Cutting device for U-shaped quartz tube processing

A cutting device and quartz tube technology, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve the problem of not being able to achieve efficient cutting operation of the nozzle, and achieve the effect of efficient and stable cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

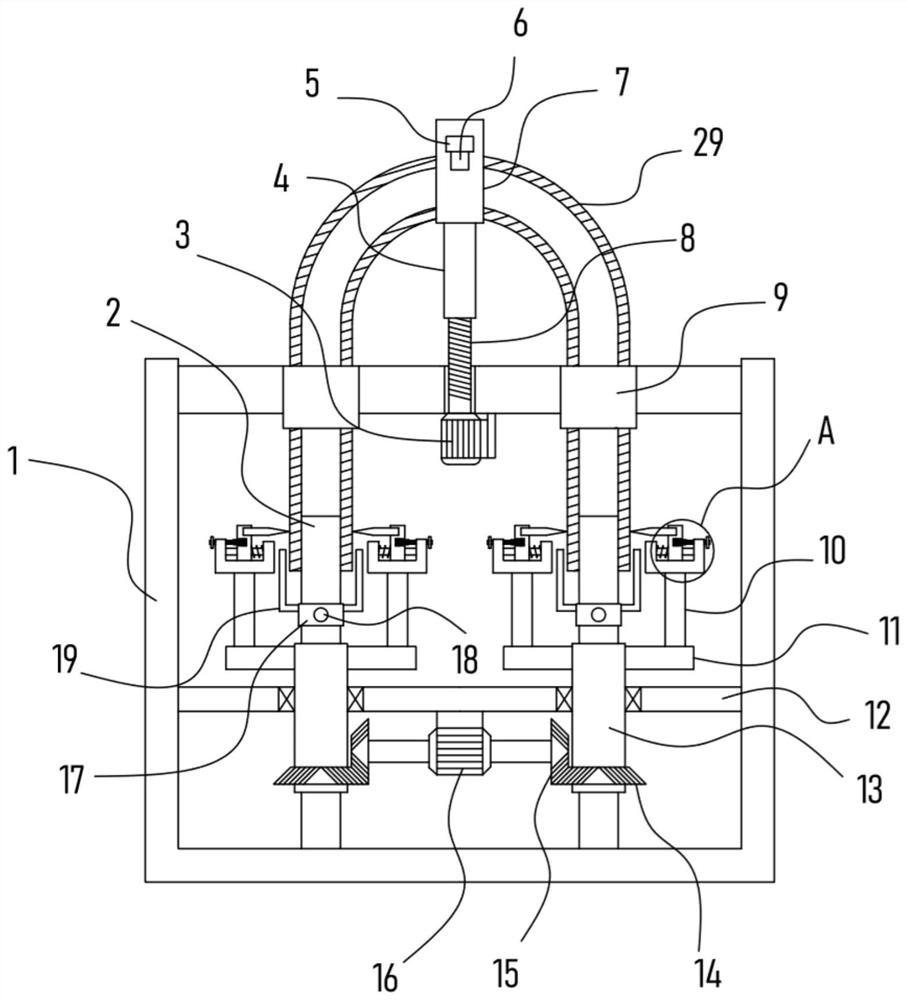

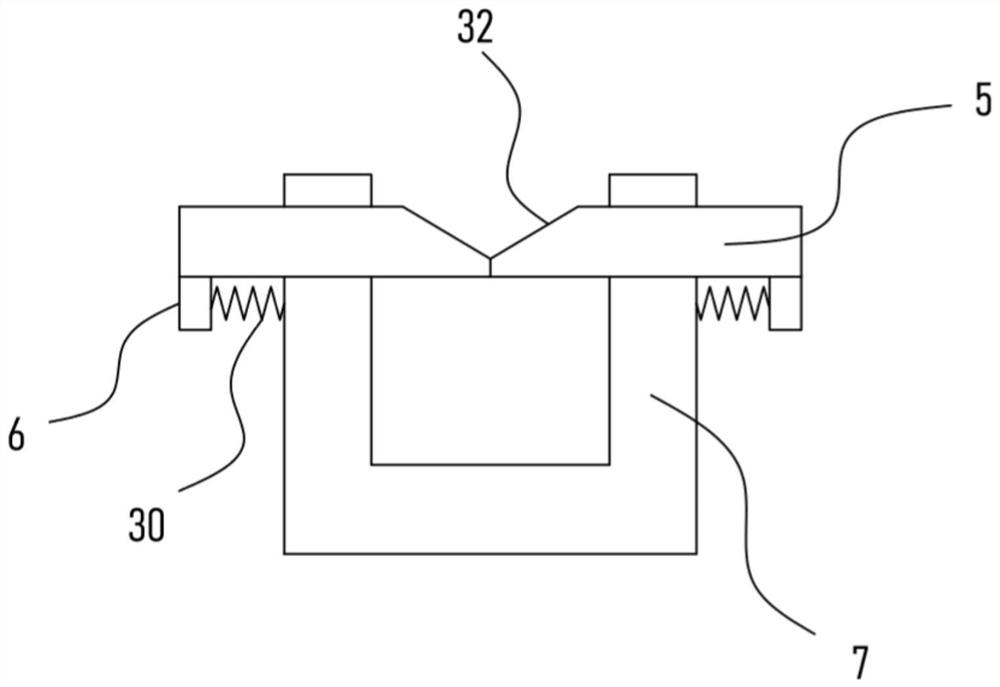

[0023] see Figure 1-5 , a U-shaped quartz tube processing cutting device, comprising a support frame 1, a horizontal plate 12 is fixed horizontally on the support frame 1, a biaxial motor 16 is fixed at the bottom of the horizontal plate 12, and a pair of supply The limiting sleeve 9 into which the U-shaped quartz tube 29 is inserted, the support frame 1 is provided with a lifting mechanism, the lifting mechanism is provided with a limiting mechanism for fixing the U-shaped quartz tube 29, and two rotating installations are mounted on the horizontal plate 12. There are symmetrically arranged rotating sleeves 13 , the inner bottom of the support frame 1 is vertically fixed with a vertical rod 2 penetrating the rotating sleeve 13 , the vertical rod 2 extends into the U-shaped quartz tube 29 , and the rotating sleeve 13 is fixed on the upper A pair of circumcision components for cutting the U-shaped quartz tube 29 are installed, and a collection mechanism is provided on the vert...

