an electric oven

A technology for electric ovens and cabinets, applied in the field of electric ovens, can solve problems such as no specific solutions have been proposed, achieve the effects of preventing uneven baking, improving baking quality, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

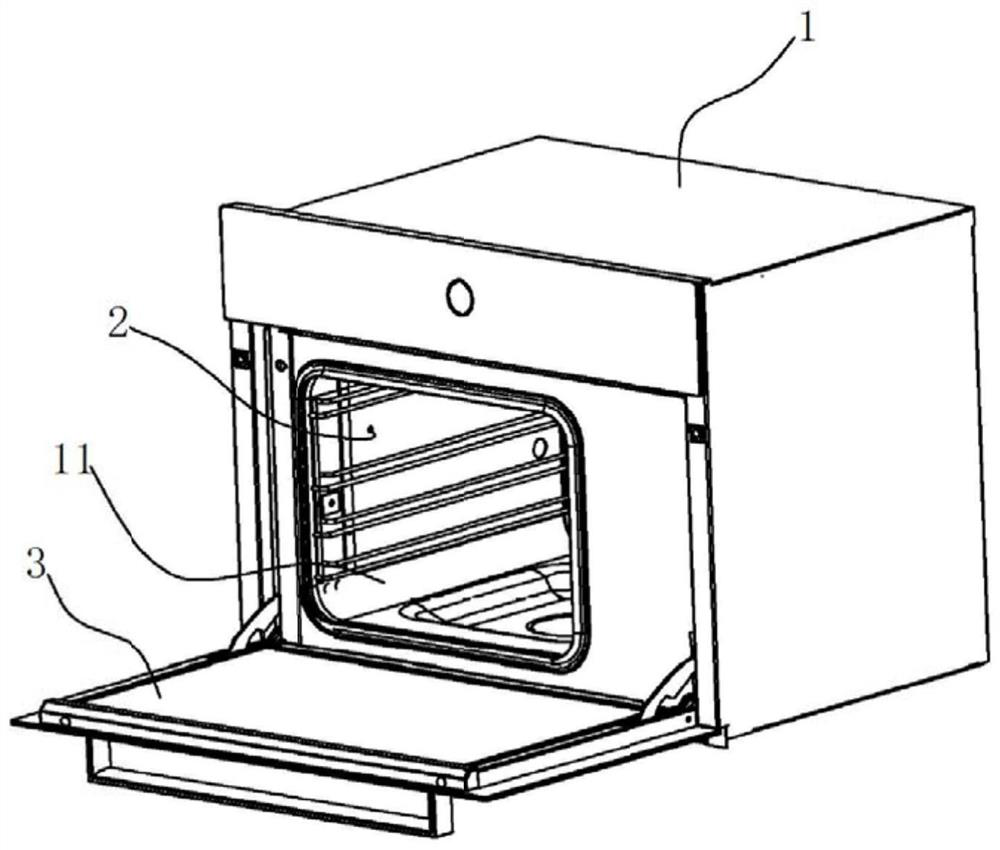

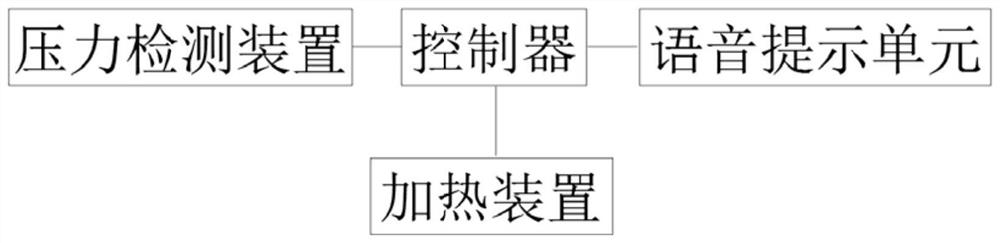

[0032] Such as figure 1 as well as figure 2 As shown, an electric oven includes a casing 1, a cooking cavity 11 disposed in the casing 1, a heating device 2 capable of heating food in the cooking cavity 11, and a controller capable of controlling the operation of the heating device 2. The front side of the box body 1 is provided with a box door 3 capable of opening the cooking cavity 11 , and the heating device 2 is installed on the side walls of the box body 1 around the cooking cavity 11 . The controller can be installed inside the box body 1, or embedded in the outside of the box body 1, and it is connected with the heating device 2 in the cooking cavity 11 through wires.

