Anti-loosening bolt assembly with buckle pin arranged along thread axis

An anti-loosening bolt and axial technology, applied in the direction of threaded fasteners, bolts, screws, etc., can solve the problems that are not suitable for repeated use, cannot meet the precise control of pre-tightening torque, increase the weight of fastening components, etc., and achieve installation and disassembly Effortless, all performances are preserved, and the effect of increasing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

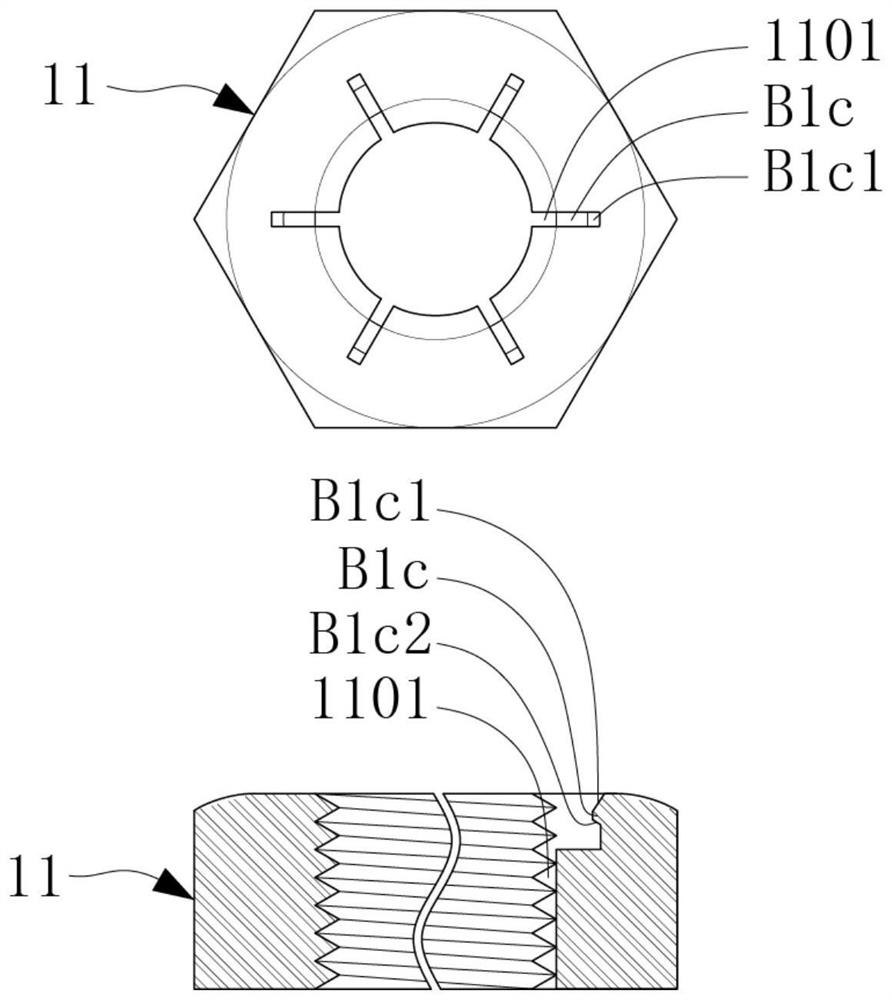

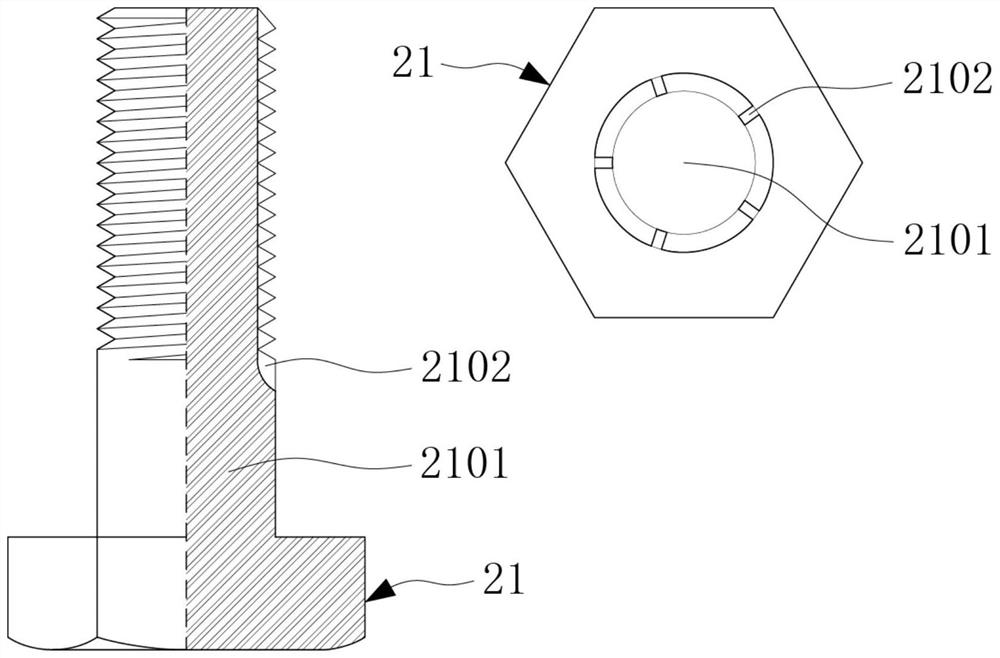

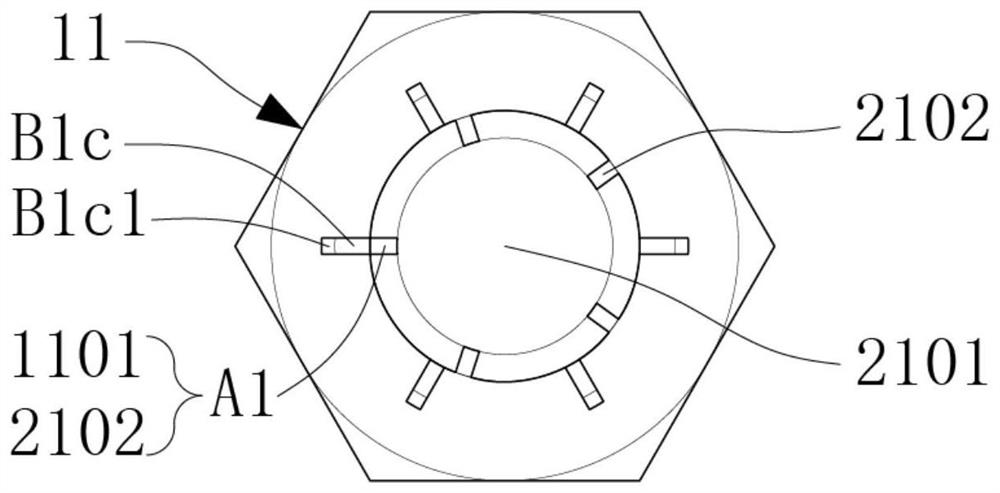

[0091] Such as figure 1 , figure 2 , image 3 , Figure 4 ,and Image 6 As shown, an anti-loosening bolt assembly with snap-fit pins arranged along the axial direction of the thread, which includes nuts 11 , bolts 21 , and pins 31 that cooperate with each other. The nut 11 is axially provided with a first groove 1101 along the internal thread, the radial depth of the first groove 1101 is preferably equal to the radial height of the thread of the internal thread of the nut 11, and the radial width of the first groove 1101 is preferably The screw rod 2101 of the bolt 21 is provided with a second groove 2102 along the axial direction of the external thread, and the radial depth of the second groove 2102 is preferably equal to the radial height of the thread of the external thread of the screw rod 2101, The second groove 2102 and the first groove 1101 have the same radial width; when the first groove 1101 and the second groove 2102 are radially aligned, they together form a...

Embodiment 2

