Method for preparing physically modified starch by using heating and freezing-thawing and adding various edible gums

A starch and modification technology is applied in the field of preparing physically modified starch to achieve the effects of improving storage stability, good stability, promoting quality and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

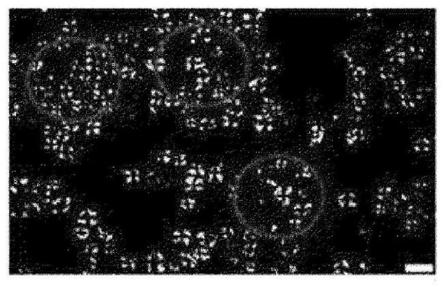

Image

Examples

example

[0060] The present invention will be explained in more detail with reference to the following examples. Those skilled in the art will appreciate that these examples are illustrative only and that the scope of the present invention should not be construed as being limited to the examples. Accordingly, the true scope of the invention should be defined by the appended claims and their equivalents.

[0061] Materials and methods

[0062] starch

[0063] Corn starch and waxy corn starch received from Samyang Genex (Korea) and potato starch and tapioca starch received from Seoan (Korea) and Daesang (Korea) were used for In the following experiments.

[0064] glue

[0065] Four kinds of gums were used in the following experiments, including: xanthan gum (Xanthan gum, XT) (Keltrol, The Nutrasweet Kelco Company, USA (USA)), guar gum (guar gum, GG) (Lotus Gum and Chemicals, India), gum arabic (GA) (The Gum Arabic Company, Sudan) and Carboxymethylcellulose (CMC) (Showa Chemic...

example 1

[0066] Example 1: Preparation of modified starch

[0067] 1-1: Preparation of modified starch

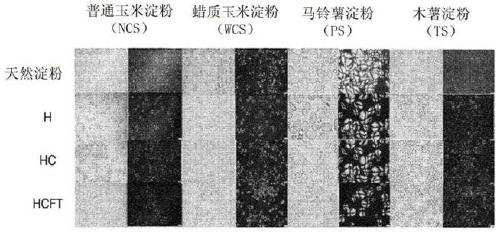

[0068] (1) each dispersion liquid in common corn starch (NCS), waxy corn starch (WCS), potato starch (PS) and tapioca starch (TS) is heated to the temperature that does not take place corresponding starch gelatinization ( 60°C for normal corn starch and waxy corn starch, and 55°C for potato starch and tapioca starch) (hereinafter referred to as "H").

[0069] (2) The heated dispersion liquid was cooled in a refrigerator for 12 hours (hereinafter referred to as "HC").

[0070] (3) The cooled dispersion was frozen in a freezer (-20°C) for 12 hours and thawed at room temperature (25°C) for 1 hour (hereinafter referred to as "HCFT").

[0071] Thereafter, the starch dispersion was dried and powdered in a drying oven at 45°C. Starch powder was used in the following experiments.

[0072] 1-1-1: Heating temperature setting

[0073] The final gluing temperature for each of the nativ...

example 2

[0102] Example 2: Prepare the modified starch that adds glue

[0103] 2-1: Preparation of modified starch

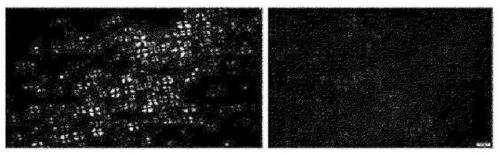

[0104] Based on the results of Example 1, potato starch (PS) was selected and used as a control native starch in subsequent experiments because of its superior characteristics compared to the other 3 starches.

[0105] First, a starch-glucose mixture is prepared. The starch-glue mixture was modified in the same manner as Example 1-1.

[0106] (1) The starch-glue mixture was heated for 1 hour at a temperature (55° C.) at which potato starch does not gelatinize, and cooled in a refrigerator for 12 hours (hereinafter referred to as “HC”).

[0107] (2) The cooled starch-glue mixture was frozen in a freezer (-20°C) for 12 hours and thawed at room temperature (25°C) for 2 hours (hereinafter referred to as "HCFT").

[0108] Thereafter, the thawed starch-gum mixture was dried in a drying oven at 45°C and pulverized. The powder was used in the following experiments.

[010...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap