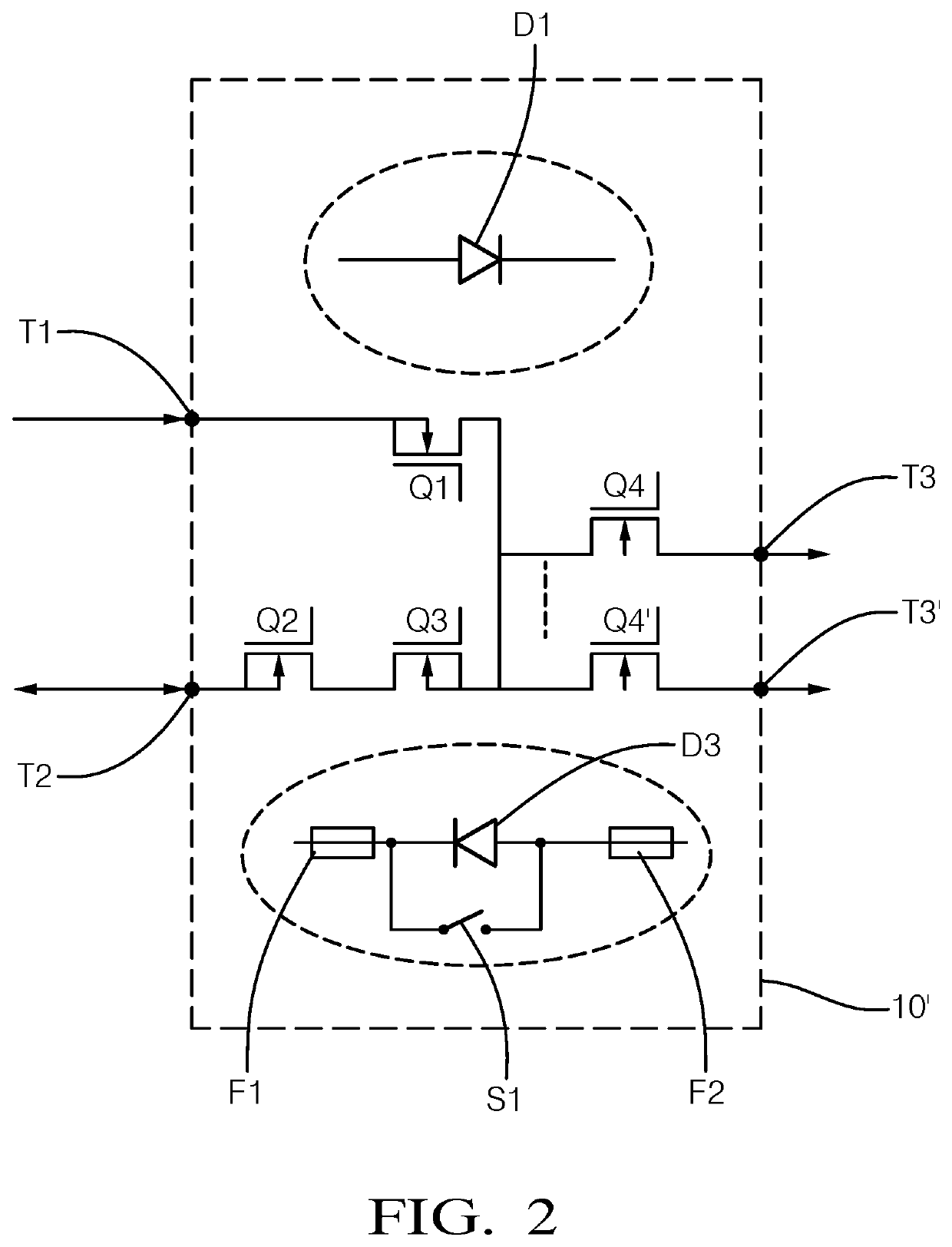

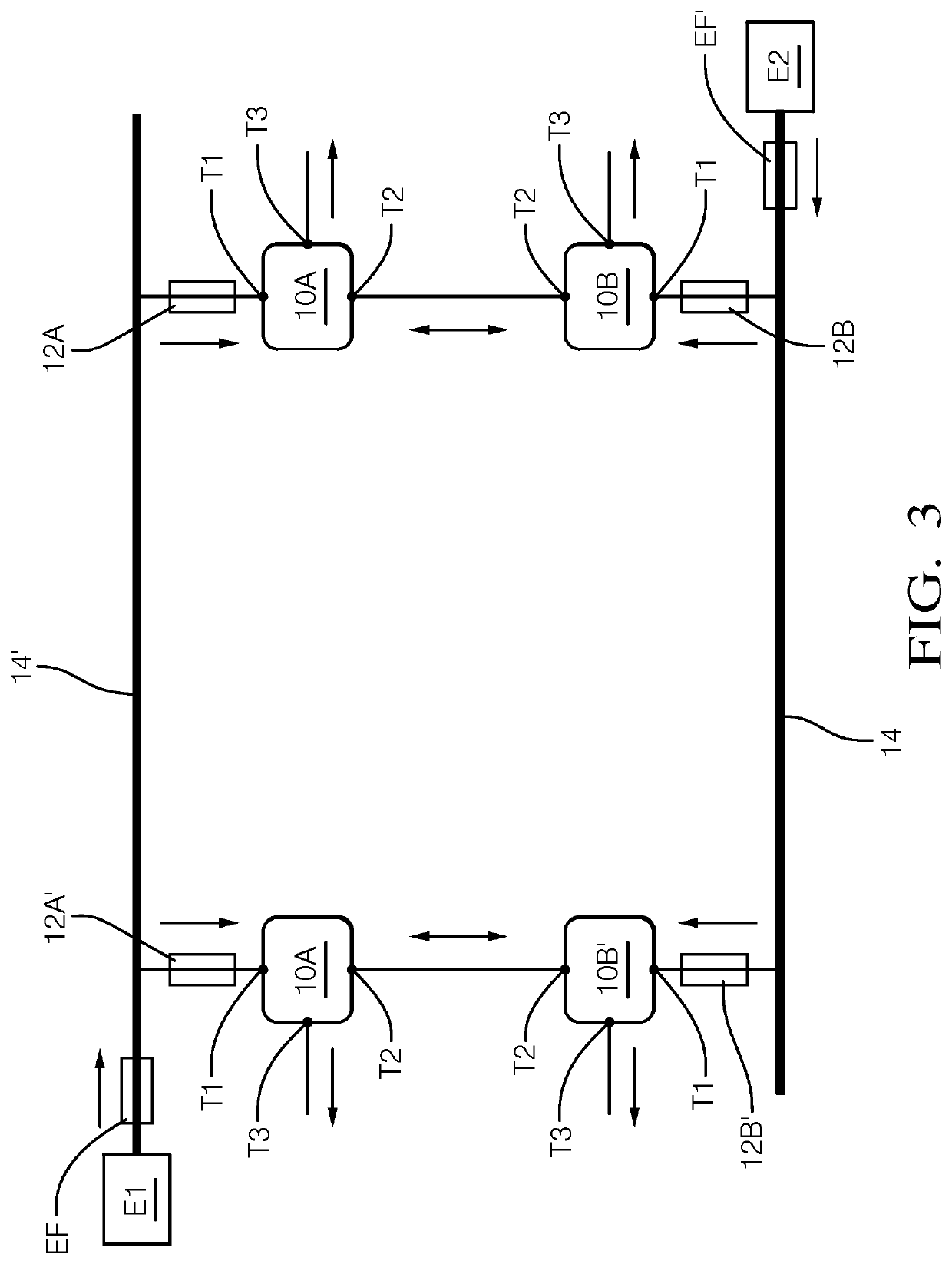

Electronic circuit for redundant supply of an electric load

ActiveUS20200136427A1Preventing situationPrevent reverse flowBatteries circuit arrangementsElectric devicesElectronic circuitPower flow

An electronic circuit for redundant supply of an electric load comprises a plurality of terminals including at least a first terminal, a second terminal and at least one third terminal, wherein the first terminal is configured to be connected to a first energy source for primary supply of the electric load; the second terminal is configured to be connected to a second energy source for secondary supply of the electric load; the at least one third terminal is configured to be connected to the electric load; the electronic circuit further comprises a plurality of electrical components interposed between the first terminal, the second terminal and the at least one third terminal, the electrical components being configured to enable power flow from either the first terminal or the second terminal to the at least one third terminal in dependence of an erroneous supply state for the electric load.

Owner:APTIV TECH LTD

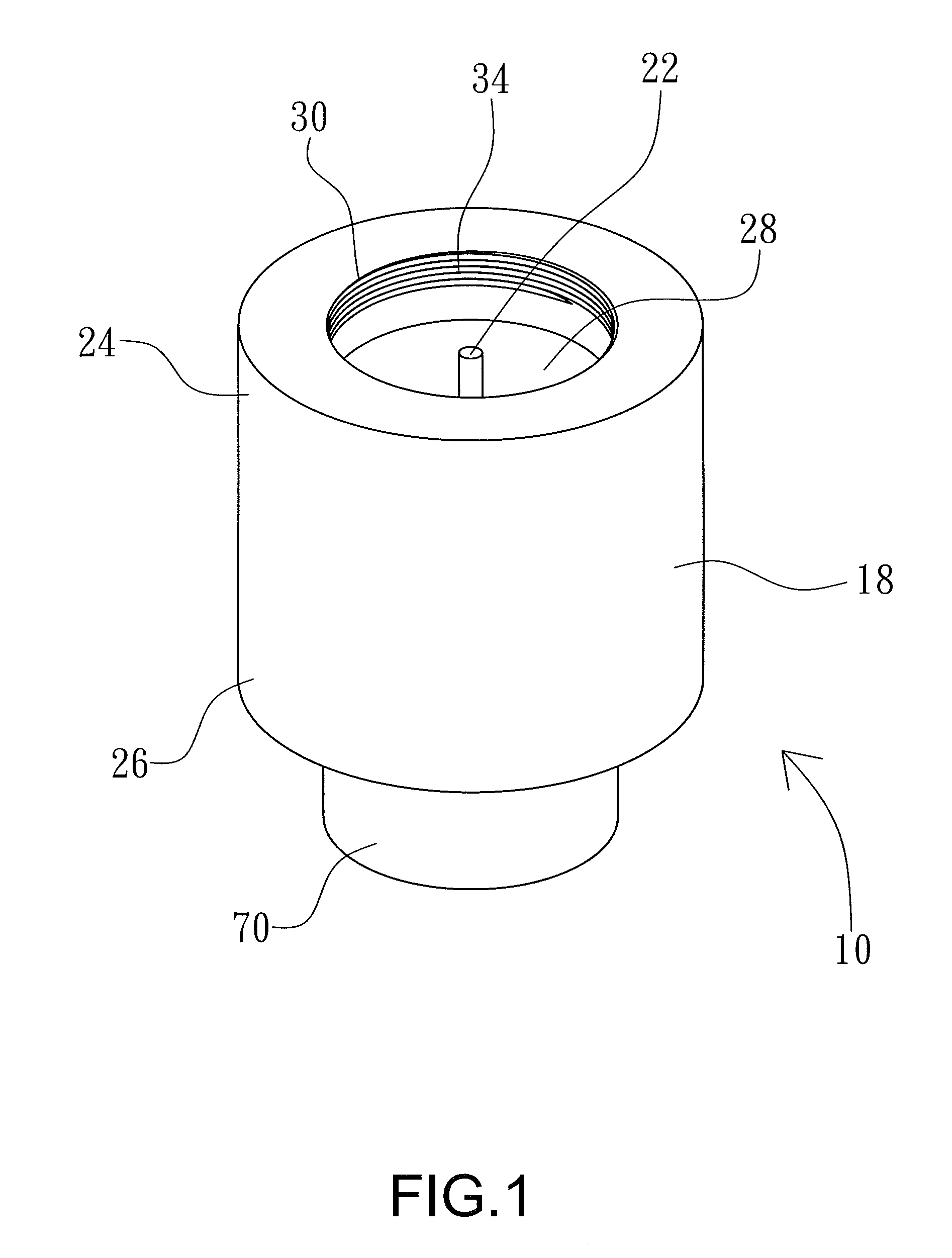

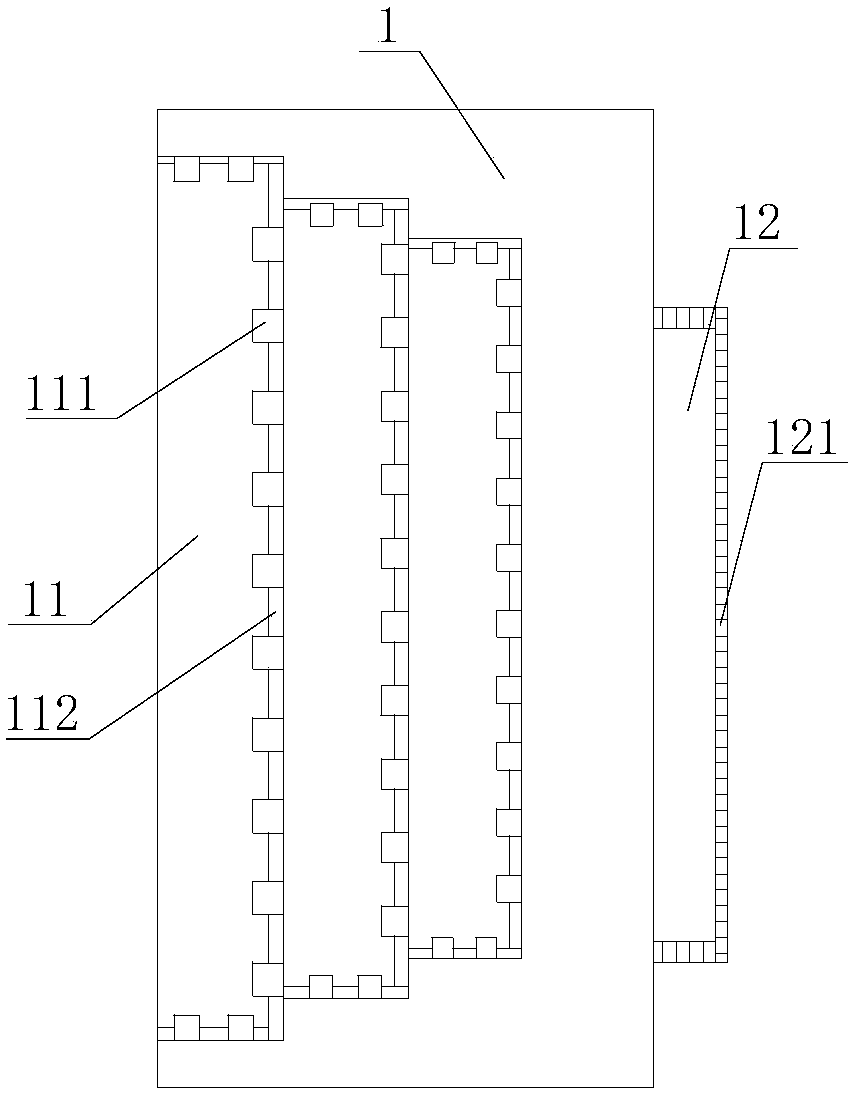

Closure Device for Drain Pipeline

InactiveUS20120117721A1Prevent reverse flowPrevent backflowWash-standsDomestic plumbingMechanical engineeringDraining tube

A closure device for a drain pipeline includes an outer sleeve, an inner sleeve mounted in the outer sleeve, and a closure member. The outer sleeve is adapted to be installed between a drain of a sink or washbasin and a drainpipe. A flow port is defined in the inner sleeve. The closure member is movably supported in the inner sleeve in a vertical direction. The closure member is normally biased by a spring to close the flow port so as to block odor from flowing into an indoor space, and the closure member is moved downwards to open the flow port when draining water into the outer sleeve.

