Transport vehicle material box discharging device

A technology of a discharging device and a transport vehicle, which is applied in the directions of transportation and packaging, transporting objects, and vehicles used for freight transportation, can solve the problems of increasing human labor and labor costs, increasing the difficulty of handling, and limited space, and achieves convenient grasping. The effect of taking, reducing labor and labor costs, and avoiding the drop of goods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

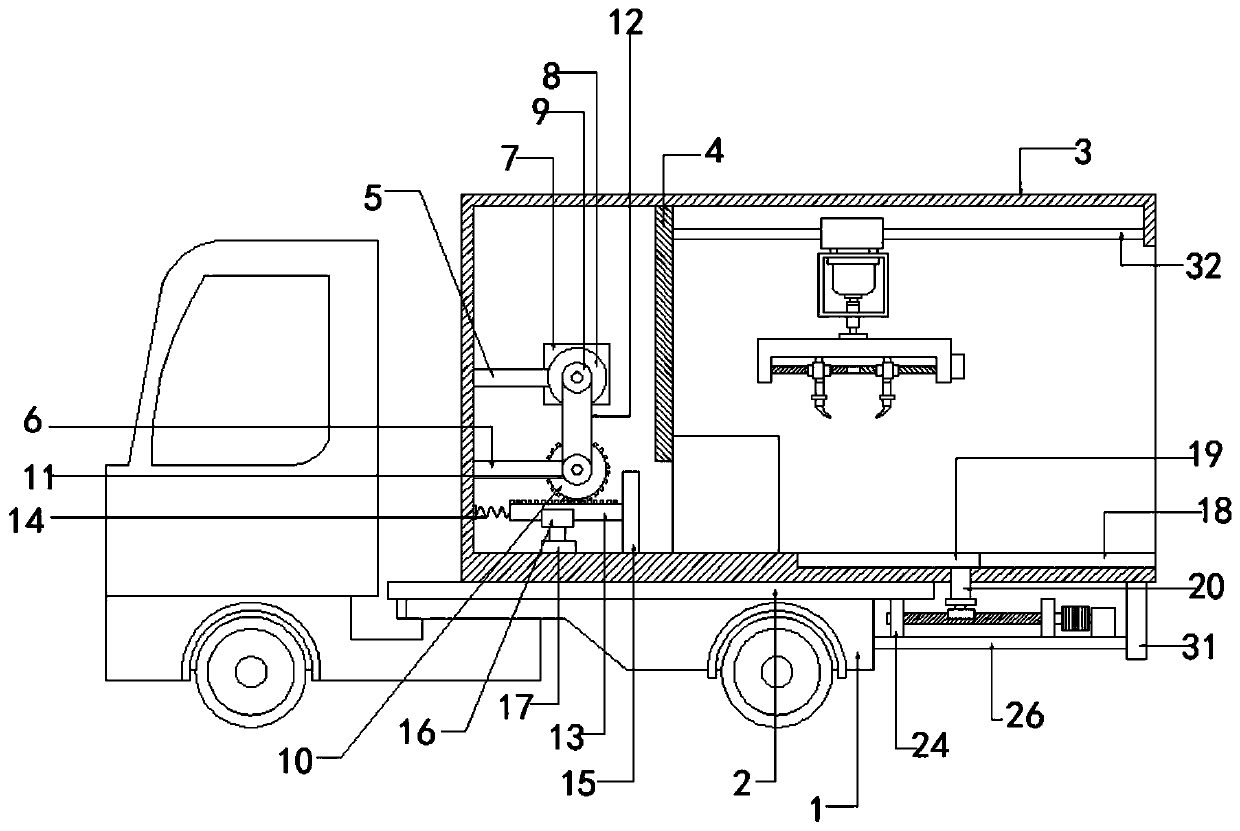

[0027] Embodiment one, such as Figure 1-3 As shown, a transport vehicle material box discharge device according to an embodiment of the present invention includes a vehicle body, a baffle plate 1, a bottom plate 2 and a vehicle material box 3, the bottom of the vehicle material box 3 is fixed with the bottom plate 2, Both sides of the bottom of the base plate 2 are provided