Novel bidirectional rotating shaft assisting damper

A damper and shaft technology, applied in the field of a new type of bidirectional shaft booster damper, can solve the problems of large reverse resistance of the rotary damper, long closing time, small angle difference, etc., and achieves low cost and labor-saving opening of the flip. , Reduce the effect of reverse damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

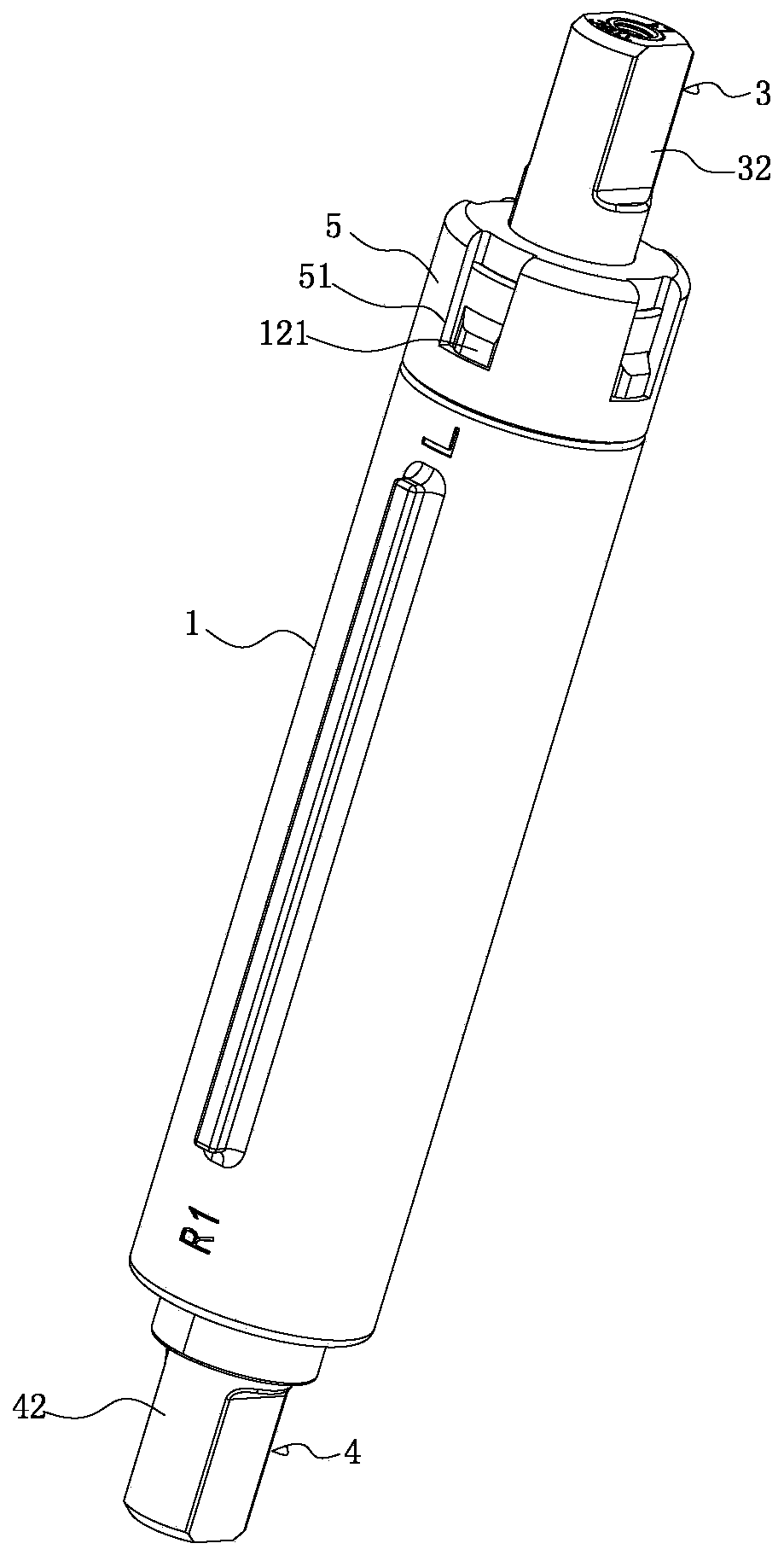

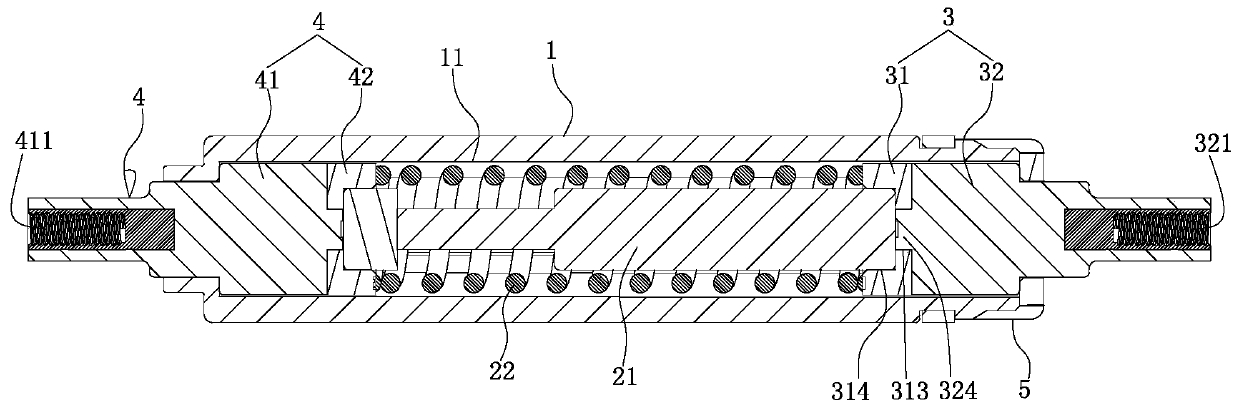

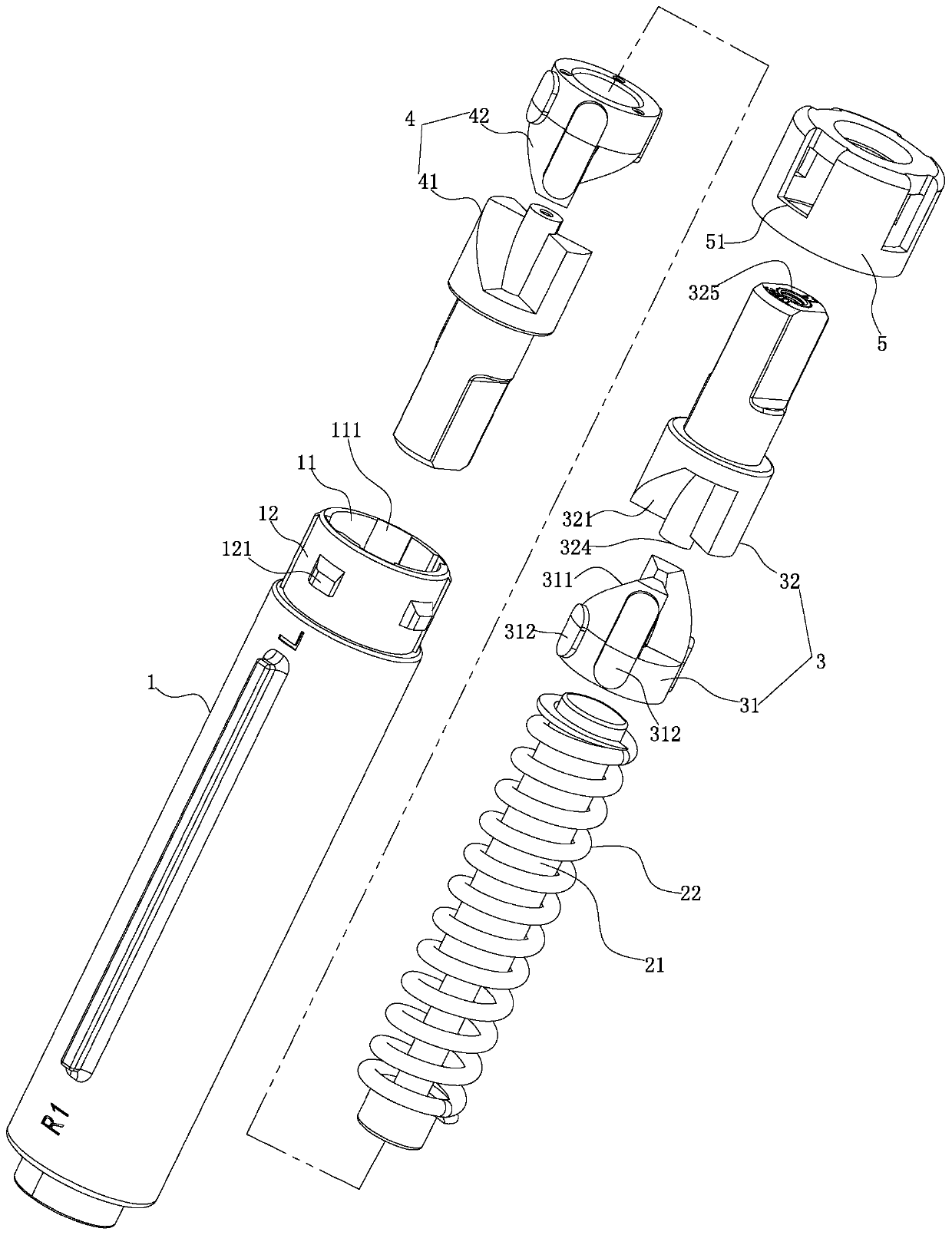

[0019] See Figure 1-3 As shown, it is a new type of two-way rotary shaft booster damper, which includes a fixed housing 1, a linear damper 21 installed in the middle of the inner cavity of the fixed housing 1, a compression spring 22 sleeved on the periphery of the linear damper 21, and a The upper and lower ends of the inner cavity of the fixed shell 1 are used to convert the rotational torque into a linear moment. 3 is in contact with the second force reversing structure 4, and the two ends of the compression spring 22 are also respectively in contact with the first force reversing structure 3 and the second force reversing structure 4, the first force reversing structure 3 in the first The rotating shaft 32 and the second rotating shaft 41 in the second force reversing structure 4 respectively protrude from the upper and lower ends of the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com