Owner:WANG YUNG HUI

Straight-through joint convenient to weld and connect

ActiveCN108506604AForward circulationEasy to replaceJoints with fluid cut-off meansNon-disconnectible pipe-jointsControl engineeringScrew thread

The invention provides a straight-through joint convenient to weld and connect. The straight-through joint comprises a welding body, a connecting pipe, a sealing sleeve, a spring piece and a sealing ring; a plurality of gradually-decreasing steps are arranged on the inner wall of the left end of the welding body, a plurality of convex strips are arranged on the steps, a protective groove is formedbetween every two adjacent convex strips, and protective strips are arranged on the protective grooves; a third thread is arranged on the right side of the second thread, a fourth thread matched withthe third thread is arranged on the inner wall of the sealing sleeve, and a fifth thread is arranged on the right side of the third thread; and a connecting strip is arranged at the left end of the fifth thread, and a check body is arranged on the inner wall of the left end of the connecting pipe. According to the straight-through joint convenient to weld and connect, by arranging the plurality of steps, welding of pipelines with different sizes can be met, and the welding performance is good; and the connecting pipe can be connected to the hard pipeline and also can be connected to the softpipeline, so that the connection adaptability is improved, and the connection sealing performance is good.

Owner:海盐双赢管件制造有限公司

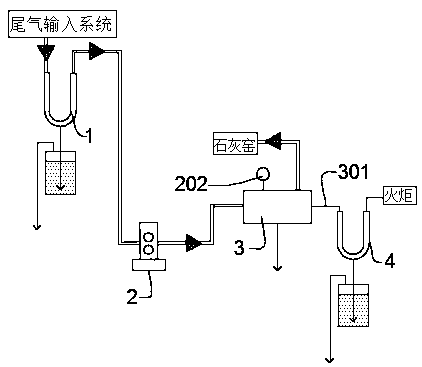

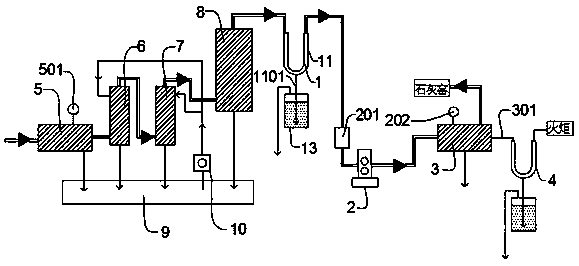

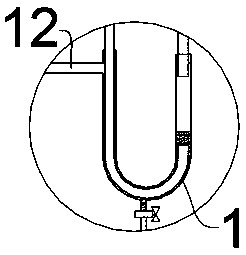

Tail gas pressurizing system for lime kiln

InactiveCN110986609AAdjust operating frequencyImprove work efficiencyIncreasing energy efficiencyIncinerator apparatusLime kilnMechanics

The invention discloses a tail gas pressurizing system for a lime kiln. The tail gas pressurizing system comprises a tail gas input system, wherein the tail gas input system is used for receiving yellow phosphorus tail gas from the tail gas input system and conveying the yellow phosphorus tail gas to the lime kiln, the output end of the tail gas input system is provided with a first water seal unit, a head end of the first water seal unit is in communication with the tail gas input system, a tail end of the first water seal unit is connected with a pressurizing fan, a tail end of the pressurizing fan is connected with a secondary air distribution cylinder, the secondary air distribution cylinder is used for outputting tail gas from the output end of the secondary air distribution cylinderto the lime kiln, the secondary air distribution cylinder is provided with a pressure relief passage, a tail end of the pressure relief passage is provided with a second water seal unit, the second water seal unit is used for outputting the tail gas from the pressure relief passage to a safety torch passing through the second water seal unit, and the secondary air distribution cylinder is providedwith a second pressure sensor. The tail gas pressurizing system is expected to solve the problem that the yellow phosphorus tail gas cannot serve as stable combustible source to supply energy to thelime kiln.

Owner:四川蓝海化工(集团)有限公司

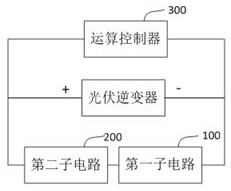

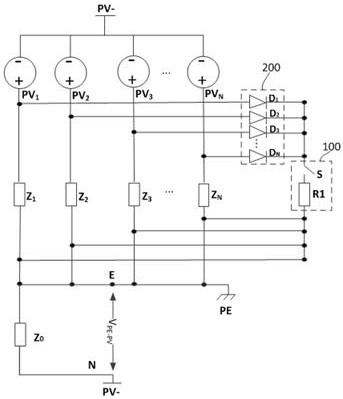

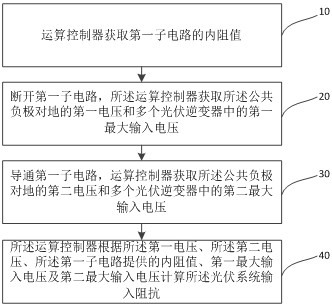

Photovoltaic system input impedance detection circuit, method and device

PendingCN114414893APrevent reverse flowImprove securityPhotovoltaic monitoringResistance/reactance/impedenceHemt circuitsControl theory

The invention discloses a photovoltaic system input impedance detection circuit method and device. The photovoltaic system input impedance detection circuit comprises a first sub-circuit, a second sub-circuit and a third sub-circuit, wherein the first sub-circuit is used for changing the internal resistance value connected into a photovoltaic system; the second sub-circuit is used for preventing current from reversely flowing into the photovoltaic inverter through the first sub-circuit; according to the invention, the first sub-circuit is arranged, and the disconnection and connection of the first sub-circuit are controlled, so that the internal resistance value connected to the photovoltaic system is changed, and the parameter data of the photovoltaic system are obtained through the operation controller, so that the input impedance of the photovoltaic system is obtained. The input impedance of the photovoltaic system is calculated, and the input impedance of the photovoltaic system can be obtained only through the combination of the first sub-circuit and the operation controller, so that the detection cost is reduced; and meanwhile, the second sub-circuit can effectively prevent the current from reversely flowing into the photovoltaic inverter through the first sub-circuit, so that the safety of the detection circuit is improved.

