Self-diagnosis method for faults of rolling bearing retainer

A rolling bearing and cage technology, applied in the field of self-diagnosis of rolling bearing cage faults, can solve the problems of signal interference by noise, poor self-diagnosis effect, difficult self-diagnosis, etc., and achieve the effect of enhancing fault characteristics and weakening interference such as abnormal impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

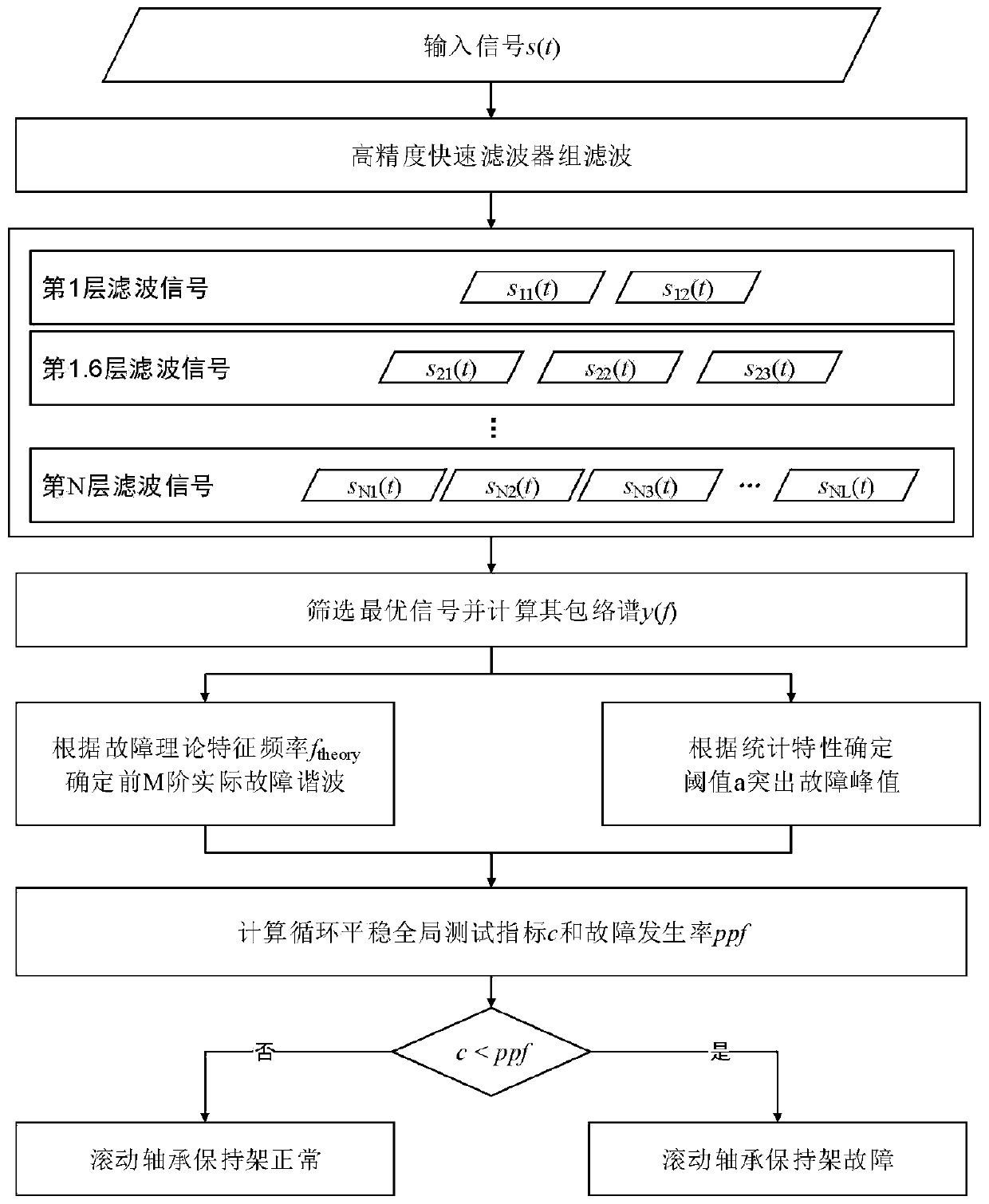

[0021] Such as figure 1 As shown, a self-diagnosis method for rolling bearing cage faults, the specific steps of the method are as follows:

