A 3D printing model laser polishing system and its application method

A 3D printing and laser polishing technology, applied in the field of 3D printing, can solve the problems of difficult control of the relationship between time and polishing amount, thermal deformation of 3D printing models, etc., to reduce the processing heat affected zone, achieve fine processing, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples. The given examples are only used to explain the present invention, and are not intended to limit the scope of the present invention.

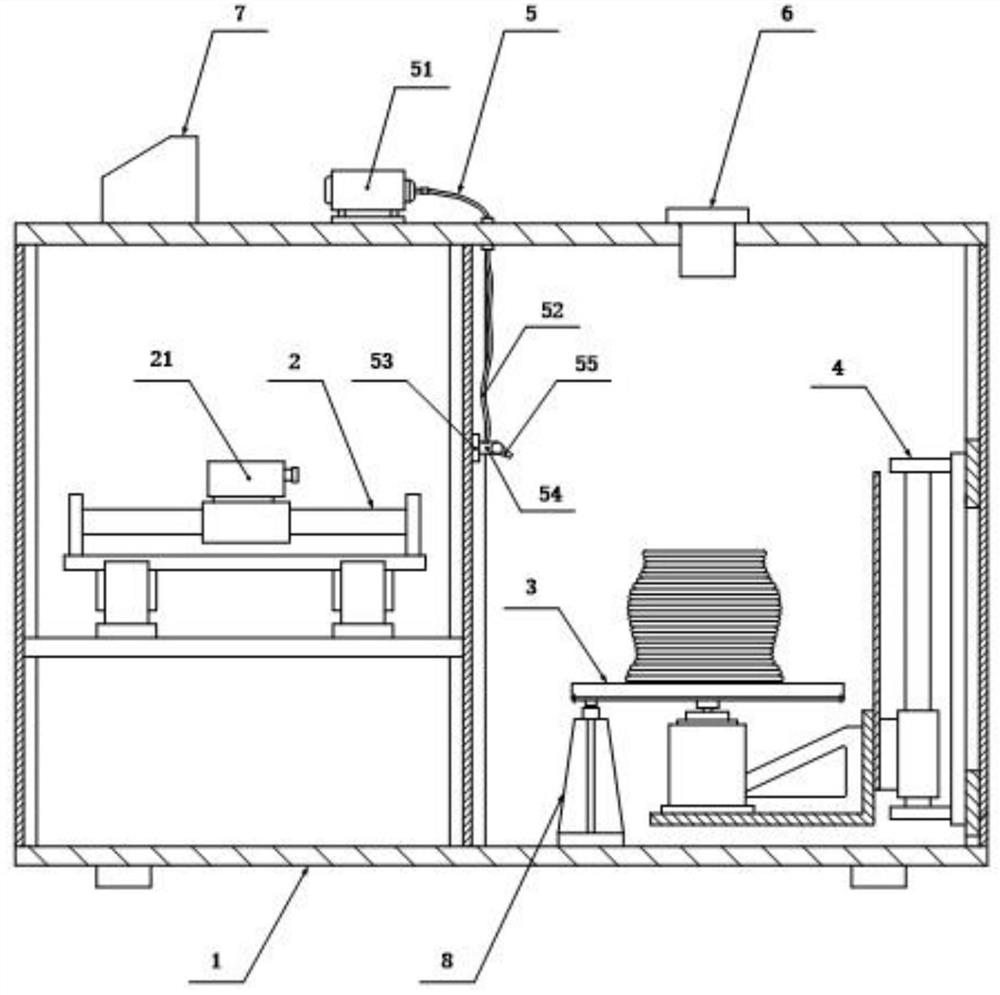

[0042] Such as figure 1 As shown, a 3D printing model laser polishing system includes a main frame 1 and a laser translation device 2 installed on the main frame 1, a Z-direction displacement component 4, a surface cleaning device 5, a gas purification device 6, a control device 7 and a power supply device 8. The model rotation device 3 is installed on the Z-direction displacement component 4;

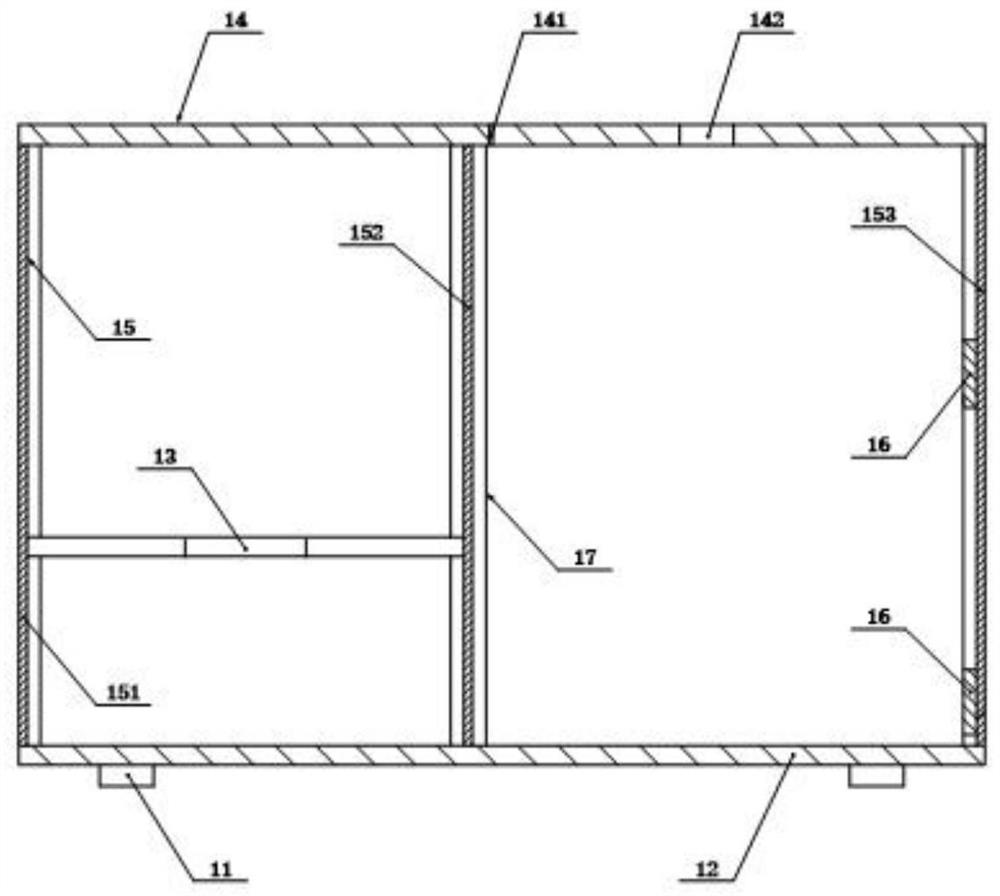

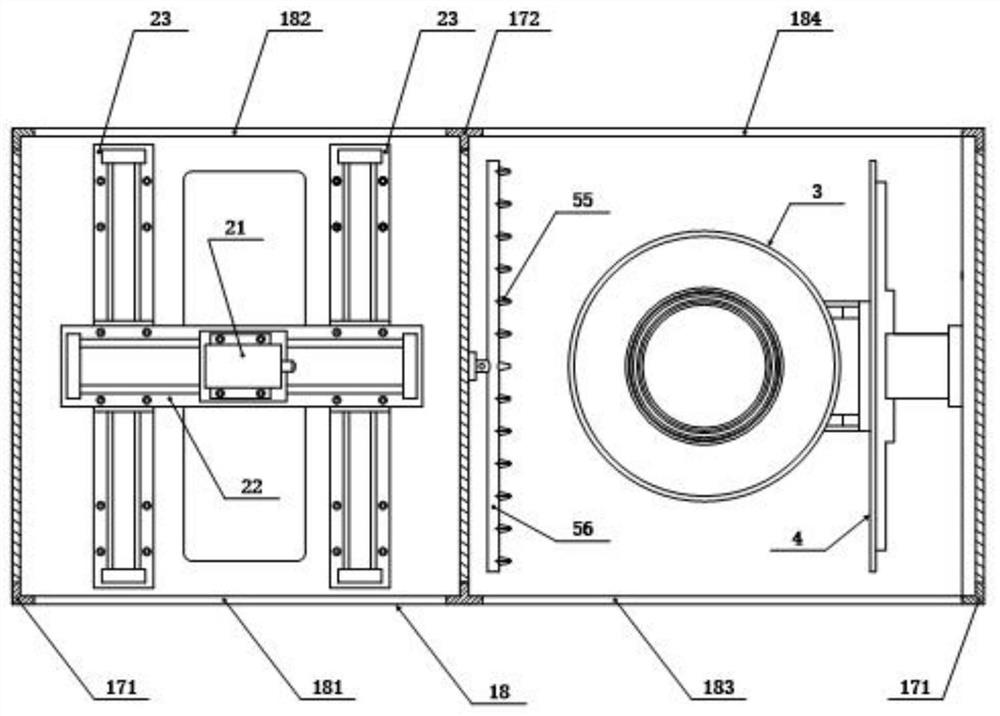

[0043] refer to figure 2 and image 3 , the main body frame 1 includes a frame connected by a bottom plate 12, a vertical plate 15, a column 17, a top plate 14, and a panel 18, and the column 17 includes an L-shaped column 171 and a T-shaped column 172, and four L-shaped columns 171 are installed On the 4 corners on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com