with the baffle plate 1, and the baffle plate 1 is fixed on the vehicle body, wherein, the opening of the vehicle material box 3 and away from the vehicle material box 3 A partition 4 is provided on the upper part of one side, and the partition 4 divides the interior of the vehicle material box 3 into a left cavity and a right cavity. The second connecting rod 6 below the connecting rod 5, the first connecting rod 5 and the end corresponding to the partition plate 4 are interspersed with a shaft one, and the input end of the shaft one is connected with a motor two 7, so The other end of the first shaft is...

Embodiment 2

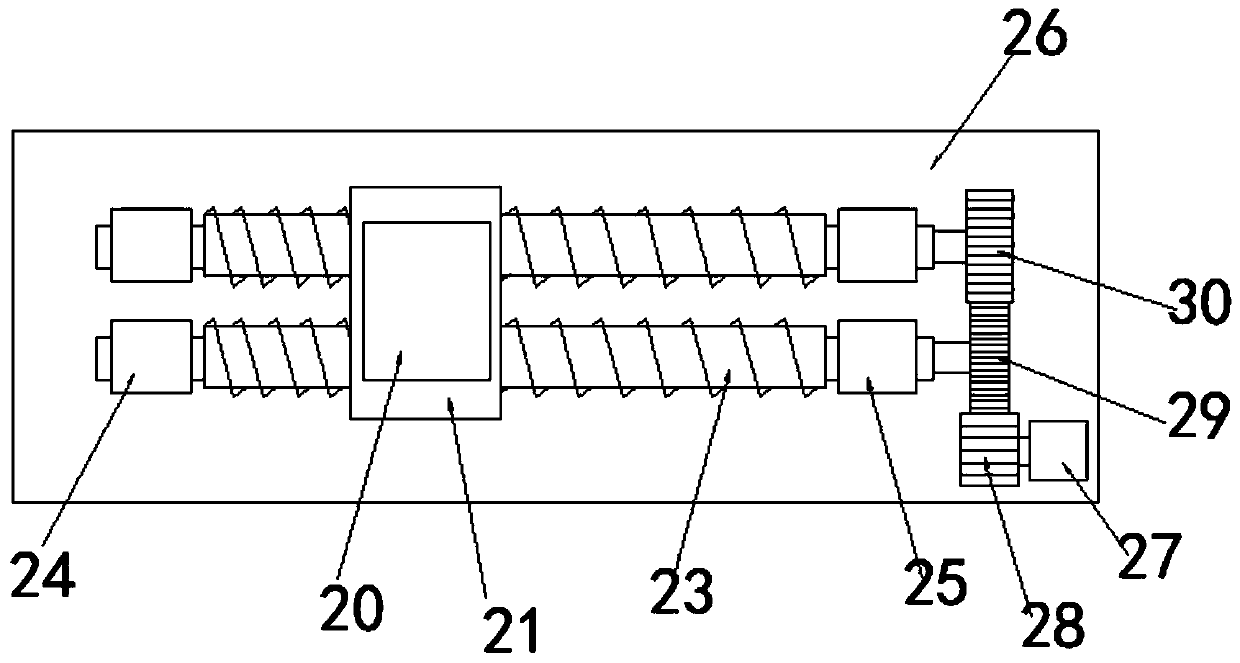

[0028] Embodiment two, such as figure 1 As shown, one end of the support plate 26 is welded to the side end of the baffle plate 1 , the other end of the support plate 26 is provided with a bracket 31 , and the top of the bracket 31 is fixed to the bottom end of the vehicle material box 3 .

