Light emitting device, display device, method of manufacturing display device, and power generation device

A technology for light-emitting devices and display devices, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems that there are no diversified quantum dot display device structures, simple layer structures, etc., and is suitable for large-scale The effect of simple production and processing technology and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

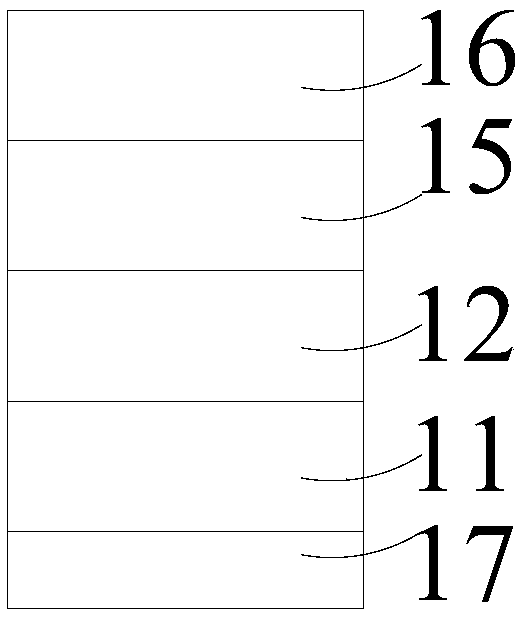

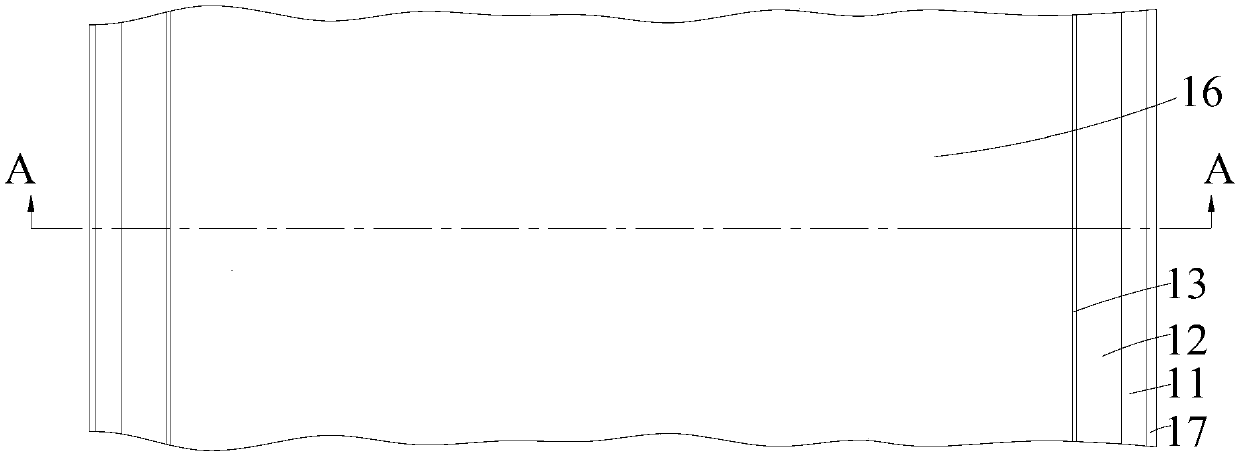

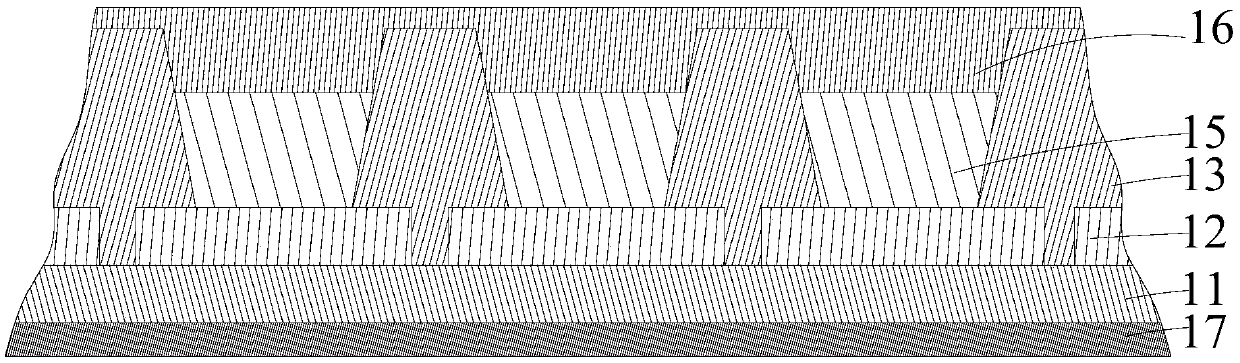

[0139] Such as Figure 21 As shown, a display device includes a light source 17, a substrate 11, an anode 12, a pixel defining layer 13, a core function layer 15 (also called a light-emitting layer), and a cathode 16; wherein, the substrate 11 is a transparent glass plate, and the anode 12 The material of the pixel definition layer 13 is silicon dioxide, the material of the core functional layer 15 is a mixture of CdSe / ZnS quantum dots and silicon dioxide, and the material of the cathode 16 is AZO.

[0140] see Figure 11-21 , the manufacturing method of the light-emitting display device is as follows:

[0141] S1. provide liner 11, this substrate 11 has opposite first surface and second surface, on the first surface of substrate 11, prepare a number of anodes 12 that are side by side and have intervals, at the edge of described anode 12 and by interval A pixel defining layer 13 is prepared on the exposed first surface of the substrate 11, and a pixel groove 14 is formed sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com