A dual-motor drive system and its shift torque control method, and vehicle

A dual-motor drive, torque control technology, applied in electric vehicles, transmission control, control drive, etc., can solve problems such as increasing shift time, reducing vehicle power, and uneven power output, reducing shift time, reducing Adjustment time, smooth effect of vehicle power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following non-limiting examples can enable those skilled in the art to understand the present invention more fully, but do not limit the present invention in any way.

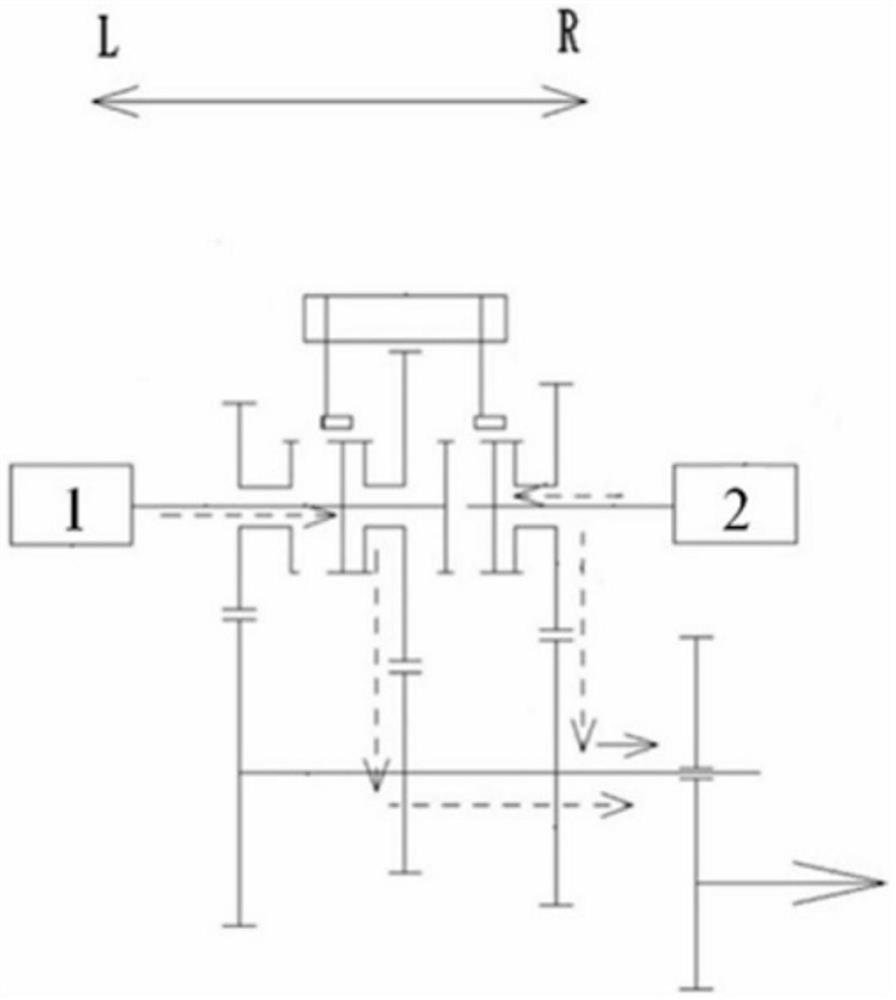

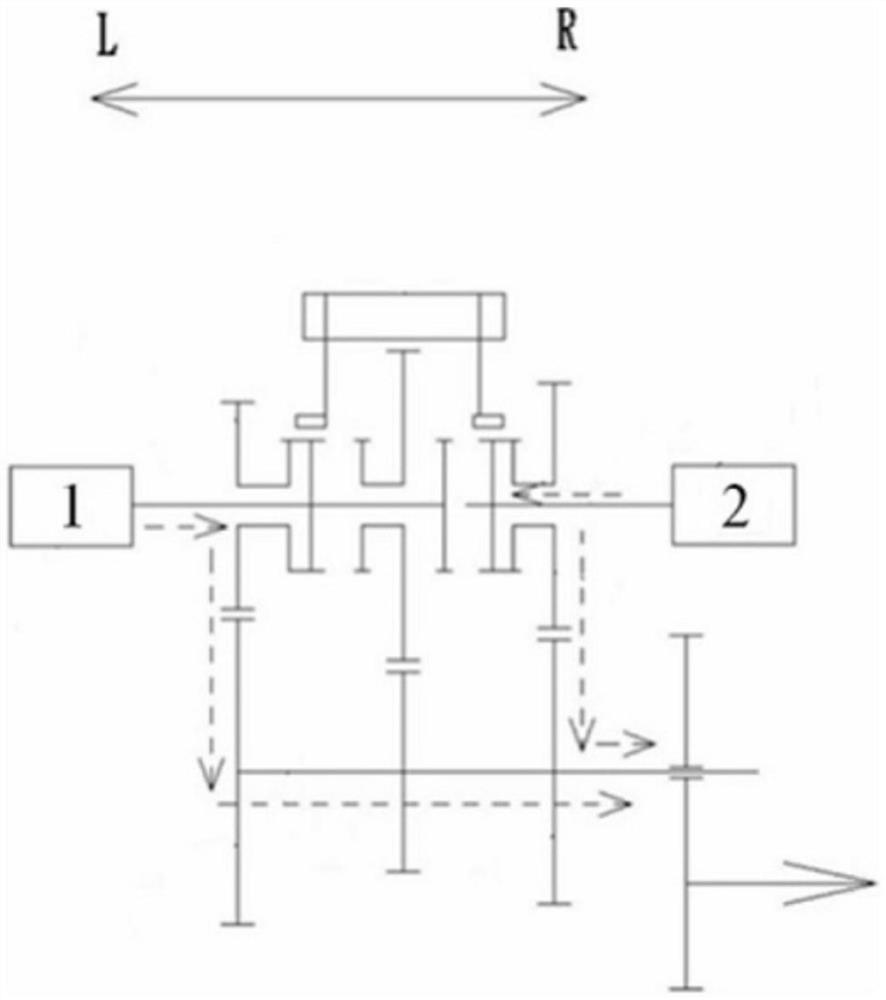

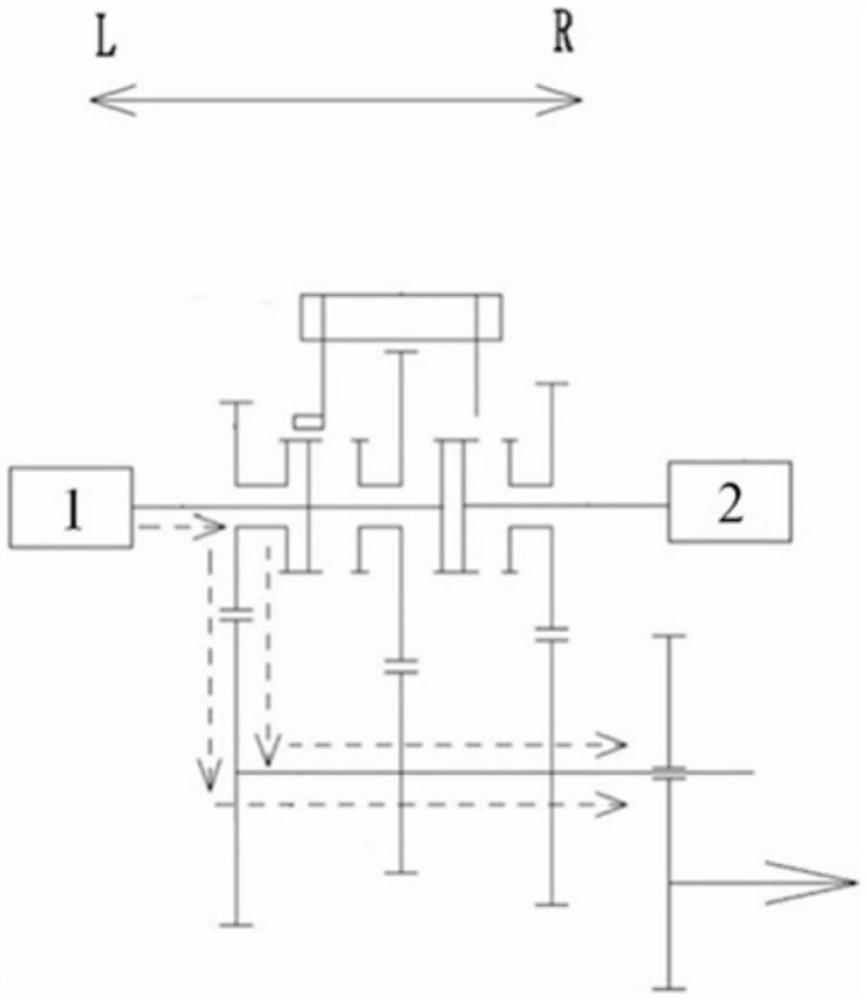

[0035] With the continuous advancement of new energy vehicle technology, more and more commercial vehicles have begun to use electric drive to solve energy consumption problems. In the prior art, there have been dual-motor dual-clutch multi-mode drive systems and their drive methods. The dual power sources respectively provide input power to the transmission unit, adopt parallel shafts to configure the gear sets of the power system, and selectively realize power coupling between the power source and the gears through the mode switching device; The coordinated switching of the dual clutch device controls one of the power sources to be input to the transmission unit to drive power on and off when shifting gears, and selectively couples the gears to the power source synchronously. Compared with the prior...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com