Wet-type braking system of urban rail vehicle

A brake system and urban rail technology, applied in the field of rail transit, can solve the problems of reducing rail vehicles, long braking time, reducing wheel speed, etc., and achieve the effects of efficient and stable braking, easy disassembly, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

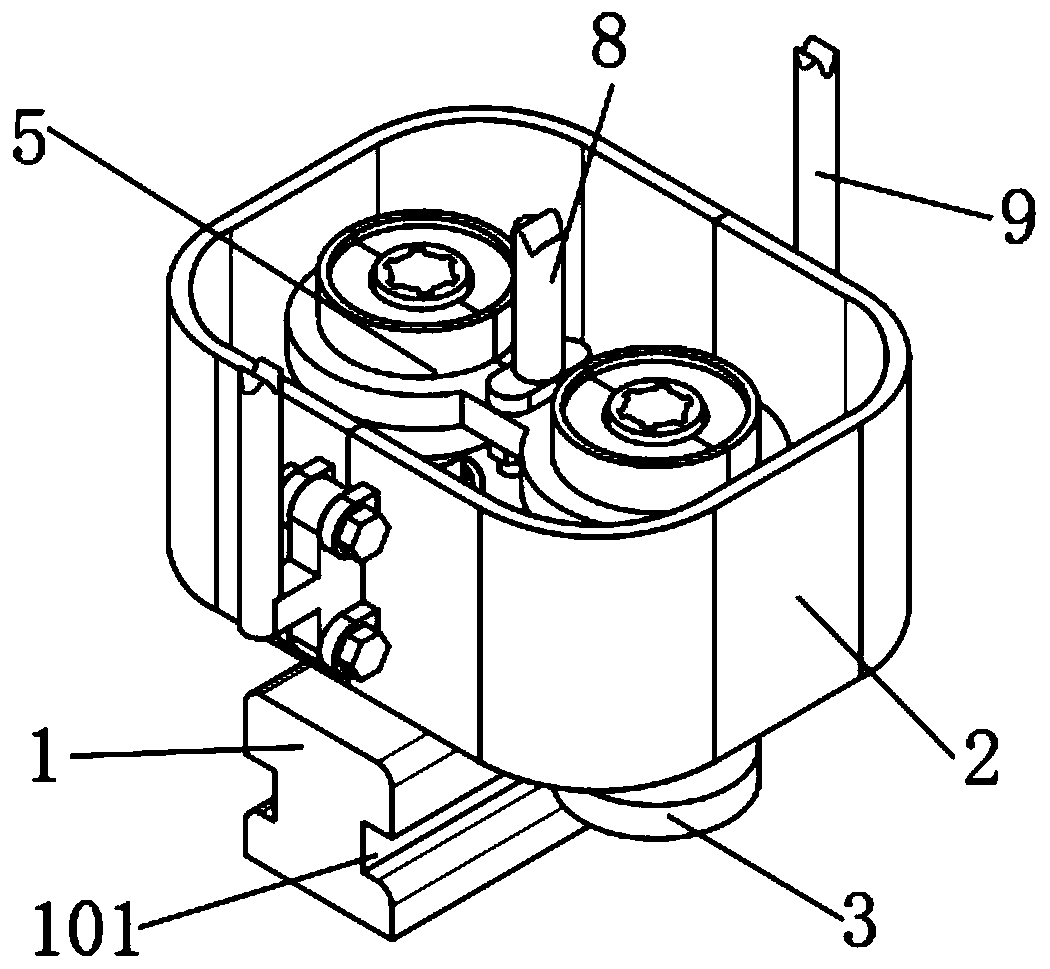

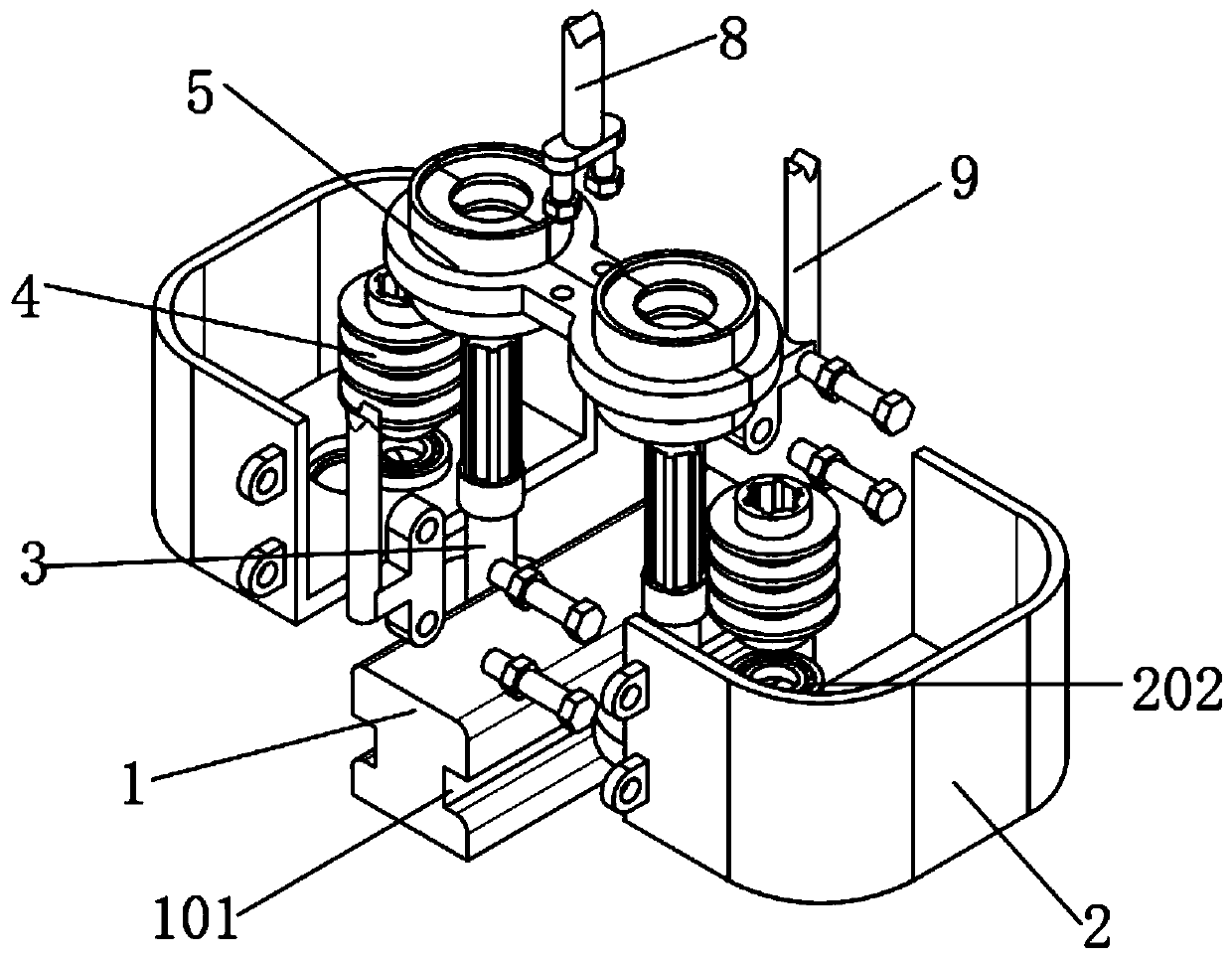

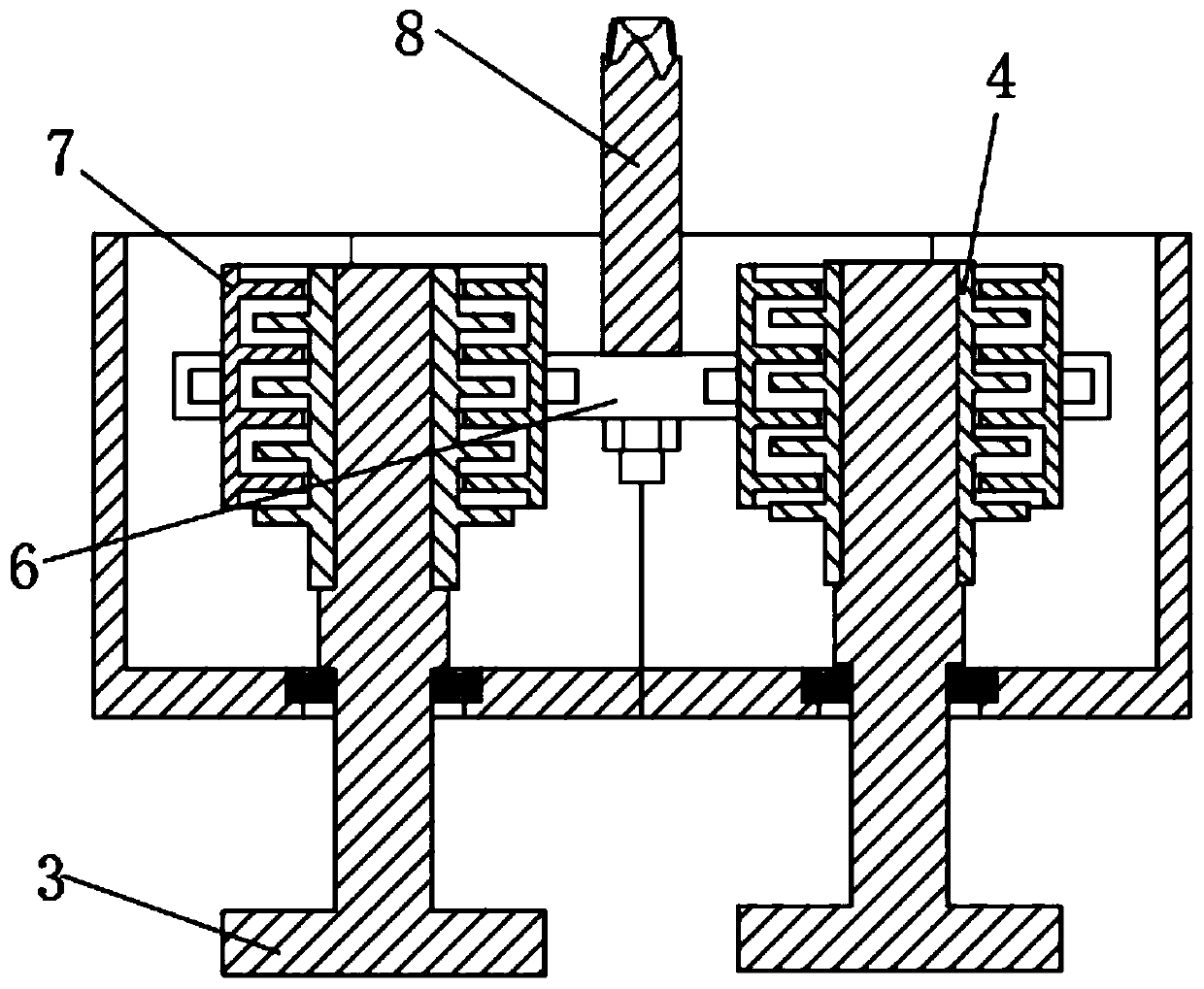

[0032] The embodiment of the invention discloses a wet brake system for urban rail vehicles, such as Figure 1-9 As shown, it includes an I-shaped track body 1 and a brake fixed on the bottom of the rail vehicle (not shown in the figure); Groove 101 (i.e. the two concave parts of the I-shaped), the upper surface of the outer casing 2 is provided with a bearing groove 201, the bearing groove 201 is fixedly connected with a rolling bearing 202, and the outer ring of the rolling bearing 202 is in contact with the bearing groove 201.

[0033] The lower surface of the outer casing 2 is provided with a limit ring 203, and the limit ring 203 and the bearing groove 201 are set to be connected and the axes coincide. The limit ring 203 is set to limit the rolling bearing 202, prevent the rolling bearing 202 from falling off from the bearing groove 201, and not Affecting the use of the rolling bearing 202 , the outer casing 2 is rotatably connected with the rolling wheel 3 through the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com