An efficient and reliable corn ear stalk and harvester

A corncob and harvesting platform technology, applied in the direction of harvesting platforms, harvesters, agricultural machinery and implements, etc., can solve problems that affect operating efficiency, poor reliability, and shaft end bending, so as to improve operational reliability and scope of application The effect of wide and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

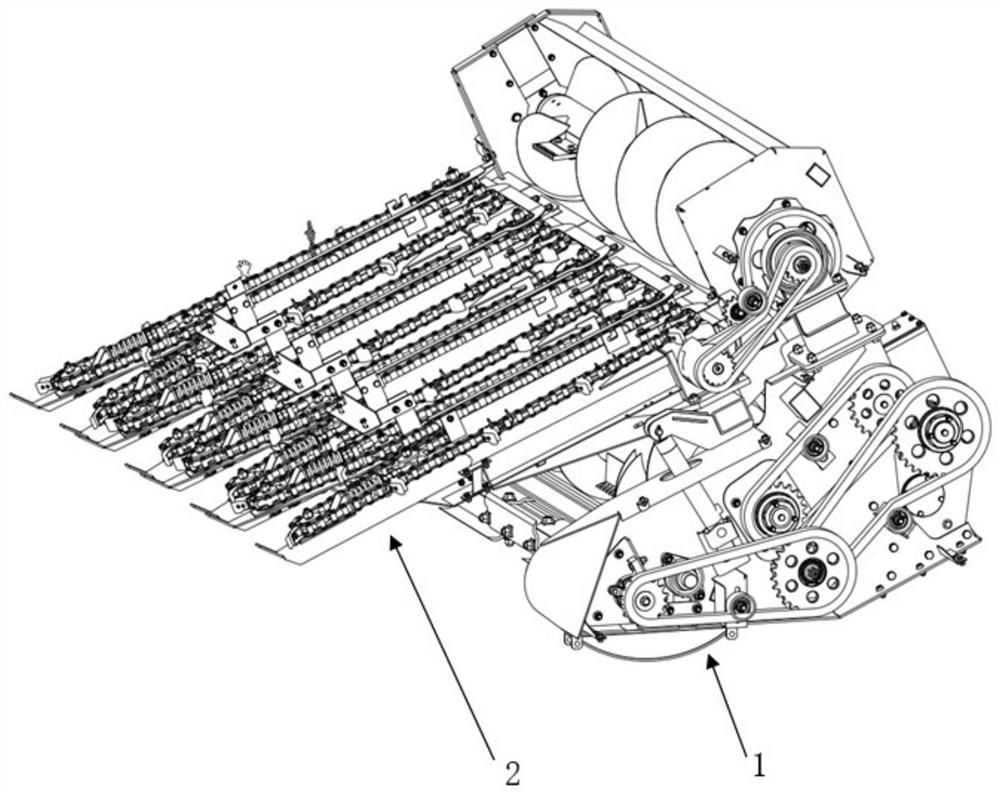

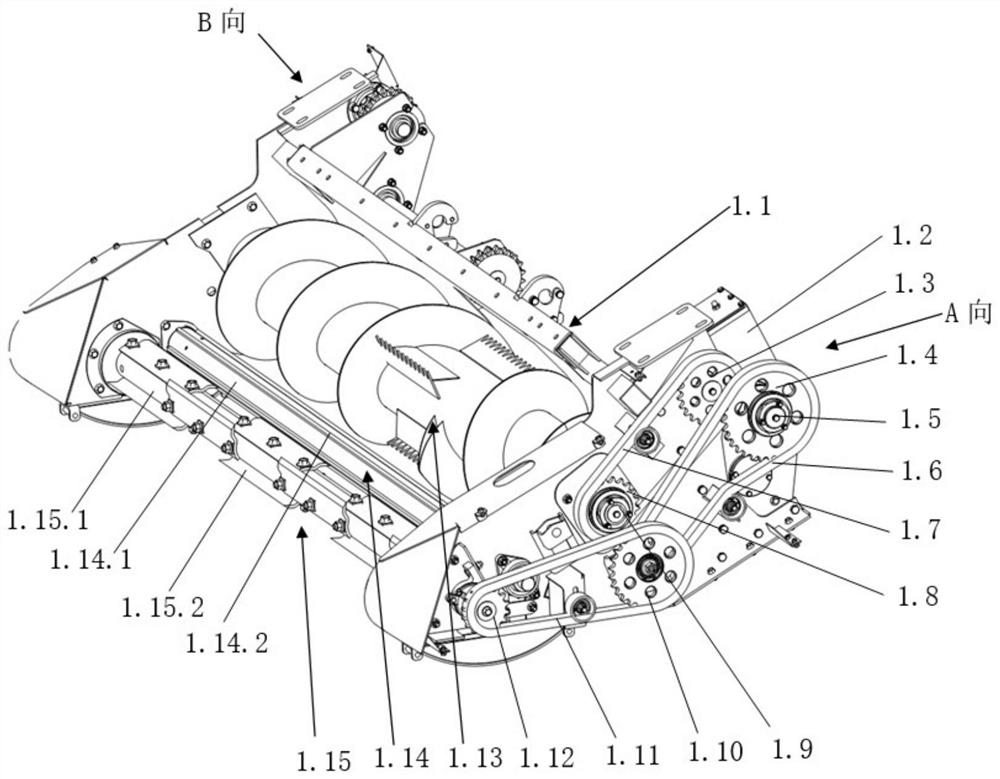

[0029] An efficient and reliable corn stalk-cum-header, see Figure 1-8 , and its invention is as follows: it includes a cutting and recycling header 1 located at the lower part and a corn ear picking header 2 located at the upper part.