Owner:深圳市鼎泰佳创科技有限公司

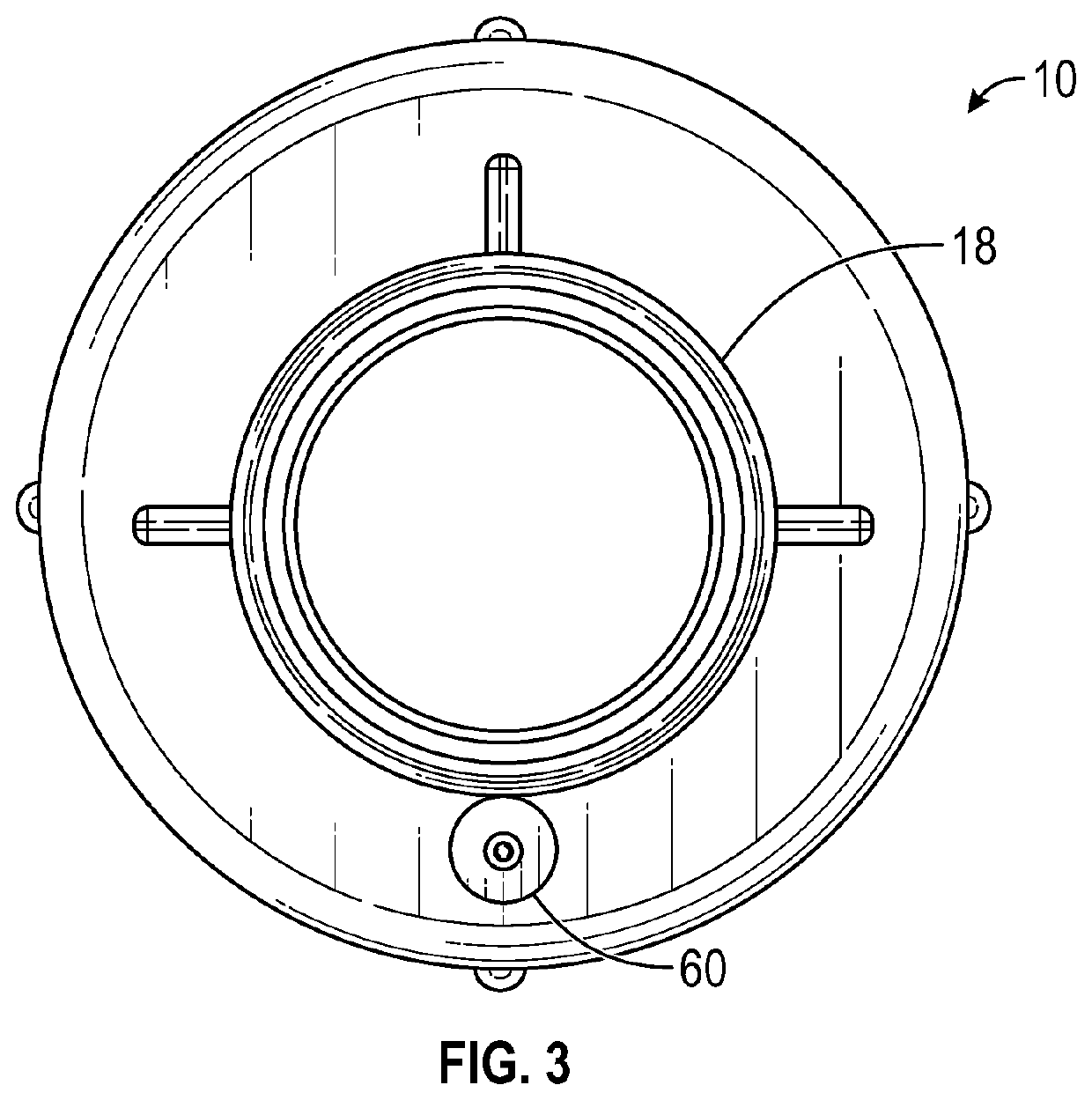

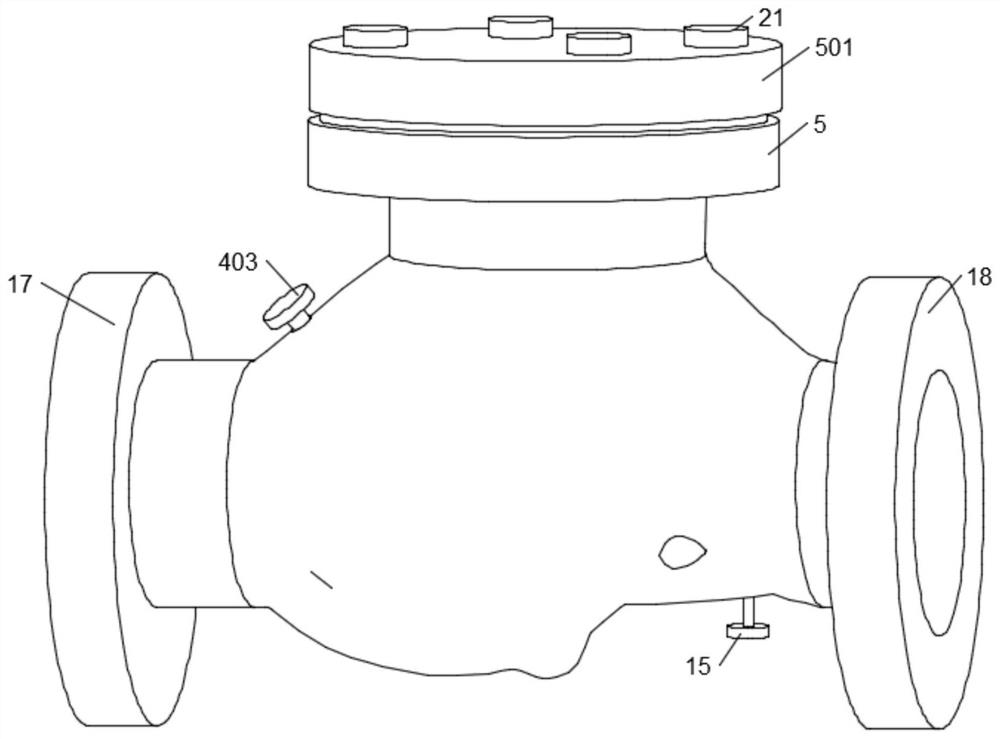

Adjustable check valve

ActiveUS11268627B1Prevent reverse flowPrevent backflowOperating means/releasing devices for valvesCheck valvesPipingEngineering

A check valve has an internal gate having an adjustable retention force, such that in the event that if the differential pressure between the upstream and downstream pressure changes, the force required to allow flow through the valve may be adjusted without removal of the valve from the piping system.

Owner:MAGIC PLASTICS

Gas generator spraying pipe one-way seal structure

The invention discloses a gas generator spraying pipe one-way seal structure, and relates to the field of initiating explosive device structures. A metal ball, a sliding rod, a spraying pipe and a shell are included. The spraying pipe is of an axial hollow pipeline structure. The shell sleeves the outer wall of the spraying pipe. The metal ball is of a sphere structure and is arranged in the spraying pipe. The sliding rod penetrates through the metal ball in the diameter direction. The two axial ends of the sliding rod are clamped at the side wall position of the spraying pipe, and sliding rodlimiting is achieved. The position, corresponding to the metal ball, of the inner wall of the spraying pipe is coated with seal glue. The effects that the metal ball is bonded, random sliding of themetal ball is prevented, and seal is achieved are achieved. The inner wall of the spraying pipe comprises a cylinder face inner wall and a conical face inner wall, wherein the conical face inner wallis arranged at the axial connecting position of the spraying pipe and the shell, and the cylinder face inner wall and the conical face inner wall are coaxially connected and are in smooth transition.By means of the gas generator spraying pipe one-way seal structure, when a plurality of generators are connected in series to work, the situation that high-temperature gas of the working generators reversely flows into the non-working generators, the non-working generators get abnormal and are ignited and combusted is prevented.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