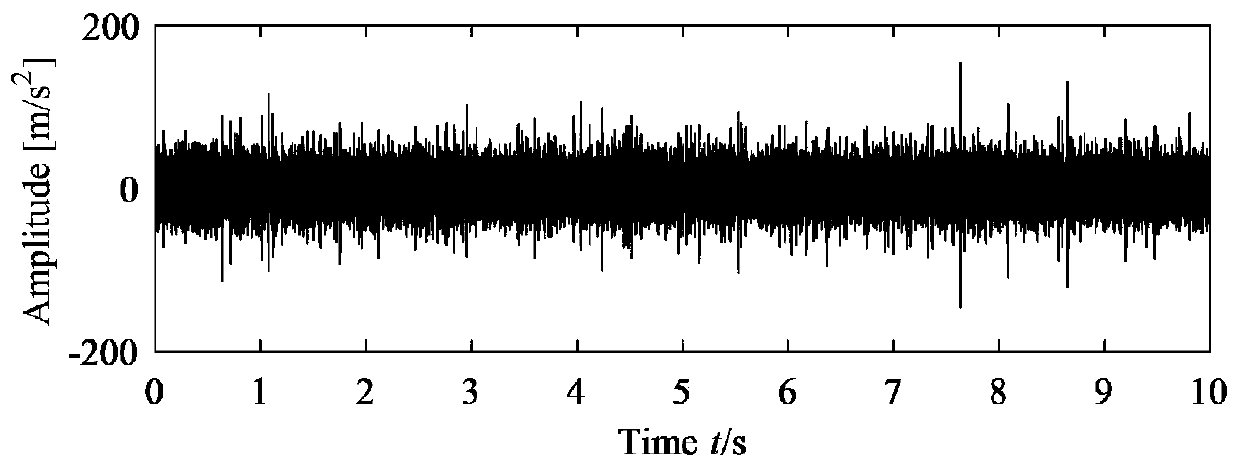

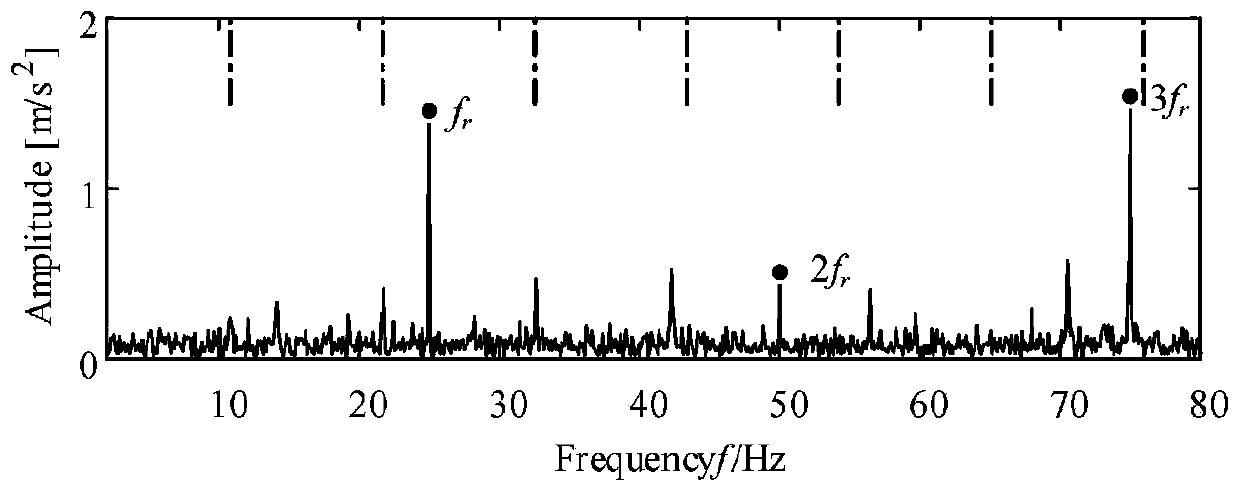

[0022] The specific parameters are as follows: 1) The test bench is composed of a driving electric spindle and a mechanical shaft. The rolling ball bearing is ZYS B7008C type, the contact angle is 0 degrees, the outer diameter of the bearing is 68mm, the inner diameter of the bearing is 40mm, and the diameter of the rolling body is 7.138mm. The number of rolling elements is 18; 2) The fault type of the cage is that the pocket beam breaks through; 3) The sampling frequency in the acquisition example is 51.2KHz, and the rotational speed of the rotating shaft is 1500r / min.

[0023] Step1. Use a three-axis acceleration sensor to obtain the vibration acceleration signal at the base of the faulty end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com