Gas generator spraying pipe one-way seal structure

A gas generator and one-way sealing technology, which is applied in the direction of weapon types and offensive equipment, can solve the problems of no technical solution, inflow, and increased length of a single generator, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0024] The invention provides a one-way sealing structure of the nozzle pipe of a gas generator, which is suitable for preventing high-temperature gas from flowing backward from the nozzle pipe into a non-working generator and causing abnormality of the generator when multiple generators are used in series. Burn normally.

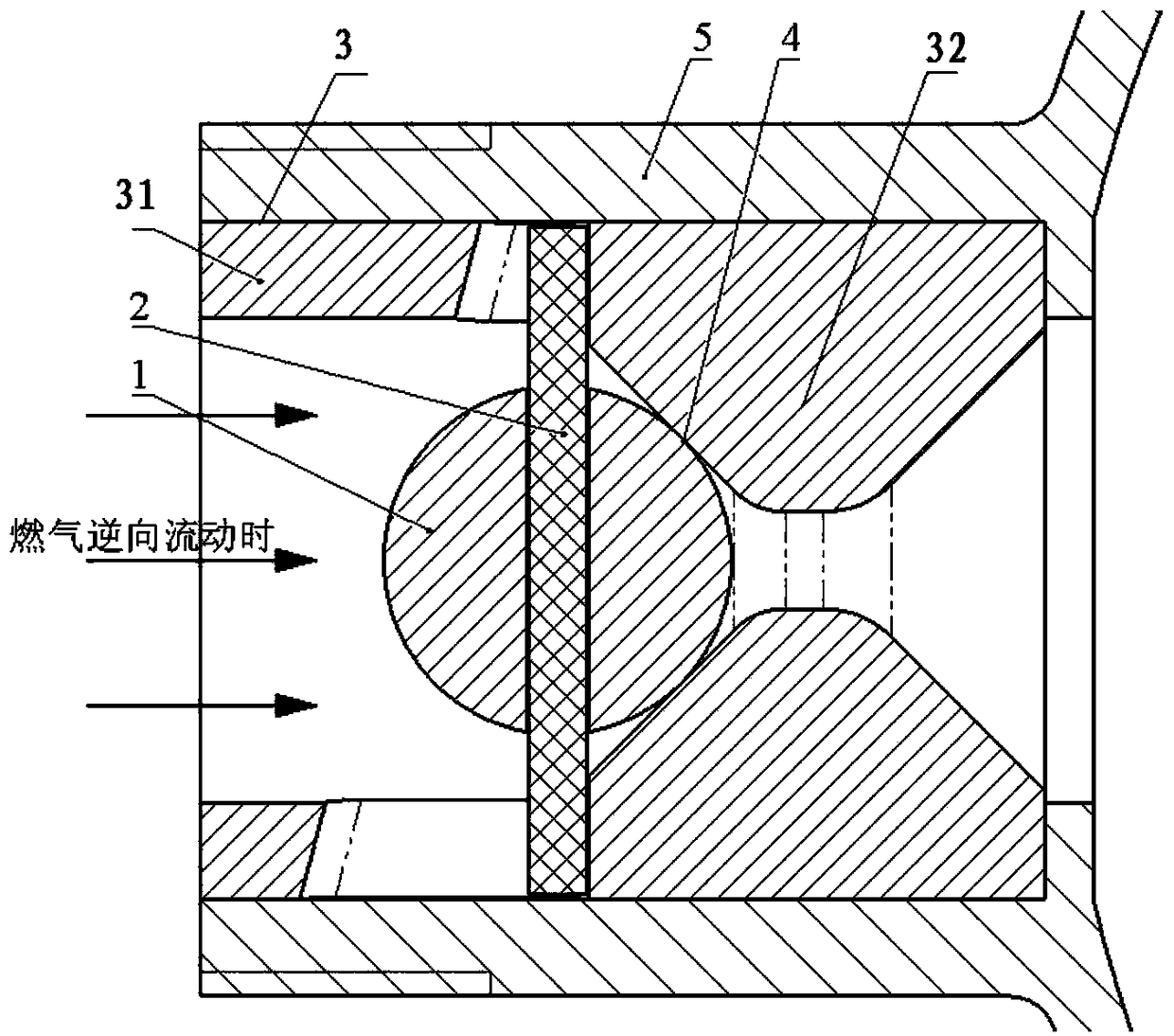

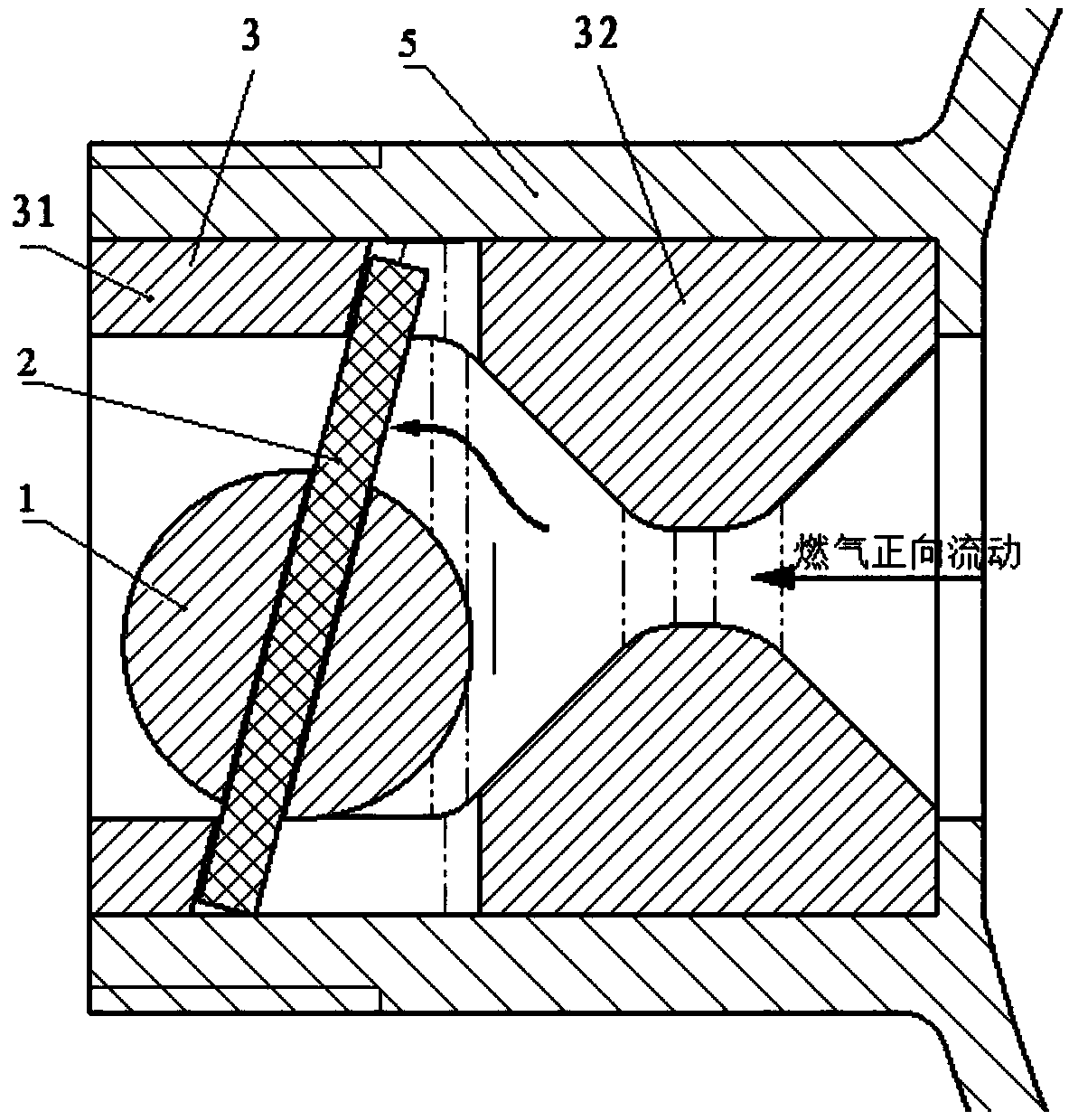

[0025] Such as figure 1 Shown is a schematic diagram of gas reverse flow, as can be seen from the figure, a gas generator nozzle one-way sealing structure, including metal ball 1, slide rod 2, nozzle 3 and housing 5; wherein, nozzle 3 is axially hollow The pipe structure; the casing 5 is set on the outer wall of the nozzle 3; the metal ball 1 is a spherical structure; the metal ball 1 is arranged inside the nozzle 3; the slide rod 2 passes through the metal ball 1 along the diameter direction; and the shaft of the slide rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com