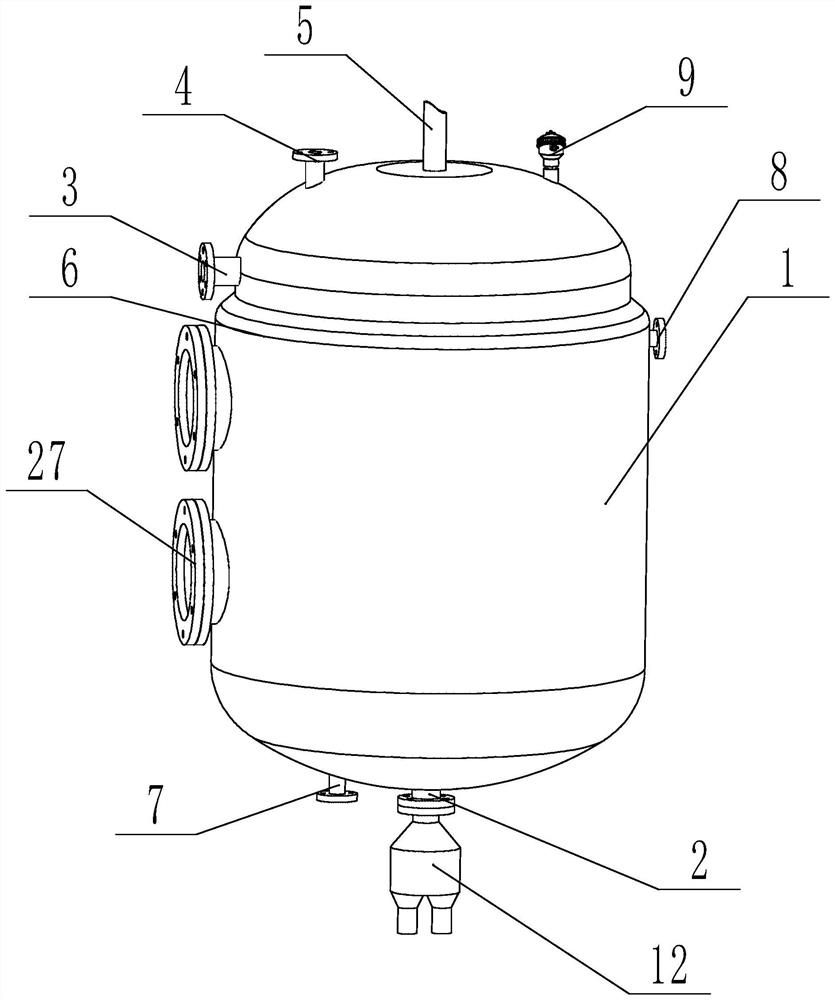

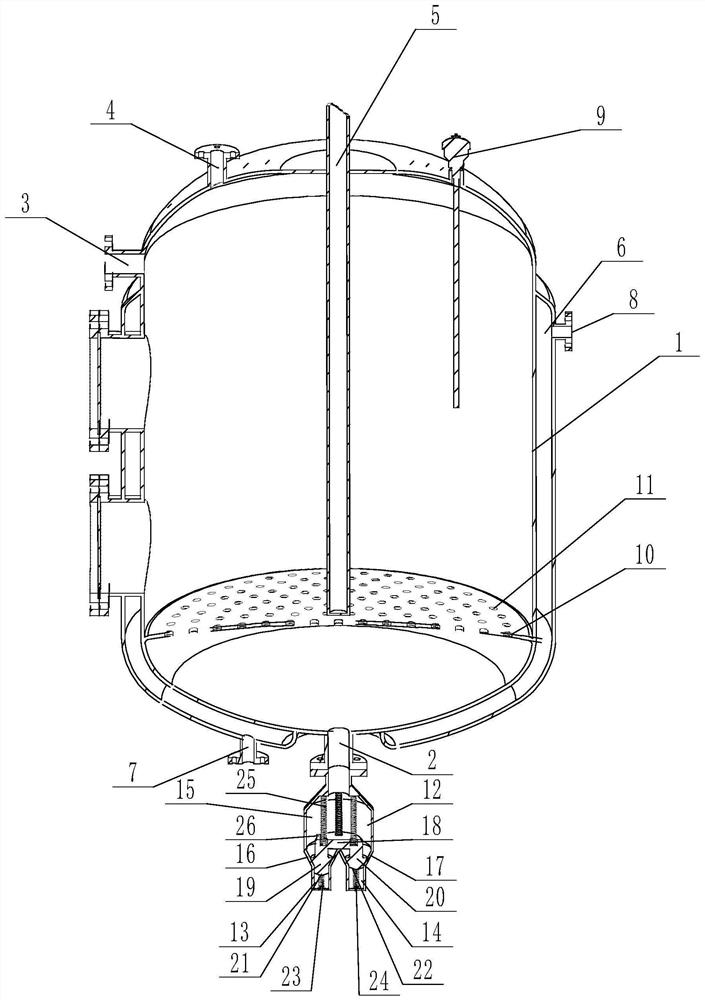

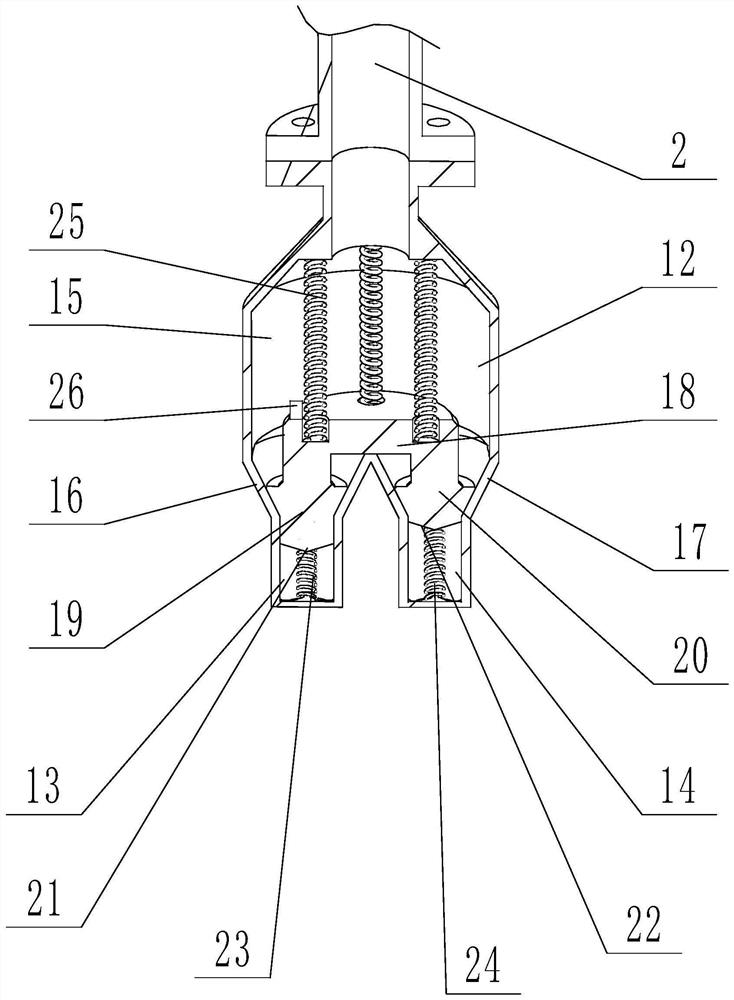

A self-cleaning pipeline filter device for water conservancy projects

ActiveCN111214876BNo need for manual disassembly and cleaningNo manual operationStationary filtering element filtersWater flowEngineering

The invention discloses a self-cleaning pipeline filter device for water conservancy projects, which comprises a filter pipe, the filter pipe includes a water inlet and a sewage outlet, a slag discharge pipe is installed on the side wall of the filter pipe, and a slag discharge pipe is installed on the slag discharge pipe A pressure valve is installed, and a filter screen and a fixed ring are installed on the inner wall of the filter pipe, and the filter screen and the fixed ring are both located between the two joints of the slag discharge pipe and the filter pipe, and the fixed ring is close to the filter screen. A spring is installed at one end, a piston is installed at one end of the spring close to the filter screen, and a clear water pipe is installed on the side wall of the filter pipe. In the present invention, after the filter screen is blocked, the pressure of the slag discharge pipe is greater than that of the filter pipe, so that the water flows along the slag discharge pipe and forms a negative pressure to peel off the impurities on the clean filter screen, and the clean water pipe is blocked by the piston to prevent the sewage from entering, and the clean water pipe and the sewage pipe are discharged side by side. It is set so that when the filter screen is clogged, the clean water pipe can be closed and the sewage pipe can be opened for self-cleaning, and the speed of self-cleaning can be further increased through the needles to save water resources.

