Battery assembly device

A combined device and battery technology, applied in battery pack components, circuits, electrical components, etc., can solve the problems of thermal expansion, damage of battery cells, and difficulty in dissipating heat from battery cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to make the above and other objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention are listed below and described in detail in conjunction with the accompanying drawings.

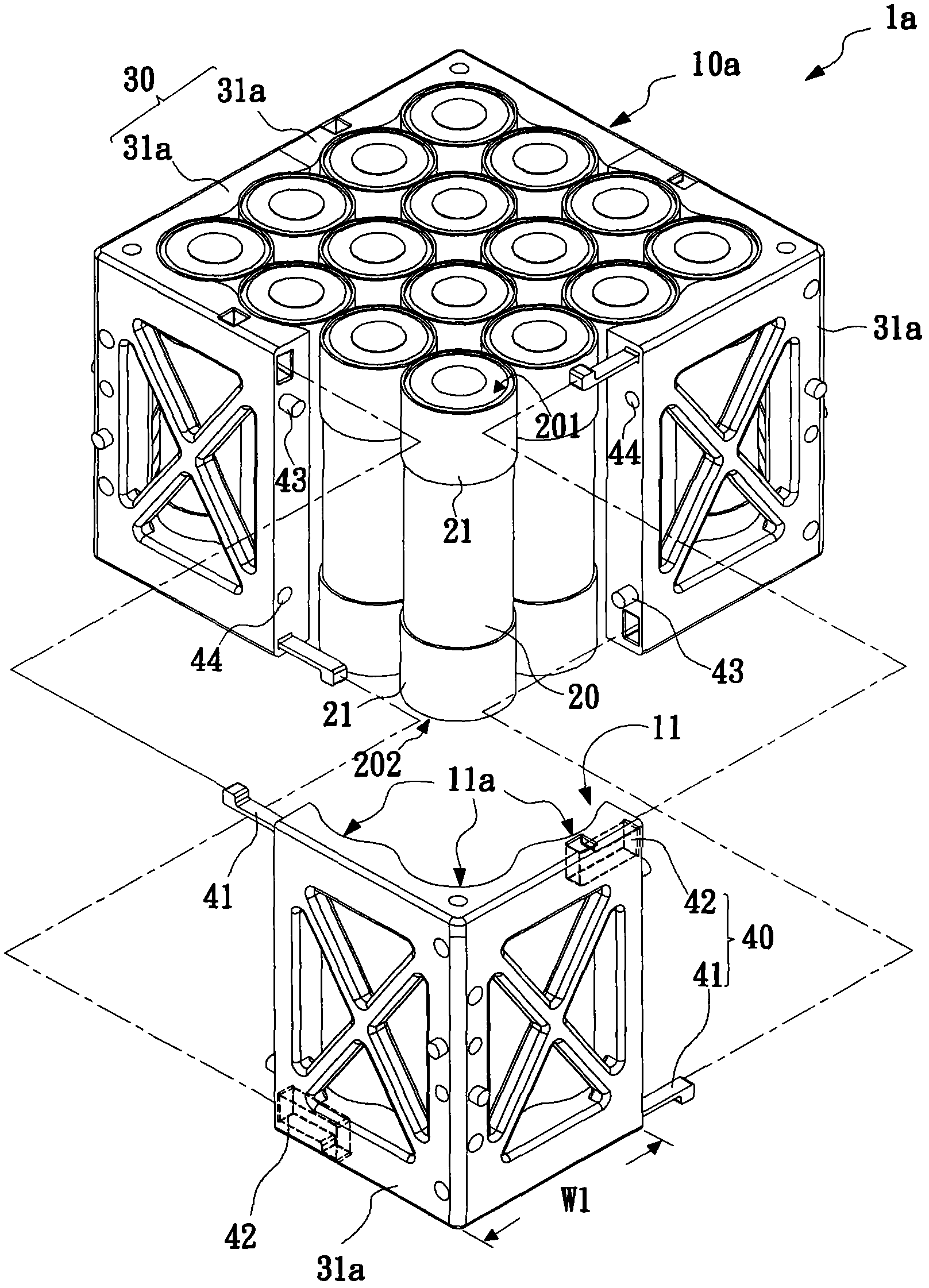

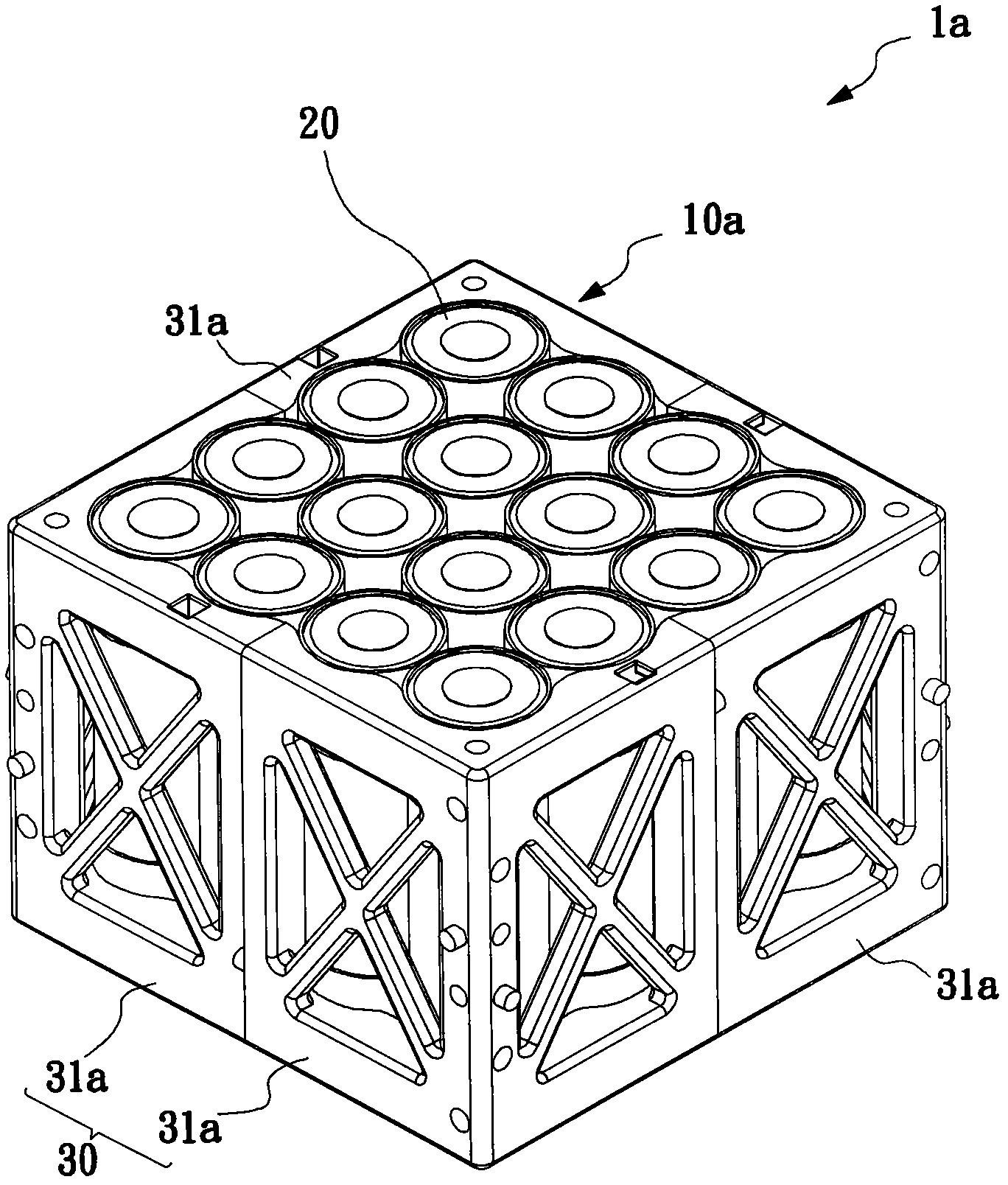

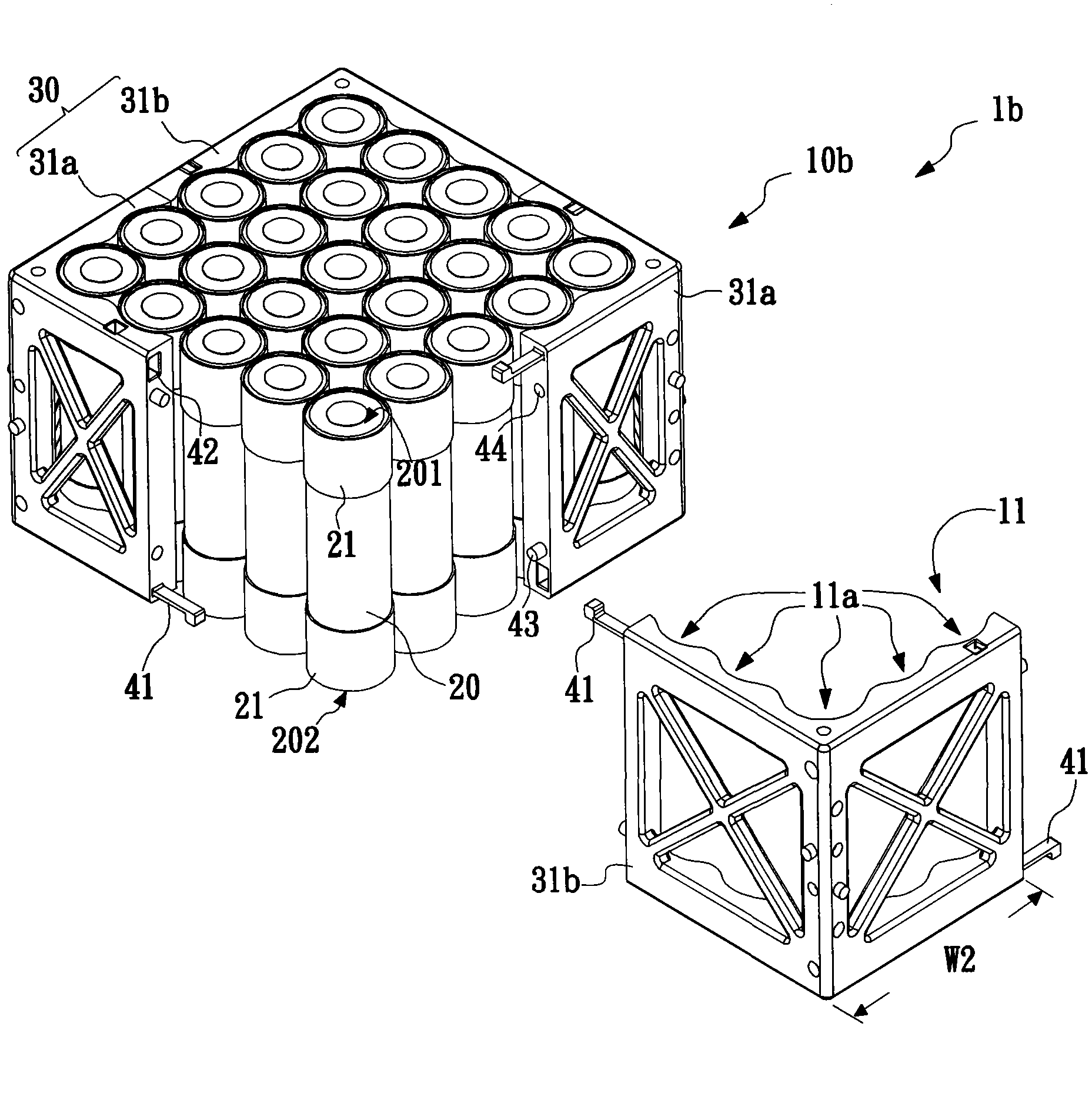

[0063] Please refer to the following Figure 1 ~ Figure 2 Relevant schematic diagrams of the first embodiment of the battery assembly device of the present invention, wherein figure 1 An exploded view of the first embodiment of the battery assembly device of the present invention, figure 2 A perspective view of the first embodiment of the battery assembly device of the present invention.

[0064] In the first embodiment of the present invention, the battery assembly device 1a includes a first frame body 10a and a plurality of battery units 20, and the plurality of battery cells 20 are disposed in the first frame body 10a. The appearance of the battery unit 20 may be cylindrical, but the present invention does not limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com