Spraying arm for cleaning machine and cleaning machine

A spray arm and washing machine technology, which is applied to household cleaning devices, tableware washing machines/washing machines, tableware washing machines/rinsing machine parts, etc., can solve the problem of reduced spray area, poor reliability, and inability to effectively spray Dead angle and other problems, to achieve the effect of increasing the spray area and the cleaning area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Such as Figure 1 to Figure 14 Shown is the first preferred embodiment of the present invention.

[0057] Such as Figure 9 with Figure 10 As shown, the washing machine of this embodiment includes a box body 5, a spray arm and a power assembly. The box body 5 has a washing cavity 5a with a hollow interior and an open top. The spray arm is horizontally rotatably arranged at a position adjacent to the bottom in the washing cavity 5a. The power assembly is arranged at the bottom of the box body 5 and at least partly located below.

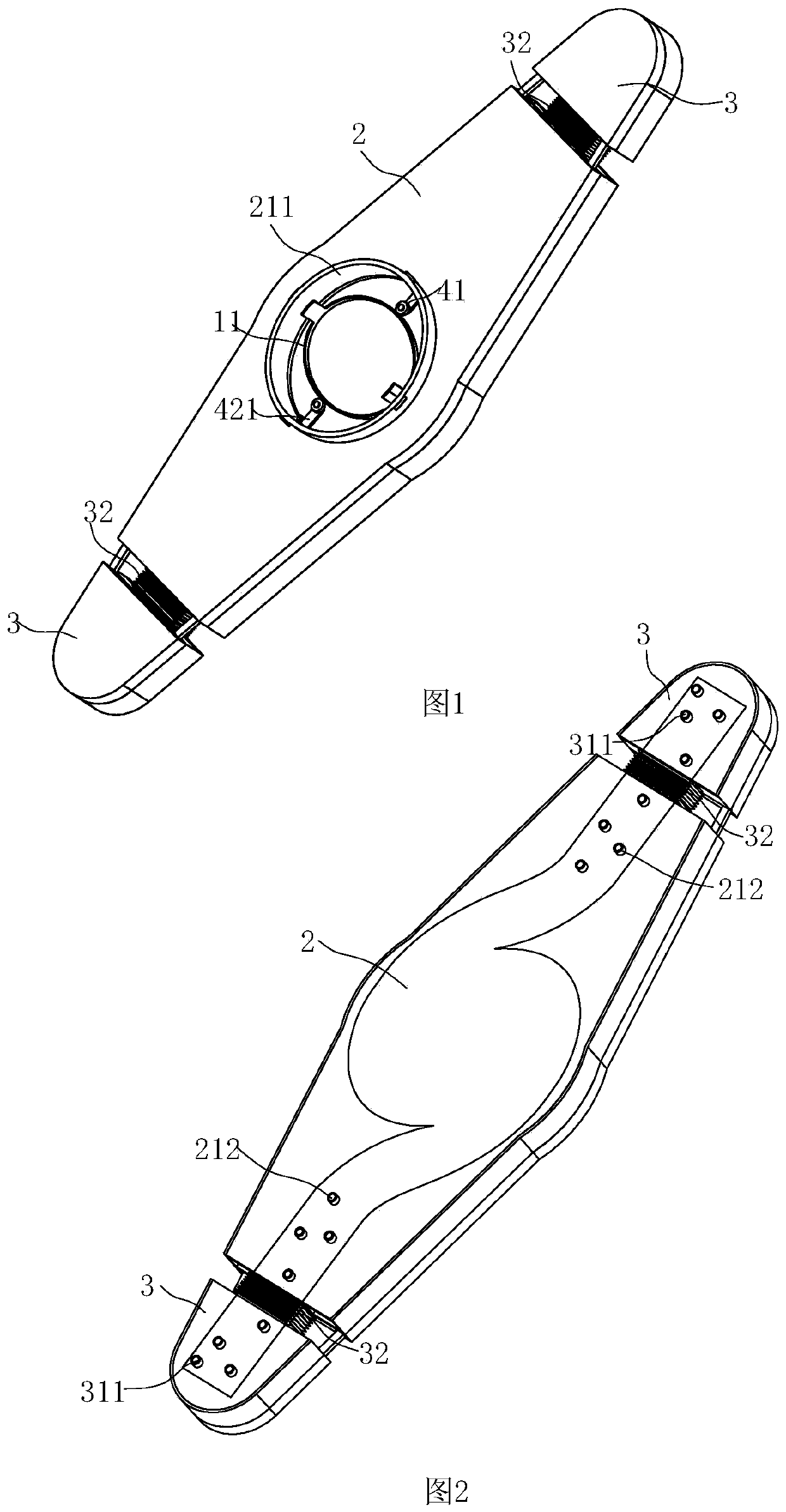

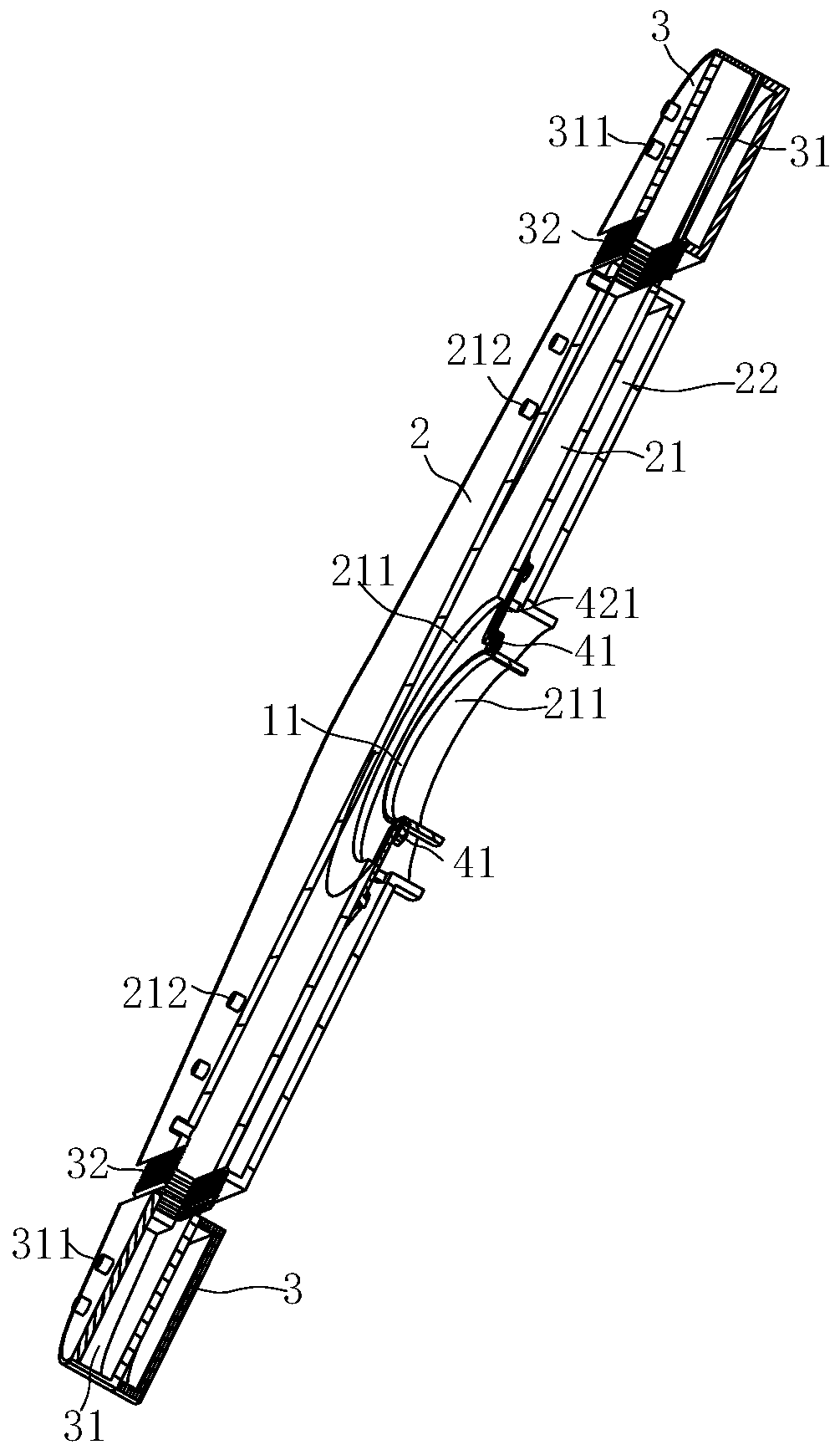

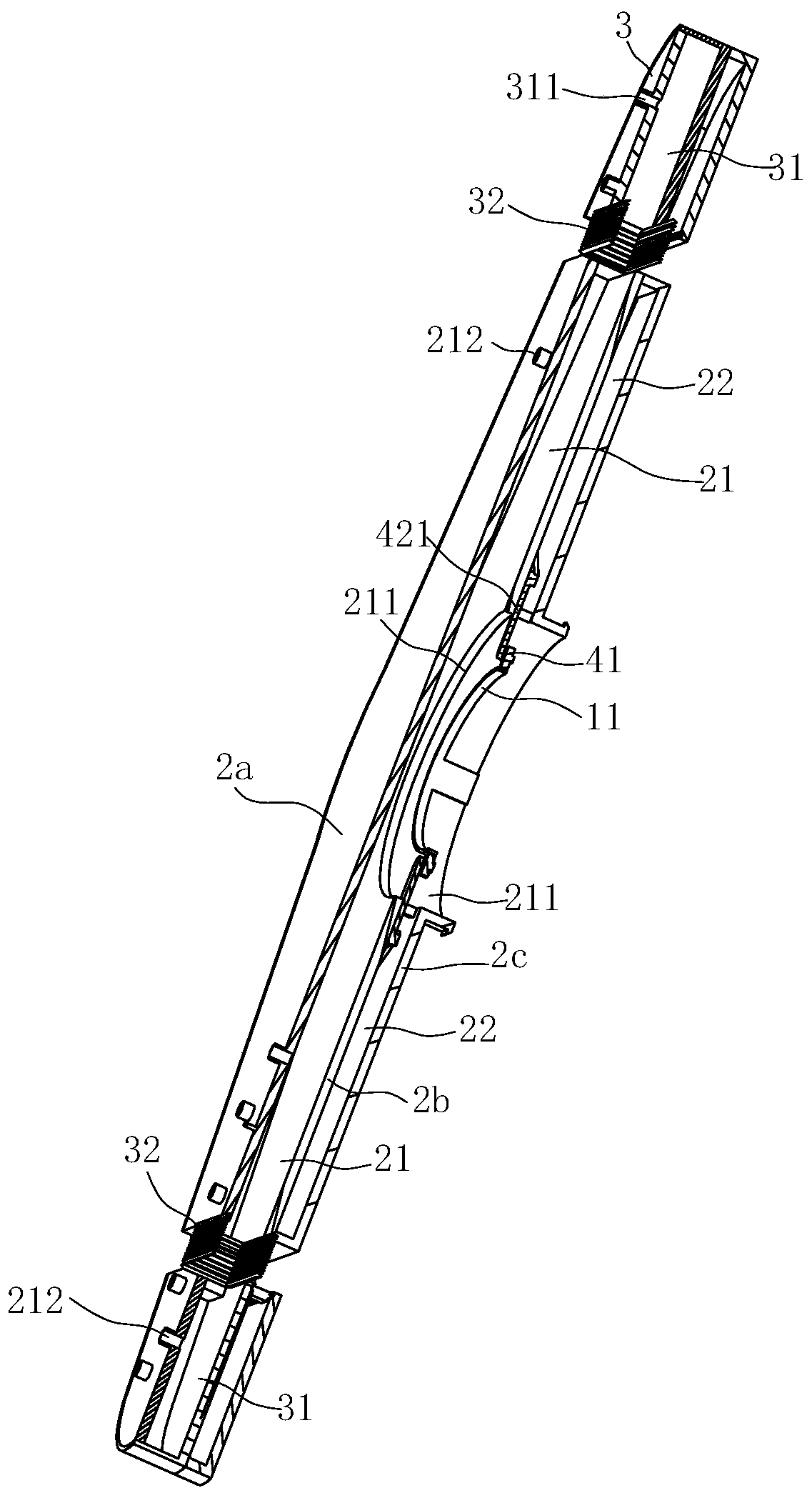

[0058] Such as Figure 1 to Figure 8 As shown, the spray arm used for the cleaning machine includes a main spray arm 2 , a secondary spray arm 3 , a linkage assembly and a fixing member fixedly connected to the bottom wall of the box body 5 .

[0059] Such as Figure 1 to Figure 8 As shown, the width of the main spray arm 2 gradually decreases from the center to both ends along the length direction, and the main spray arm 2 is arranged t...

Embodiment 2

[0067] Such as Figure 15 to Figure 17 Shown is the second preferred embodiment of the present invention.

[0068] The difference between this embodiment and the first embodiment above is only:

[0069] The ball 41 in the linkage assembly is matched with the connecting ring 11 in a different manner. Specifically, the connecting ring 11 has a slideway 112 extending along its circumference. The slideway 112 is an annular groove with an open top, and the ball 41 in the linkage assembly slides The position is limited in the slideway of the connecting ring 11, so that the ball 41 is limited on the connecting ring 11 along the circumferential movement of the connecting ring 11. For details, see Figure 15 to Figure 17 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com