Owner:郭新生

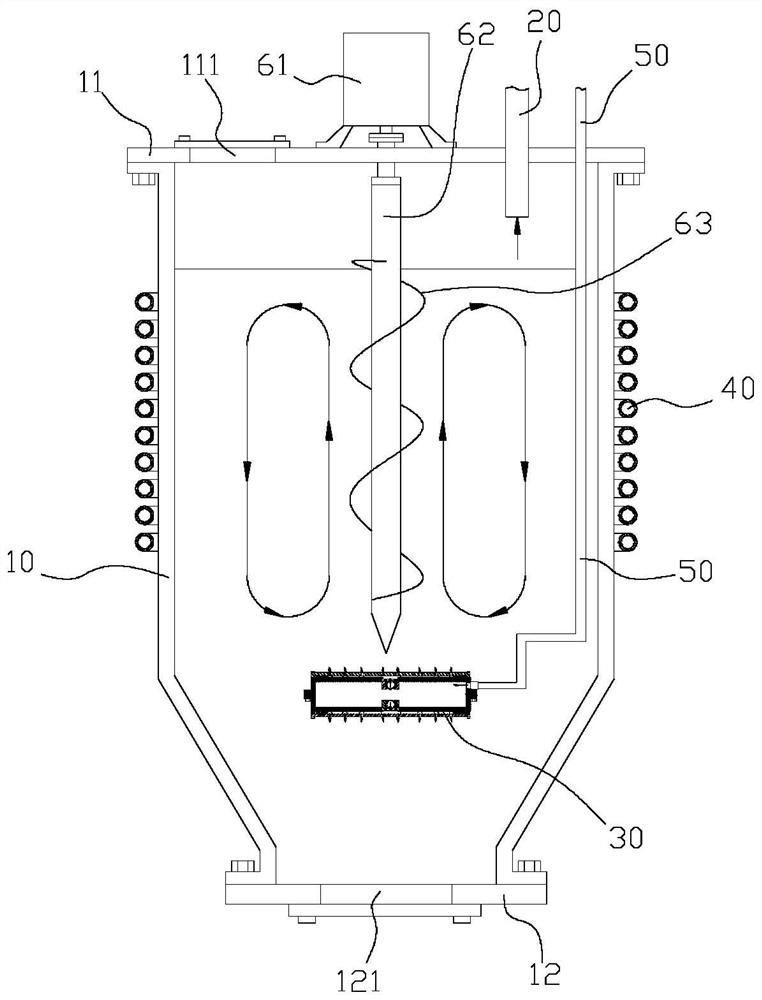

Photoreactor for organic silicon photochlorination reaction

PendingCN114534664AIncrease profitHigh speedGroup 4/14 element organic compoundsGas treatmentEnvironmental chemistryOrganosilicon

The invention provides a photoreactor for organic silicon photochlorination reaction, which comprises a kettle body, the bottom of the kettle body is provided with a gas-liquid feed pipe, a mixture of chlorine and methyl trichlorosilane liquid enters the kettle body from the gas-liquid feed pipe, the top of the kettle body is laterally provided with a product discharge pipe, the top of the kettle body is vertically provided with a tail gas discharge pipe, and the tail gas discharge pipe is communicated with the product discharge pipe. The reaction kettle further comprises a light source pipe, the light source pipe extends into the lower portion in the kettle body from the top of the kettle body, a heating jacket is arranged outside the kettle body, and a water inlet and a water outlet are formed in the heating jacket. The photoreactor for the organic silicon photochlorination reaction is provided with a built-in light source, high in safety performance and capable of adjusting gas-liquid two-phase feeding.

