A Power Supply Air Guide Cover Structure for Realizing Optionality

An air hood and power supply technology, which is applied to electrical components, electrical equipment housings/cabinets/drawers, chassis/boxes/drawer parts, etc. problems such as increased consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

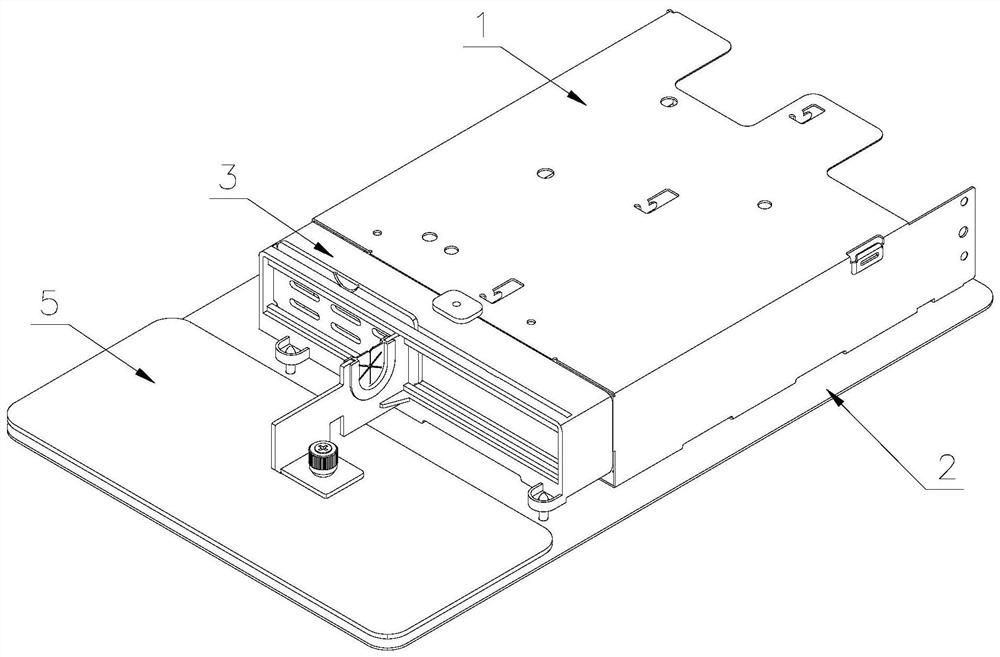

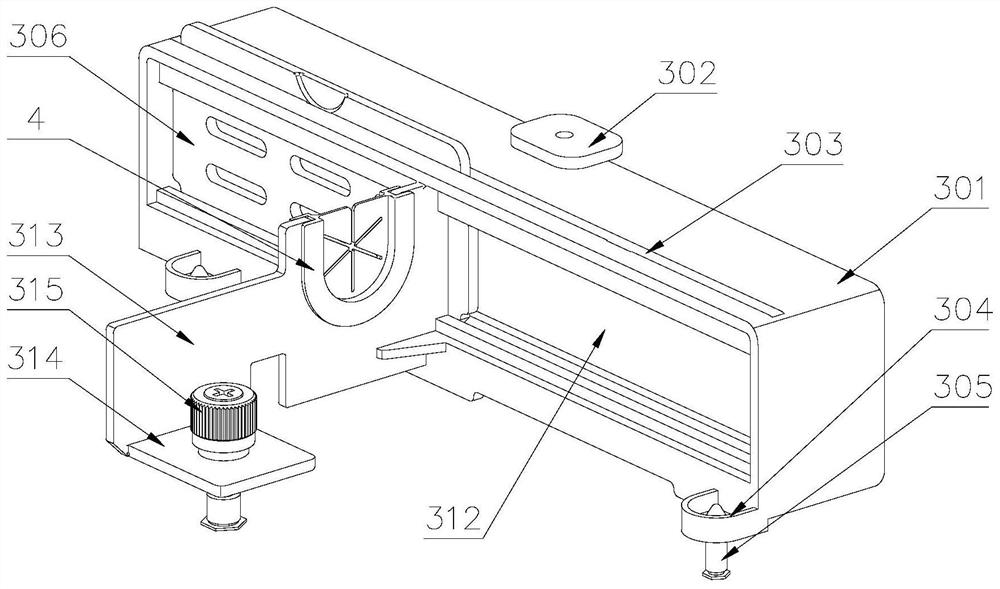

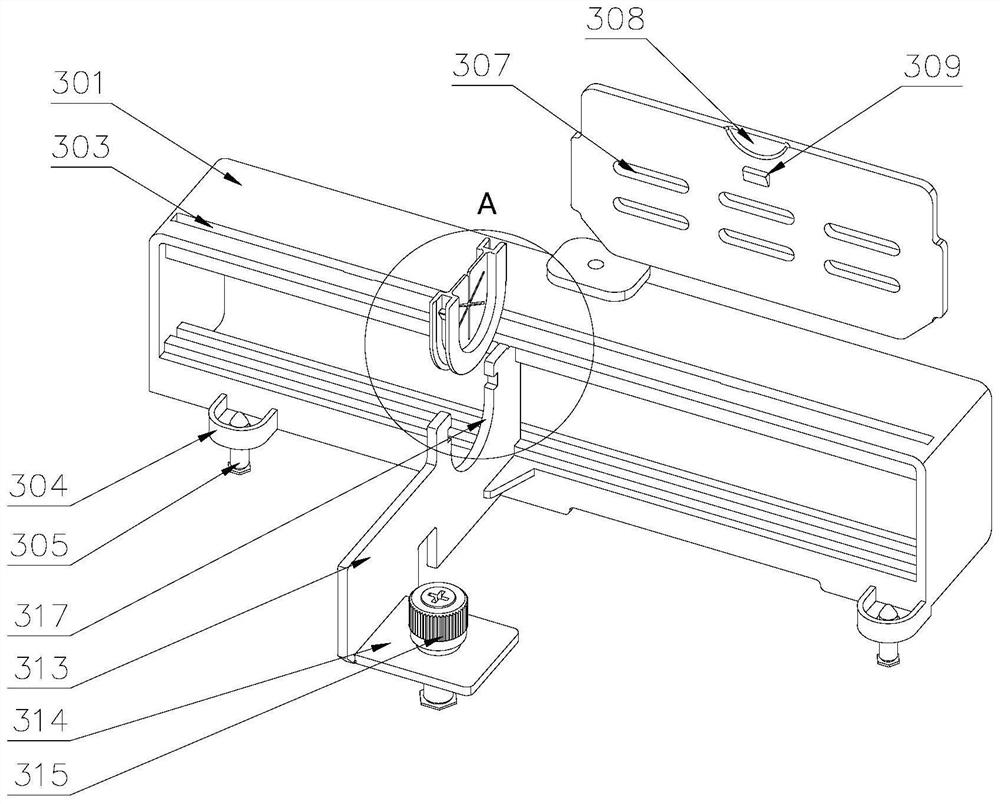

[0039] refer to Figure 1-3 , an optional power supply air guide structure, including a power supply bracket 1 and an air guide cover 3, the lower part of the power supply bracket 1 is installed on the chassis base 2, and the power supply module is installed inside the power supply bracket 1. The air guide cover 3 includes a main body 301 and a vertical plate 313. The main body 301 is provided with an air guide hole 312. One end of the upper part of the main body 301 is fixedly connected with the upper part of the power supply bracket 1 through a fixing plate 302, and the front part of the air guide cover 3 is fixed. On the power supply support 1, a vertical plate 313 is provided on one side of the middle part of the body 301, and a connecting plate 314 is provided on one side of the vertical plate 313, and a fastening screw 315 is provided on the connecting plate 314, and the fastening screw 315 is connected with the The chassis base 2 is threaded, and the tail of the air gui...

Embodiment 2

[0049] refer to Figure 7 , Figure 8 , the difference from Embodiment 1 is that the fixing device 309 includes a housing 320 disposed on the body 301 and a rear cover 321 disposed on one side of the housing 320 , and the housing 320 and the rear cover 321 are connected by several connecting columns 322 , the connecting column 322 on one side is fixedly equipped with a second catch 323, one side of the second catch 323 is provided with a buckle 324, and the end of the buckle 324 near the second catch 323 is provided with an arc buckle Groove 325, the upper part of the other side of the buckle plate 324 is provided with a step-connected third slot 327 and a fourth slot 328, the side of the buckle plate 324 is provided with a first torsion spring 326, and one end of the first torsion spring 326 Set on the lower part of the pinch plate 324, the other end of the first torsion spring 326 is set on the shell 320; one side of the pinch plate 324 is provided with a clamping plate 329...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com