A burner for a gas stove

A technology for burners and gas stoves, applied in the field of gas stoves, can solve the problems of waste of resources, low efficiency, excess secondary air, etc., and achieve the effects of improving thermal efficiency, accurate positioning, and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

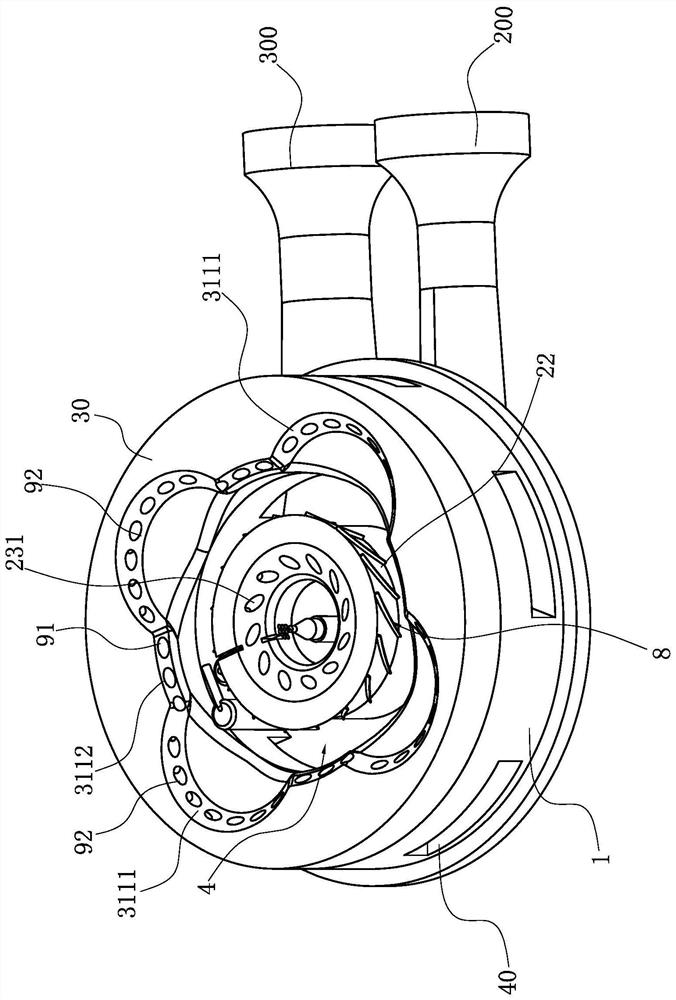

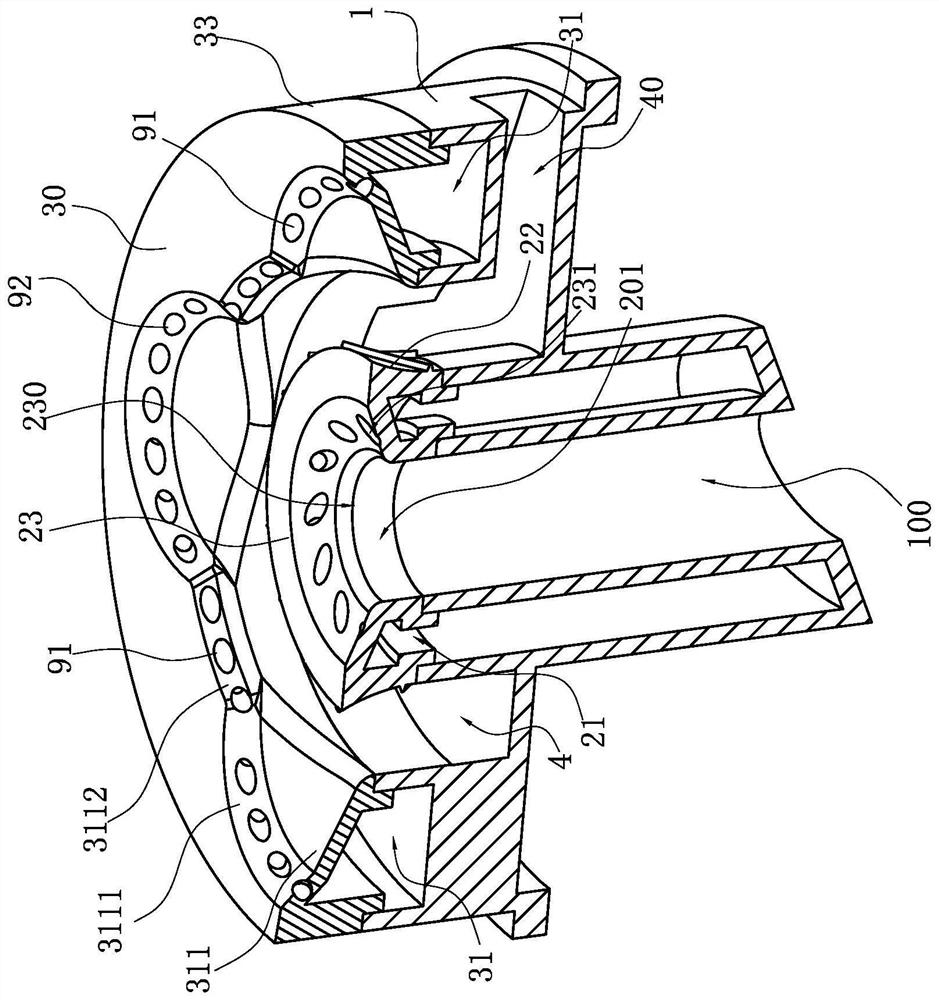

[0030] Such as Figure 1~5 As shown, it is the best implementation mode of the present invention. The burner used in the gas stove in this embodiment includes a base 1, which is arranged on the base 1 and forms a central mixing chamber with the base 1. The inner ring fire cover 2 of the gas chamber 21 is also arranged on the base 1, at the periphery of the inner ring fire cover 2, and forms an outer ring gas mixing chamber 31 with the base 1, the central gas mixing chamber 21 and the outer ring An air supply chamber 4 is formed between the annular air mixing chambers 31, and a plurality of radial secondary air supply passages 40 for connecting the air supply chamber 4 with the outside world are provided at intervals along the circumferential direction on the base 1, and the outer ring The air mixing chamber 31 is provided with fire outlets at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com