Owner:潜江宜生新材料有限公司

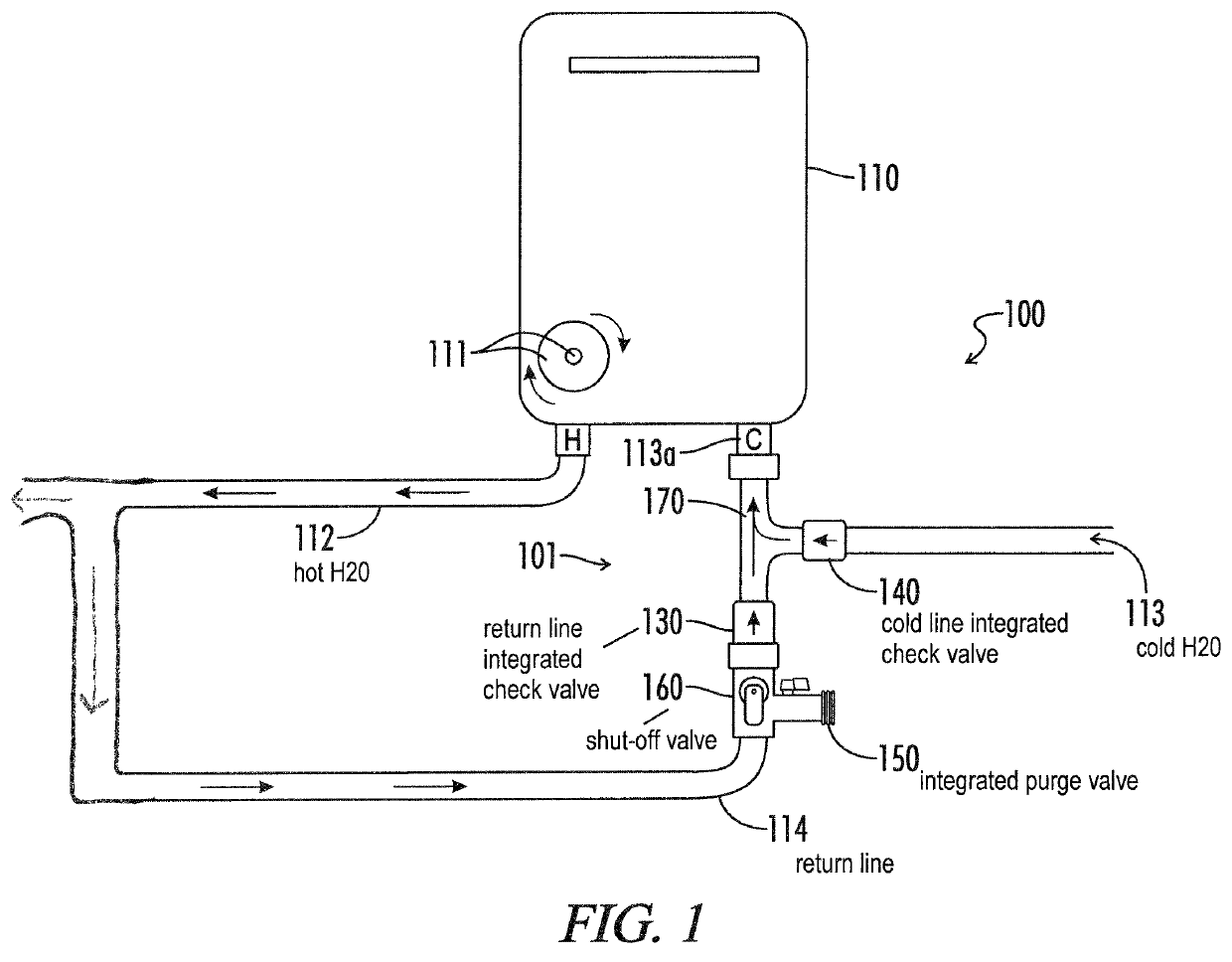

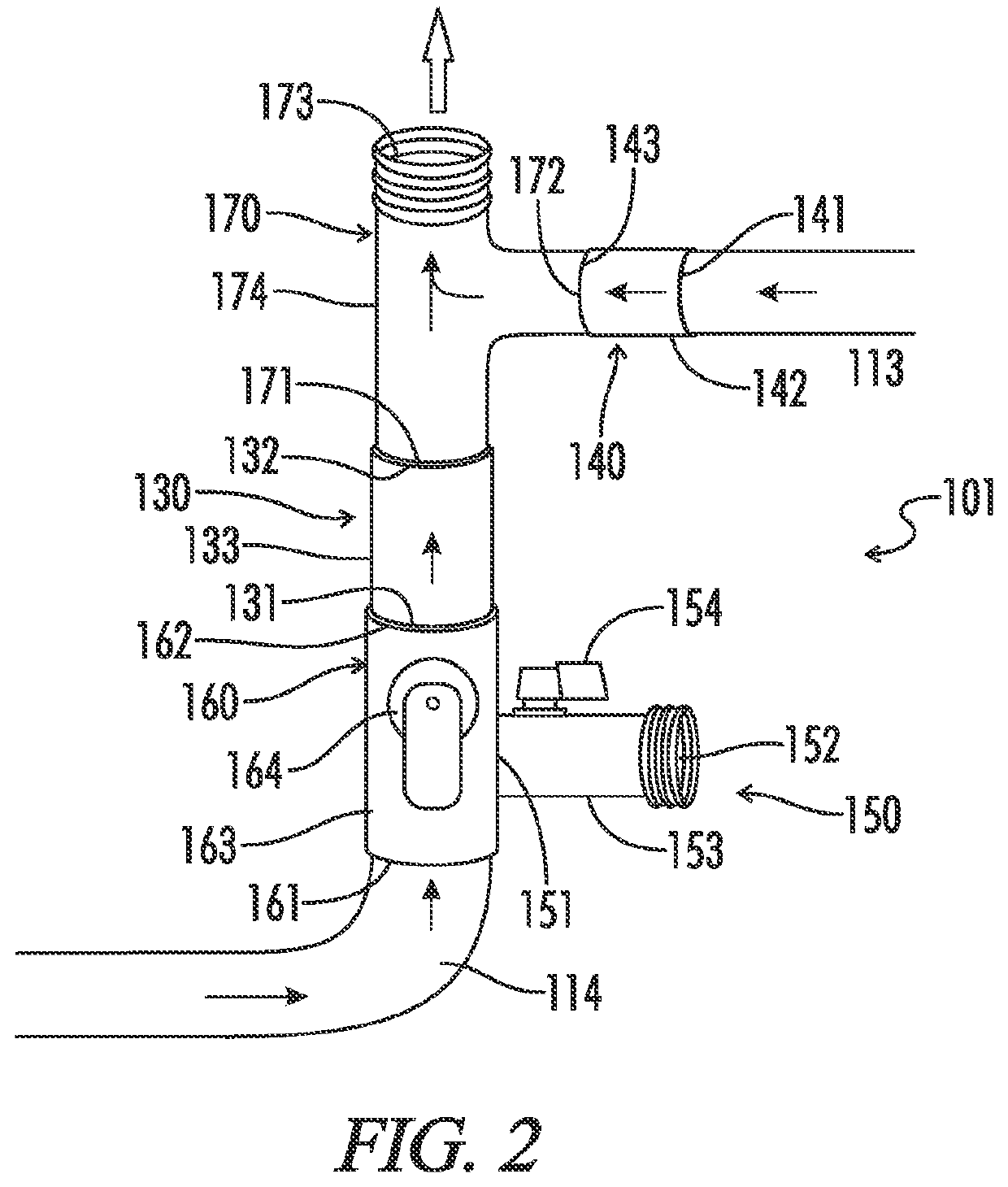

Return tee for hot water recirculation system

ActiveUS11421896B1Prevent reverse flowPrevent from flowSpace heating and ventilation detailsDomestic hot-water supply systemPipingWater supply

The present disclosure is directed to a hot water recirculation system with a return tee. The system includes a water heater, several supply lines, and a return tee. The hot water supply line is communicatively coupled to the water heater and at least one fixture and provides heated water from the water heater to the at least one fixture. The cold water supply line provides cold water from a cold water source to the water heater. Finally, the return line is communicatively coupled to the hot water supply line and delivers cooled water from the hot water supply line to the water heater. A return tee is communicatively coupled to the return line, the cold water supply line, and the water heater. This return tee provides cooled water from the return line and cold water from the cold water supply line to the water heater, which heats the water.

