Self-unloading steel corrugated plate arch culvert

A corrugated plate and self-unloading technology, applied in the field of culvert support system, can solve the problems of low construction efficiency and insignificant economic benefits, and achieve the effect of shortening the construction period, obvious economic benefits and ensuring construction safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

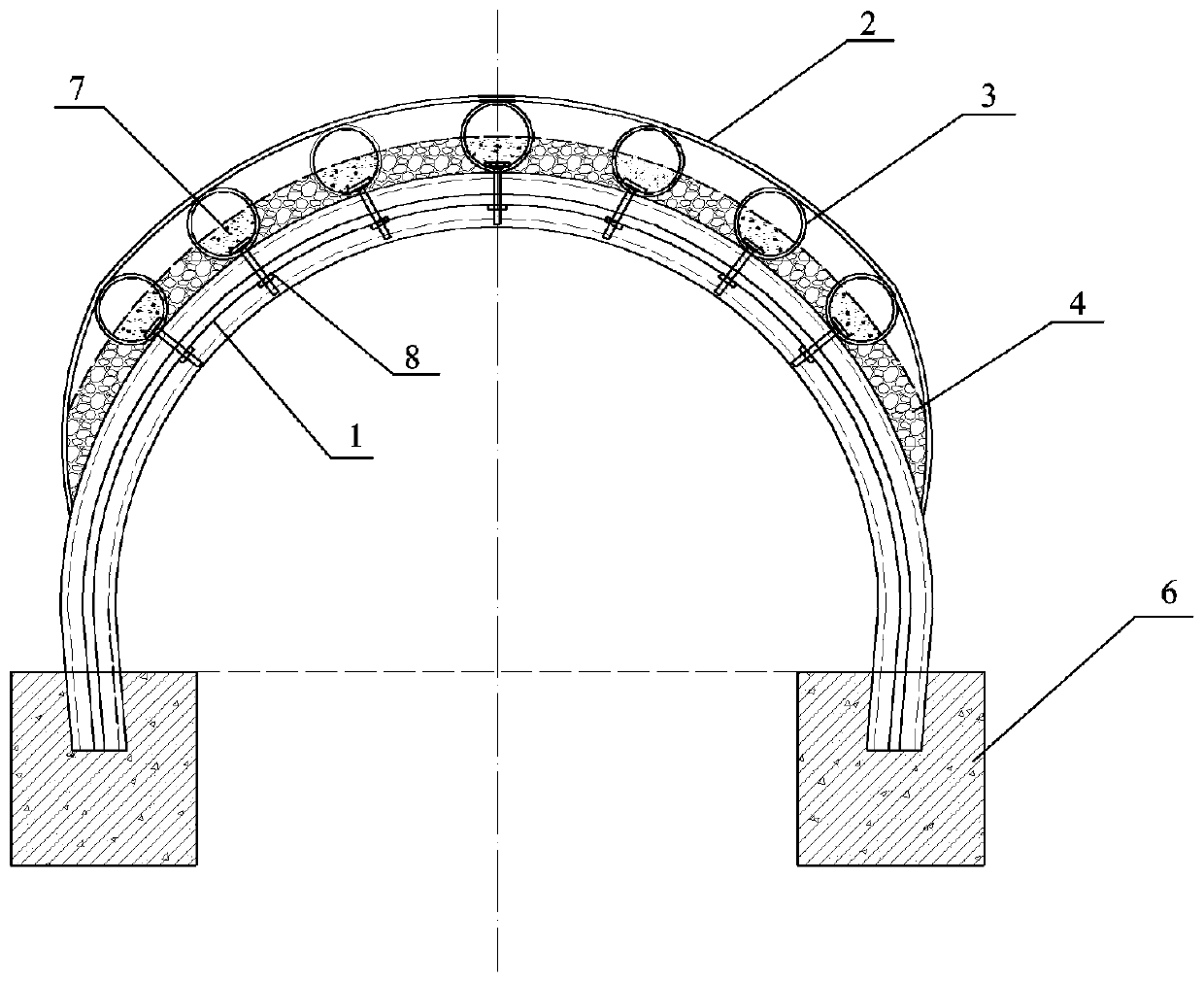

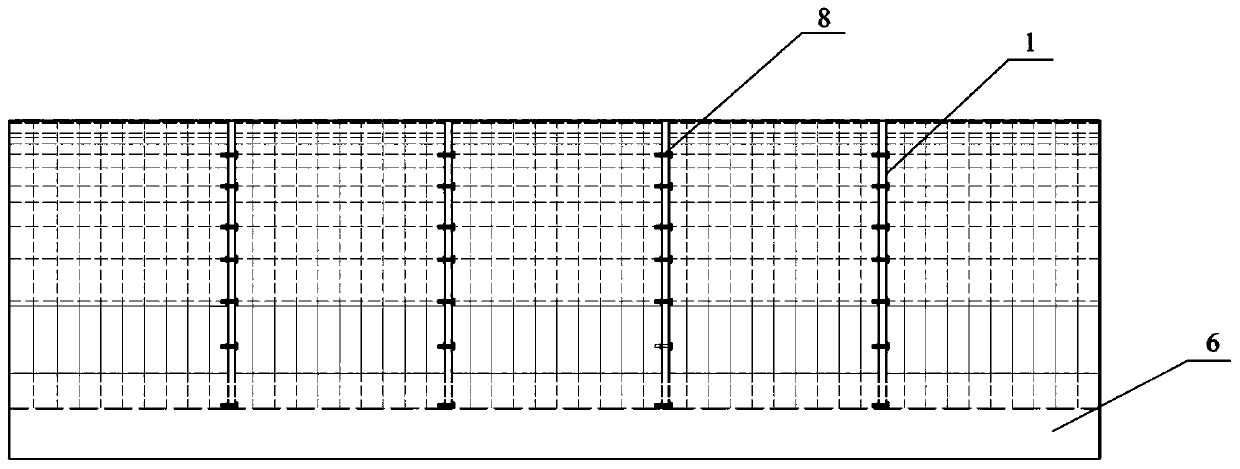

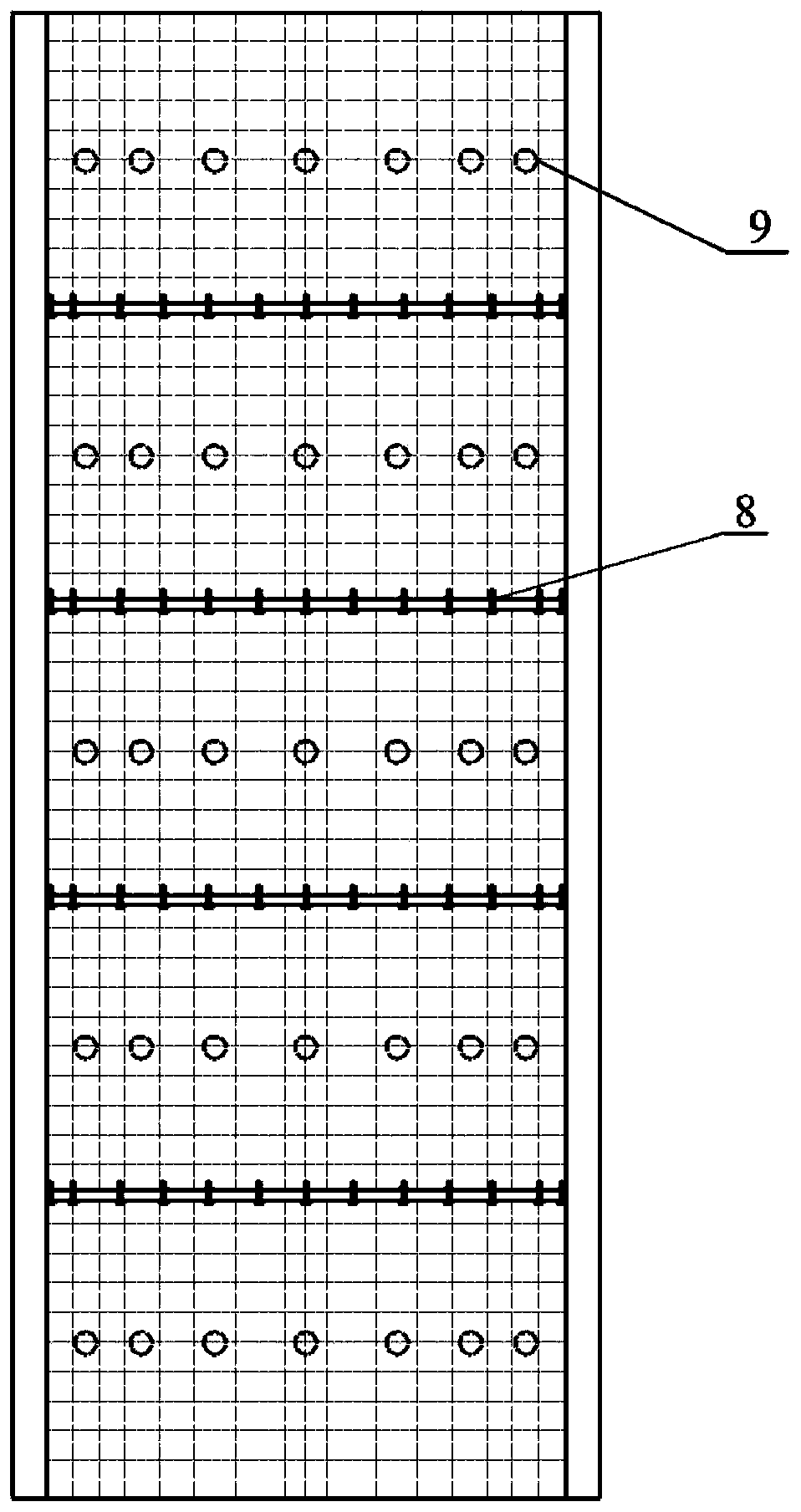

[0026] Such as Figure 1~3 As shown, a self-unloading steel corrugated plate arched culvert includes an arched steel corrugated plate 1 arranged along the direction of the culvert, and a concrete foundation 6 is arranged at the arch foot of the steel corrugated plate 1; 1 The upper self-unloading unit; the self-unloading unit includes a plurality of steel pipes 3 arranged along the direction of the culvert and uniformly distributed on the outside of the steel corrugated plate 1, and a steel plate 2 is arranged above the steel pipes 3; unloading effect.

[0027] A filling layer 4 is arranged between adjacent steel pipes 3 . The filling layer 4 is formed by mixing one or two of crushed stones or sand pebbles in any proportion; the steel pipe 3 is provided with cement slurry 7 . The filling layer 4 and the cement slurry 7 are injected through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com