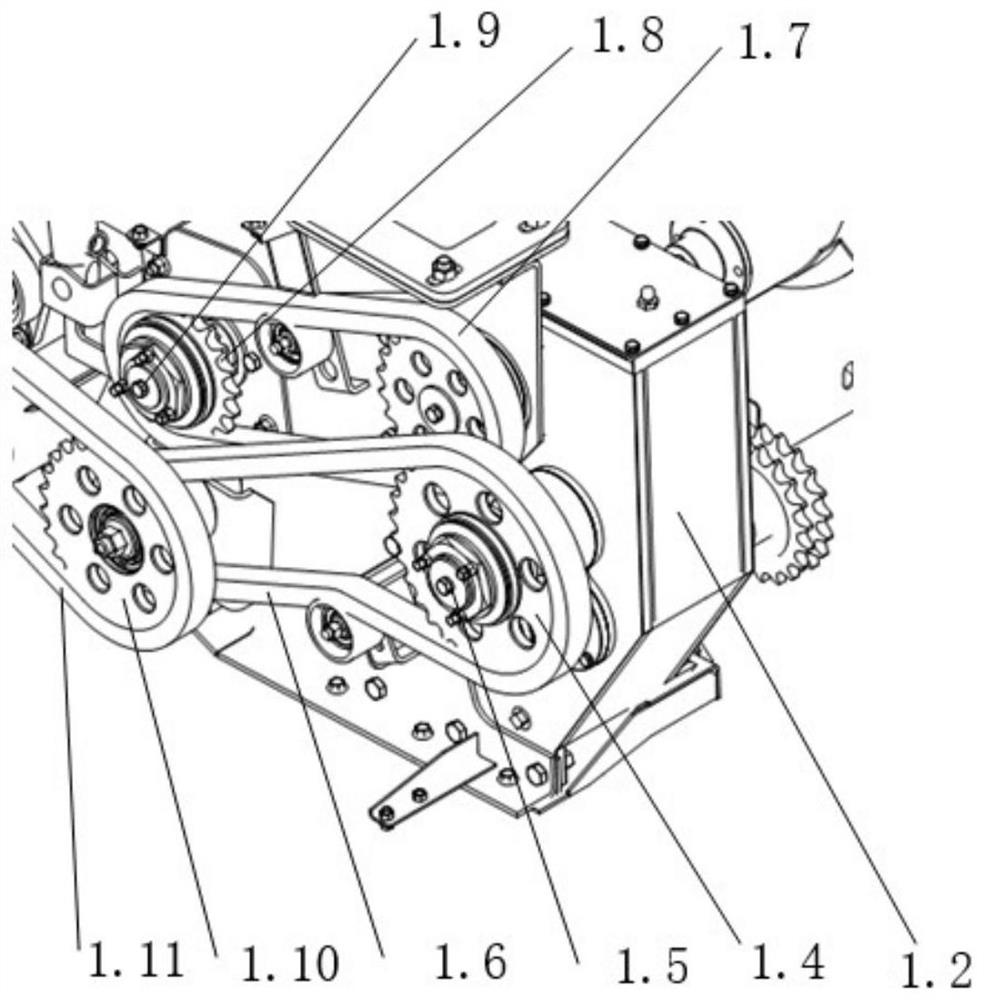

[0030]The header including cutting and recovering stalks includes a lower header frame 1.1, and the lower header frame is mainly composed of left and right side walls and a cross bar connecting part connecting the rear parts of the two side walls. A rotatable roller cutter 1.15, a conveying roller assembly 1.14, and a feeding auger assembly 1.13 are installed in sequence from front to back between the two side walls of the lower header frame. On the roller cutter, the left s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com