Owner:MCCAIN ERIC

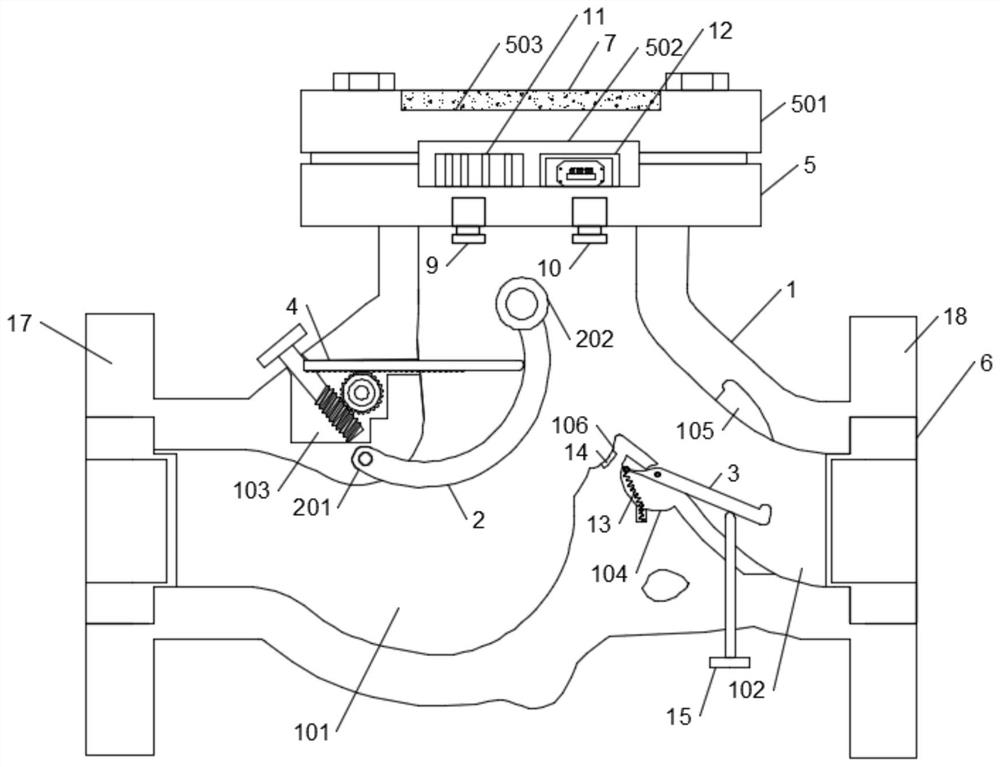

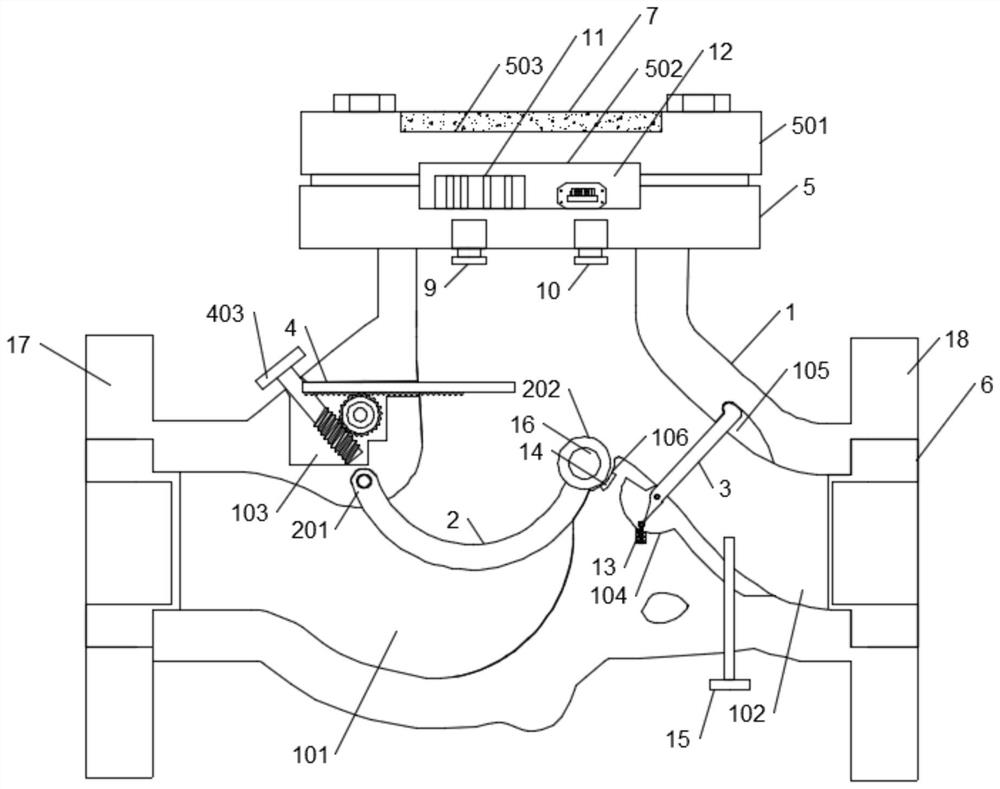

Check valve for petroleum pipeline transportation and using method thereof

PendingCN114263769AAct as a decompressorPrevent reverse flowCheck valvesLift valvePipeline transportCheck valve

The invention relates to the technical field of petroleum exploitation, in particular to a check valve for petroleum pipeline transportation and a using method thereof.The check valve comprises a check valve body, a check valve oil inlet and a check valve oil outlet are formed in the check valve body, and a stop plate is rotationally arranged in the check valve oil inlet; a stop plate is arranged in the check valve body, a stop brake mechanism is arranged on the portion, on one side of the stop plate, of the check valve body, the stop plate is used for conducting pressure reduction sealing on the check valve oil inlet, a sealing plate is rotationally arranged in the check valve oil outlet, and one end of the sealing plate is arranged in the check valve oil outlet through a spring. The stop plate in the oil inlet of the check valve and the sealing plate in the oil outlet of the check valve can conduct sealing immediately after petroleum transportation is stopped, reverse backflow of petroleum is prevented, the flow stopping effect is obviously enhanced, meanwhile, the stop plate in the oil inlet of the check valve and the sealing plate in the oil outlet of the check valve can further achieve the pressure reducing effect, and the sealing effect is greatly improved. The structure is simple, resistance is small, and the sealing effect is good.

Owner:JIANHU COUNTY HAOHUI POWER PETROCHEMICAL MASCH CO LTD

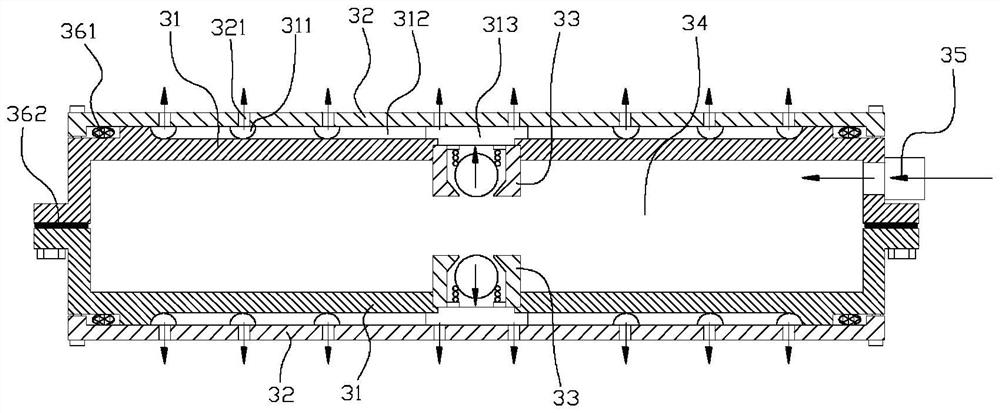

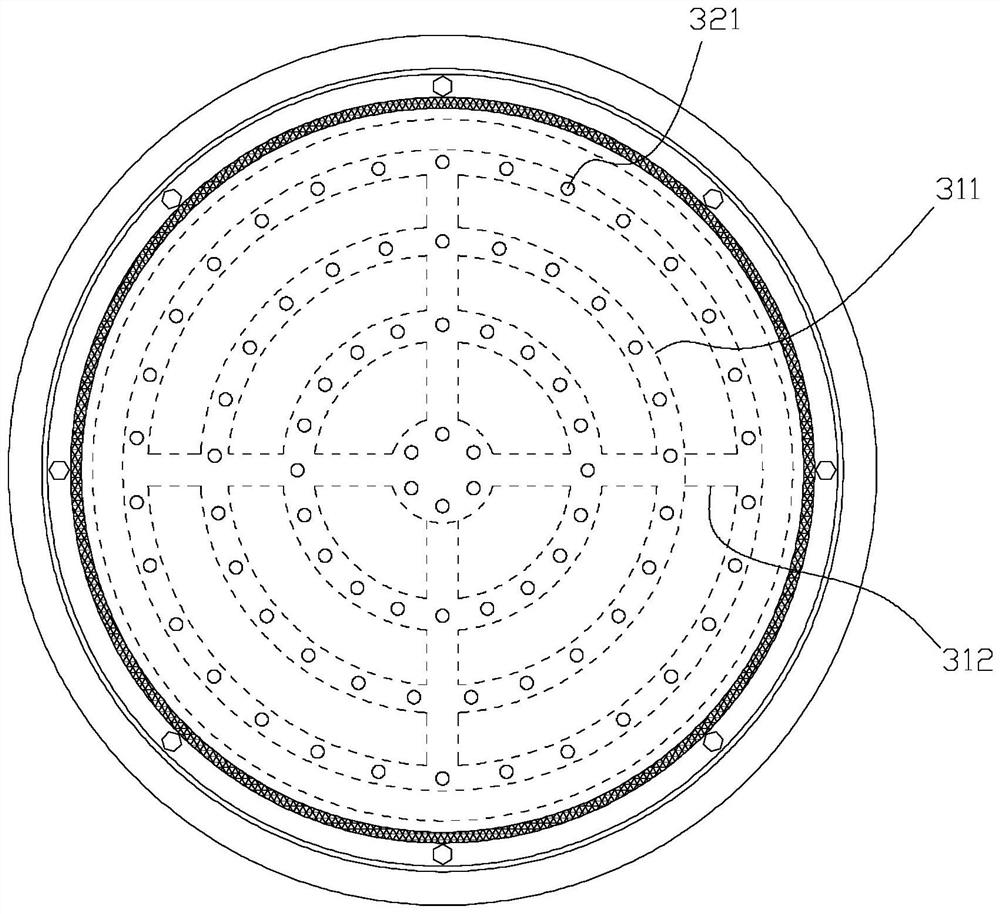

Air injection box and reaction kettle

InactiveCN112535874AImprove evaporation efficiencyPrevent reverse flowEvaporator accessoriesChemical/physical/physico-chemical stationary reactorsInjection airMechanical engineering

The invention discloses an air injection box and a reaction kettle. The air injection box comprises two half shells and two cover bodies; the two half shells are buckled to form an air cavity, the outer surface of each half shell is provided with a plurality of annular grooves and linear grooves communicating with the corresponding two adjacent annular grooves; the two cover bodies are used for covering the outer surfaces of the two half shells respectively, annular air channels are defined by the annular grooves and the cover bodies, and linear air channels are defined by the linear grooves and the cover bodies; the cover bodies are provided with a plurality of circles of vent holes corresponding to the annular air channels respectively. Air inlets communicating with the linear air channels are formed in the middles of the half shells. One-way valves are arranged at the air inlets, and the air inlet end of the one-way valves face the air cavity.

Owner:廊坊和田生物化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com