Centrifugal pump grease lubrication mechanical seal ring

A technology of grease lubrication and mechanical sealing, applied in mechanical equipment, pumps, pump components, etc., can solve problems such as increased mechanical friction resistance, increased pressure difference, and reduced head, and achieve the effect of eliminating leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

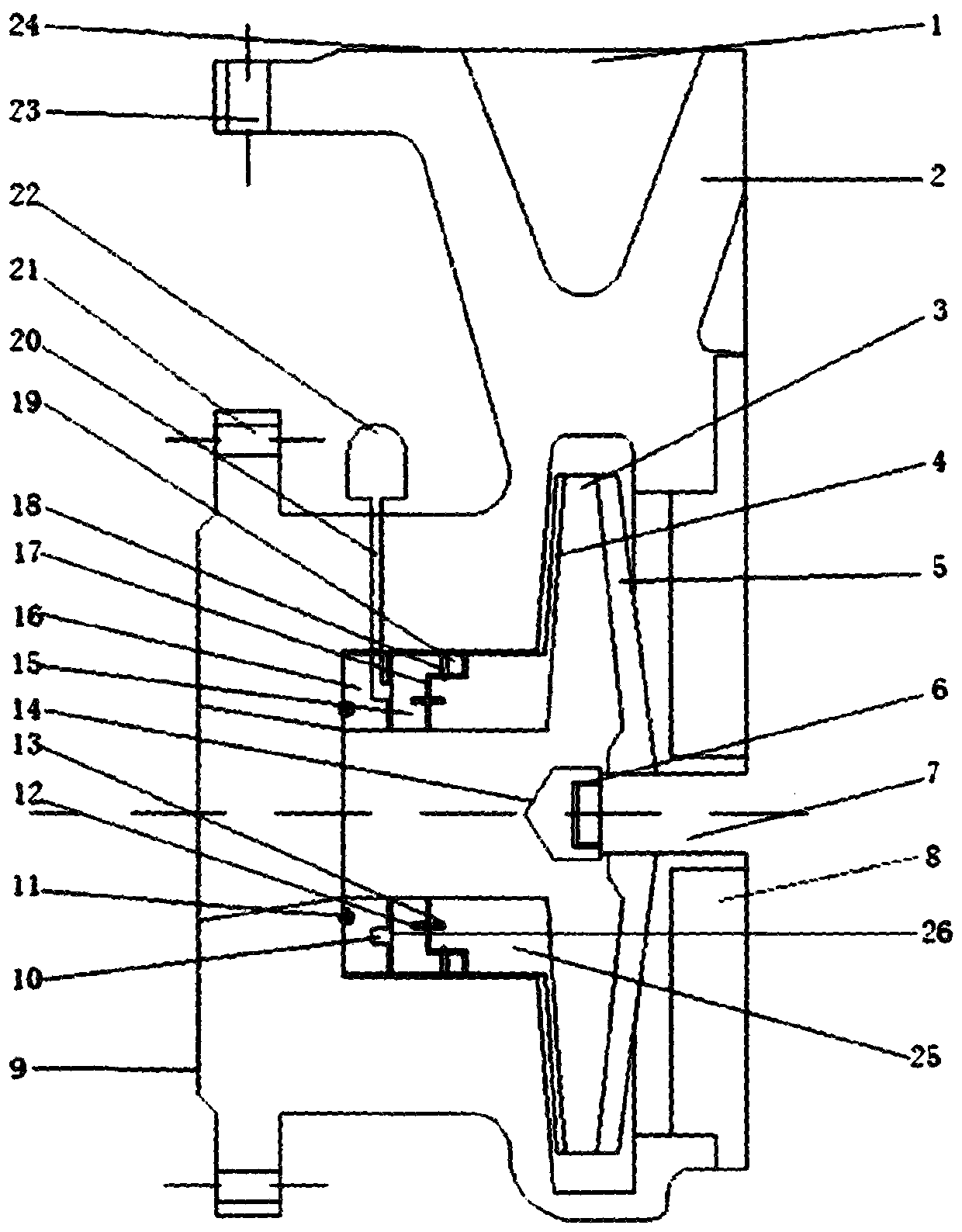

[0012] Specific embodiments: the invention discloses a centrifugal pump grease lubricated mechanical seal ring, which consists of a pump liquid outlet 1, a pump volute body 2, an impeller liquid outlet 3, an impeller front cover plate 4, an impeller rear cover plate 5, a shaft Head connection thread 6, pump shaft 7, pump cover body 8, pump liquid inlet flange surface 9, fixed ring corrugated groove surface 10, fixed ring sealing ring 11, spring 12, spring hole 13, fixed impeller nut 14, moving Ring 15, fixed ring 16, moving ring impeller connecting surface 17, moving ring impeller positioning bolt 18, moving ring impeller connecting step 19, oil supply hole 20, pump liquid inlet flange outer connection hole 21, oil supply cup 22, pump Outlet flange outer connecting hole 23, pump outlet flange surface 24, impeller body 25, moving ring sealing surface 26 are composed of pump volute housing 2 which is composed of pump outlet 1, pump inlet Liquid port flange surface 9, oil supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com