Pipeline dirt removal device used for civil engineering

A civil engineering and pipeline technology, applied in the field of pipeline cleaning devices for civil engineering, can solve the problems of surrounding influence, difficult to clean the inner wall of the pipeline, time-consuming and laborious, etc., and achieve the effect of thorough cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

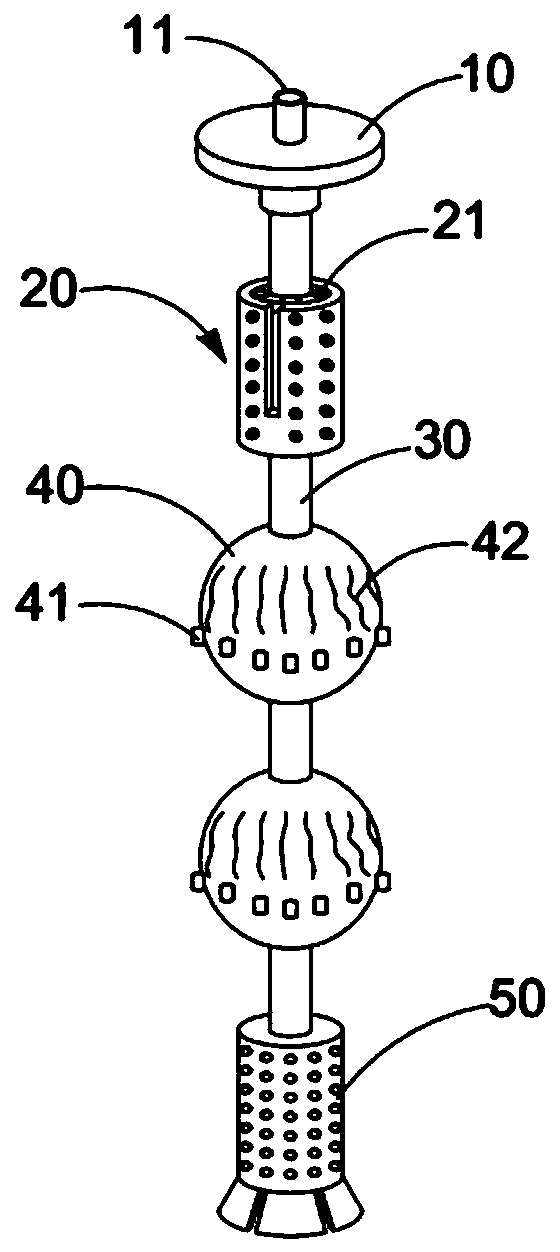

[0028] see Figure 1-5 Shown, a kind of pipeline cleaning device for civil engineering, comprising:

[0029] water pipe 30,

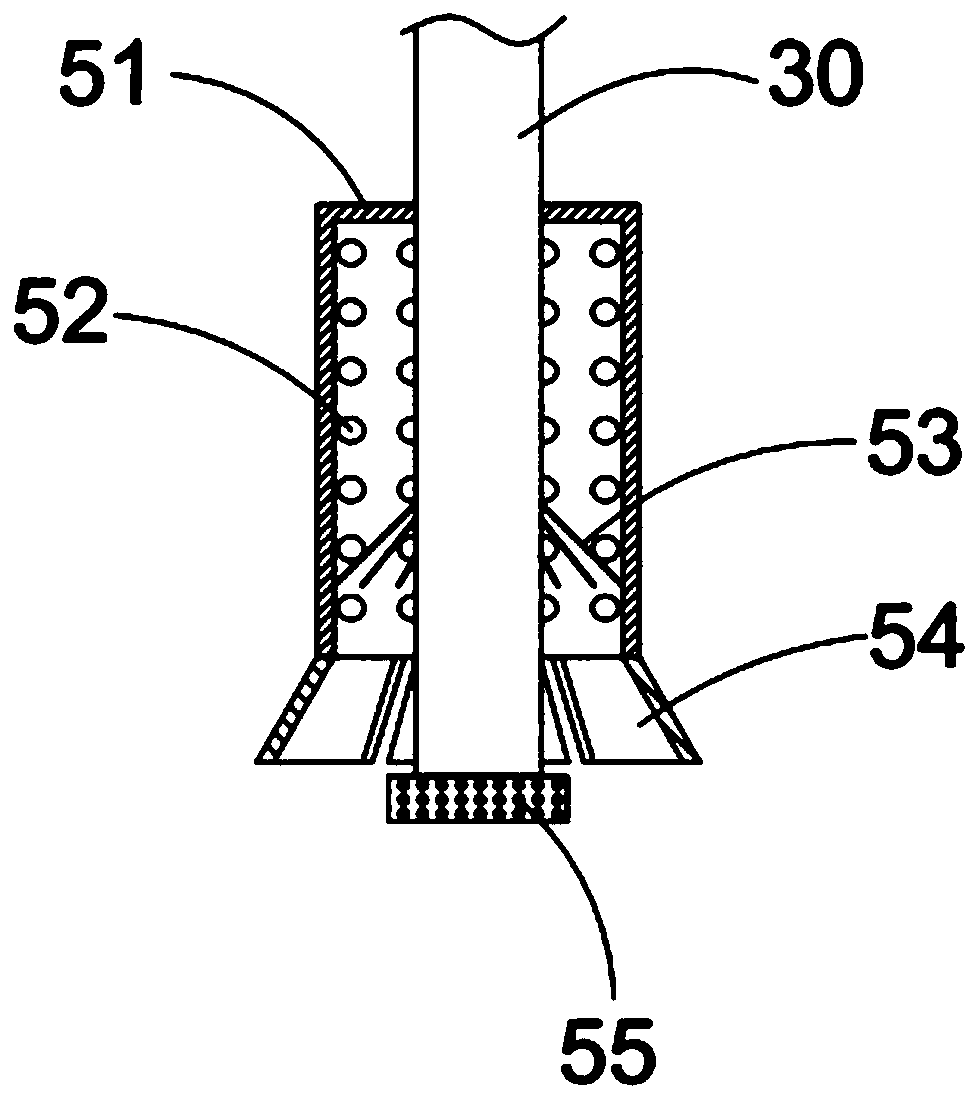

[0030] The collection assembly 50 is installed at one end of the water delivery pipe 30, and the other end of the water delivery pipe 30 is connected to the water delivery port 11. The water delivery pipe 30 behind the collection assembly 50 is installed with a scraping assembly 40 and a cleaning assembly 20 in sequence,