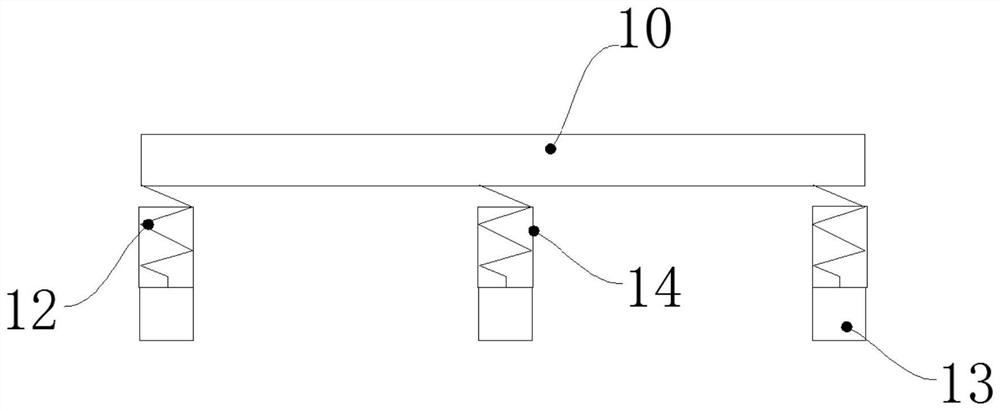

[0033] Such as image 3 As shown, the cooking cavity 11 is provided with a disc 10 for placing food, and several pressure detection devices are evenly distributed on the peripheral edge of the disc 10, and the pressure detection device includes a spring 12, a pressure sensor 13 and a sleeve. One end ...

Embodiment 2

[0041] Such as figure 1 as well as figure 2 As shown, an electric oven includes a casing 1, a cooking cavity 11 disposed in the casing 1, a heating device 2 capable of heating food in the cooking cavity 11, and a controller capable of controlling the operation of the heating device 2. The front side of the box body 1 is provided with a box door 3 capable of opening the cooking cavity 11 , and the heating device 2 is installed on the side walls of the box body 1 around the cooking cavity 11 . The controller can be installed inside the box body 1, or embedded in the outside of the box body 1, and it is connected with the heating device 2 in the cooking chamber 11 through wires.

[0042] Such as image 3 As shown, the cooking cavity 11 is provided with a disc 10 for placing food, and several pressure detection devices are evenly distributed on the peripheral edge of the disc 10, and the pressure detection device includes a spring 12, a pressure sensor 13 and a sleeve. One end...

Embodiment 3

[0058] Such as figure 1 as well as figure 2 As shown, an electric oven includes a casing 1, a cooking cavity 11 disposed in the casing 1, a heating device 2 capable of heating food in the cooking cavity 11, and a controller capable of controlling the operation of the heating device 2. The front side of the box body 1 is provided with a box door 3 capable of opening the cooking cavity 11 , and the heating device 2 is installed on the side walls of the box body 1 around the cooking cavity 11 . The controller can be installed inside the box body 1, or embedded in the outside of the box body 1, and it is connected with the heating device 2 in the cooking chamber 11 through wires.

[0059] Such as image 3 As shown, the cooking cavity 11 is provided with a disc 10 for placing food, and several pressure detection devices are evenly distributed on the peripheral edge of the disc 10, and the pressure detection device includes a spring 12, a pressure sensor 13 and a sleeve. One end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com