Embodiment 3

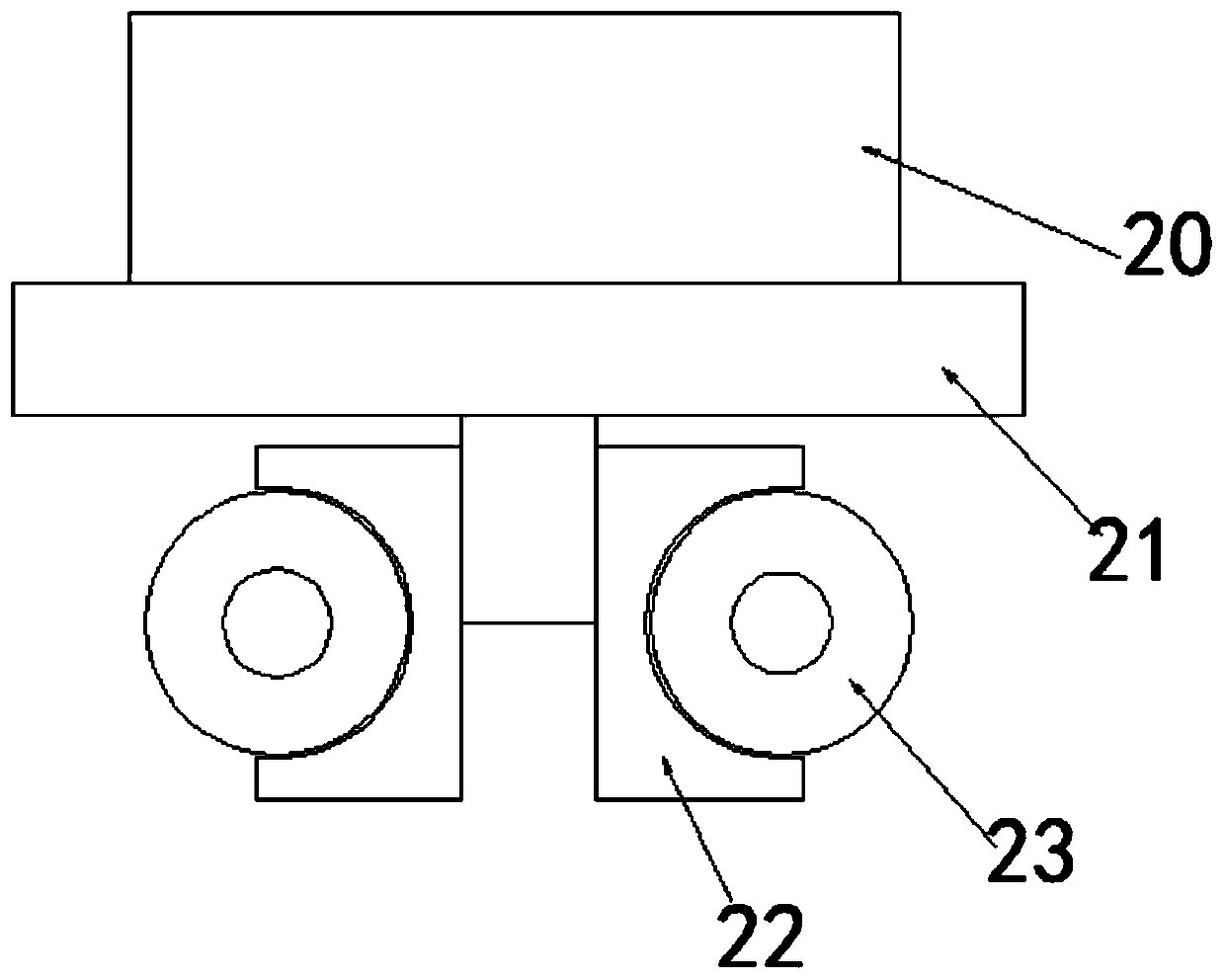

[0029] Embodiment three, such as image 3 As shown, the clamping blocks 22 on both sides and the side that is in contact with the screw 23 are both provided with a half-arc groove, and an internal thread structure 1 that is threadedly matched with the screw 23 is provided in the half-arc groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com