Embodiment 2

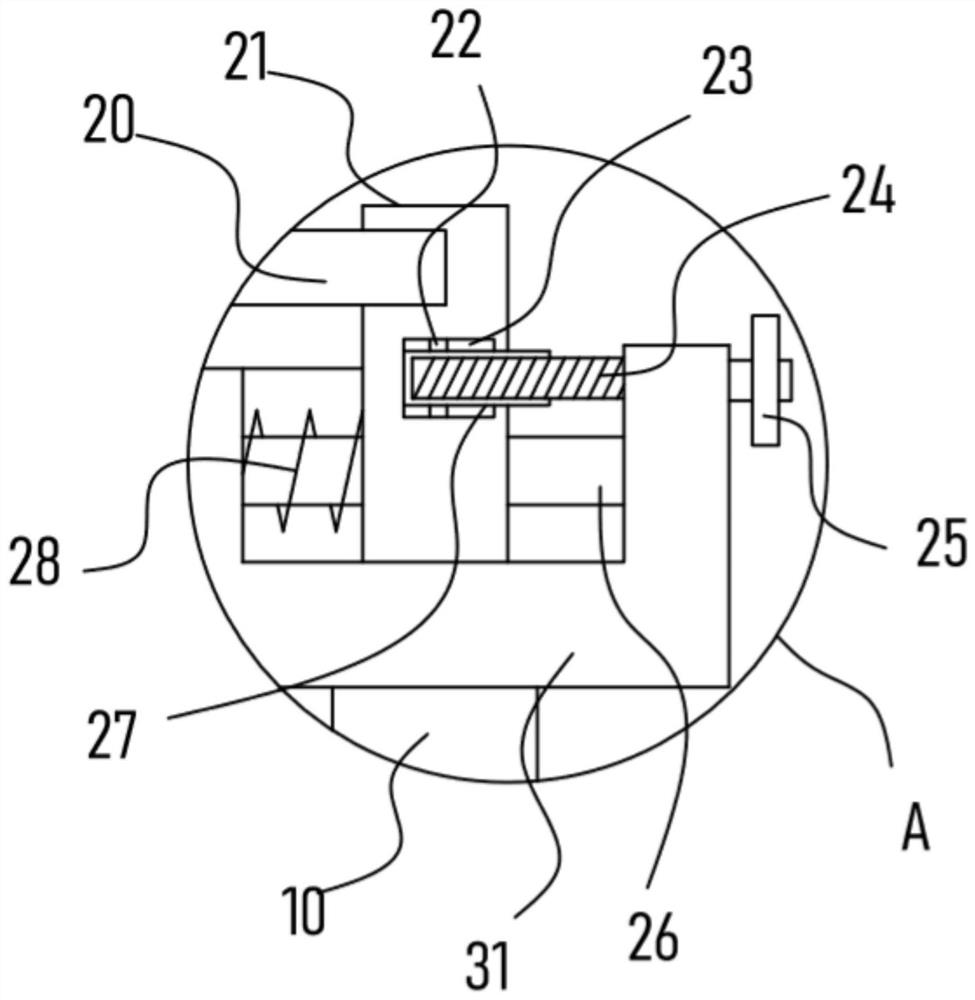

[0029] On the basis of Embodiment 1, in addition, the adjustment mechanism provided by the device includes a threaded sleeve 27 slidably installed in the tool seat 21, and the threaded sleeve 27 is internally threaded and installed with an adjustment screw 24 connected to the bearing of the bracket 31. , the end of the adjusting screw 24 is fixed with a hand wheel 25, the bracket 31 is horizontally fixed with a guide rod 26 passing through the knife seat 21, a spring ring 28 is fixed between the knife seat 21 and the bracket 31, the knife seat 21 A sliding groove 23 is opened inside, and a sliding block 22 fixed on the side wall of the threaded sleeve 27 is slidably embedded in the sliding groove 23 .

[0030] In the process of circumcising the U-shaped quartz tube 29, the elastic pulling force of the provided spring ring 28 drives the knife seat 21 to move towards the U-shaped quartz tube 29. During the cutting operation of the U-shaped quartz tube 29 by the blade 20 , the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com