Package code spraying device and using method thereof

A technology of inkjet and inkjet printers, which is applied in printing devices, power transmission devices, printing, etc., can solve the problems of inability to accurately detect the deviation, double code, and missing code of goods, and achieve the effect of reducing the required time and facilitating adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

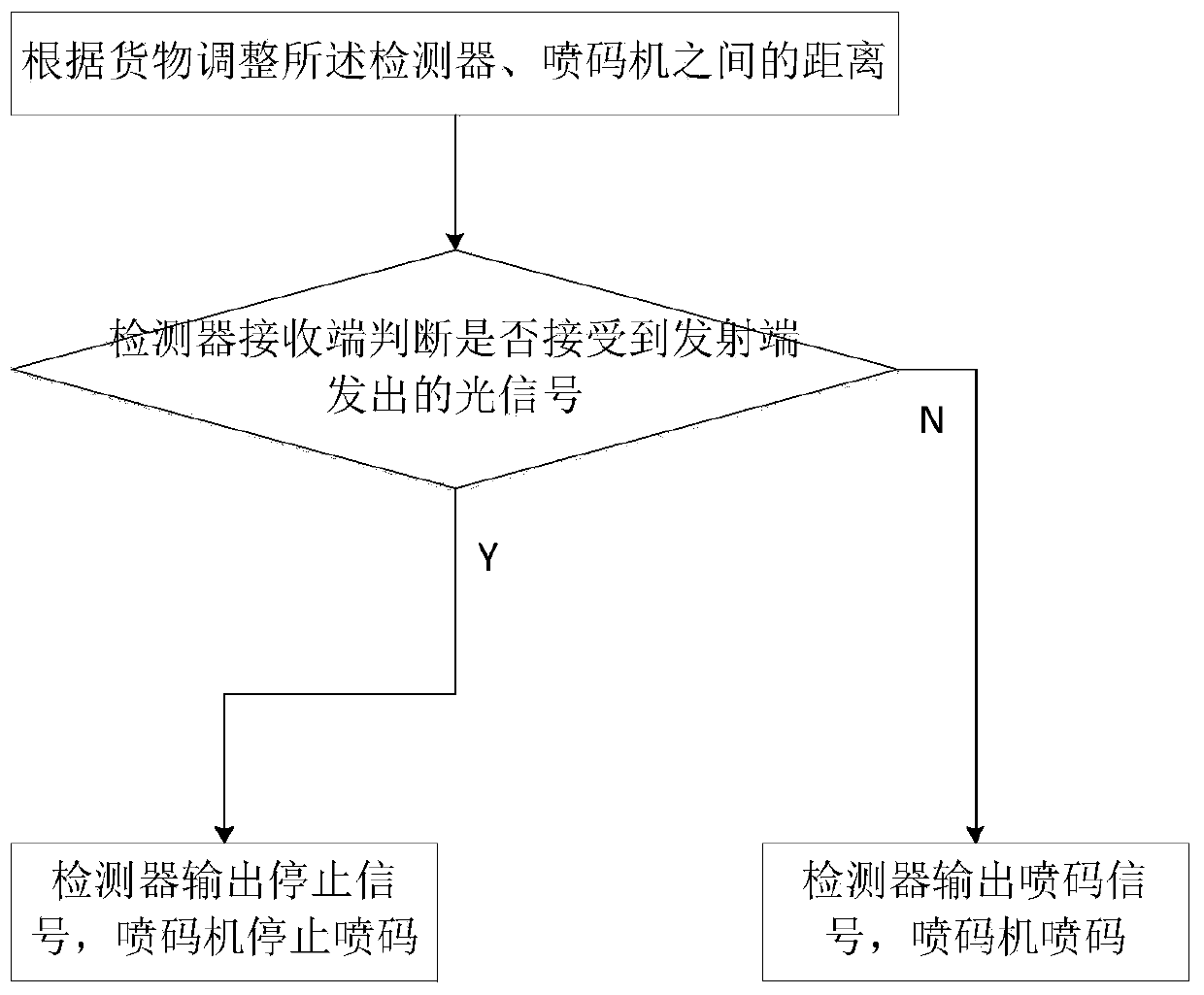

[0041] Such as image 3 As shown, the present invention also provides a method for using the aforementioned packaging code spraying device, which specifically includes the following steps:

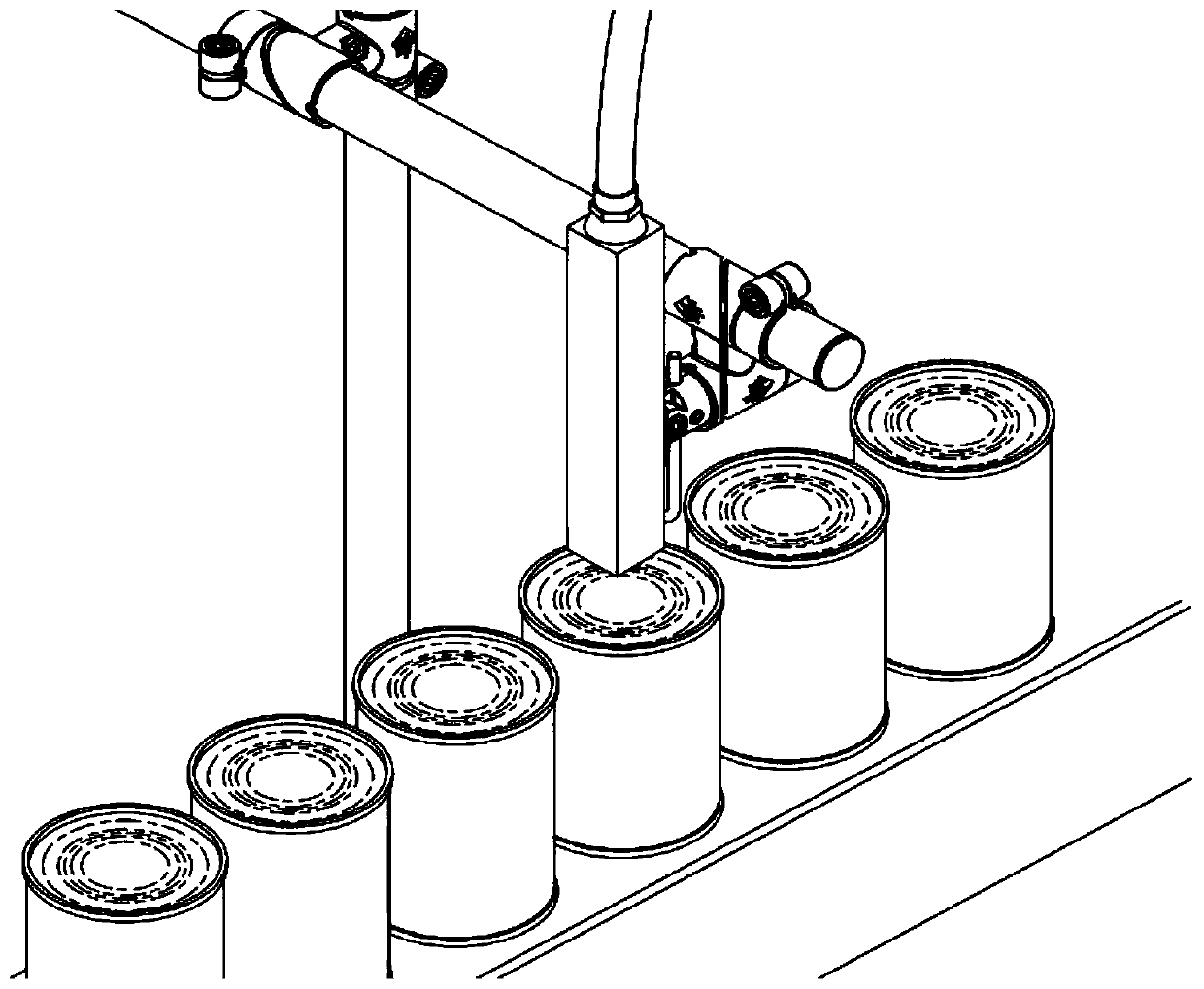

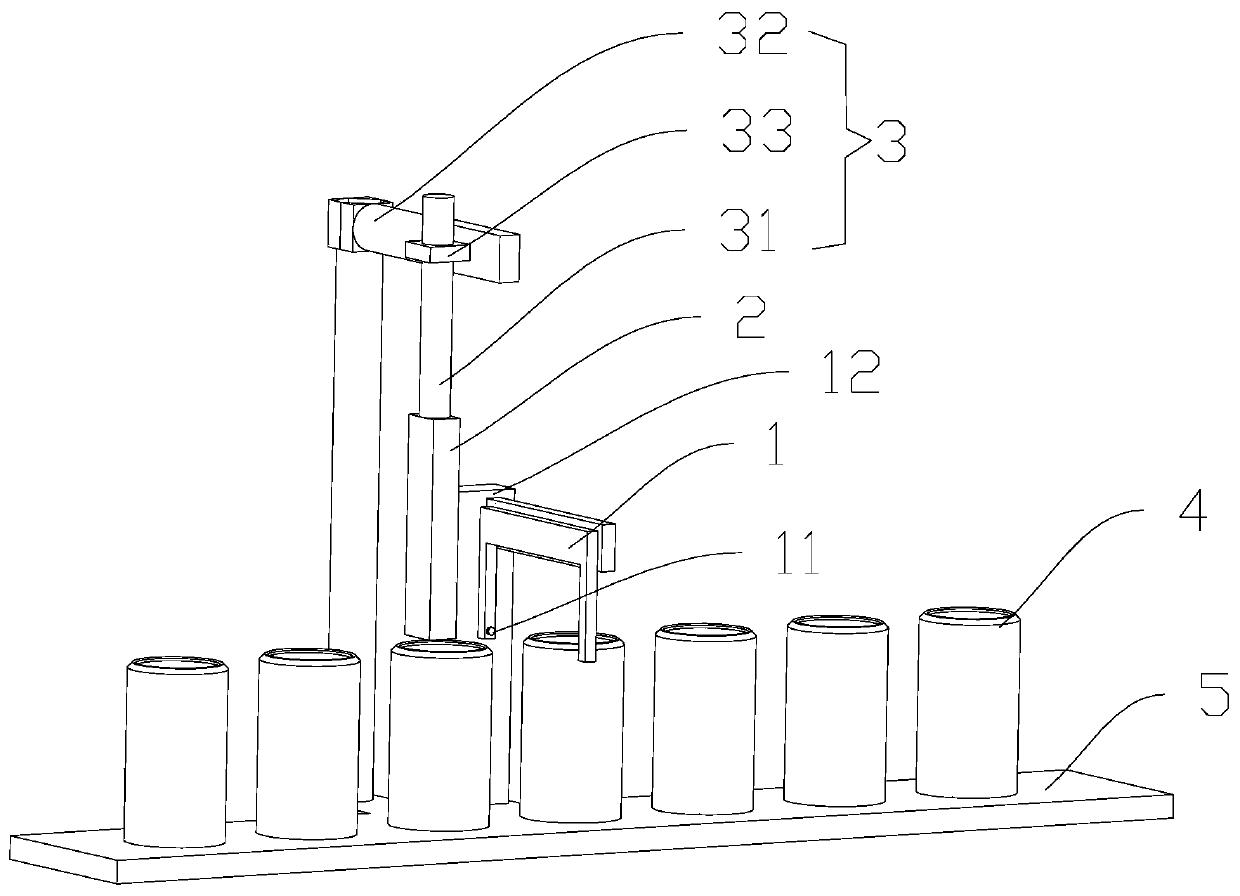

[0042] S1. Adjust the distance between the detector and the printer according to the goods 4; the detector includes a transmitting end 11 and a receiving end, the transmitting end 11 is fixed on the side of the conveyor belt 5; the detector The distance between the printer and the printer is half the length of the cargo 4, so that the nozzle 2 can accurately spray the complete marking content into the designated area of the cargo 4.

[0043] S2. The conveyor belt 5 transports the cargo 4, and the detector judges whether the cargo 4 passes by whether the receiving end receives the light signal output by the transmitting end 11; if the receiving end cannot receive the signal sent by the transmitting end 11, Then go to S3; if the receiving end receives the signal sent by the transmitting end 11...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap