An inverted pendulum quasi-zero stiffness vibration isolator capable of isolating large-amplitude and low-frequency vibrations

A low-frequency vibration, quasi-zero stiffness technology, applied in the direction of shock absorbers, spring/shock absorber functional characteristics, spring/shock absorber design features, etc. Vibration can not play the quasi-zero stiffness vibration isolation and other problems, to achieve the effect of isolating low-frequency vibration, meeting vibration isolation requirements, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

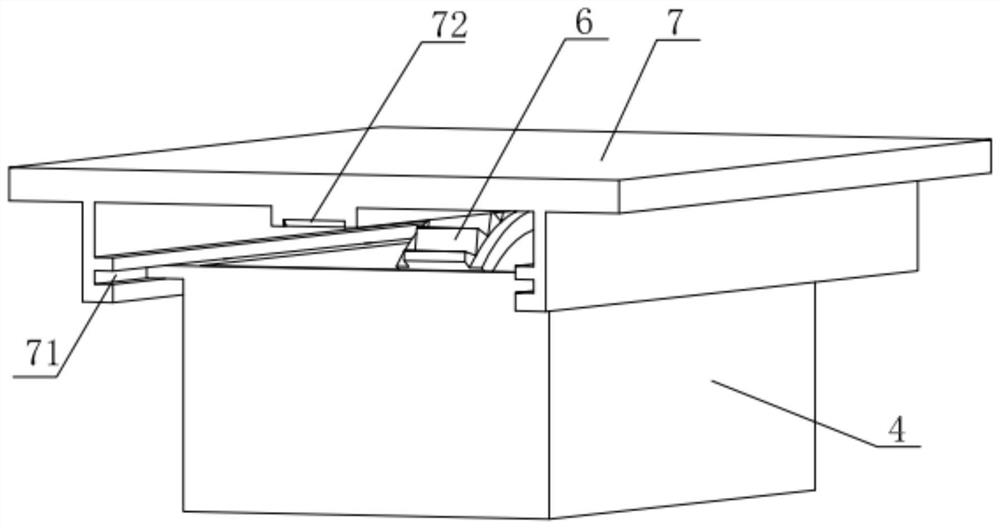

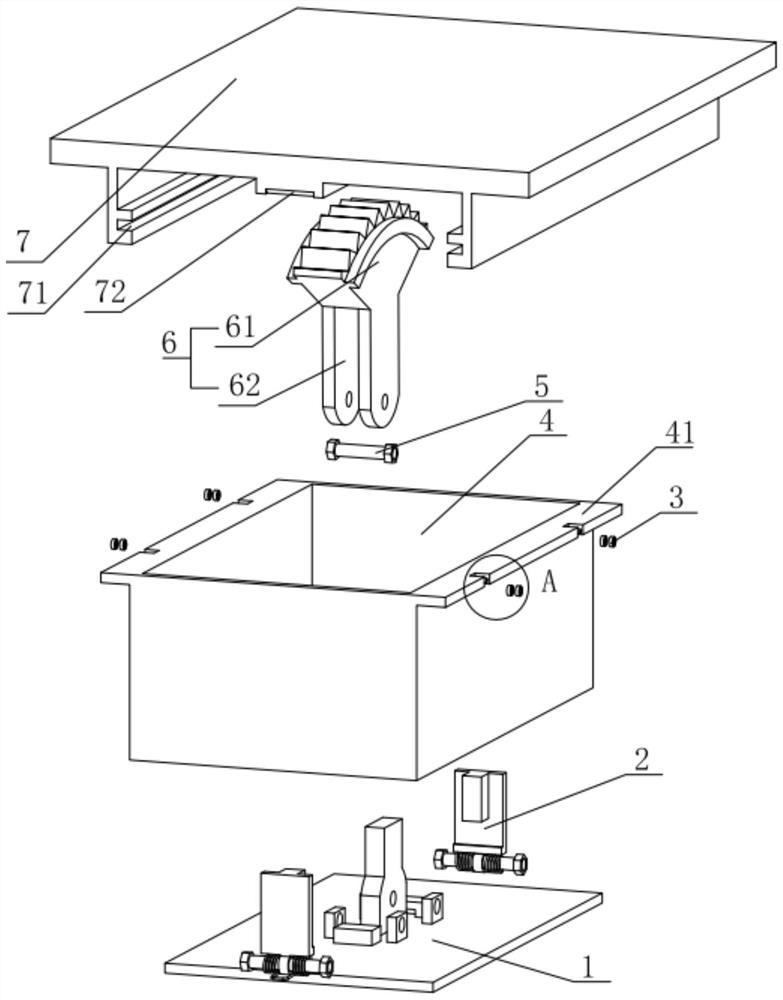

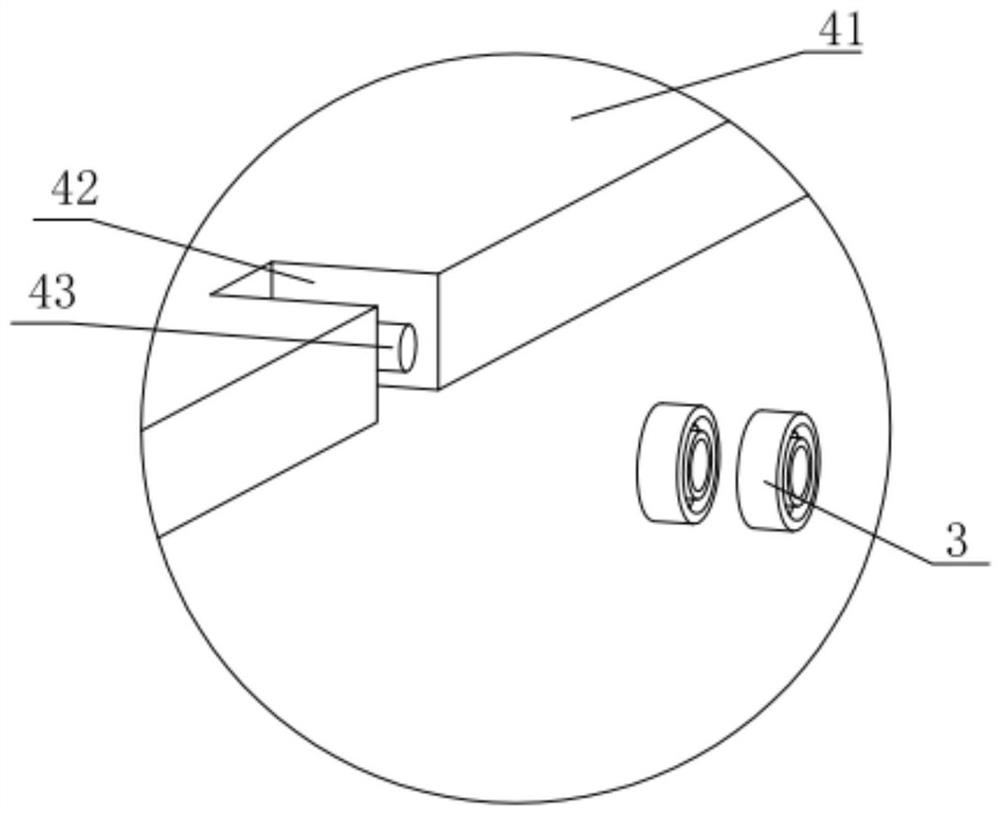

[0036] Such as figure 1 and figure 2 As shown, an inverted pendulum quasi-zero stiffness vibration isolator in this embodiment that can isolate large-amplitude low-frequency vibrations includes a bottom plate 1, a vertical plate 12 extending upward from the middle of the bottom plate 1, and an inverted pendulum 6 is installed on the vertical plate 12. The inverted pendulum 6 swings back and forth relative to the base plate 1, and the reset mechanism 2 is symmetrically installed on the base plate 1 located in front and rear of the inverted pendulum 6, and a coaming plate 4 is installed along the edge of the base plate 1; the top of the inverted pendulum 6 is provided with a gear structure 61, Cooperating with the gear structure 61, a top plate 7 is installed, and the top plate 7 is slidingly connected with the surrounding plate 4 back and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com