Ammonium salt anti-blocking filtering device of waste gas combustion treatment equipment

A treatment equipment and exhaust gas combustion technology, applied in the field of anti-blocking devices, can solve the problems of wasting resources, inconvenient promotion and use, and easy to block ceramics, etc., and achieve the effects of reducing resource consumption, reducing cleaning dead ends, and reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

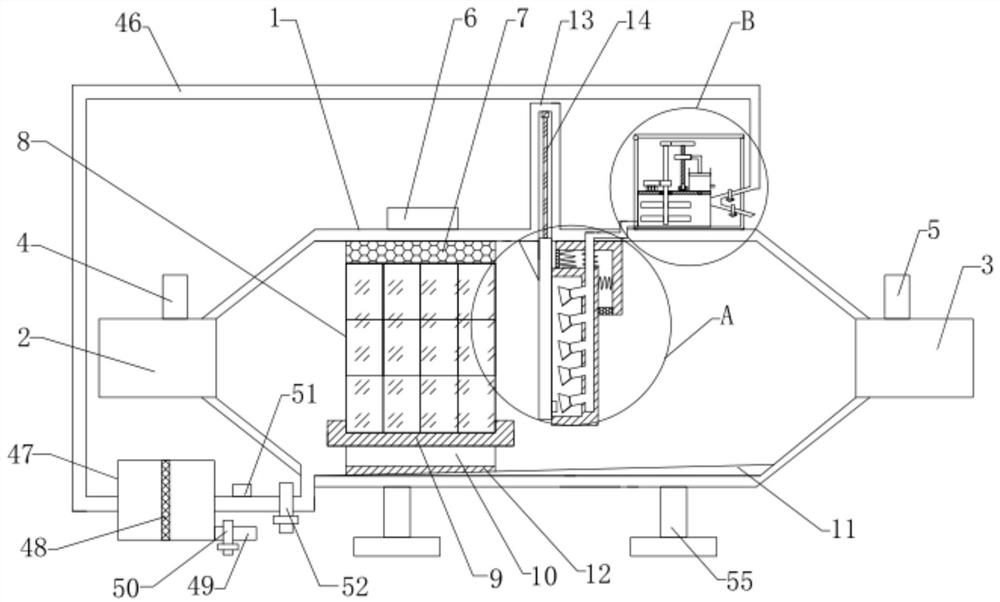

[0043] Embodiment 1: The most suitable temperature range for this device is 50-110°C. At the above temperature, it can promote the formation of ammonium salts and remove ammonia and chlorine in the gas phase. When installing, connect the inlet pipe 2 on the outer shell 1 to the The flue gas inlet in the combustion chamber connects the outlet pipe 3 to the flue gas outlet in the combustion chamber, and the ceramic ring 801 in the inner cavity of the outer casing 1 can effectively adsorb and filter the ammonium salt in the flue gas.