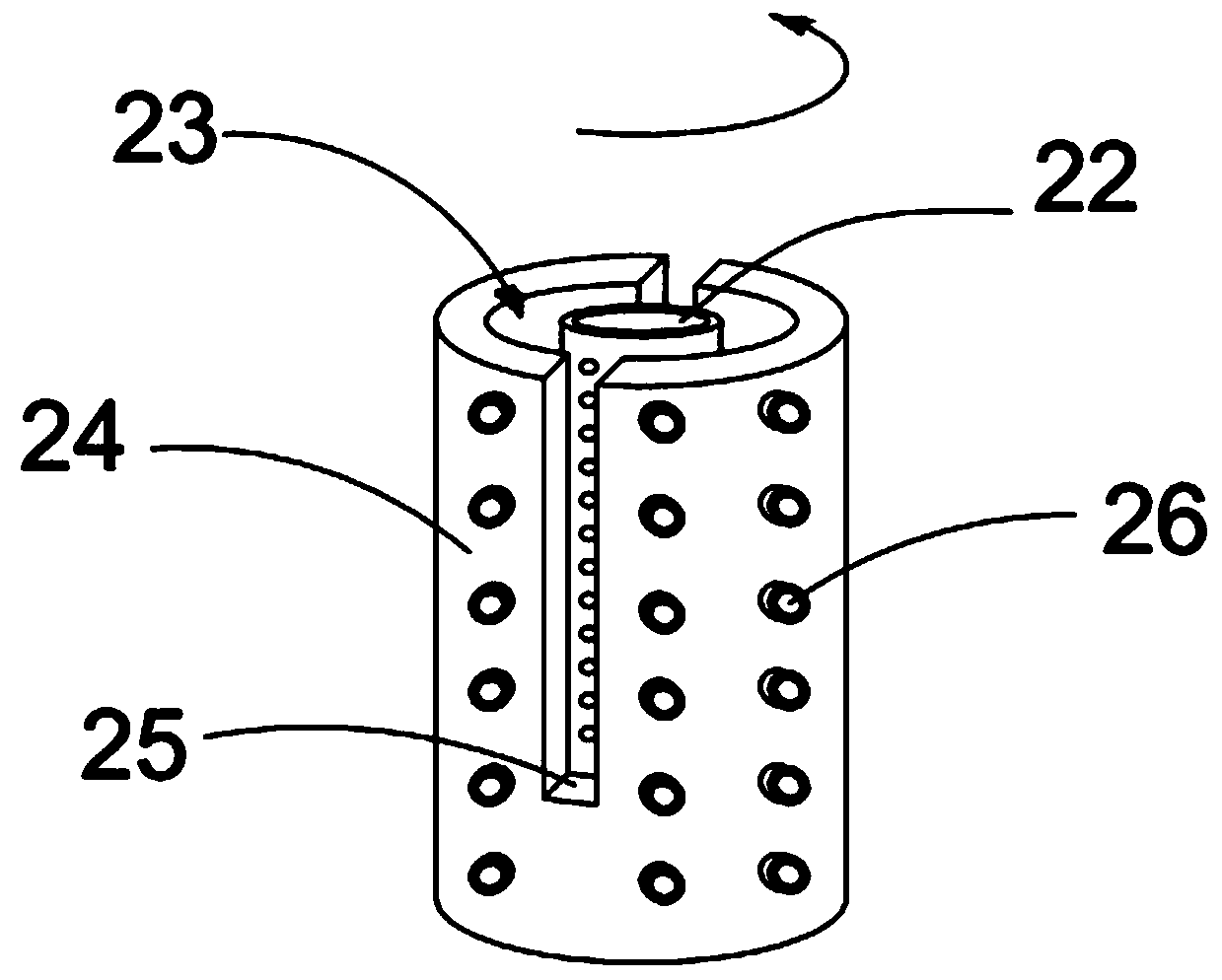

[0031]Wherein, the cleaning assembly 20 includes an inner pipe 22 which is socketed with a water delivery pipe 30, and a rotatable outer pipe 24 is connected to the outside of the inner pipe 22 through a bearing 21, and the surfaces of the outer pipe 24 and the inner pipe 22 are evenly provided with water outlet ports 26, and the outlet The water outlet end of the water pipe mouth 26 is convex. A water outlet corresponding to the position of the outlet pipe 26 is opened on the surface of the joint between the water delivery pipe 30 ...

Embodiment 2

[0041] When the pipeline cleaning device for civil engineering of the present invention is actually used: connect and fix the water delivery port 11 with the external water delivery pipe, insert the collection assembly 50, the scraping assembly 40, and the cleaning assembly 20 into the pipeline to be cleaned in sequence, and turn on the delivery pipe. For the water input of the nozzle 11, the operator uses the push rod to push the plug plate 10 to move forward in the cleaning pipeline to clean the inside of the pipeline. rod connection.

Embodiment 3

[0043] In this embodiment, the sewage pipe used in the hotel is used as the cleaning object, and two sewage pipes are selected. The sewage pipe is a polypropylene pipe with a pipe diameter of 30mm and a total length of 2 meters. Head tube connection.

[0044] Selected two groups of equipments are used to carry out blowdown operation to the blowdown pipes respectively, the device of the present invention is the device used by the experimental group, the cleaning method adopts the method of embodiment 2 to carry out, the water body used by the experimental group is consistent with the matched group and is hot water, the matched group uses The cleaning agent is rinsed with heated water. After cleaning, check and count the residual ratio in the pipeline, the results are as follows: Figure 6 As shown, it can be seen that the device and method of the present invention can control the residual ratio of dirt in the pipeline to be below 10%, while the residual ratio of commonly used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com