Device for evaluating the firmness of a ground

A ground and hardness technology, applied in the input parameters of external conditions, control devices, tire measurement, etc., can solve the problems of not establishing ground hardness and reducing the work efficiency of drivers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

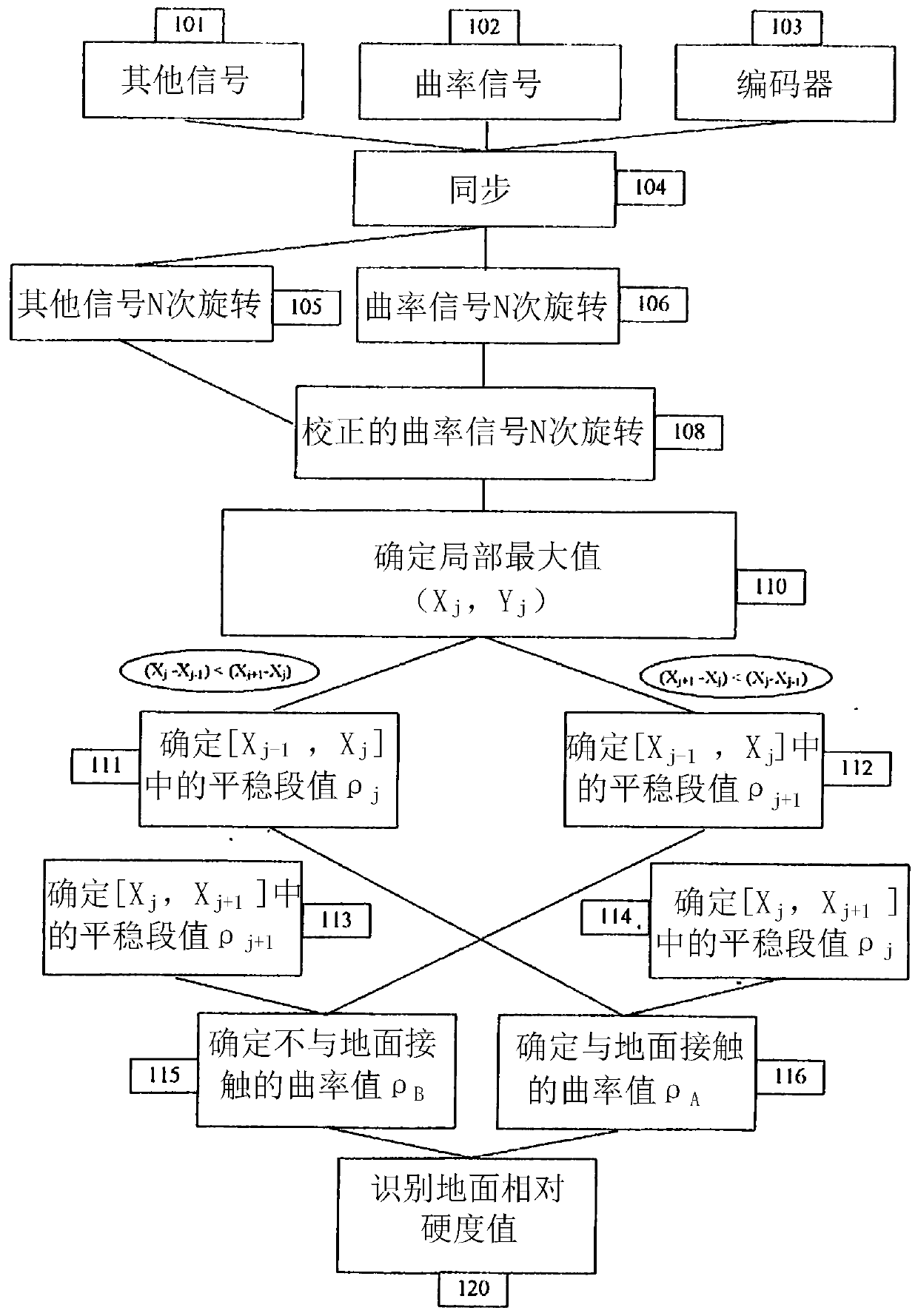

[0101] figure 1 A flow chart showing various mandatory and optional steps pertaining to the method for assessing the hardness of a ground. The starting point is located in the signal 102 emitted by the sensor sensitive to the circumferential curvature. The spatial discretization of this signal needs to be sufficient to properly describe the pathway through the contact region. At least six measurement points are required in the contact area. This signal may be a direct measurement of the circumferential curvature via a flex sensor, or an indirect measurement via, for example, a uniaxial accelerometer positioned radially relative to the tire casing, or an indirect measurement via a piezoelectric sensor whose The primary direction is located circumferentially relative to the tire casing.

[0102] This signal may be supplemented by other signals 101 and 103 useful for exploiting the curvature signal 102 . Specifically, in the case that the curvature signal 102 is affected by v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com