Embodiment 2

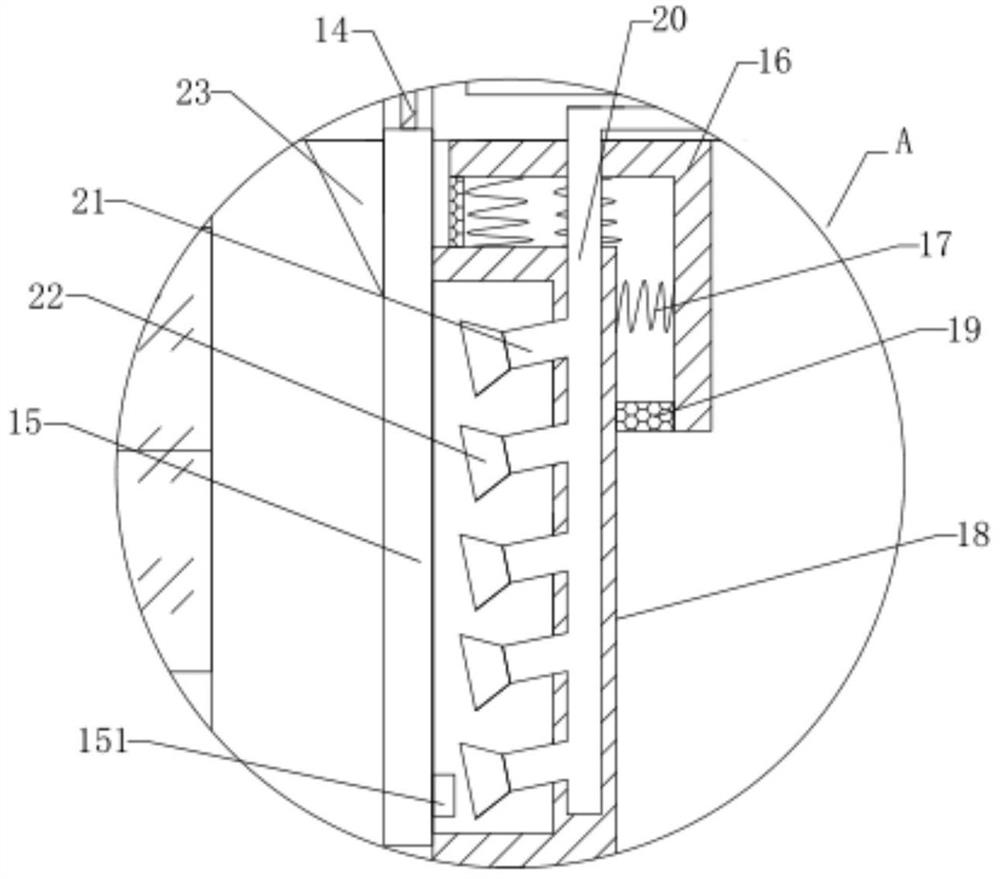

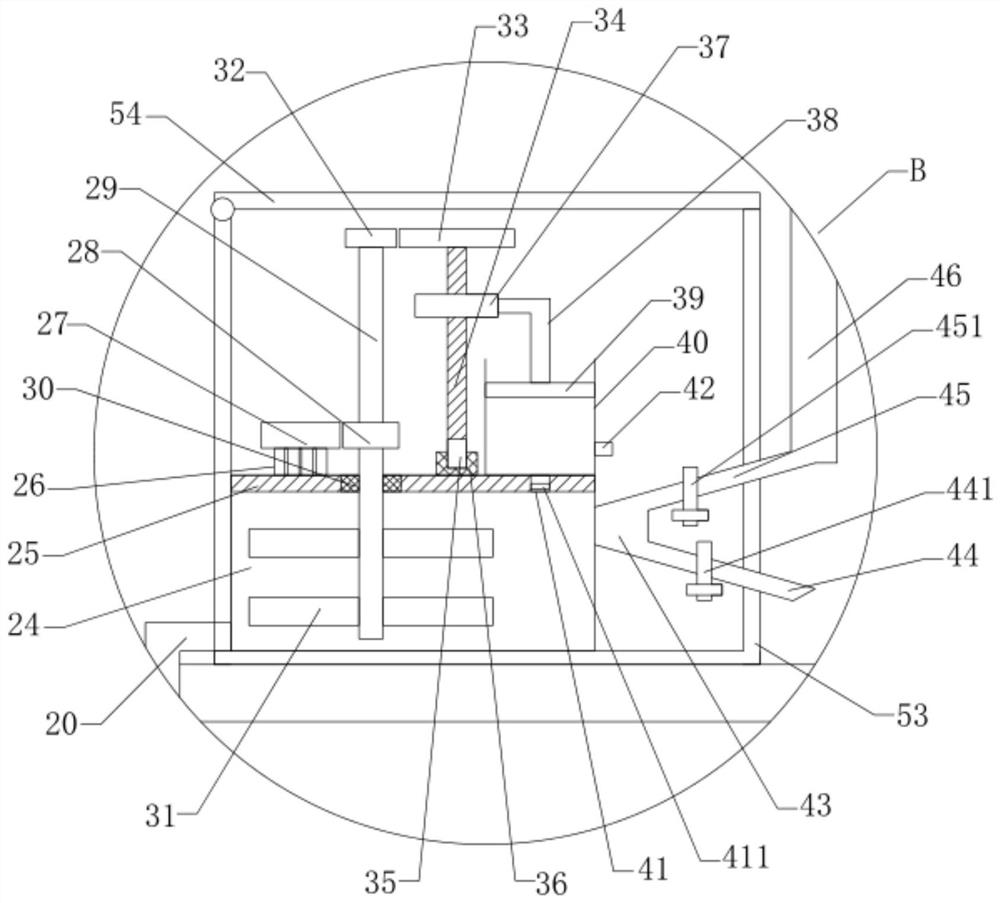

[0044] Embodiment 2: When the difference detected by the first detection head 4 of the differential pressure gauge and the second detection head 5 of the differential pressure gauge exceeds a predetermined value, or when the weight increase value measured by the waterproof weighing device 10 exceeds a predetermined value , which shows that the ceramic ring 801 at this time is blocked by ammonium salt. At this time, the PLC controller 6 starts the cylinder 14 and the rotary motor 26. On the one hand, the cylinder 14 drives the baffle 15 to move upward, and the baffle 15 can move upward during the upward movement. With the help of scratch block 23, the impurities attached to it are scraped off until the baffle plate gradually enters the raised housing 13, and the shower head 22 is completely exposed. On the other hand, the rotating motor 26 drives the driving wheel 27 to rotate, and the driving wheel 27 Drive the stirring shaft 29 to rotate through the transmission wheel one 28, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com