Tail gas pressurizing system for lime kiln

A technology of pressurization system and lime kiln, which is applied in the field of exhaust gas pressurization system, can solve the problem of yellow phosphorus exhaust gas being unable to supply energy, and achieve the effects of optimizing work efficiency and stability, preventing reverse flow, and ensuring flow and pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

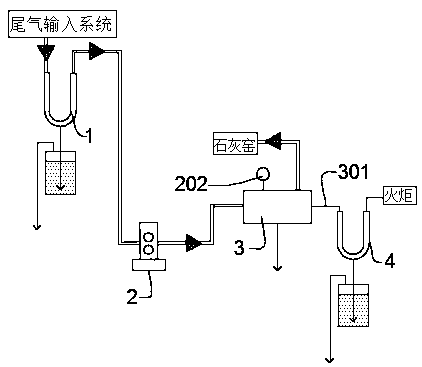

[0027] refer to figure 1 As shown, one embodiment of the present invention is a tail gas pressurization system for a lime kiln, including a tail gas input system, which is used to transport the yellow phosphorus tail gas to the lime kiln by the tail gas input system, compared to the traditional coal Lime-burning kiln, using gas-fired lime kiln, has uniform temperature in the kiln, and the calcined lime product has high activity.

[0028] The gas fuel used in the gas-fired lime kiln is under the same conditions. The calorific value of fuel combustion determines the flame temperature it can achieve. The flame temperature should be higher than the temperature required for lime calcination; the combustion temperature of its yellow phosphorus tail gas can reach 900 degrees Celsius , and the heat radiation area is wide, and the yellow phosphorus tail gas is used as fuel, which can realize the resource recycling of waste gas.

[0029] When the yellow phosphorus tail gas is used as a...

Embodiment 2

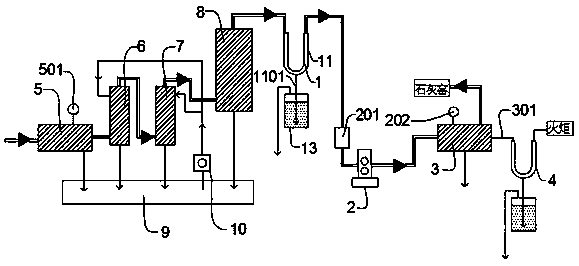

[0036] Based on the above examples, refer to figure 2 As shown, another embodiment of the present invention is, in order to improve the quality of tail gas calcined lime, because there are many kinds of harmful impurities in the yellow phosphorus tail gas, hinder the effective utilization of yellow phosphorus tail gas; As we all know, as the content increases, the activity of lime decreases. The reason is that impurities react with calcium oxide in active lime, such as calcium sulfide, calcium sulfite, calcium phosphide and other calcium compounds. If the oxygen content When the concentration of sulfur dioxide is high, sulfur dioxide is easily oxidized to sulfur trioxide, and the generated sulfur trioxide will react with calcium oxide to form calcium sulfate, which will lead to the bonding between lime particles and block the pores on the particle surface, which will not only reduce the activity of lime, but also It will block the carbon dioxide emission channel generated by ...

Embodiment 3

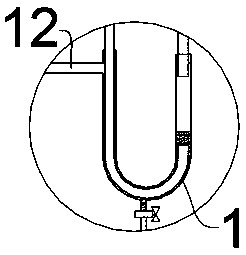

[0045] An embodiment of the present invention is, with reference to figure 1 , image 3 As shown, the above-mentioned first water seal unit 1 and the above-mentioned second water seal unit 4 both include a U-shaped pipe 11, and a raw water pipe 12 is installed on the side wall of the above-mentioned U-shaped pipe 11, which is used to input liquid from the raw water pipe 12 to the U-shaped pipe 11 , and form a water seal structure; inject liquid through the raw water pipe 12, and use the liquid to form a water seal in the U-shaped pipe 11, so that the tail gas of different sections can be relatively independent, and the backflow of tail gas in different sections can be avoided.

[0046] Further, a water seal groove 13 is provided below the above-mentioned U-shaped pipe, and a drain pipe 1101 is provided at the lower end of the above-mentioned U-shaped pipe 11. , use the drainpipe 1101 as an explosion-proof pipeline, and use the water seal groove 13 to prevent the outside air f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com