A steel formwork for automatic wharf box corner beams and a construction method for box corner beams

A technology for automated wharf and steel formwork, applied in marine engineering, water conservancy engineering, infrastructure engineering and other directions, can solve the problems of unsatisfactory flatness error, box angle beam top elevation, etc., and achieves simple and easy operation and adjustment accuracy in the adjustment process. High, easy to operate and implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be described in detail below, and it should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

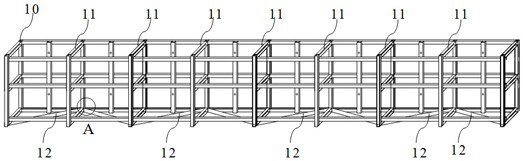

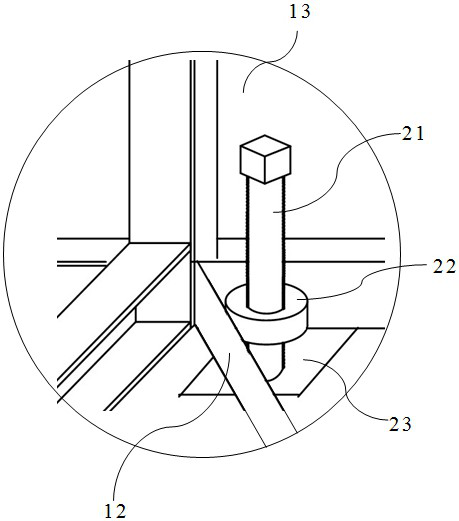

[0020] Such as Figure 1-Figure 4 As shown, the steel formwork used for the box corner beam of the automated wharf in this embodiment includes a steel formwork body, which includes a cuboid frame 10, a plurality of vertical support frames 11 are welded at equal intervals in the frame, and a plurality of vertical support frames 11 are welded at the bottom of the frame 10. Reinforcing rod 12, reinforcing rod 12 is positioned between adjacent two bracing frames 11; Fine-tuning device, it comprises adjusting screw rod 21, is threaded on adjusting screw rod 21 and is connected with adjusting bolt 22, and adjusting bolt 22 is fixed on the reinforcing rod; The bottom of the screw rod 21 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com