[0093] Such as figure 1 , figure 2 , Figure 4 ,and Figure 7 As shown, an anti-loosening bolt assembly with snap-fit pins arranged along the axial direction of the thread, which includes nuts 11 , bolts 21 , and pins 31 that cooperate with each other. This embodiment is basically the same as Embodiment 1, except that: (1) the female snap B1c of the nut 11 is not provided with an outlet; (2) the nut 11 is provided with a radial through hole 1102, and the radial through hole 1102 penetrates radially Set at the deepest bottom of the box B1c in the radial direction, the number of radial through holes 1102 and the first groove 1101 are the same and they are radially aligned with each other: (3) The diameter of the radial through hole 1102 is preferably not smaller than that of the first groove 1101 radial width, and the radial through hole 1102 needs to be deepened, and its increased depth is not less than the radial height of the male buckle B1d of the bolt 31: (4) the male...

Embodiment 3

[0095] Such as figure 1 , figure 2 , Figure 5 ,and Figure 8 As shown, an anti-loosening bolt assembly with snap-fit pins arranged along the axial direction of the thread, includes nuts 11 , bolts 21 , and pins 32 that cooperate with each other. This embodiment is basically the same as Embodiment 1, except that: (1) the female snap B1c of the nut 11 is not provided with an outlet; (2) the male snap B2d of the bolt 32 is not provided with an outlet; (3) the outlet of the latch 32 The second straight arm 3202b of the U-shaped elastic arm 3202 is set close to the bottom of the first groove 1101 of the nut 11; (4) The U-shaped elastic arm 3202 of the latch 32 is useful for setting the arm section exposed outside the female buckle B1c The release-assisting protrusion 3202a2 for assisting the buckle release and prying up the latch, the release-assisting protrusion 3202a2 is arranged radially on the outer surface of the part where the extended bending 3202a1 of the first strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com